Damp-absorbing fast-drying and sweat-repelling fabric finishing agent, its preparing method and use

A fabric finishing agent, hygroscopic and quick-drying technology, applied in textiles, papermaking, fiber processing, etc., can solve the problem that cannot improve the moisture absorption, quick-drying sweat-wicking, antistatic and wearing comfort of polyester fabrics, and does not have hydrophilicity. and antistatic properties, reducing the friction coefficient of fibers, etc., to achieve smooth wearing comfort, smooth hand feel, hydrophilic and antistatic properties and softness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

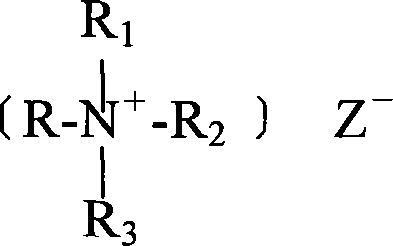

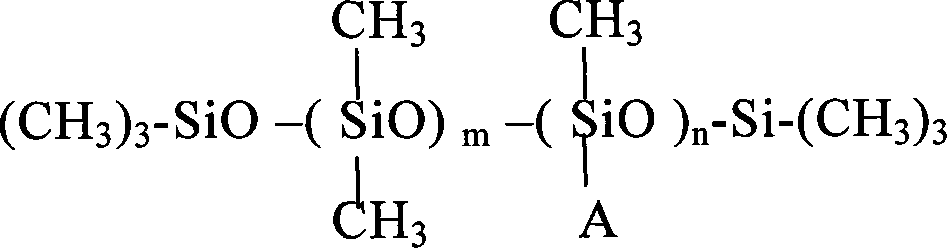

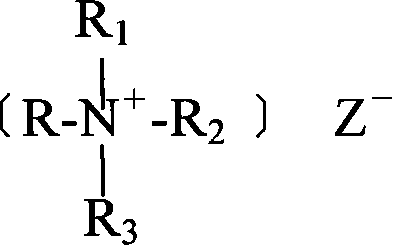

[0021] The object of the present invention is to provide a preparation method for moisture absorption, quick-drying and sweat-wicking fabric finishing agent, the method comprising the steps of: using hydrophilic finishing agent or antistatic agent and at least one silicone softener and water as main raw materials, adding PH Value adjuster, viscosity stabilizer, phase balance stabilizer, antifreeze, bactericide (preservative), defoamer, fragrance release agent, and pigments are compounded into a moisture-absorbing, quick-drying and sweat-wicking fabric finishing agent.

[0022] The hydrophilic finishing agent used in the present invention is a polymer compound with a polyether group, such as: polyethylene glycol, polypropylene glycol, polyglycerol, fatty alcohol polyoxyethylene ether, fatty acid polyoxyethylene ether, polyether ester, Polyurethane, polyethylene glycol methyl ether, polyethylene glycol dimethyl ether, polypropylene glycol methyl ether, polypropylene glycol dimeth...

Embodiment 1

[0044] Add 530 parts of water to a 1-liter glass reactor equipped with an electric mixer, a thermometer, and a reflux condenser, turn on the electric mixer, and heat up with an electric heating pot. When the temperature reaches 80-90°C, add 70 parts of SBL-H6180, Then at 80-90°C, stir for 3 hours, then cool down to room temperature, filter to obtain a milky white viscous liquid (A), with a solid content of 11.5%, take 250 parts of (A), and add 100 parts of silicone fabric softener SIB-H6120 (20% solid content, the same below), 5 parts of polyethylene glycol (400), 8 parts of ethylene glycol (used in winter), stir well and add acetic acid to adjust the pH value of the material to 6.0- 6.5. Finally, add an appropriate amount of silicone defoamer, antibacterial preservative (not used in winter) and fragrance release agent, and stir evenly to prepare a moisture-absorbing, quick-drying and sweat-wicking fabric finishing agent.

[0045] The process of using this finishing agent for ...

Embodiment 2

[0062] According to the same method as in Example 1, get 200 parts of (A), add 100 parts of silicone fabric softener SIB-H-6120, 10 parts of SIB-H6343 (content 98%), 40 parts of water, and stir evenly to obtain hygroscopic, Quick dry wicking fabric finish2.

[0063] According to the method of Example 1, the finishing agent 2 was used for fabric post-finishing, and the test results are shown in Tables 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com