Control method and device of mixing station and mixing station

A technology for control devices and mixing stations, which is applied in the direction of control devices, cement mixing devices, mixing operation control devices, etc. It can solve the problems of lack of pre-mixing function, poor mixing efficiency and quality, poor batching accuracy, etc., and shorten the mixing time. , improve the precision, improve the effect of stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

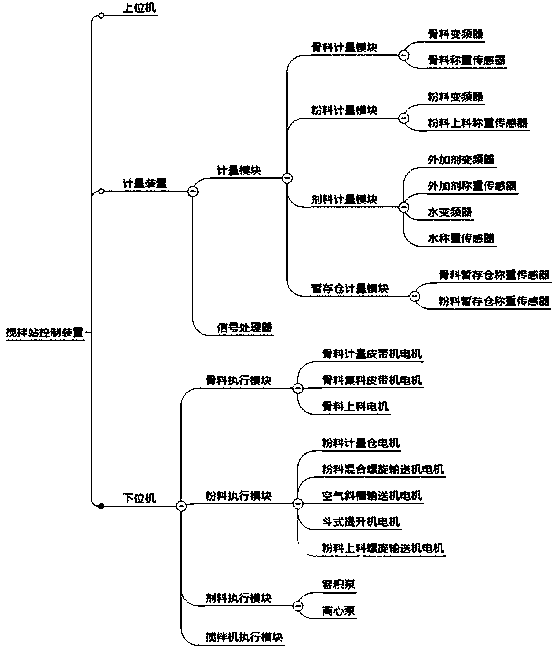

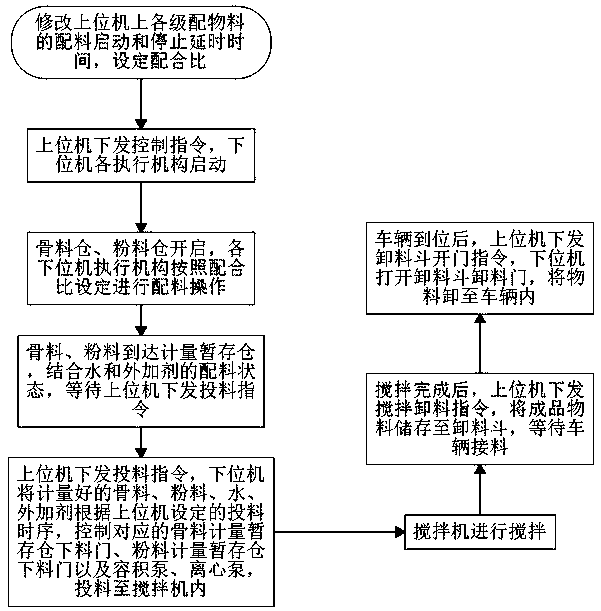

[0038] Such as figure 1 , figure 2 Shown, a kind of control method of mixing plant, this method comprises:

[0039] Step 1: The host computer issues control instructions, and the actuators of the lower computer are activated to enter the state of waiting for production;

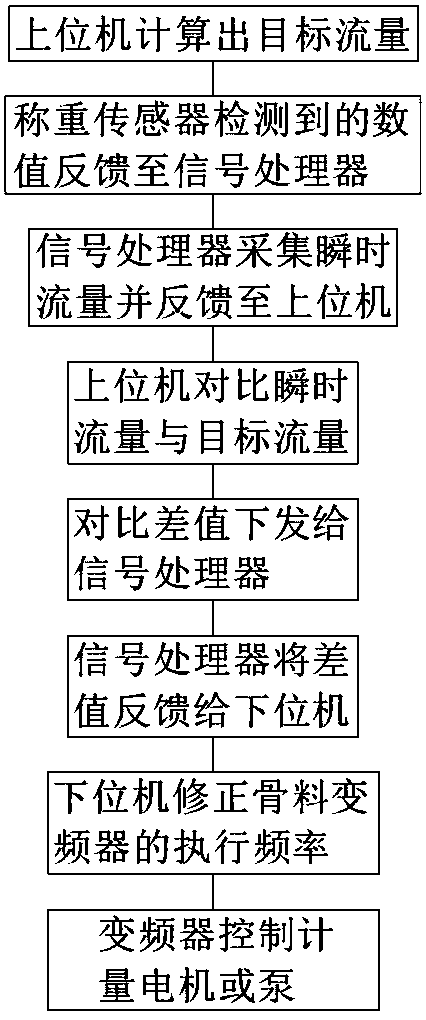

[0040] Step 2: According to the needs of materials, modify the batching start and stop delay time of all levels of ingredients on the upper computer, and then set the mixing ratio on the upper computer and send it out. The aggregate bin and powder bin are opened, and the actuators of each lower computer The batching operation is carried out according to the setting of the mixing ratio; the batching instructions issued by the upper computer are executed through the lower computer to ensure that the aggregates are stacked sequentially on the aggregate collection belt conveyor, and the powder is pre-mixed in the powder feeding screw conveyor, water and The admixture is mixed in advance in the pipeline; the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com