Double-bin proportioning mortar storage tank

A material storage tank and mortar technology, which is applied in the direction of batching storage, batching and batching equipment, and sales of raw material supply devices, etc. It can solve the problems of increasing operating procedures, not having a quantitative feeding mechanism, and reducing operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below.

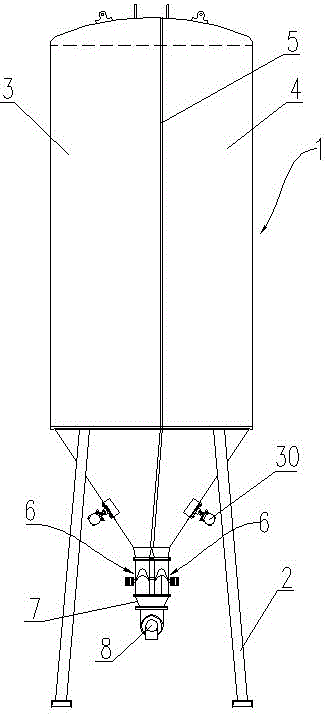

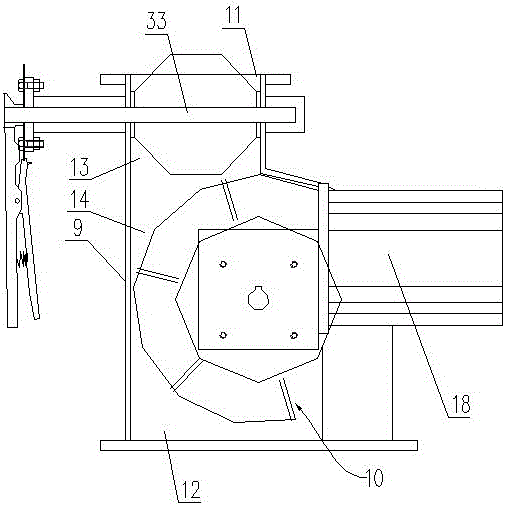

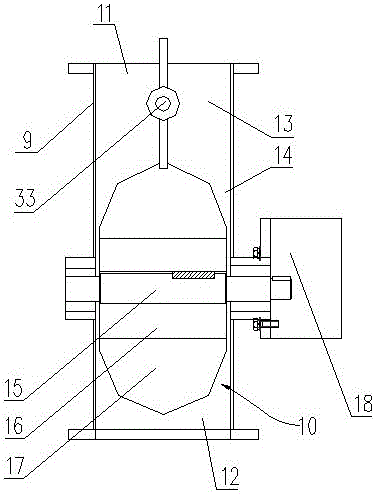

[0025] Such as Figure 1 to Figure 7 As shown, a double-compartment proportioning mortar storage tank includes a storage tank body 1 and a support leg 2 assembly fixedly arranged at the lower part of the storage tank body 1 for supporting purposes, and the inside of the storage tank body 1 is set There is a compartment plate 5 that divides its inner cavity into the aggregate bin 3 and the cement bin 4. The volume ratio of the aggregate bin 3 and the cement bin 4 is preferably the mixing ratio of aggregate and cement. The lower end of the storage tank body 1 is covered with The compartment plate 5 is separated into an aggregate discharge port and a cement discharge port, each of the aggregate discharge port and the cement discharge port is fixedly provided with a quantitative feeding mechanism 6, and the outlets of the two quantitative feeding mechanisms 6 The lower end of the feed port is communicated with the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com