Adhesive sheet and surface protective film

A technology for adhesive sheets and adhesives, applied in the directions of adhesives, transportation and packaging, conductive adhesives, etc., which can solve the problems of reduced identification and reduced transparency of antistatic layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0157] Hereinafter, some embodiments related to the present invention will be described, but the present invention is not intended to be limited to such specific examples. In addition, "part" and "%" in the following description are based on mass unless otherwise indicated.

[0158] In addition, each characteristic in the following description was measured or evaluated as follows, respectively.

[0159]

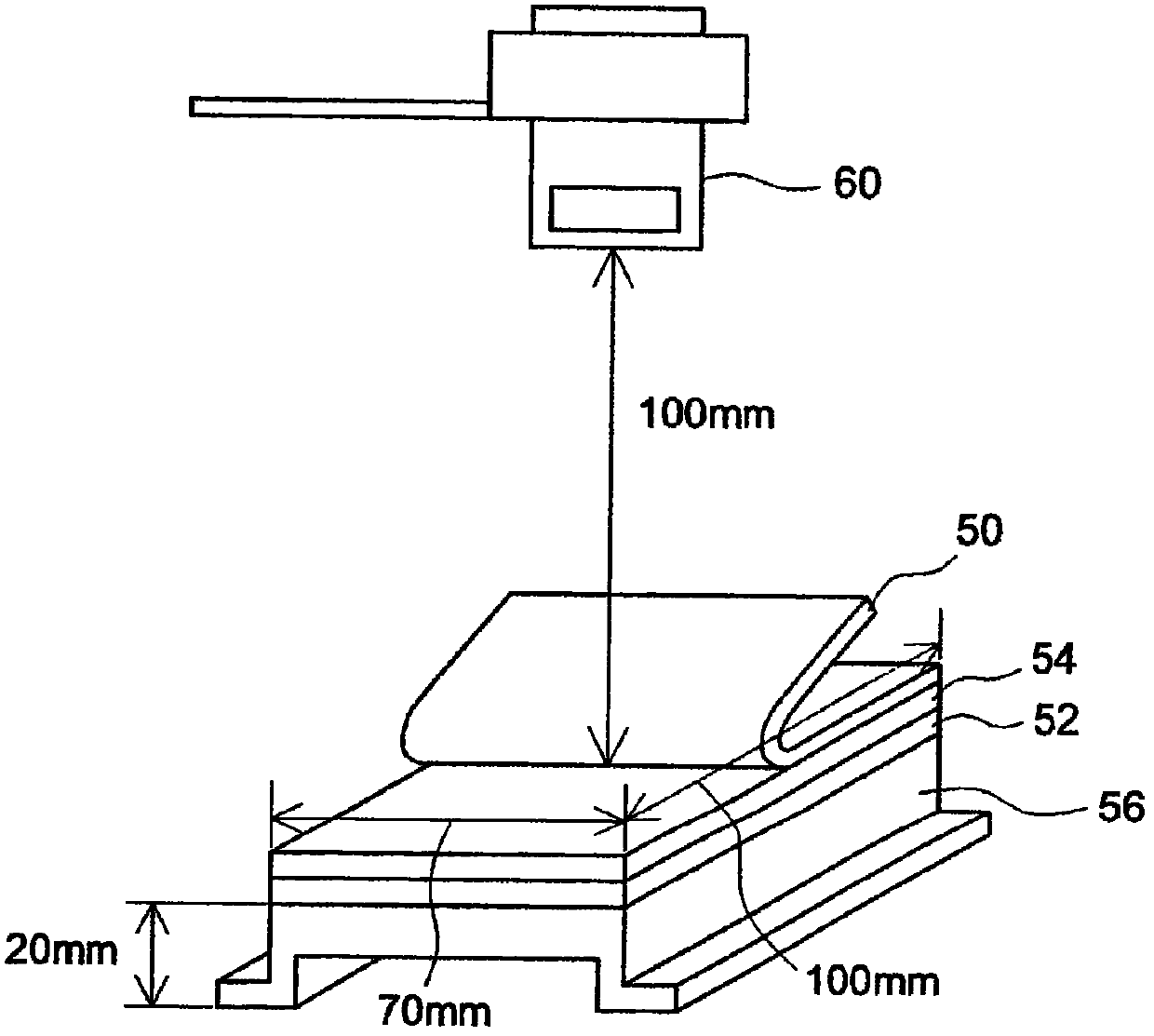

[0160] The glass transition temperature (Tg) (° C.) was determined by the following method using a dynamic viscoelasticity measuring device (manufactured by Rheometrics, ARES).

