Circulating treatment system and process of high concentration salt-containing wastewater

A high-concentration salt-containing and cyclic treatment technology, applied in energy wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc., can solve low evaporation efficiency, high energy consumption of falling film evaporation, and low heat reuse and other issues, to achieve the effect of safe and reliable system operation, high energy reuse rate, and system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

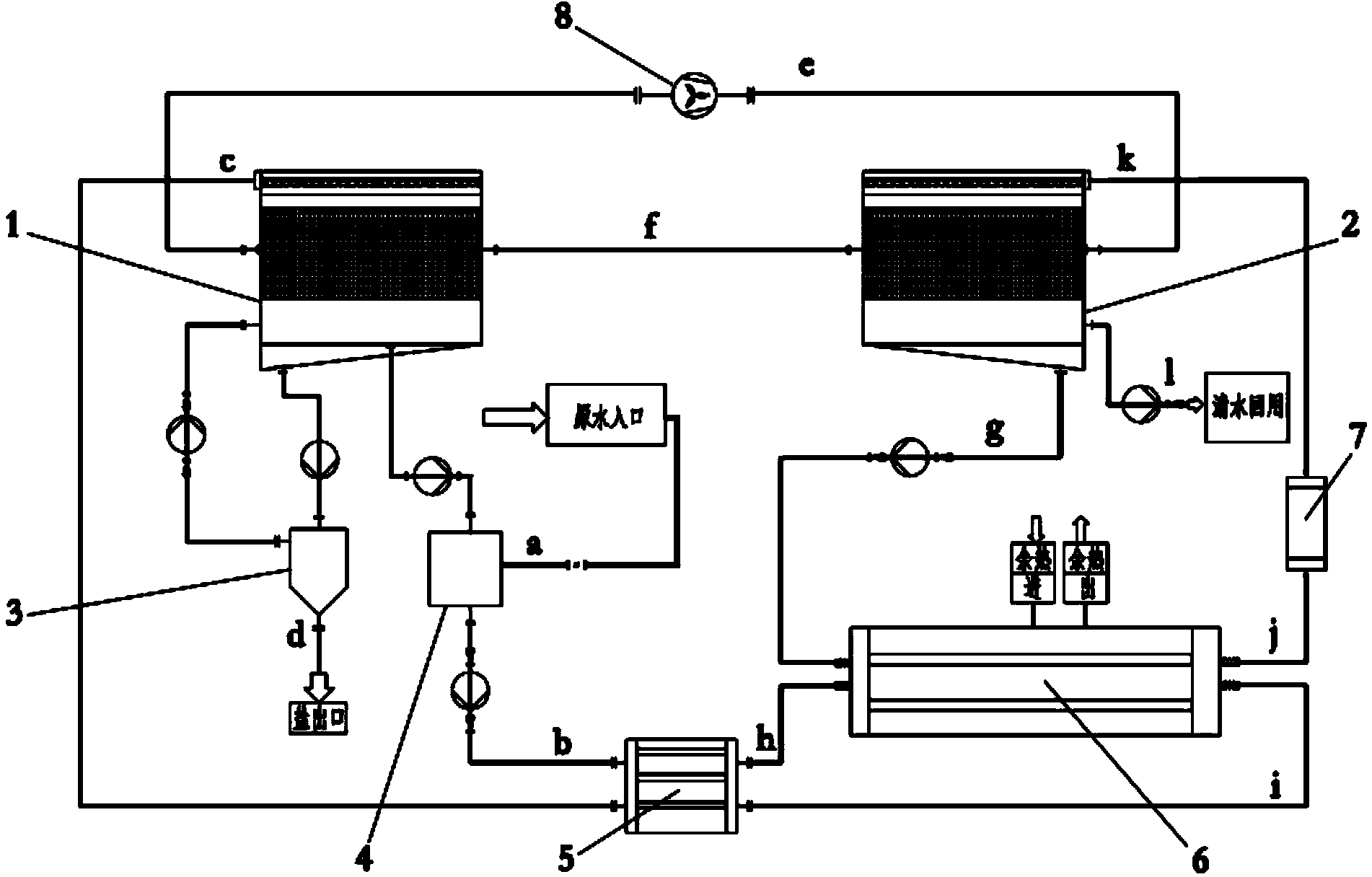

[0045] 20% sodium chloride concentrated brine at 0.80m 3 The flow rate of / h enters the circulation processing system of the present invention and is processed, and its processing result is as shown in table 1: wherein, a, b to l in table 1 correspond to respectively figure 1 Sampling points a, b to l in.

[0046] The treatment result table of table 1 sodium chloride concentrated brine

[0047]

[0048] After the concentrated brine is treated by the circulation system and process of the present invention, the waste heat required to obtain per cubic water produced is less than 40KW·h.

Embodiment 2

[0050] 20% sodium sulfate concentrated brine with 0.76m 3 The flow rate of / h enters the circulation processing system of the present invention to process, and its processing result is as shown in table 2: wherein, a, b to l in table 2 correspond to respectively figure 1 Sampling points a, b to l in.

[0051] The treatment result table of table 2 sodium sulfate concentrated brine

[0052]

[0053] After the concentrated brine is treated by the circulation system and process of the present invention, the waste heat required to obtain per cubic water produced is less than 40KW·h.

Embodiment 3

[0055] 10% sodium chloride and 10% sodium sulfate mixed concentrated brine in 0.5m 3 The flow rate of / h enters the circulation processing system of the present invention and is processed, and its processing result is as shown in table 3: wherein, a, b to l in table 3 correspond to respectively figure 1 Sampling points a, b to l in.

[0056] Table 3 Processing result table of mixed concentrated brine

[0057]

[0058] After the concentrated brine is treated by the circulation system and process of the present invention, the waste heat required to obtain per cubic water produced is less than 40KW·h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com