Preparation method of sub-high efficiency polytetrafluoroethylene (PTFE) micro-porous film and film lamination material

A polytetrafluoroethylene and cladding material technology, applied in the field of polytetrafluoroethylene microporous membrane preparation, can solve the problems of reduced membrane strength, large loss of membrane thickness, low resistance, etc. Damage and detachment prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

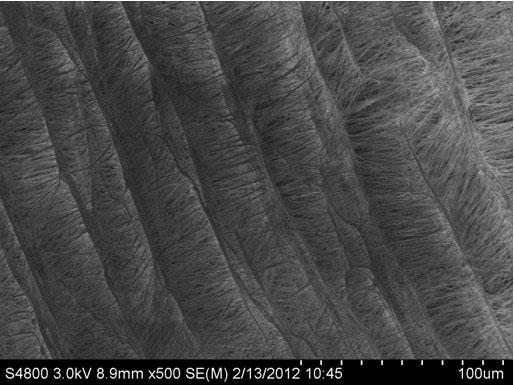

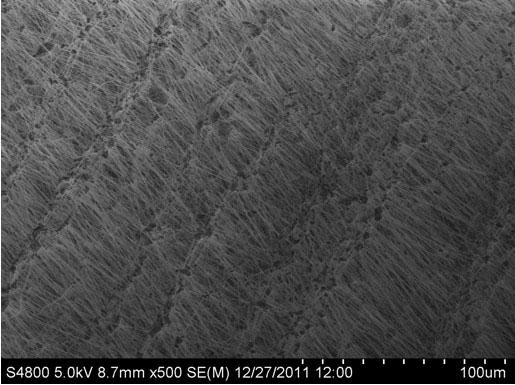

Image

Examples

preparation example Construction

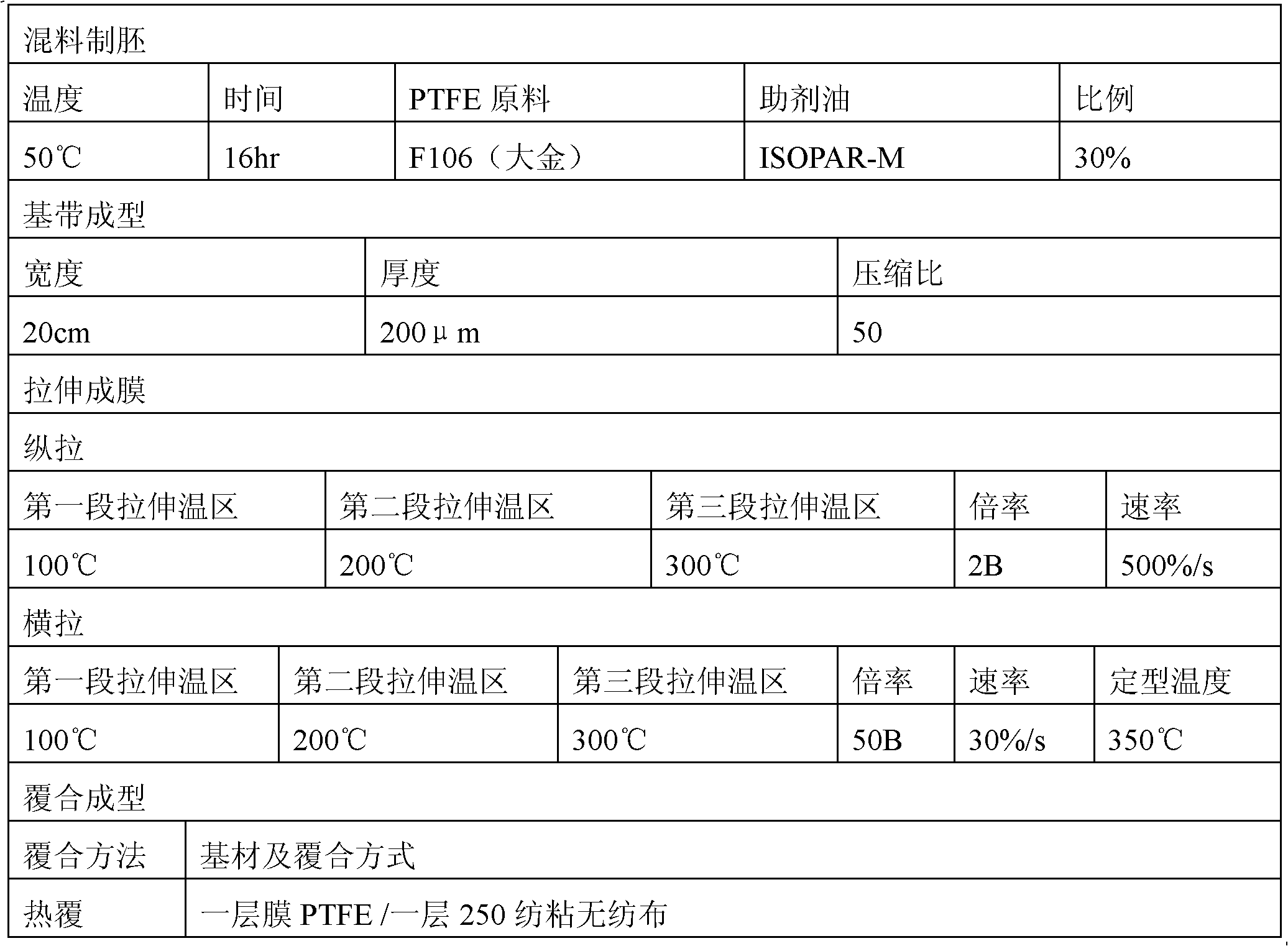

[0020] The preparation method of the sub-efficient polytetrafluoroethylene microporous membrane and the membrane cladding material comprises the following steps:

[0021] 1) Embryo making by mixing materials: Mix additive oil with a mass ratio of 30% to 40% and polytetrafluoroethylene evenly, place it in a constant temperature oven at 50°C for 16 hours, and pre-press it into a columnar embryo, in which polytetrafluoroethylene Vinyl fluoride is F106 produced by Daikin Company or 601A produced by DuPont Company, its standard relative density is less than 2.16, and the additive oil is ISOPAR-M or ISOPAR-K;

[0022] 2) Baseband molding: put the columnar blank into the extruder, and make a baseband with a width of 20-30cm and a thickness of 100-300μm through extrusion, calendering and drying processes, and the extrusion compression ratio is 30-100;

[0023] 3) Stretching film formation: Stretching film formation in two steps, in which the first step is to gradually increase the tem...

Embodiment 1

[0029] 1) Embryo making by mixing materials: mix the auxiliary oil with a mass ratio of 30% and polytetrafluoroethylene evenly, place it in a constant temperature oven at 50°C for 16 hours, and pre-press it into a columnar embryo, in which polytetrafluoroethylene is The standard relative density of F106 produced by Daikin Company is less than 2.16, and the additive oil is ISOPAR-M;

[0030] 2) Baseband molding: Put the columnar blank into the extruder, and make a baseband with a width of 30 cm and a thickness of 100 μm through extrusion, calendering and drying processes, and the extrusion compression ratio is 30;

[0031] 3) Stretching to form a film: Stretch to form a film in two steps. In the first step, the base belt is gradually stretched longitudinally with a gradient temperature increase. The gradient temperature zone is divided into: the first stretching temperature zone is 80 ° C, the second stretching The temperature zone is 150°C, the third stretching temperature zon...

Embodiment 2

[0034] Embodiment 2 preparation steps are the same as embodiment 1.

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com