Domestic sewage treatment system

A technology for treatment system and domestic sewage, applied in biological water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of high cost reduction, high energy consumption, unfavorable development, etc. The effect of interaction force, viscosity reduction and dispersion improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

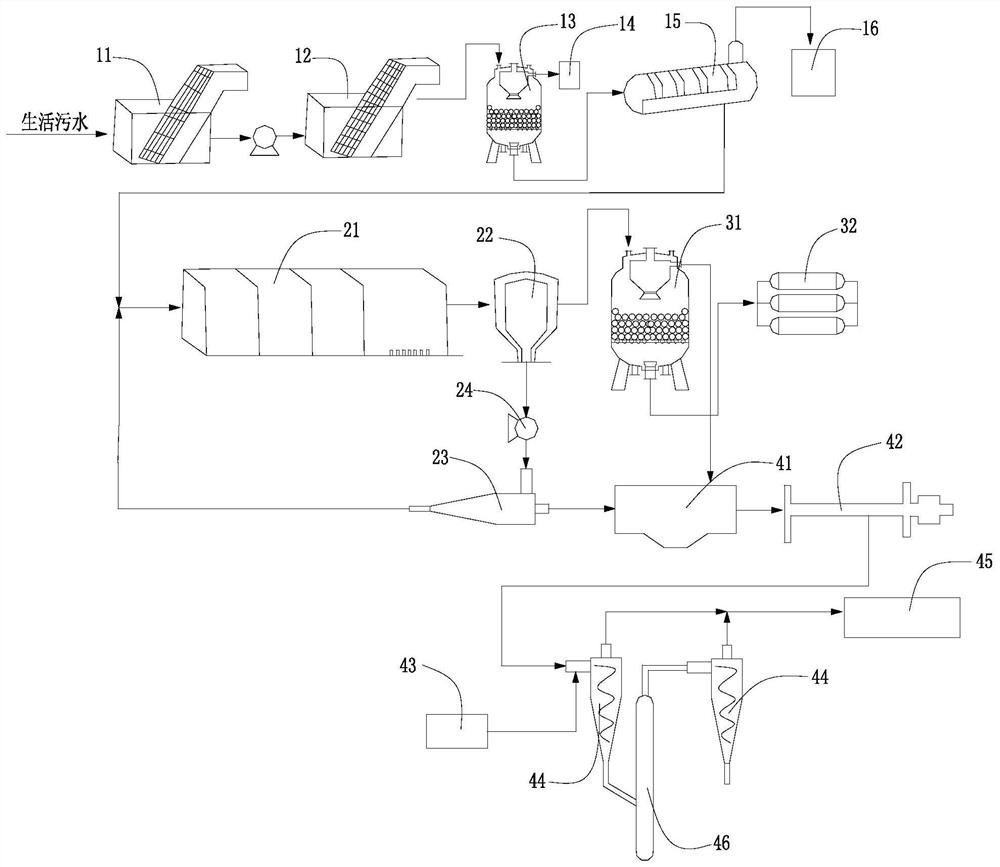

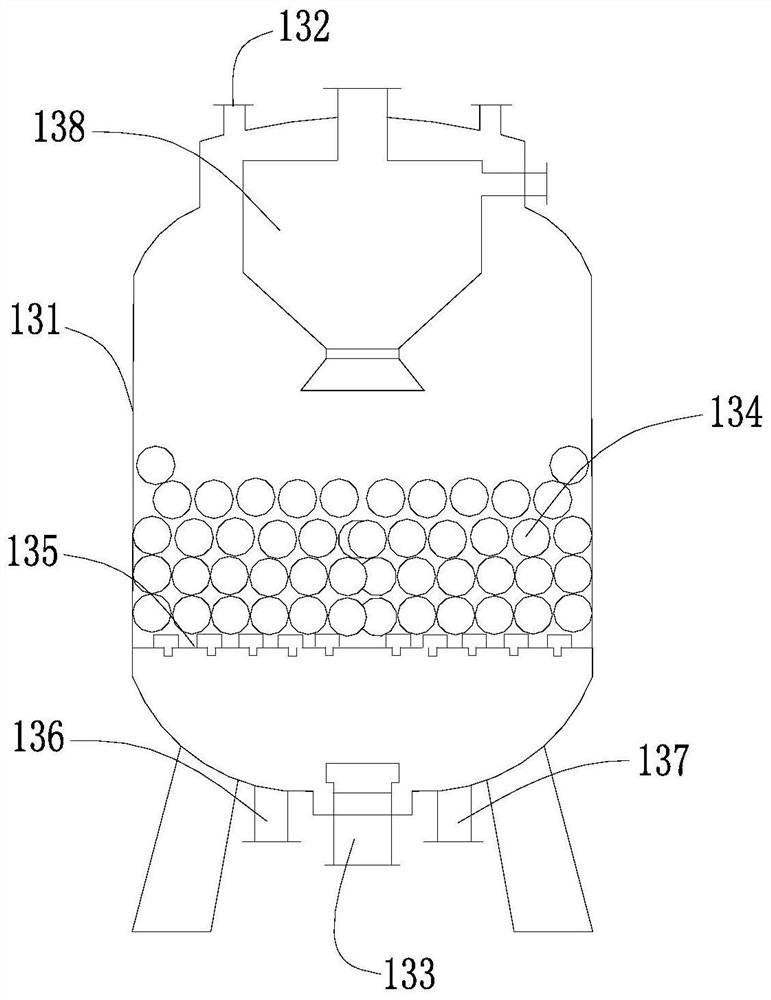

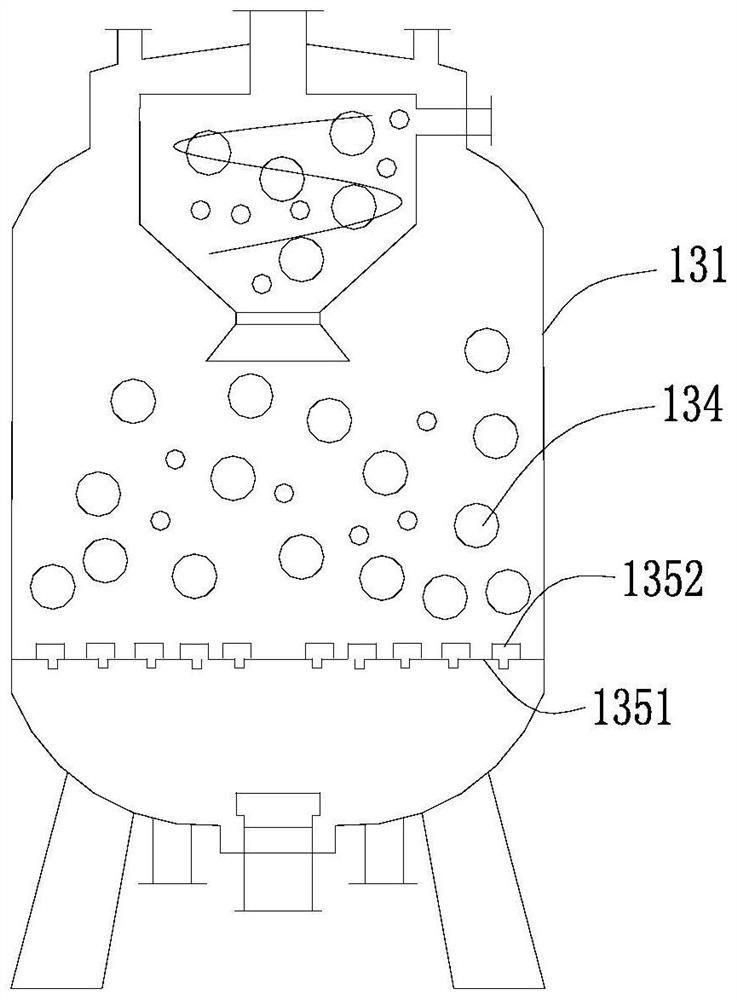

[0020] Such as figure 1 , Figure 7 As shown, the domestic sewage treatment system includes a primary treatment system, a secondary treatment system, an advanced treatment system, and a non-phase-change drying treatment system for excess sludge. The primary treatment system is connected to the secondary treatment system, and the secondary treatment system The system is connected with the advanced treatment system and the excess sludge non-phase change drying treatment system. The excess sludge non-phase change drying treatment system is also the sludge treatment system. The excess sludge non-phase change drying treatment system includes the storage sludge Pool 41, belt dehydrator 42, hot gas generator 43, gas-liquid separator 45, multiple first cyclone separators 44 connected in series in sequence, mud storage tank 41 and secondary treatment system, belt dehydrator 42, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com