Castor oil-based UV-cured polyurethane acrylate and preparation method and application thereof

A urethane acrylate, castor oil-based technology, applied in the field of UV-curable polymer materials, can solve problems such as no castor oil involved, and achieve the effects of good overall performance, excellent hydrolysis resistance, and good low-temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

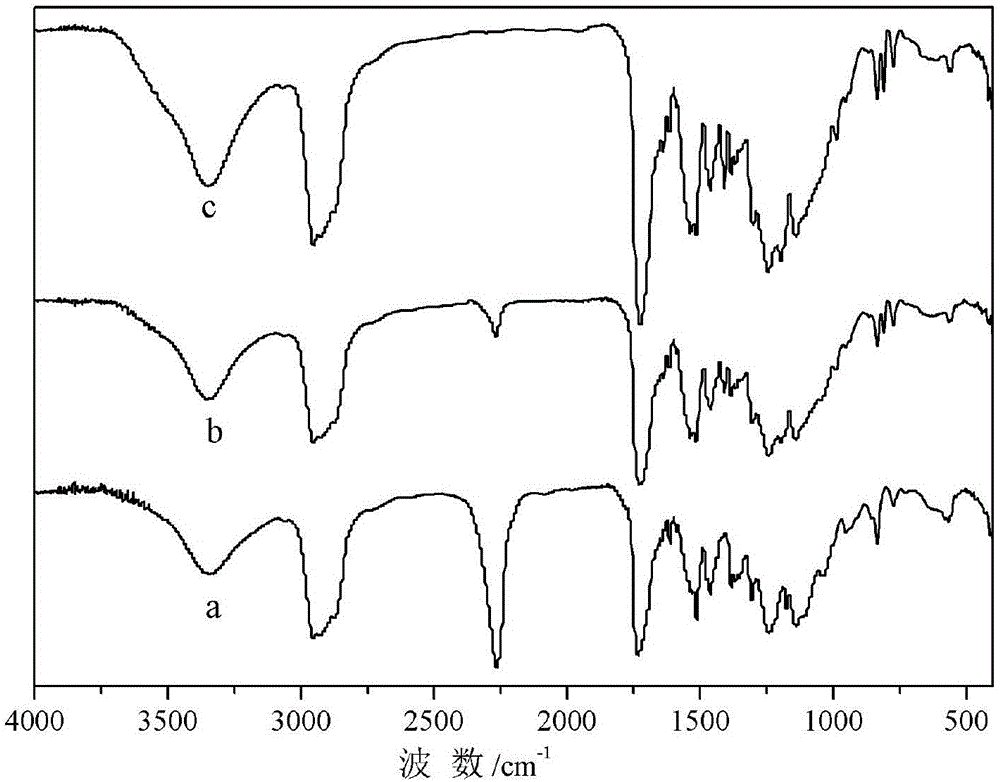

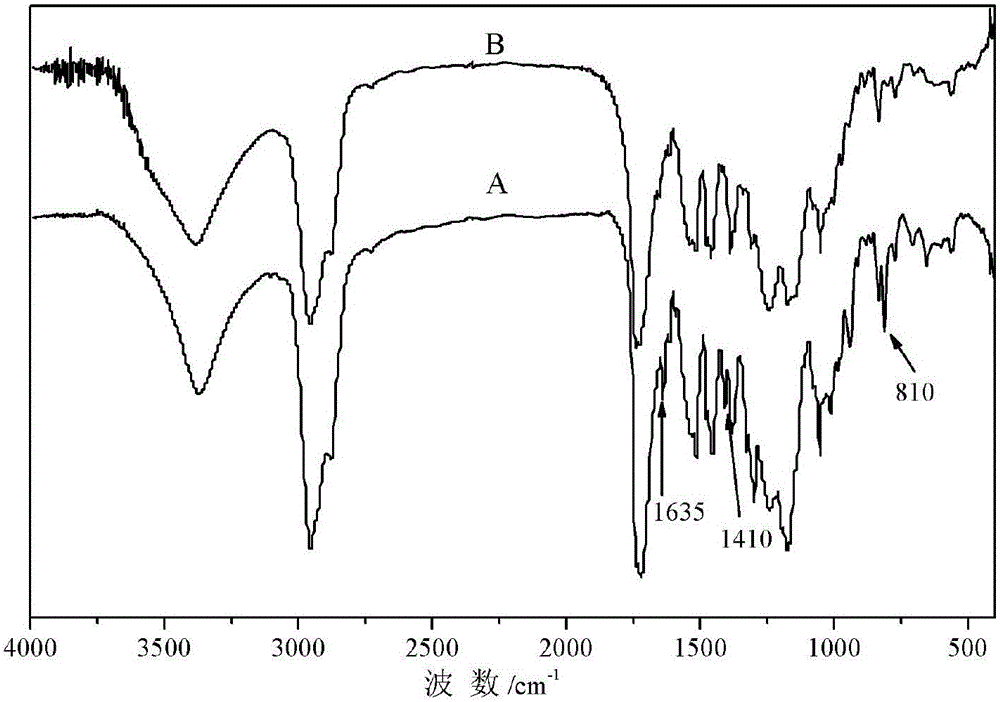

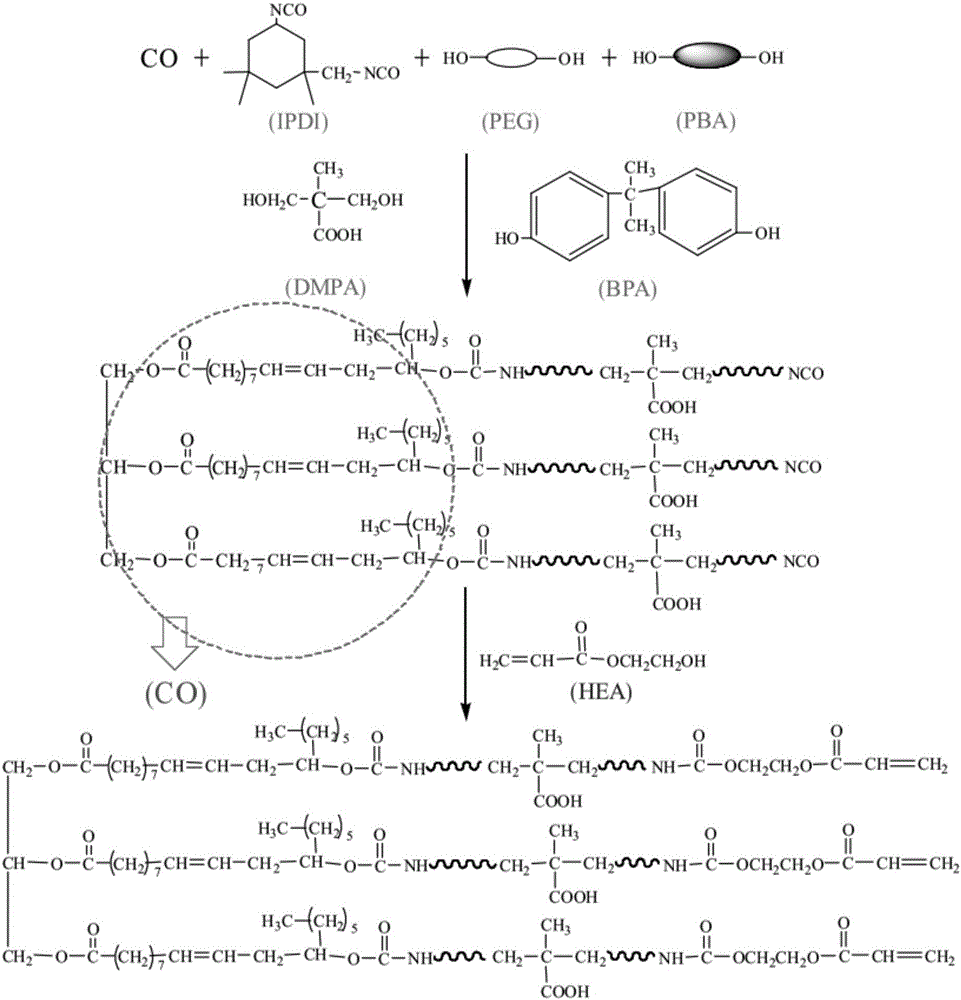

[0027] (1) Add the measured polyethylene glycol, polyethylene glycol and castor oil in turn into the reactor, stir and heat up to 115°C, dehydrate under reduced pressure for 2 hours and then cool down to 65°C, then gradually add isofor The mixture of ketone diisocyanate and dibutyltin dilaurate (0.1% of urethane acrylate prepolymer weight), pay attention to control its drop rate, add with the speed of 1g / min, after reacting for 3h, will be dissolved in bisphenol A and Add the N,N-dimethylformamide and acetone mixed solution of 2,2-dimethylolpropionic acid into the reactor and continue the reaction. During the period, take samples to measure the -NCO group content until it reaches the theoretical value. The first step is to react Finish;

[0028] (2) The temperature of the above-mentioned intermediate product is lowered to 45° C., and hydroxyethyl acrylate, hydroxyethyl methacrylate and p-hydroxyanisole (being 1 / 2 of the weight of hydroxyethyl acrylate and hydroxyethyl methacry...

Embodiment 2

