A production device for a thermoplastic wound reinforced plastic composite tube and a production method of the composite tube

A technology of winding reinforcement and production device, applied in the direction of tubular articles, household appliances, other household appliances, etc., can solve the problems of scrapping, poor bonding strength between steel wire layers and plastic inner and outer pipes, reducing product performance and use effect, etc., to achieve strength High, reduced wall thickness, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

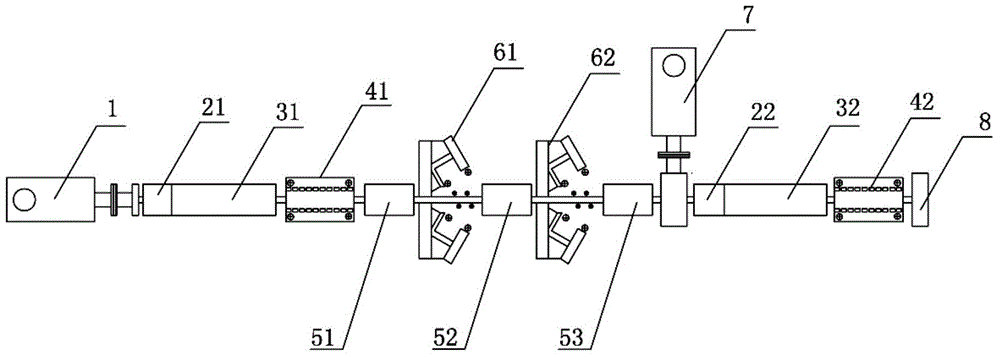

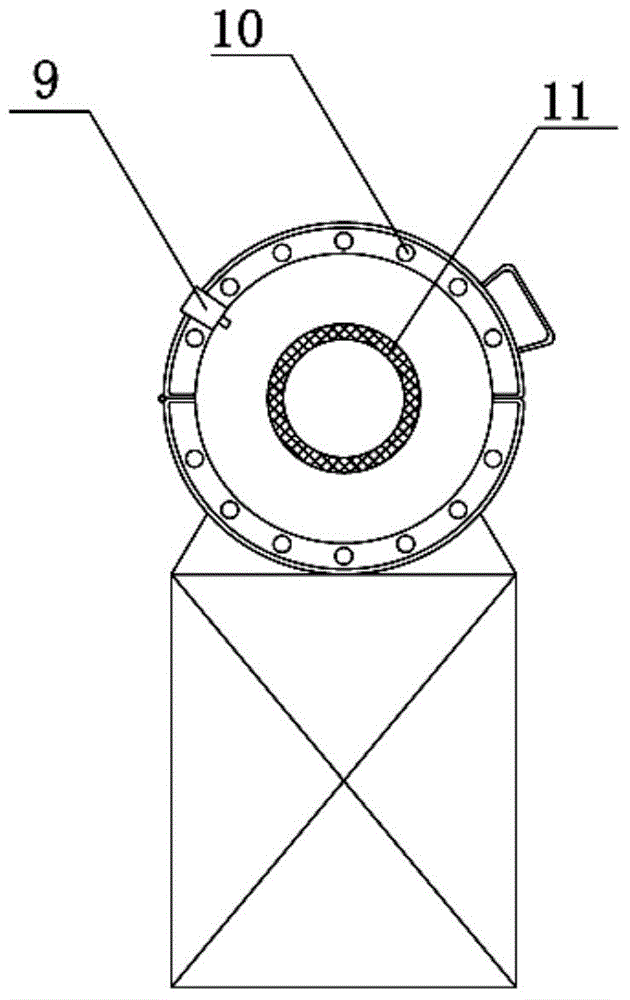

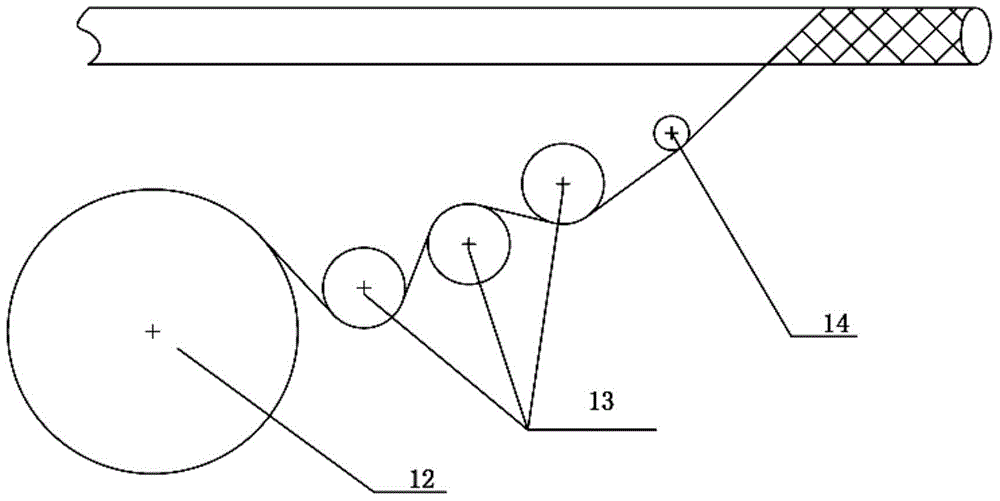

[0054] Such as figure 1 , 2 As shown in and 3, a production device for thermoplastic winding reinforced plastic composite pipe, the device mainly includes an inner pipe extrusion module, crawler tractors 41, 42, heating devices 51, 52, 53, continuous fiber reinforced thermoplastic composite material winding device 61, 62, outer tube extrusion module, composite tube cutting machine 8. The inner tube extrusion module includes an inner tube extruder 1 , a vacuum sizing tank 21 and a spray water cooling tank 31 . The heating devices 51 , 52 , 53 are composed of a heating tube 10 and a thermometer 9 , and the inner tube 11 passes through the heating device 51 to be heated. The continuous fiber reinforced thermoplastic composite material winding devices 61 and 62 are composed of an unwinding reel 12 , a guide roller 13 and a tension regulating device 14 . The outer tube extrusion module includes an outer tube extruder 7 , a vacuum sizing tank 22 and a spray water cooling tank 32 ...

Embodiment 2

