Chemical Injection System

a chemical injection and system technology, applied in the direction of sealing/packing, instruments, borehole/well accessories, etc., can solve the problems of not being able to communicate with other the chemical injector may not be able to communicate with equipment and/or monitoring systems communicably coupled with the chemical injector, and the need for increasing the set amount of additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

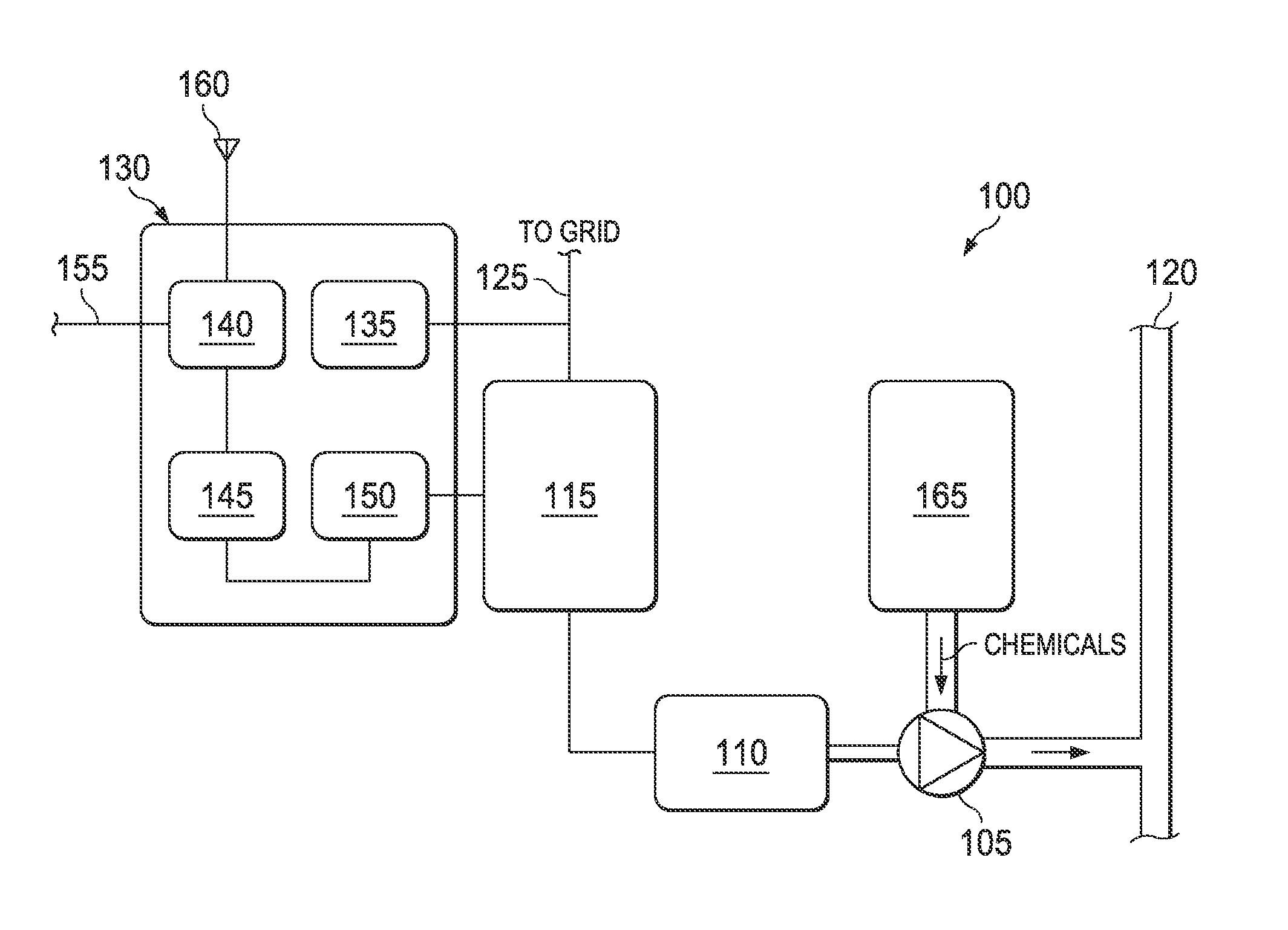

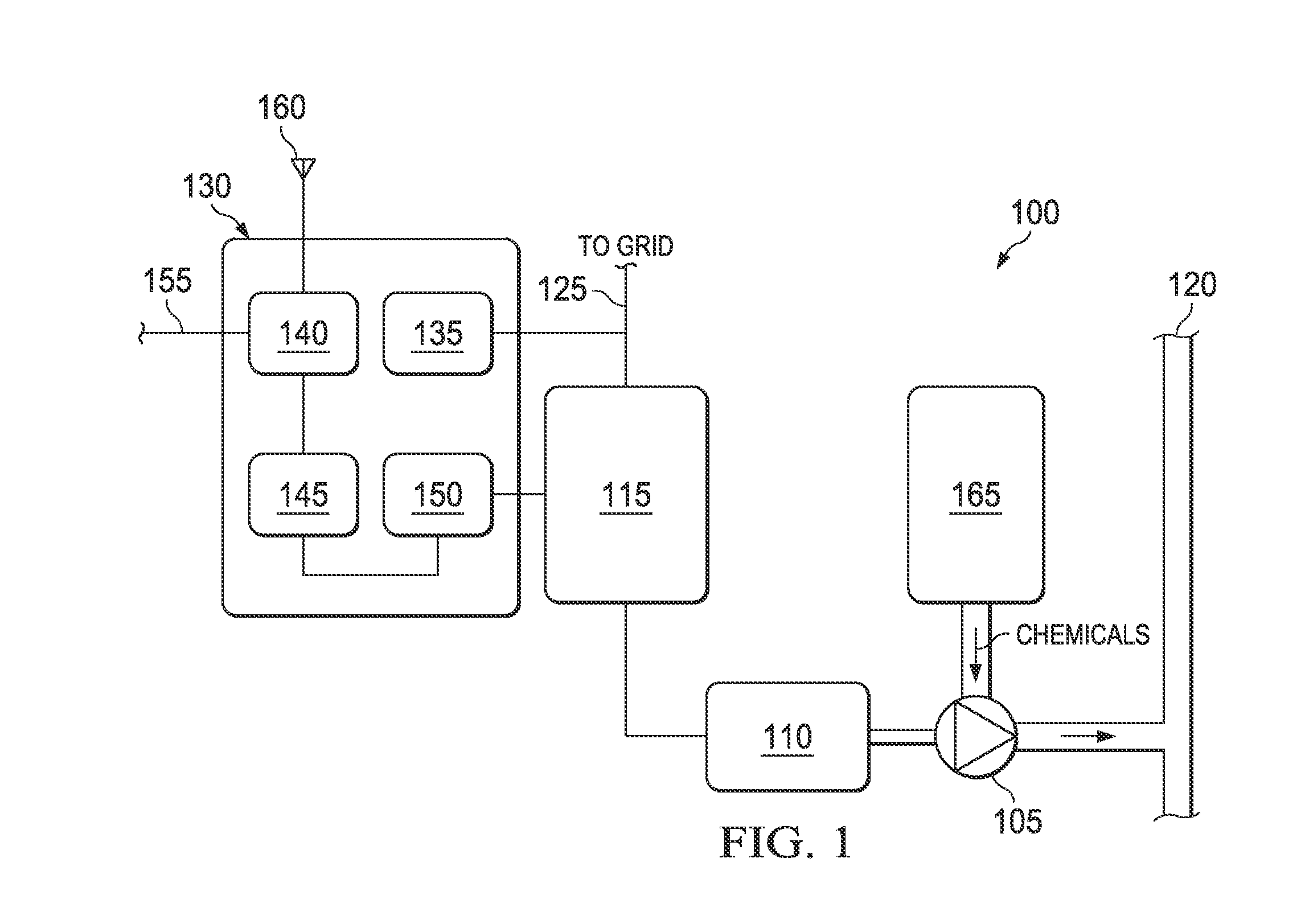

