Chinese fir chip-based supercapacitor electrode, preparation method and supercapacitor

A technology of supercapacitors and capacitors, applied in the field of capacitors, to achieve the effects of excellent overall performance, high specific capacitance and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

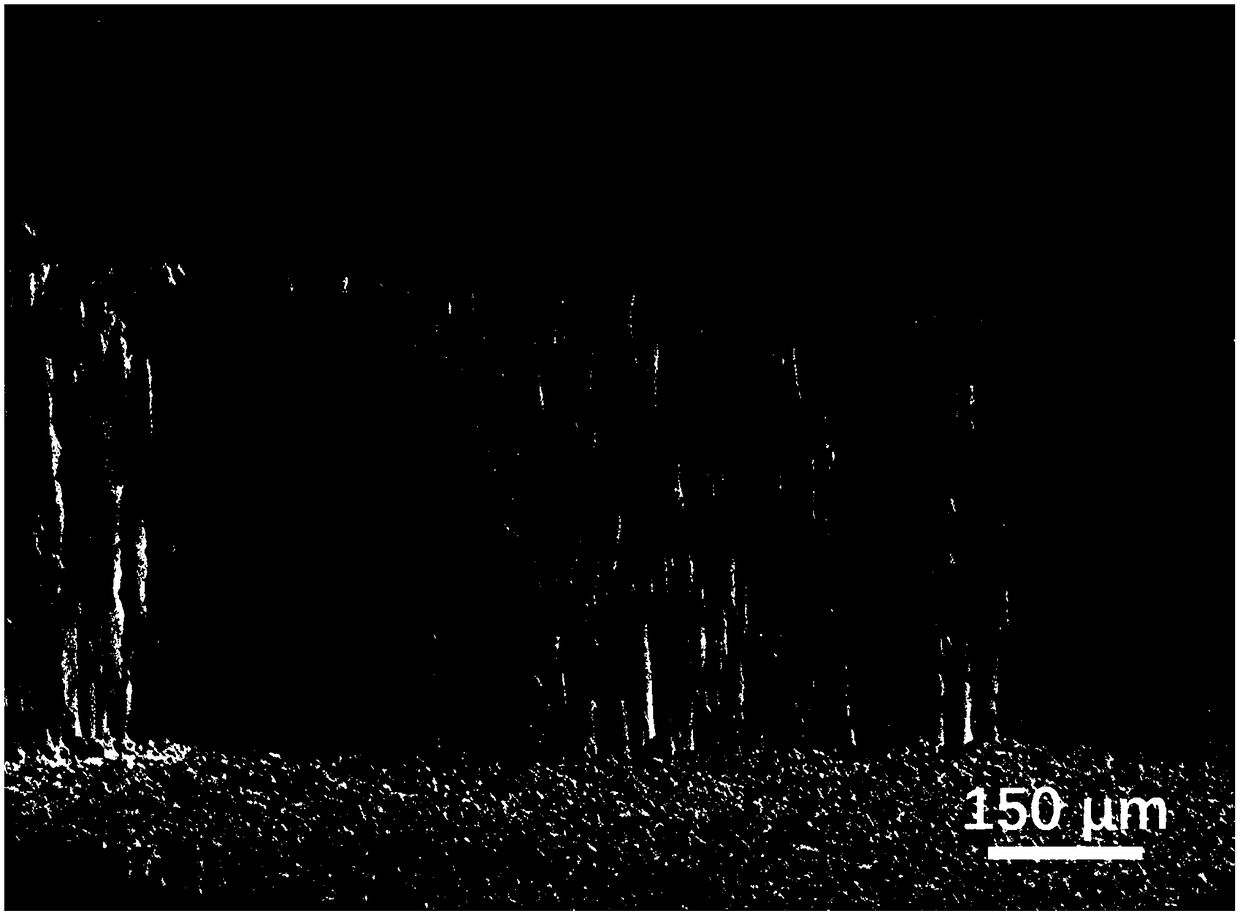

Image

Examples

Embodiment 1

[0054] The method for preparing supercapacitor electrodes based on fir sheets in the present embodiment may further comprise the steps:

[0055] 1) Air-dry the natural Chinese fir wood until the moisture content is lower than 30%, and cut it into thin slices of 3mm×20mm×40mm to obtain fir chips. In this example, natural Chinese fir was purchased from Shaodong County, Hunan Province, China.

[0056] 2) Carbonization, place the fir chips in step 1) in a blast drying furnace at 250°C for pre-carbonization for 6 hours, then transfer the fir chips to a tube furnace at 1000°C, and carry out carbonization for 10 hours under the protection of argon Processed to obtain OWC flakes.

[0057] 3) Put the OWC sheet in the CO with 100 standard cubic centimeters per minute 2 In the gas, it was activated at a temperature of 750 degrees Celsius for 10 hours, and then the activated fir chips were polished into thin slices with a thickness of 0.8 mm. Polishing is done by sanding with 2000 mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com