Heat-resistant grease

A lubricating grease and heat-resistant technology, which is applied in the field of heat-resistant lubricating grease, can solve the problems of shortening the service life of mechanical equipment, easy softening and volatilization, and unsatisfactory varieties, so as to improve high-temperature oxidation resistance and hydrolysis resistance. The effect of excellent extreme pressure performance and anti-wear performance, excellent high temperature and oxidation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

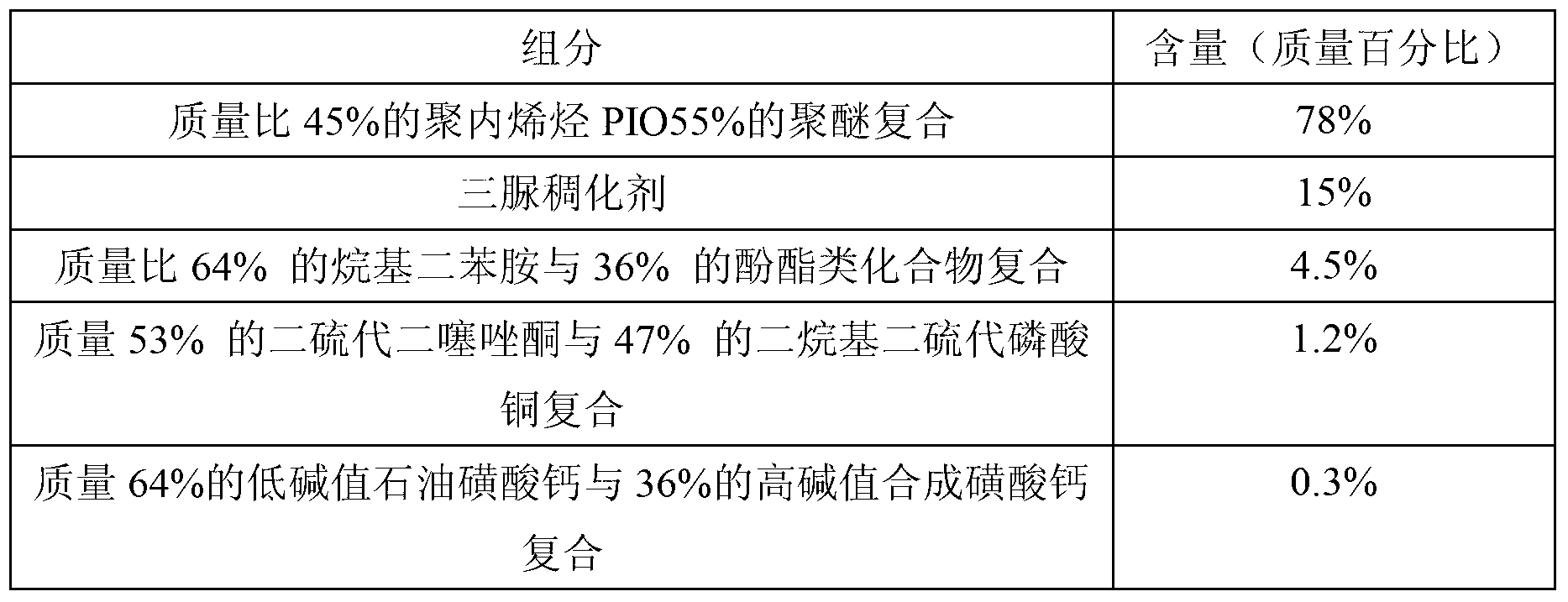

Embodiment 3

