Multi-row mini-pile enclosing structure for blocking soil and construction process

A technology of enclosure structure and construction technology, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems that the enclosure pile construction cannot be unfolded, and the bending stiffness is small, so as to achieve small construction machinery, high bending stiffness, and construction The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

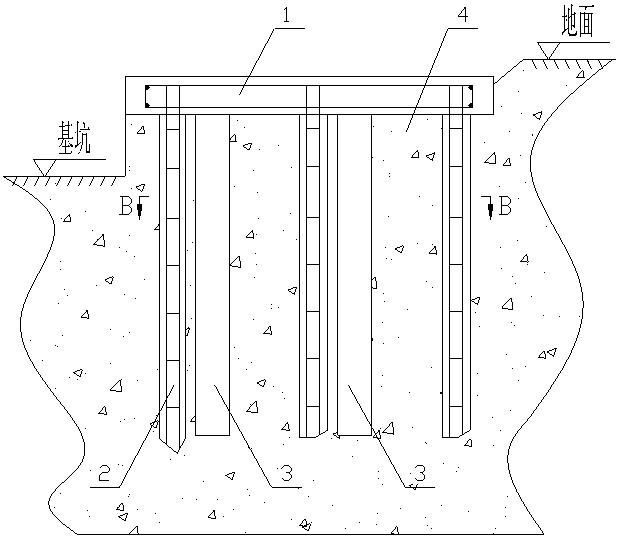

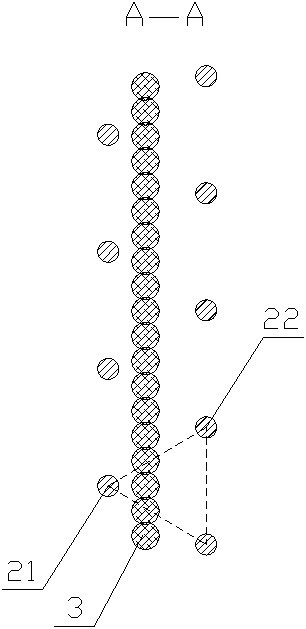

[0031] Multiple rows of mini-pile retaining enclosures, such as Figure 1 to Figure 2 As shown, it includes a crown beam 1 and more than two rows of mini piles 2. The mini piles 2 include a front row of piles 21 and a rear row of piles 22, and a cement-soil mixing pile is arranged between the front row of piles 21 and the rear row of piles 22. 3. The top ends of the mini piles 2 are connected together through the crown beam 1 . Multiple rows of piles are connected with the crown beam 3 to form a unified whole, and the rear row of piles 22 transmits part of the lateral earth pressure to the front row of piles 21 through the crown beam 3 and the soil between the piles, and the passive area provides lateral pressure; at the same time, the front row of piles 21 bears pressure, and the rear row of piles 22 bears tensile force, which generates a certain bending moment, and finally makes the enclosure structure have a higher anti-overturning capability.

[0032] The crown beam 1 is ...

Embodiment 2

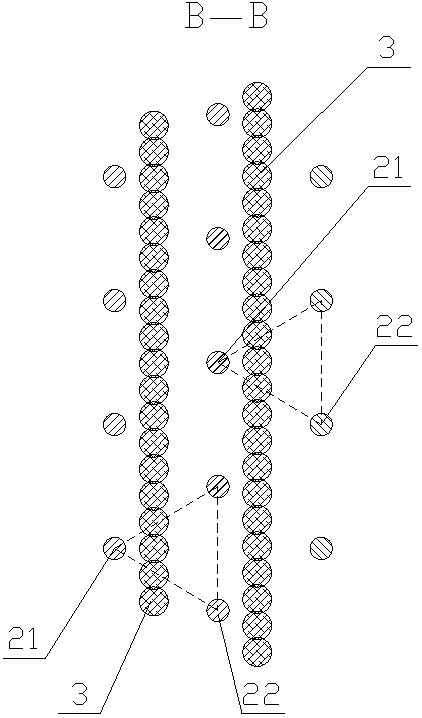

[0049] See image 3 , 4 , the difference between this embodiment and Embodiment 1 is that there are three rows of mini piles 2, and two rows of cement-soil mixing piles 3; Rear row pile 22; When the soil quality is poor or water-stopping requirements are high, multiple rows of mini piles 2 and multiple rows of cement-soil mixing piles 3 can be used to achieve a better anti-seepage effect.

[0050] The construction technology of multi-row mini-pile retaining enclosure includes the following steps:

[0051] a. Excavate a trench around the foundation pit, and the excavation depth is greater than or equal to the design height of the crown beam 1;

[0052] b. Select the position of the pile, locate the pile head, select a geological exploration drilling rig or a bolter drilling rig, and drill through a small-diameter hollow drill bit. While drilling, use a mud wall to protect the pile hole. Different rows of mini piles 2 The pile positions are arranged in a staggered manner, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com