Continuous feeding system for cement pipe making machine

A technology of feeding system and pipe making machine, applied in cement mixing device, ingredient storage, supplying device and other directions, can solve problems such as low production efficiency and failure, and achieve the effect of improving production efficiency, reducing failure and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

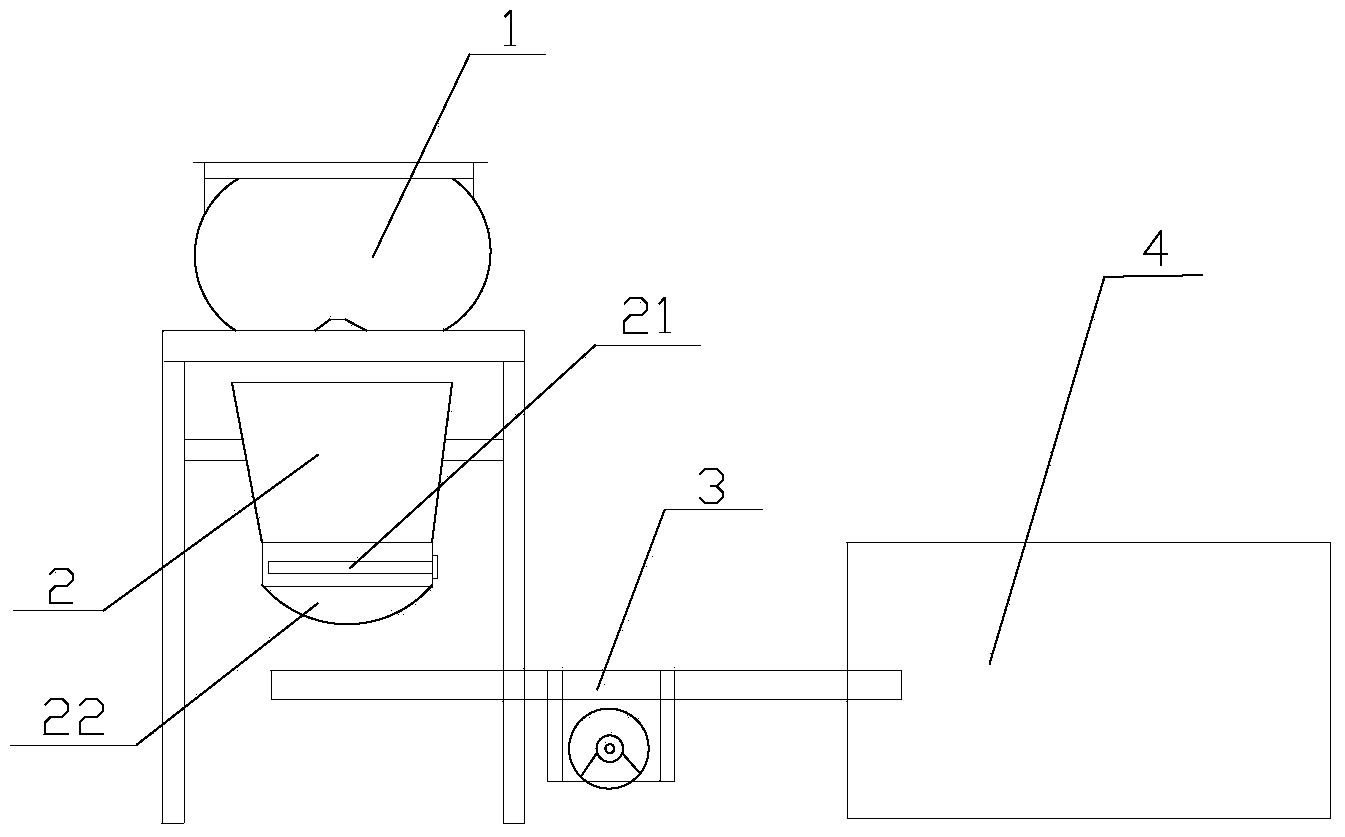

[0019] See attached figure 1 , the present invention comprises a mixer 1 and a conveyor 3, the mixer 1 is provided with a feed inlet and a discharge port, a storage bin 2 is arranged between the mixer 1 and the conveyor 3, the mixer 1 The discharge port is connected with the feed port of the storage bin 2, the discharge port of the storage bin 2 is connected with the feed end of the conveyor 3, and the discharge end of the conveyor 3 is connected with the pipe making The machine 4 is connected; the volume of the storage bin 2 is greater than or equal to the volume of the mixer 1, and the discharge port of the storage bin 2 is provided with a looser 21, and the looser 21 includes a horizontally arranged transmission Shaft and loose material rods evenly distributed on the transmission shaft, the transmission shaft is connected with the motor through a chain, the discharge port of the storage bin 2 is also provided with a valve 22, the valve 22 is connected with a cylinder, and t...

