Near-beta ultrahigh-strength titanium alloy with tensile strength of more than 1450 MPa and preparation method thereof

A high-strength titanium alloy and tensile strength technology, applied in the field of near-beta ultra-high-strength titanium alloy and its preparation, can solve problems such as restricting application, contradiction between strength performance and plasticity and toughness, plasticity decline, etc., to promote engineering application, shorten The effect of development cycle and reduction of development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

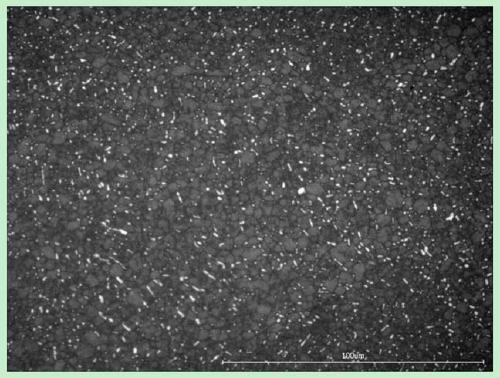

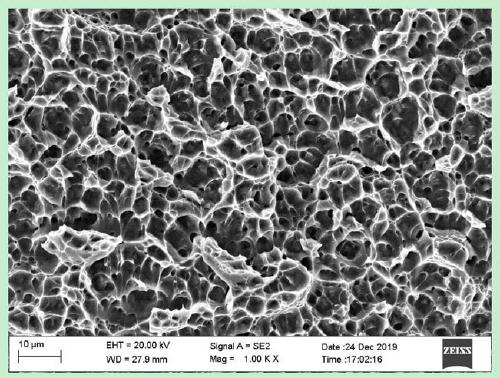

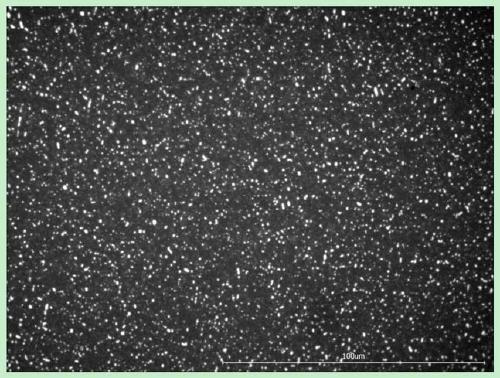

Image

Examples

Embodiment 1

[0027] A method for preparing a Ti-Al-V-Mo-Cr series near-β ultra-high-strength titanium alloy with a tensile strength greater than 1450MPa, comprising the following steps:

[0028] (1) Determine the main component system of the new ultra-high-strength titanium alloy, and realize the active optimization design of the composition of the new ultra-high-strength titanium alloy: based on the principle of multi-component strengthening under the condition of critical molybdenum equivalent, the new ultra-high-strength titanium alloy is calculated using first principles combined with CALPHAD calculation tools. The type and scope of the main components of high-strength titanium alloys, and then check the main components of the newly obtained new ultra-high-strength titanium alloys through the composition design method, and finally determine the main composition system of the new ultra-high-strength titanium alloys. The composition design method includes molybdenum equivalent and d elect...

Embodiment 2

[0033] A method for preparing a near-beta ultra-high-strength titanium alloy with a tensile strength greater than 1450MPa, comprising the following steps:

[0034] (1) In this embodiment, the main component system of the ultra-high-strength titanium alloy is: according to the weight percentage, aluminum 3%-4%, vanadium 6%-7%, molybdenum 5%-6%, chromium 1.5%-3%, Iron 0.5% ~ 2%;

[0035] (2) Prepare a titanium alloy ingot with uniform chemical composition and structure through three times of vacuum consumable melting, measure its β transformation temperature as 830-840°C, carry out billet forging in the temperature range of 1050-1100°C, and break the original coarseness of the ingot Then gradually reduce the forging temperature to below the phase transition point for repeated upsetting and drawing forging, and realize the static and dynamic recrystallization of its microstructure through multiple times of forging, and coordinate its microstructure and performance;

[0036] (3) ...

Embodiment 3

[0039] A method for preparing a near-beta ultra-high-strength titanium alloy with a tensile strength greater than 1450MPa, comprising the following steps:

[0040] (1) In this embodiment, the main component system of the ultra-high-strength titanium alloy is: by weight percentage, aluminum 5.5%-7%, vanadium 2%-4%, molybdenum 3%-5%, chromium 4%-5.5%, Zirconium 2% ~ 3%;

[0041] (2) Prepare a titanium alloy ingot with uniform chemical composition and structure through three times of vacuum self-consumption smelting, measure its β transformation temperature as 840-850°C, carry out billet forging in the temperature range of 1050-1100°C, and break the original coarseness of the ingot Then gradually reduce the forging temperature to below the phase transition point for repeated upsetting and drawing forging, and realize the static and dynamic recrystallization of its microstructure through multiple times of forging, and coordinate its microstructure and performance;

[0042] (3) Pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com