Temperature-pressure dual-control explosion suppression device and petrochemical industry safety reaction device

A technology for suppressing explosions and dual control, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve problems such as high failure rate, impact on suppressing explosive devices, and low failure rate, etc. Achieve the effect of increasing security, good overall performance, and low failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

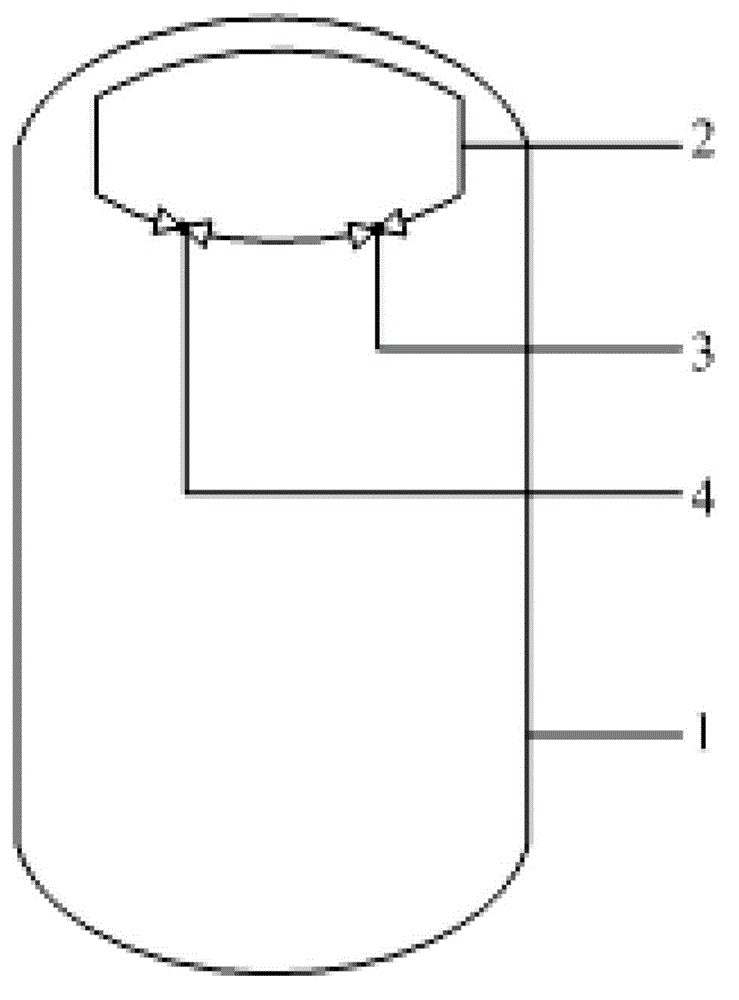

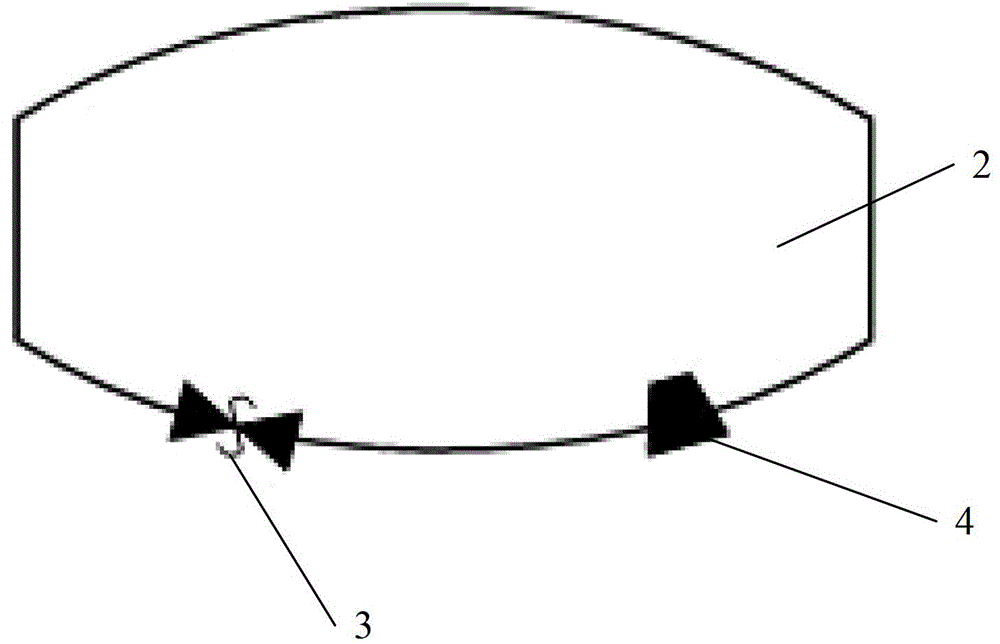

[0025] The invention provides a temperature and pressure dual control explosion suppression device, which includes an explosion suppression storage tank, a pressure control trigger device and a temperature control trigger device, the pressure control trigger device and temperature control trigger device are installed in the explosion suppression storage tank superior.

[0026] Further, the temperature and pressure dual control explosion suppression device is only composed of an explosion suppression storage tank, a pressure control trigger device and a temperature control trigger device.

[0027] The opening and closing of the pressure control trigger device is controlled by an electronic control element.

[0028] The explosion-suppressing storage tank is equipped with high-pressure suppressing gas, and the pressure of the suppressing gas in the explosion-suppressing storage tank is greater than the out-of-control critical pressure of the reactor.

[0029] The suppressive gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com