Embodiment 2

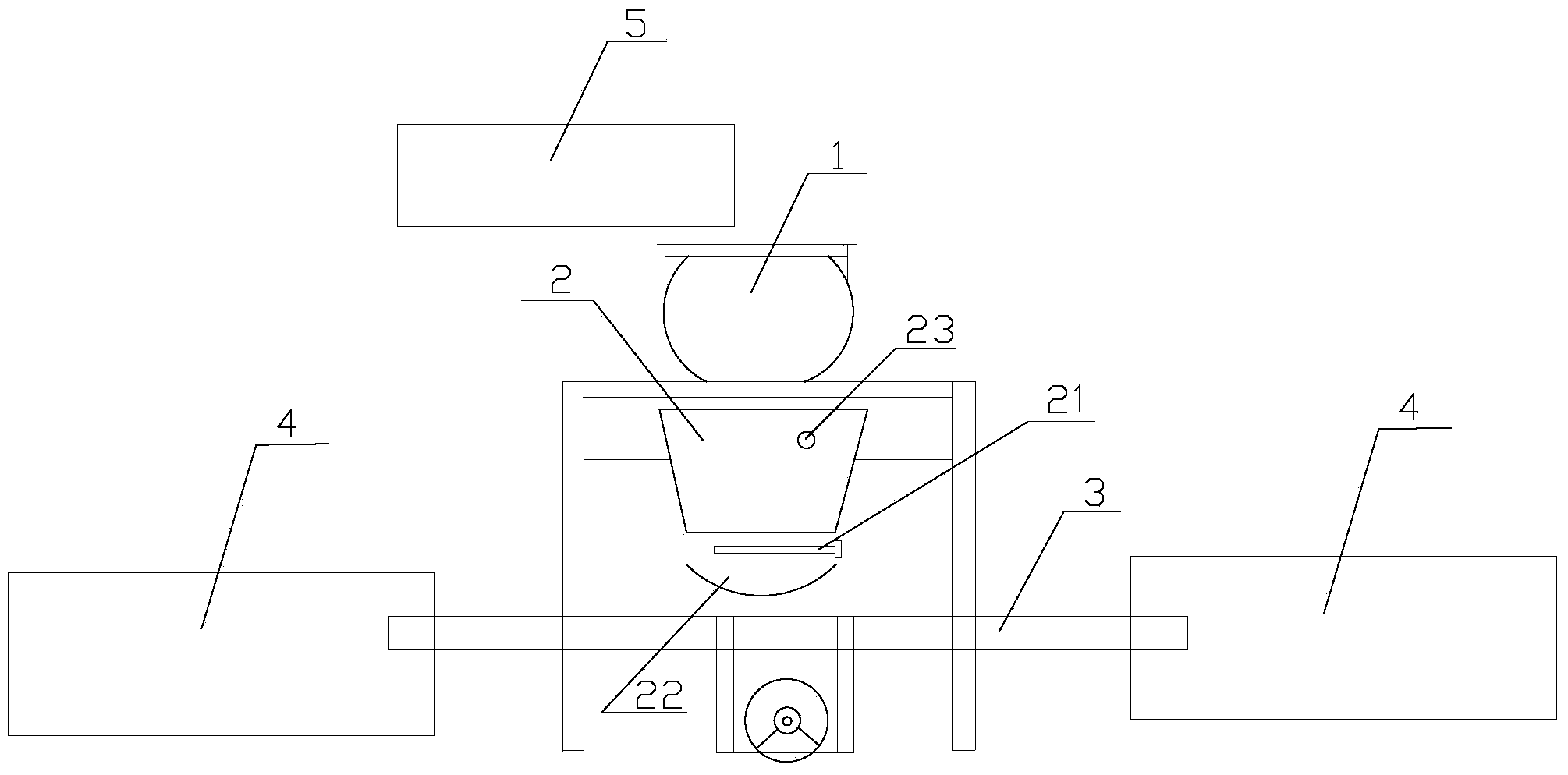

[0022] See attached figure 2 , the present invention comprises a mixer 1, a conveyor 3, a storage bin 2 is arranged between the mixer 1 and the conveyor 3, a feed inlet and a discharge port are arranged on the mixer 1, and the mixer 1 The feed inlet is connected with a batching device 5, and the batching device 5 includes a batching hopper and a transmission mechanism; the discharge port of the mixer 1 is connected with the feed port of the storage bin 2, and the discharge port of the storage bin 2 The feed port is connected to the feed end of the conveyor 3, and the discharge end of the conveyor 3 is connected to the pipe making machine 4; the volume of the storage bin 2 is greater than or equal to the volume of the mixer 1, the The inside of the storage bin 2 is provided with a looser 21, and the looser 21 includes a horizontally arranged transmission shaft and a looser rod evenly distributed on the transmission shaft, and the transmission shaft is connected with the motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com