Vehicle-mounted repairing equipment and method for polluted site soil and underground water body

A groundwater, vehicle-mounted technology, applied in the field of soil/water body remediation technology equipment for polluted sites, can solve the problems of high price, no mention, no introduction of injection equipment and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

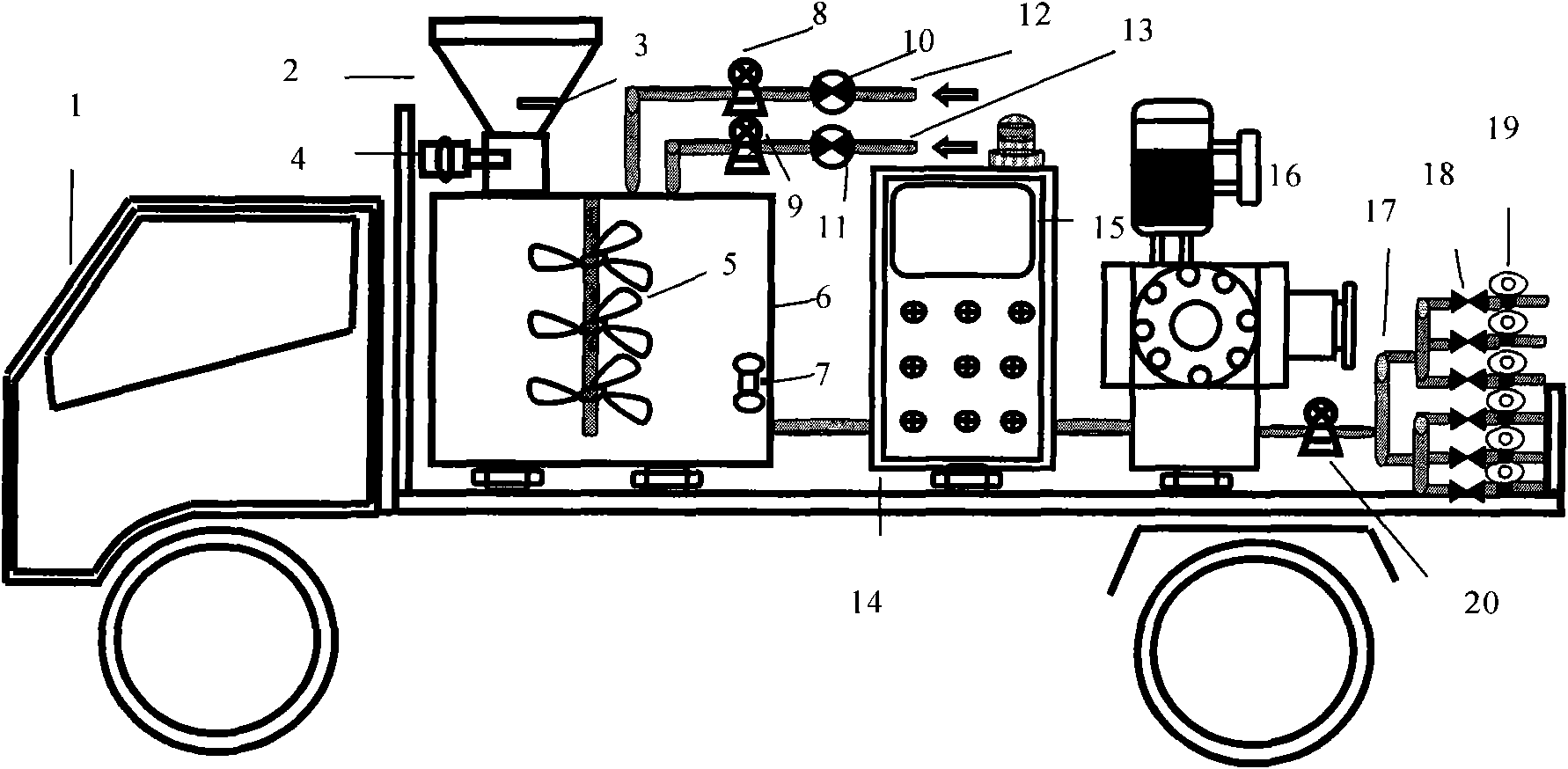

[0035] Use automatic operation mode to inject solid preparation potassium permanganate into two layers 4.5-5.5m and 7-10m below the surface of the coking plant that are heavily polluted by high-concentration polycyclic aromatic hydrocarbons.

