Method and system for automatic counting, monitoring and controlling water content of fuel tank car

An automatic measurement, monitoring and control technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that cannot represent the average water content value, inaccurate water content measurement in sampling and testing, and consume a lot of manpower and material resources. Oil topping phenomenon, avoiding the loss of oil quantity, and preventing the effects of human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

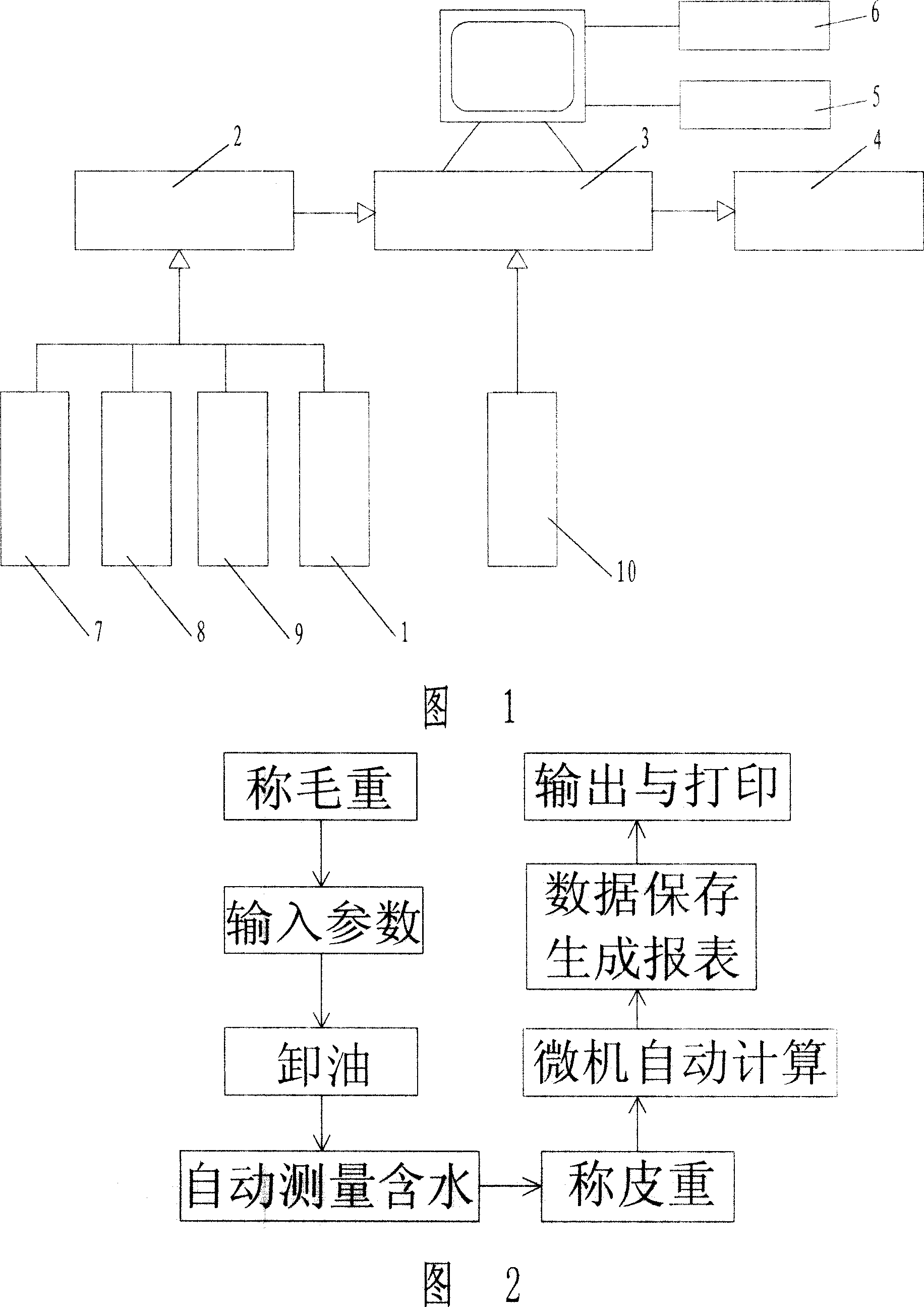

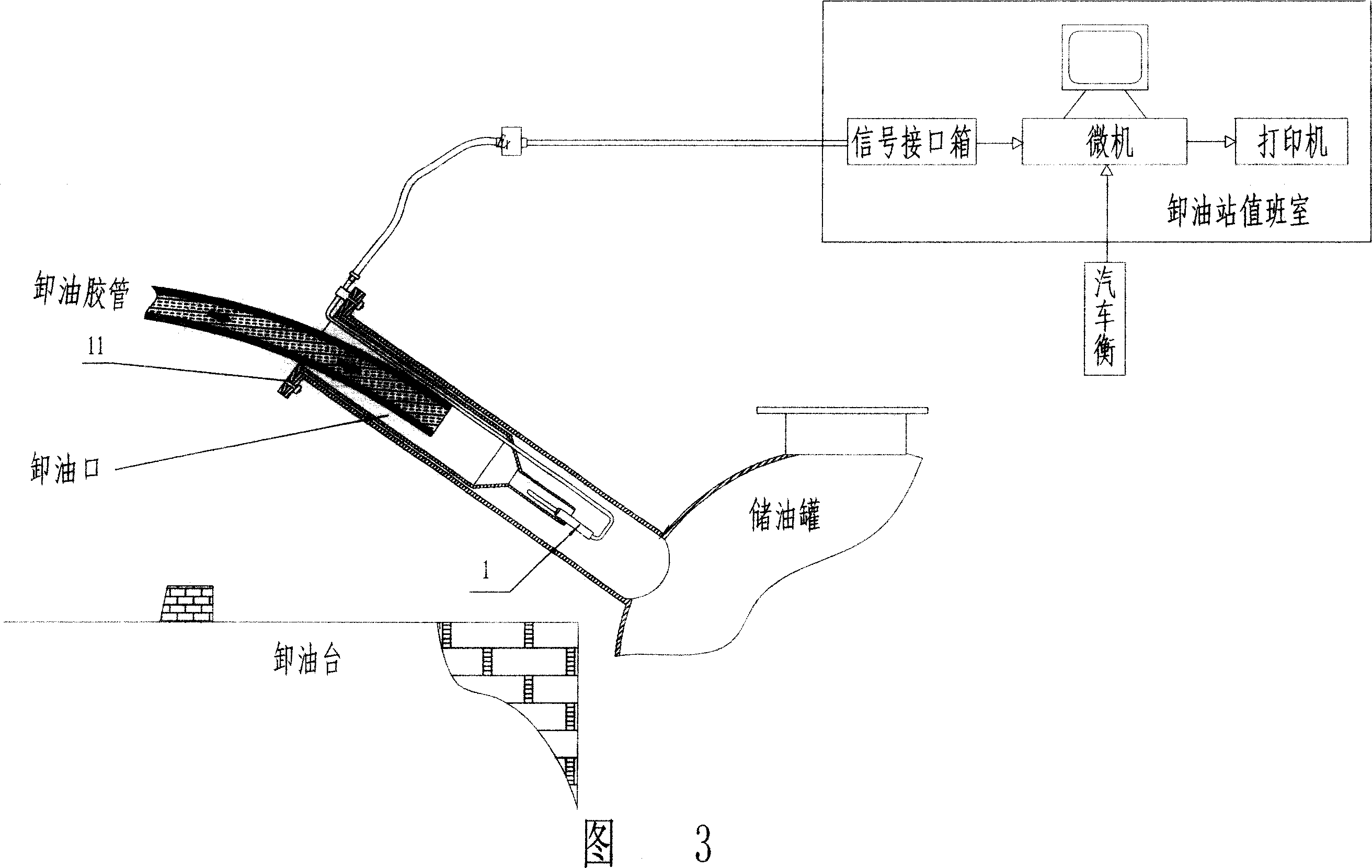

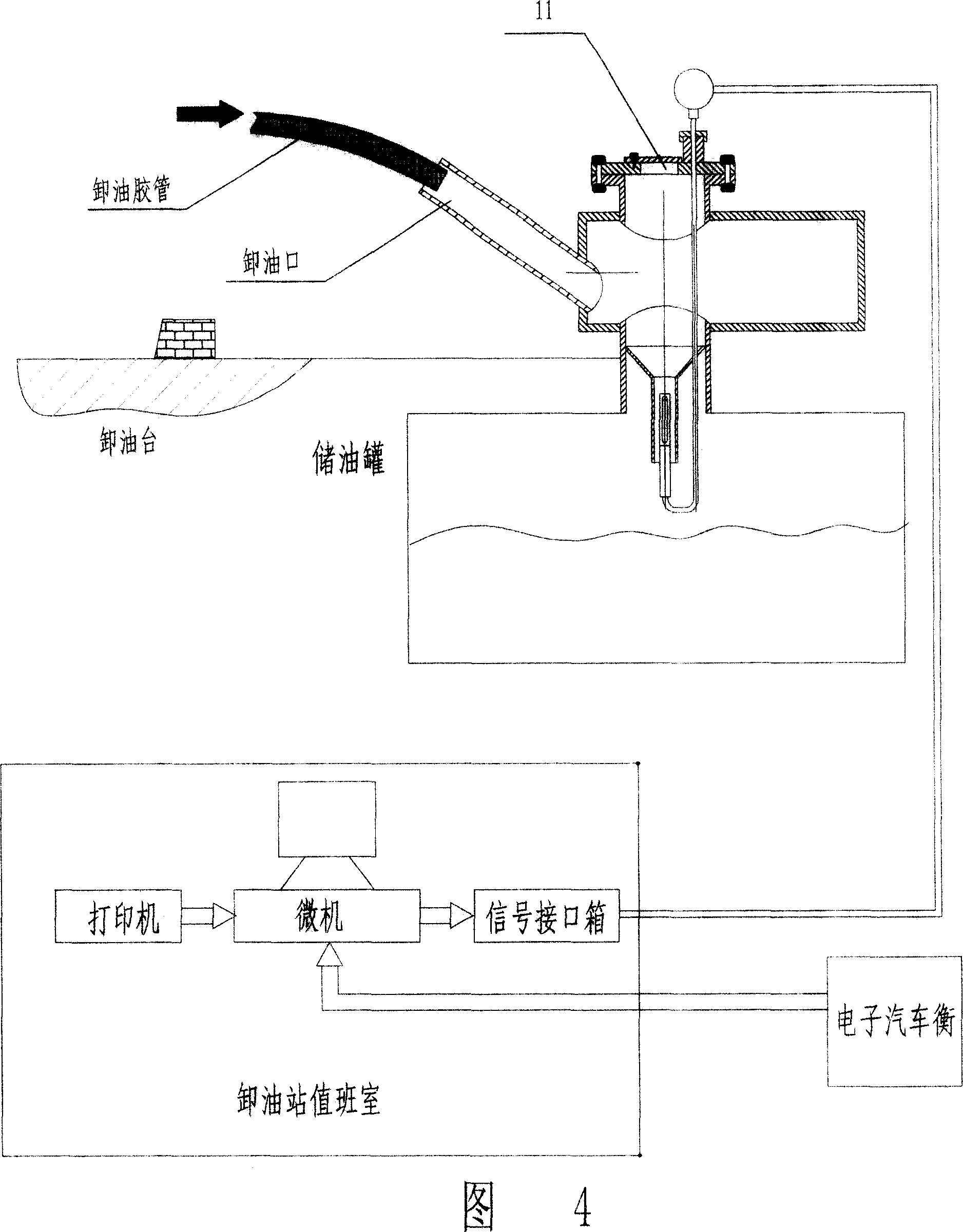

[0025] As shown in Figure 1, the automatic measurement and monitoring system for the water content of the oil tanker is composed of a microcomputer 3 with an internal automatic measurement program, a signal interface box 2 connected to the input