A kind of iron-silicon-boron amorphous nanocrystalline composite microsphere material and its preparation method

A technology of amorphous nanocrystals and composite microspheres, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of difficulty in controlling the size of crystallized precipitated phase structure, varying mechanical and magnetic properties, and complex processes, etc., to achieve The effect of active control process, large amorphous critical size, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

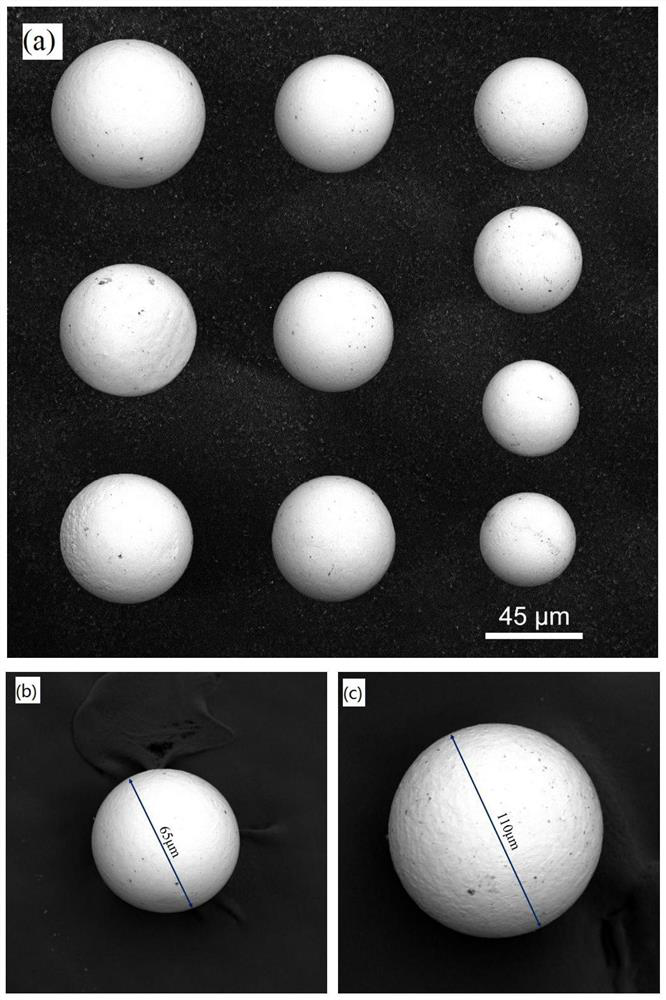

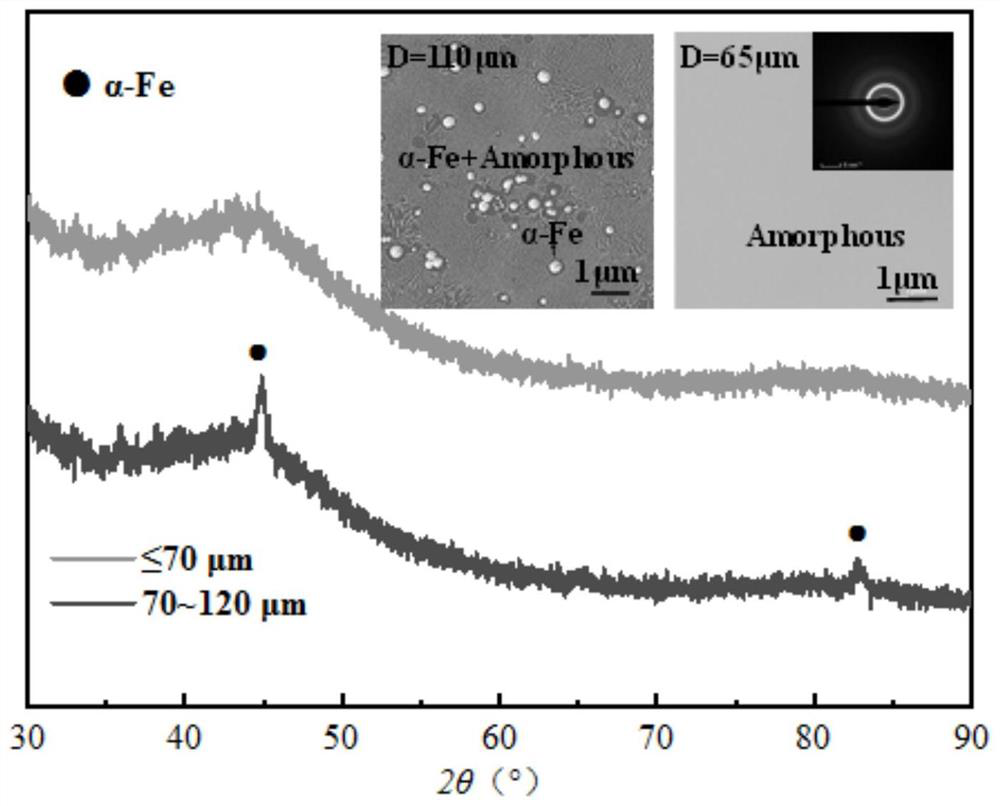

[0030] In this embodiment, a FeSiB amorphous nanocrystalline composite microsphere material is designed with an alloy composition of Fe 78Si 9 B 13 (at.%), calculate and weigh the corresponding proportioning mass of each element according to the atomic percentage;

[0031] Put the prepared raw materials into a vacuum arc melting device, the melting atmosphere is an inert gas Ar gas, the melting current is 130A, and the time is 15 minutes;

[0032] Put the obtained master alloy into a quartz test tube with a round hole at the bottom, and a small hole with a diameter of 0.2 mm at the bottom of the test tube, and install the test tube at the center of the heating coil inside the drop tube cavity;

[0033] Vacuum the drop tube cavity to 5.0×10 -5 After Pa, backfill the mixed gas of high-purity He and Ar 1:1 to 0.1Mpa.

[0034] The sample is melted and superheated at 200K by high-frequency induction melting equipment, and He gas is blown into the test tube to cause the alloy me...

Embodiment 2

[0037] In this embodiment, a FeSiB amorphous nanocrystalline composite microsphere material is designed with an alloy composition of Fe 75 Si 12 B 13 (at.%), calculate and weigh the corresponding proportioning mass of each element according to the atomic percentage;

