Automatic addition proportioner in concrete mixer transportation tank truck transportation process

A technology of mixing transportation and transportation process, which is applied in cement mixing devices, mixing operation control devices, clay preparation devices, etc., can solve the problems of grading, deterioration, and quality control indicators decline in concrete, so as to solve the problems of grading deterioration, Reasonable structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0018] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

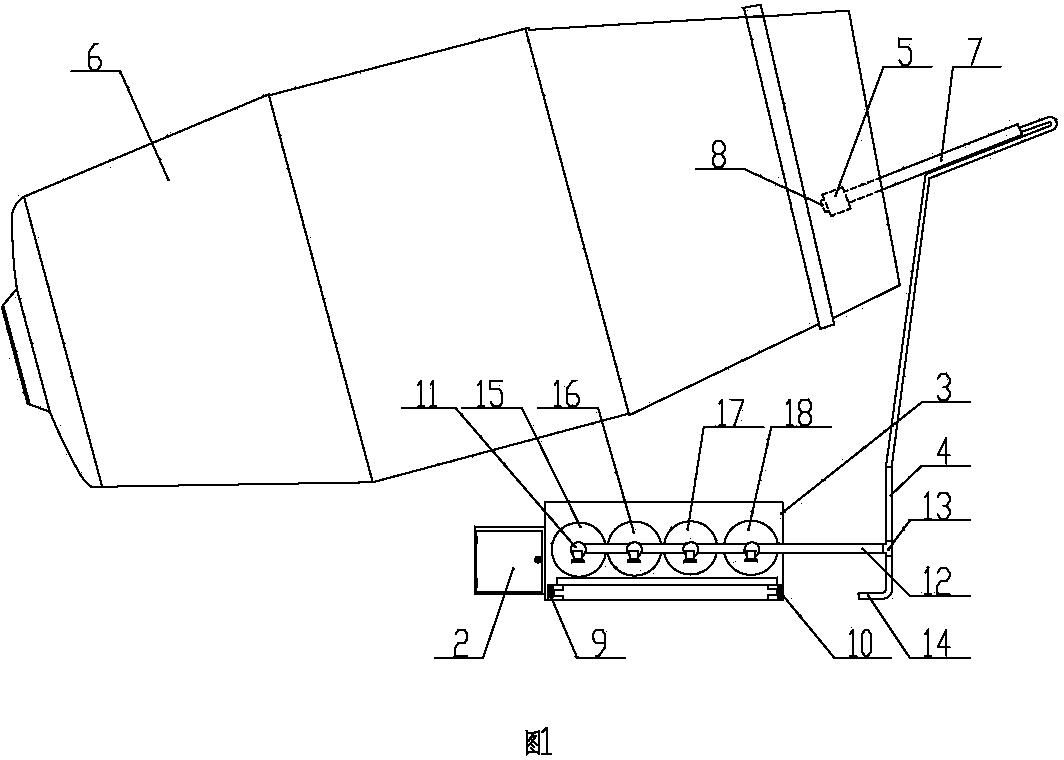

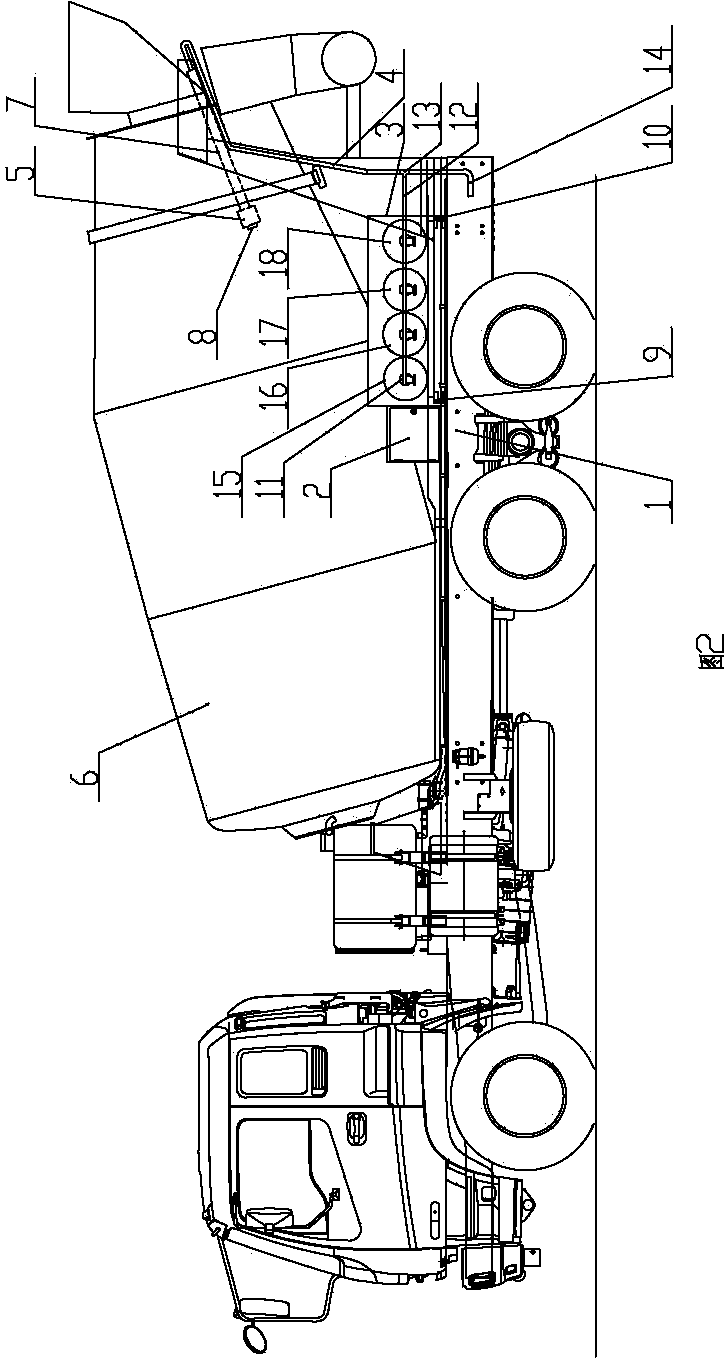

[0019] as attached figure 1 , 2 As shown, the automatic batching device during the transportation of the concrete mixing and transportation tank truck includes an electric control box 2 that can be fixedly installed on the tank truck chassis 1, a material tank storage box 3, a weighing and measuring device, a transportation and distribution device, and a material transportation pipe 4. The detection sensor 5 and the spray pipe 7 that can extend to the inside of the mixing tank body 6; the bottom of the material tank storage box 3 is equipped with a weighing and measuring device, and the inside of the material tank storage box 3 is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com