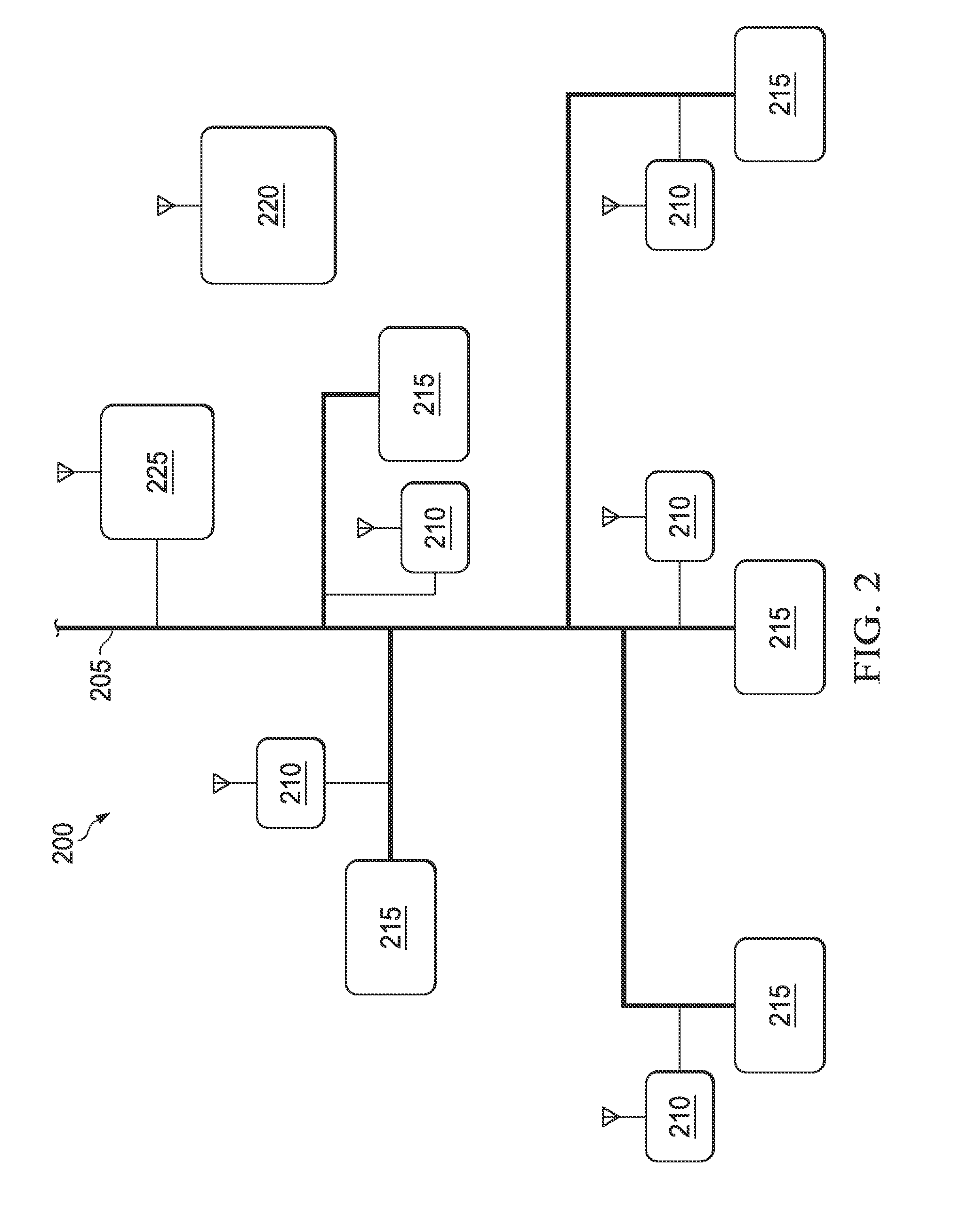

[0034]In one embodiment, a chemical injection system for a hydrocarbon transmission system includes a pumping system adapted to inject a specified amount of chemical additive into the transmission system; and a controller communicably coupled to the pumping system and adapted to receive one or more operational parameters of the transmission system and transmit a command to the pumping system based on the one or more operational parameters, where the pumping system injects the specified amount in response to the command.

[0035]In another embodiment, a chemical injection system for a hydrocarbon transmission system includes a pumping system adapted to inject a specified amount of chemical additive into the transmission system; and a controller communicably coupled to the pumping system and adapted to receive one or more operational parameters of the transmission system in a first communication protocol and transmit a command to the pumping system based on the one or more operational pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com