port of the microcomputer 3, and connected with the microcomputer 3 through the signal interface box 2 The moisture analyzer 1 is connected to the printer 4 connected to the output port of the microcomputer 3, connected to the network interface 5 with output and networking functions and the sound and light alarm circuit 6 to form, and the microcomputer can be an industrial computer. As shown in Figures 3 to 5, during actual installation, the water content analyzer 1 is installed in the middle of the oil discharge port through the flange 11, and the signal is connected to the interface box 2, the microcomputer 3, the printer 4, the network interface 5 and the sound and light alarm The circuit 6 is installed in the duty room of the oil un...

Embodiment 2

[0027] First install the water content analyzer 1 on the oil discharge port of the oil storage tank through the flange 11 (as shown in Figure 3 and Figure 4 ) or install it on the oil pipeline connected to the oil discharge port through the flange 11 (as shown in Figure 5 Shown), described moisture analyzer 1 is short-wave radio frequency method, low-energy nuclear ray method, capacitance method or microwave method moisture analyzer, according to the requirement of environmental protection, it is best mode to use short-wave radio frequency method moisture analyzer. Flow sensor 7 or temperature sensor 8 or pressure sensor 9 or flow sensor 7 and temperature sensor 8 or flow sensor 7 and pressure sensor 9 or temperature sensor 8 and pressure sensor 9 or flow sensor 7, temperature sensor 8 and The pressure sensor 9 and the microcomputer 3 perform compensation through a preset program according to the signal obtained by the sensor, so as to improve the measurement accuracy. As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com