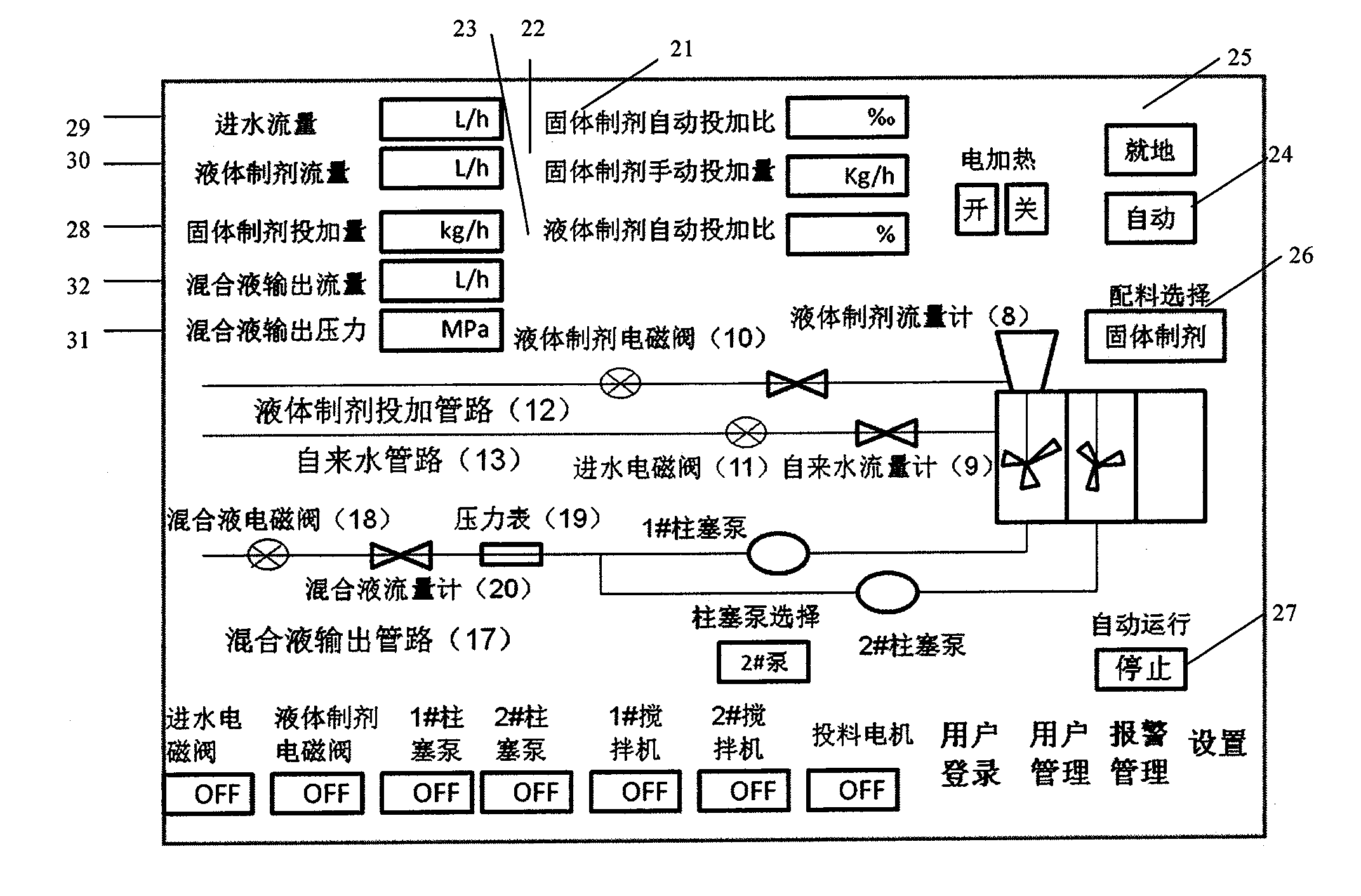

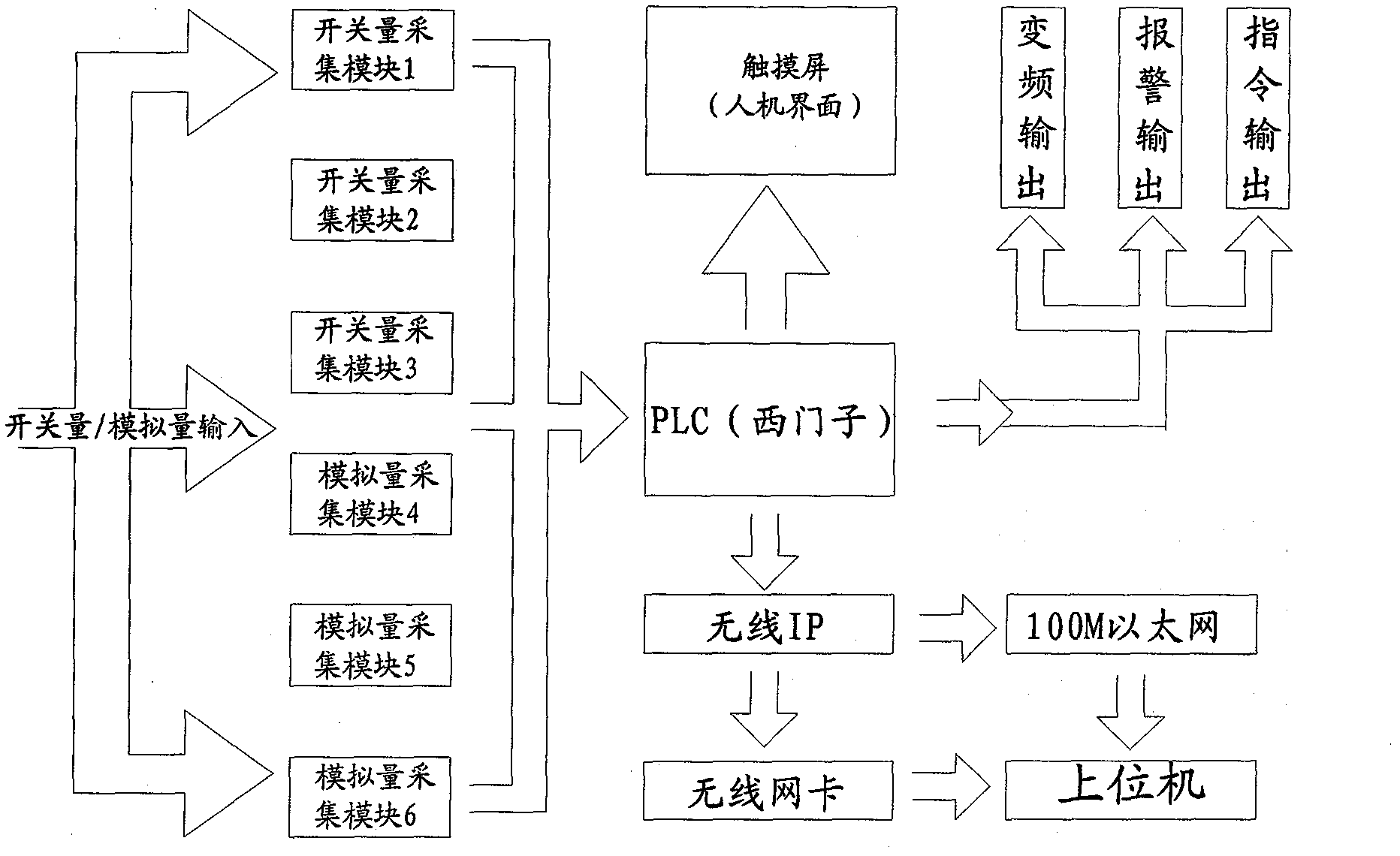

[0036] Connect the power supply, water inlet pipeline, and mixed solution output pipeline. Turn on the power, log in to the touch screen operating system, set the system parameters, select the preparation type as solid, select the operation mode as automatic operation, and set the automatic dosing ratio of solid preparation to 15‰. Add potassium permanganate into the dry powder hopper, start the automatic operation, the system automatically opens the water inlet solenoid valve, adds tap water into the mixing tank, and at the same time turns on the feeding motor, and feeds the solid preparation in the dry powder hopper into the mixing tank. And start the mixer to fully dissolve the solid preparation and configure it into an oxidizing prep...

Embodiment 2

[0040] The liquid preparation hydrogen peroxide (concentration is 30%) is injected into the soil polluted by high-concentration polycyclic aromatic hydrocarbons 4.5-5.5m below the surface of the coking plant by using a manual operation mode.

[0041] Connect the power supply, water inlet pipeline, and mixed solution output pipeline. Turn on the power, log in to the touch screen operating system, set the system parameters, select the preparation type as liquid, the operation mode as manual, the water flow rate as 500L / h, and adjust the liquid preparation flow rate as 500L / h. Open the water inlet solenoid valve and the liquid preparation solenoid valve, add tap water to the mixing tank, add the liquid preparation hydrogen peroxide at the same time, turn on the mixer, fully mix the hydrogen peroxide and water, and prepare a 30% oxidizing preparation. 0.8 hours after the start of equipment operation, the liquid in the liquid storage tank exceeds the low level, and the plunger pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com