[0057] (1) Using the device provided by the present invention, extrude the PE inner pipe whose outer diameter D of the inner pipe is φ=100mm from the inner pipe extruder 1, and pull it through the crawler tractor 41, and the PE inner pipe passes through the vacuum sizing tank 21 After the sizing and spraying water cooling tank 31 is cooled and shaped, the inner tube is heated by an infrared heating device 51, the surface temperature of the inner tube at the outlet of the infrared heating device 51 is 120°C, and the inner tube is passed through a continuous fiber reinforced thermoplastic composite winding device 61, 62 Prepare the reinforcement layer, the winding process is: cross winding 2 layers, continuous fiber reinforced thermoplastic composite material winding device 61 wind the continuous fiber reinforced thermoplastic composite material with a width d of 133mm (hereinafter referred to as strip) to the outer wall of the inner tube at a winding angle of 65° , the winding d...

Embodiment 3

[0062] (1) Using the device provided by the present invention, extrude the PE inner pipe whose outer diameter D of the inner pipe is φ=300mm from the inner pipe extruder 1, and pull it through the crawler tractor 41, and the PE inner pipe passes through the vacuum sizing tank 21 Sizing and spraying water cooling tank 31 for cooling and shaping;

[0063] (2) After cooling and shaping, the inner tube is heated by an infrared heating device 51, the surface temperature of the inner tube at the outlet of the infrared heating device 51 is 120°C, and the inner tube is prepared with a continuous fiber reinforced thermoplastic composite winding device 61, 62, 63 to reinforce the layer , the winding process is: 2 layers of cross winding, 1 layer of hoop winding, the continuous fiber reinforced thermoplastic composite material with a width of 180mm (hereinafter referred to as the strip) is wound to the outer wall of the inner tube at a winding angle of 55°, and 3 winding devices are unwou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com