Road concrete transporting and stirring device and using method thereof

A technology of mixing device and concrete, which is applied in cement mixing device, mixing operation control device, clay preparation device, etc., can solve the problems of low space utilization rate, high space requirements, complex product structure, etc., and achieves compact structure and automation. High-level, high-efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

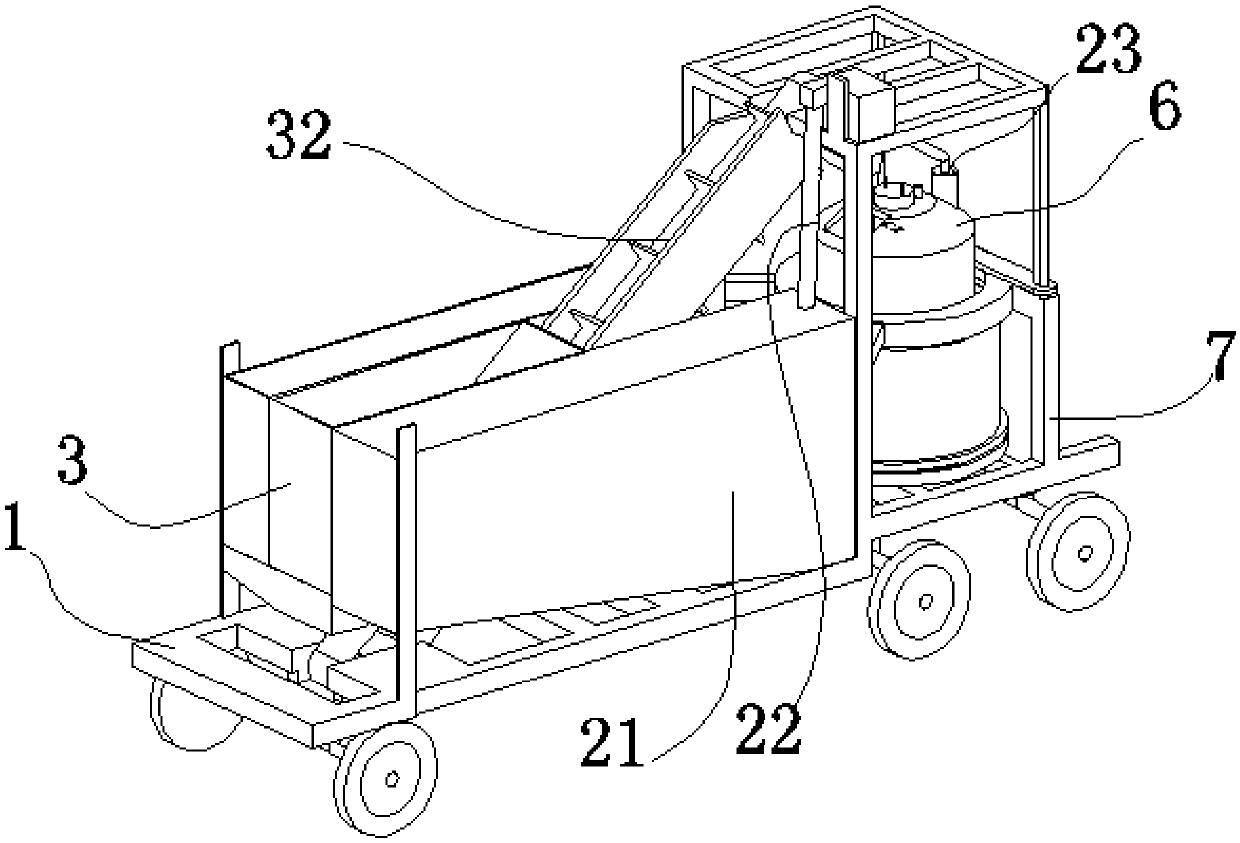

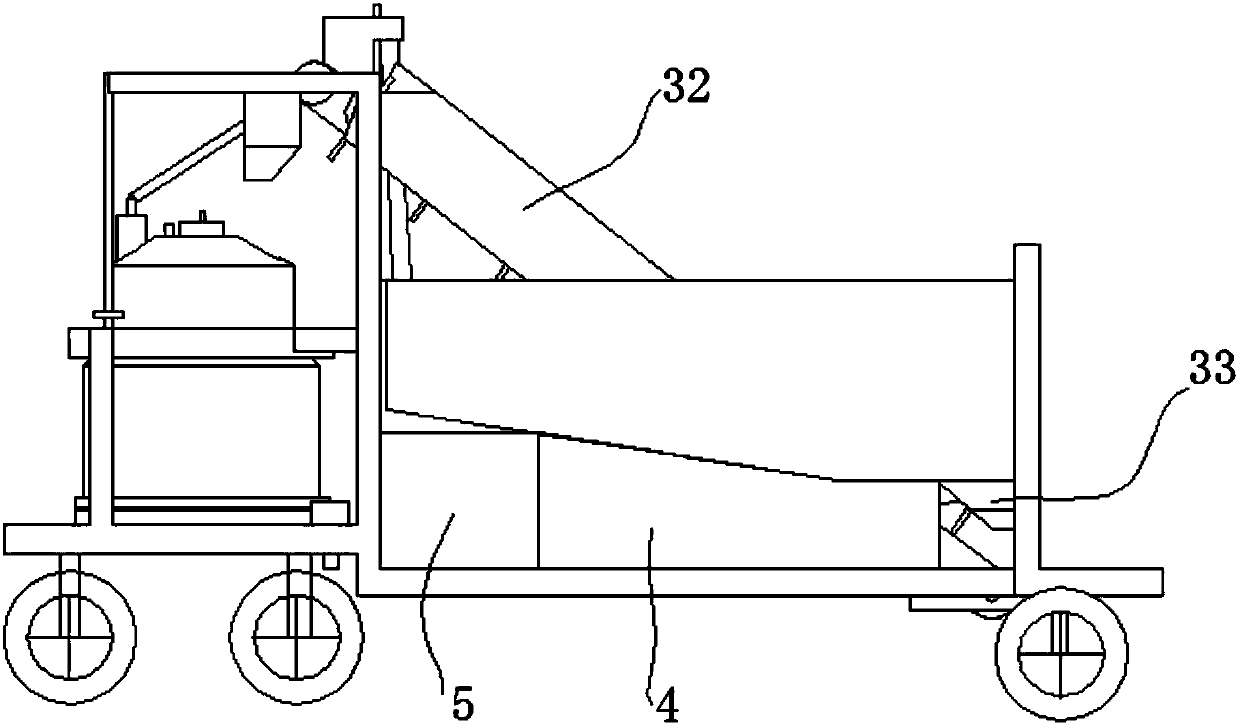

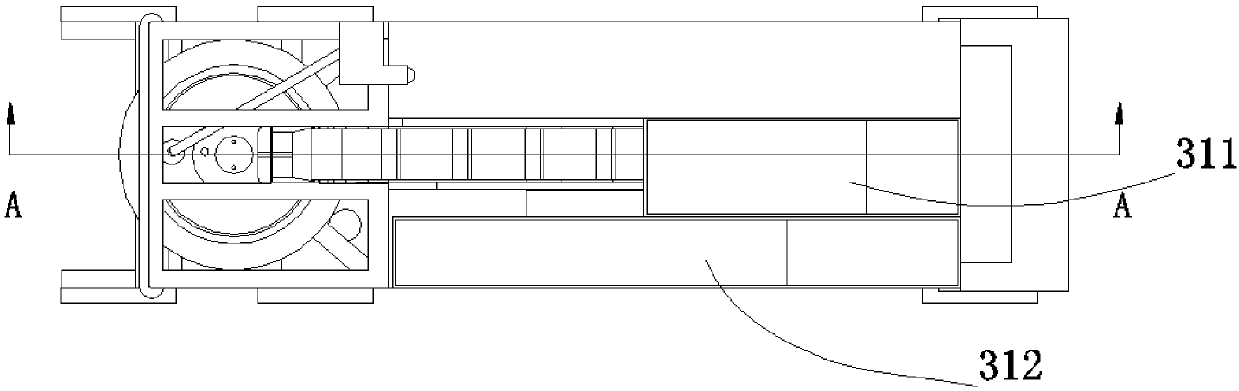

[0052] A mixing device for road concrete transportation, comprising a chassis, a base bracket 1, a mixing module 6, a powder storage and supply module 2, an aggregate storage and supply module 3, a liquid storage and supply module 4, an electric control module 5, a mixing mechanism fixing module 7 and Cleaning module 8; the base bracket 1 is fixed on the chassis; also includes: the stirring mechanism fixing module 7 is fixed on the base bracket 1; the stirring module 6 is fixed inside the stirring mechanism fixing module 7; The powder storage supply module 2, the aggregate storage supply module 3, and the liquid storage supply module 4 are all fixed on the base support 1 and connected to the stirring module 6; the electric control module 5 is fixed on the base support 1; The powder storage and supply module 2, the aggregate storage and supply module 3, the liquid storage and supply module 4, the stirring module 6 and the cleaning module 8 are all connected to the electric contr...

Embodiment 2

[0062] Same as Example 1, the difference is: the major axis of the elliptical blind hole is 7.5 cm, the minor axis is 6.6 cm, and the radius of the upper stirring rod 631 is 10 cm.

