Fracturing system with antifreezing performance

A kind of antifreeze performance and fracturing technology, which is applied in the direction of isolation device, production fluid, wellbore/well parts, etc., can solve the problems of poor heat insulation effect of insulation cotton, no clear requirement for injection time, icing of coiled tubing, etc., to increase liquid Cross-linking effect, ensuring the normal operation of equipment, and preventing equipment from freezing and blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

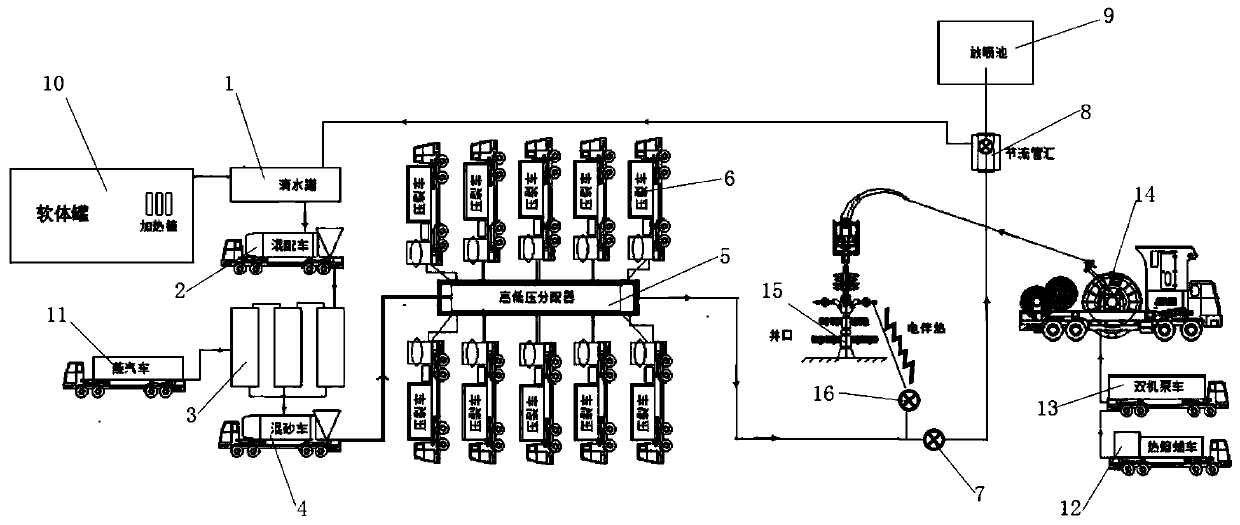

[0024] Example 1, as figure 1 As shown, the biggest problem in winter construction is that the water temperature is too low. In the continuous mixing and rapid dosing, the liquid flow rate is too fast. When the guar gum is in the glue solution, the guar gum adheres to the surface and the electric heating rod is burned out due to the high temperature. The steam car 11 can be used to heat the liquid rapidly. It will not damage the performance of the guar gum liquid; and the swing of the steam car 11 hose in the water will increase the swelling of the guar gum.

[0025] Adopt steam car 11 to heat and swell the guar gum liquid system, and the steam quality X required when reaching the heat exchange balance can be calculated as follows:

[0026] X(H 1 -H 2 ) = QρC(T 2 -T 1 )

[0027] Among them, H 1 is the enthalpy of water vapor;

[0028] H 2 is the enthalpy of water after steam liquefaction and heat exchange;

[0029] Q is the displacement of fracturing construction;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com