[0038] Put the prepared raw materials into the vacuum arc melting device, the melting atmosphere is inert gas Ar gas, the melting current is 120A, and the time is 20min;

[0039] Put the obtained master alloy into a quartz test tube with a round hole at the bottom, and a small hole with a diameter of 0.1 mm at the bottom of the test tube, and install the test tube at the center of the heating coil inside the drop tube cavity;

[0040] Vacuum the drop tube cavity to 1.0×10 -5 After Pa, backfill the mixed gas of high-purity He and Ar 1:1 to 0.1Mpa.

[0041] The high-frequency induction melting device is used to heat the sample to melt and overheat to 50K, and He gas is blown into the test tube to make the alloy...

Embodiment 3

[0043] In this embodiment, a FeSiB amorphous nanocrystalline composite microsphere material is designed with an alloy composition of Fe 76 Si 10 B 14 (at.%), calculate and weigh the corresponding proportioning mass of each element according to the atomic percentage;

[0044] Put the prepared raw materials into the vacuum arc melting device, the melting atmosphere is inert gas Ar gas, the melting current is 140A, and the time is 5 minutes;

[0045] Put the obtained master alloy into a quartz test tube with a round hole at the bottom, and a small hole with a diameter of 0.6 mm at the bottom of the test tube, and install the test tube at the center of the heating coil inside the drop tube cavity;

[0046] Vacuum the drop tube cavity to 2.0×10 -4 After Pa, backfill the mixed gas of high-purity He and Ar 1:1 to 0.1Mpa.

[0047] The high-frequency induction melting device is used to heat the sample to melt and overheat to 300K, and He gas is blown into the test tube to make the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com