[0161] That is, an acrylic polymer sheet (thickness: 20 μm) was laminated so as to have a thickness of about 2 mm, and this was punched out into cylindrical pellets of 7.9 mm in diameter, and used as a sample for Tg measurement. The measurement sample was fixed in a jig of a Φ7.9mm parallel plate, and the temperature dependence of the loss modulus G" was measured by the dynamic viscoelasticity mea...

example 1

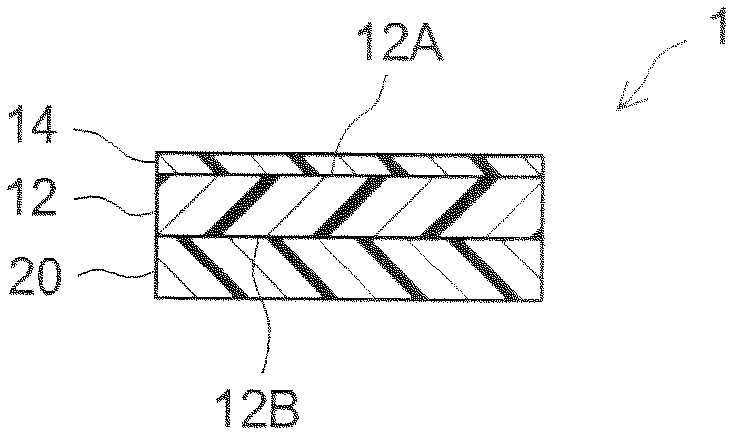

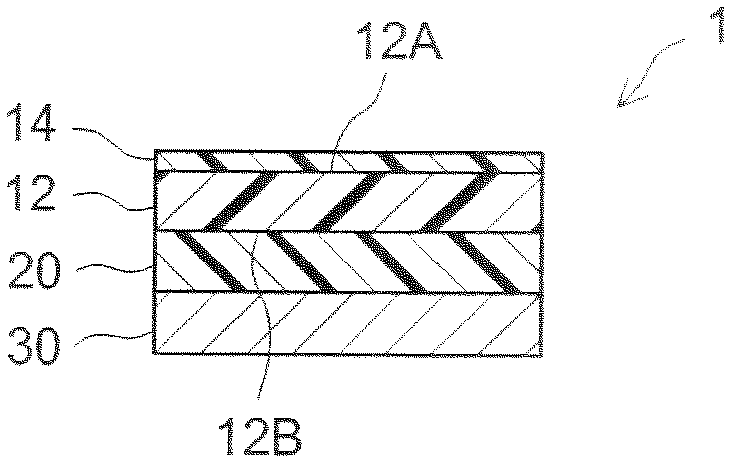

[0220] Apply corona treatment on one side (first side) to the corona treatment side of a transparent polyethylene terephthalate (PET) film with a thickness of 38 μm, a width of 30 cm, and a length of 40 cm. The above-mentioned coating composition (D1) was made to have a dried thickness of 10 nm. The coating material was heated and dried at 130° C. for 2 minutes, thereby producing a base film with an antistatic layer (E1) having an antistatic layer on the first surface of the PET film. An adhesive composition (G1) containing an ionic liquid was applied on the second surface of the base film (E1), and dried by heating at 130° C. for 2 minutes to form an adhesive layer with a thickness of 15 μm. On one side of this adhesive layer, the release-treated surface of a PET film (release liner) with a thickness of 25 μm that was released with a silicone-based release treatment agent was attached to one side, and an adhesive sheet related to this example was produced. . The adhesive sh...

example 2

[0222] Except having adjusted the coating amount of the coating composition (D1) so that the thickness of the antistatic layer might be 20 nm, it carried out similarly to Example 1, and produced the base film (E2) with an antistatic layer. Except having used this base film (E2), it carried out similarly to Example 1, and produced the adhesive sheet concerning this example. The adhesive sheet has an antistatic layer with a thickness of 20 nm formed by the coating composition (D1) on the first side of the PET film, and has an antistatic layer formed by the adhesive composition (G1) on the second side of the PET film. Adhesive layer with a thickness of 15 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com