[0032] (1) Add the measured polyethylene glycol, polyethylene glycol and castor oil in sequence in the reactor, stir and raise the temperature to 115°C, decompress and dehydrate for 2 hours, then cool down to 65°C, and then gradually add hexaethylene glycol dropwise The mixture of methyl diisocyanate, toluene diisocyanate and dibutyltin dilaurate (0.1% of the weight of urethane acrylate prepolymer), pay attention to control the dropping speed, add it at a speed of 1g / min, after reacting for 3h, it will be dissolved in The mixed solution of bisphenol A and 2,2-dimethylolpropionic acid in N,N-dimethylformamide and acetone is added to the reaction kettle, and the reaction is continued, during which samples are taken to measure the content of -NCO groups until the theoretical value is reached. The first step reaction ends;

[0033] (2) The temperature of the above-mentioned intermediate product is lowered to 45° C., and hydroxypropyl acrylate, hydroxypropyl methacrylate and p-hydr...

Embodiment 3

[0036] (1) Add measured polyethylene glycol, polyethylene glycol and castor oil in sequence in the reactor, stir and raise the temperature to 115°C, dehydrate under reduced pressure for 2 hours, then cool down to 65°C, then gradually add p-benzene The mixture of diisocyanate, 4,4'-diphenylmethane diisocyanate and dibutyltin dilaurate (0.1% of the weight of urethane acrylate prepolymer), pay attention to control its dropping speed, add at a speed of 1g / min, react After 3 hours, add the mixed solution of N,N-dimethylformamide and acetone dissolved in bisphenol A and 2,2-dimethylolpropionic acid into the reaction kettle, and continue the reaction, during which time samples are taken to measure the -NCO group content until reaching the theoretical value, the first step reaction ends;

[0037] (2) Lower the temperature of the above-mentioned intermediate product to 45°C, and add hydroxybutyl acrylate, hydroxybutyl methacrylate and hydroquinone (0.05% of the weight of hydroxybutyl a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com