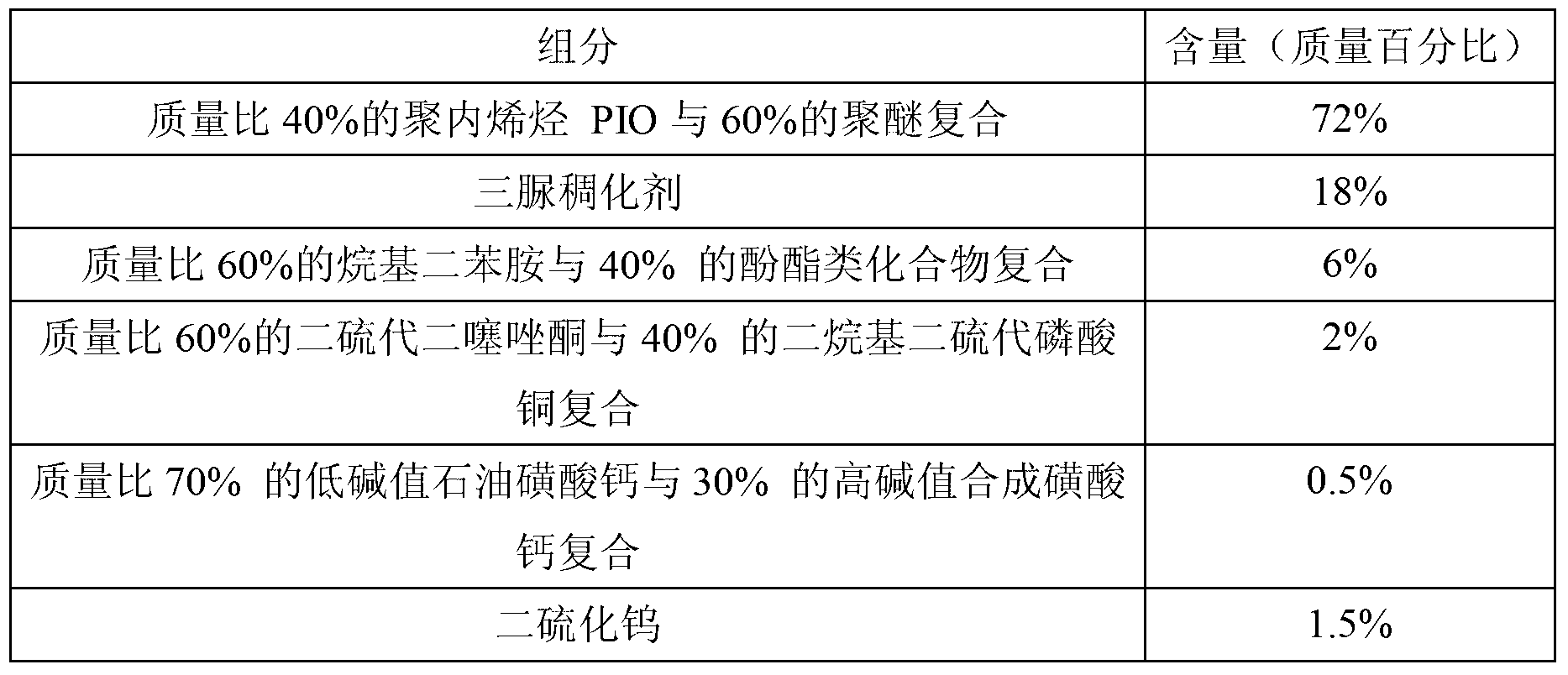

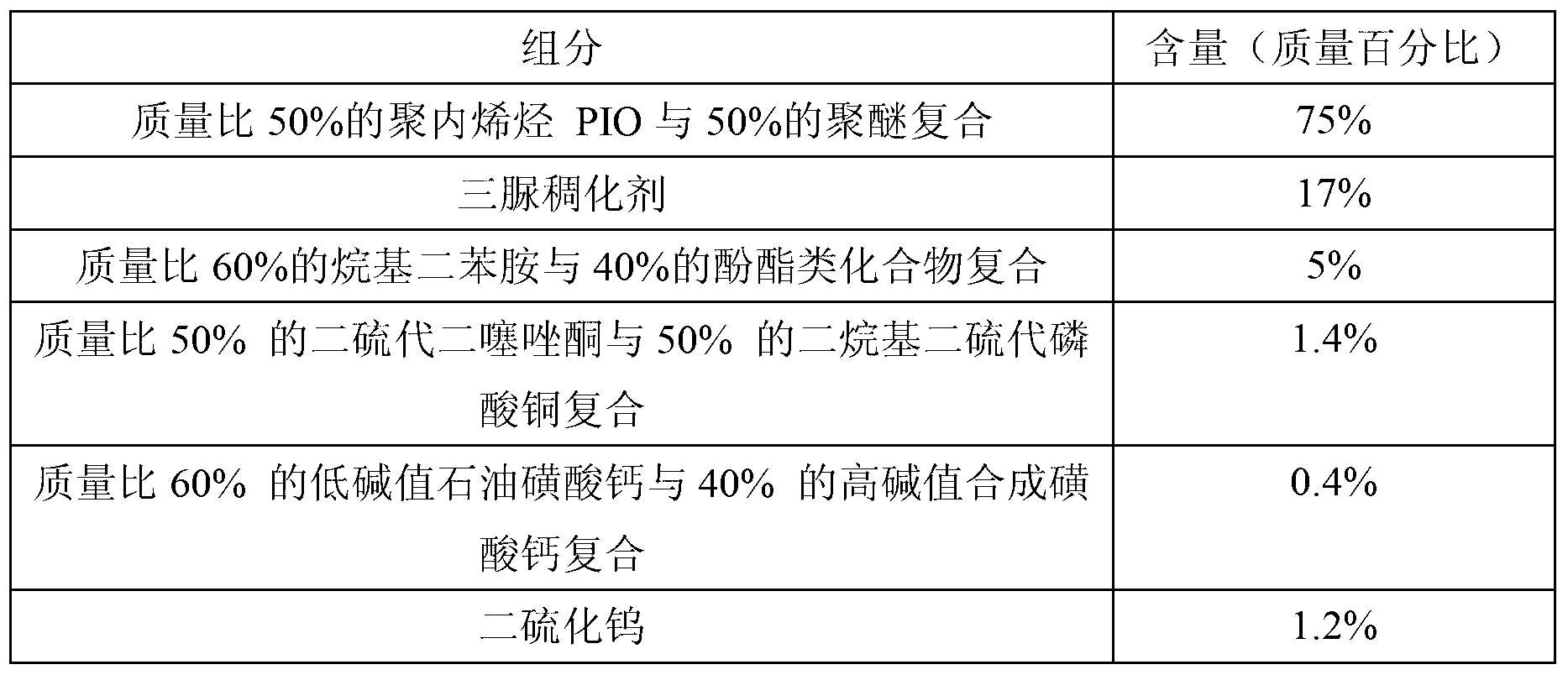

[0026] It is blended according to the following mass percentage components:

[0027]

[0028]

[0029] Measured by the provincial technical supervision department, the physical and chemical indexes of the product of the present invention all meet the requirements for use, and the typical physical and chemical indexes of the product of Example 1 are shown in Table 1.

[0030] Table 1 Typical physical and chemical indicators of heat-resistant grease

[0031]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com