[0063] The equipment of this embodiment is applied to a certain road reconstruction project, the pavement on site is 15m wide, 10cm thick, and 400m in length; After arriving at the operation site after 1.5 hours at the speed of 50km per hour, the road concrete transportation mixing device is quickly debugged and put into production, which is completed within 1 hour; the power unit is started, and an excavator is used to add raw materials to it. At the same time, The power device drives the gear to rotate clockwise, drives the lower mixing drum 61 to rotate counterclockwise, drives the upper mixing drum 62 to rise, and then increases the mixing volume; the concrete mix ratio is controlled by the electronic control module 5; when production starts, the road concrete transportation mixing device Prod...

Embodiment 3

[0065] Same as Example 1, the difference is: the major axis of the elliptical blind hole is 9 cm, the minor axis is 4.4 cm, and the radius of the upper stirring rod 631 is 10 cm.

[0066] The equipment of this embodiment is applied to a certain road reconstruction project. The existing paving width is 15m, the thickness is 12cm, and the length is 1500m; After arriving at the operation site after 2 hours at the speed of 50km per hour, the road concrete transport mixing device is quickly debugged and put into production, which is completed within 1 hour; start the power unit, and use an excavator to add raw materials to it. At the same time, The power device drives the gear to rotate clockwise, drives the lower mixing drum 61 to rotate counterclockwise, drives the upper mixing drum 62 to rise, and then increases the mixing volume; the concrete mix ratio is controlled through the electronic control module 5; when production starts, the road concrete transportation mixing device P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com