Load type catalyst, load type non-metallocene catalyst and preparations thereof

A supported catalyst, non-metallocene technology, applied in the field of supported catalysts for olefin polymerization, can solve the problems of short polymerization activity life, low olefin polymerization activity, low polymer bulk density, etc., and achieve the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0122] First of all, the present invention relates to a method for preparing a supported catalyst, including: dissolving a magnesium compound in a mixed solvent composed of tetrahydrofuran and alcohol to obtain a magnesium compound solution; mixing a porous carrier with the magnesium compound solution to obtain a mixed solvent The step of slurrying; the step of drying the mixed slurry to obtain a composite support; and the step of contacting a chemical treatment agent selected from group IVB metal halides with the composite support to obtain the supported catalyst.

[0123] The procedure for obtaining the magnesium compound solution will be described below first.

[0124] According to an embodiment of the present invention, the magnesium compound may be selected from, for example, magnesium halides, alkoxy magnesium halides, alkoxy magnesium, alkyl magnesium, alkyl magnesium halides, alkyl alkoxy magnesium or any one thereof Or a mixture of multiple.

[0125] Specifically, the mag...

Embodiment 1

[0306] Example 1 (Preparation example of supported catalyst)

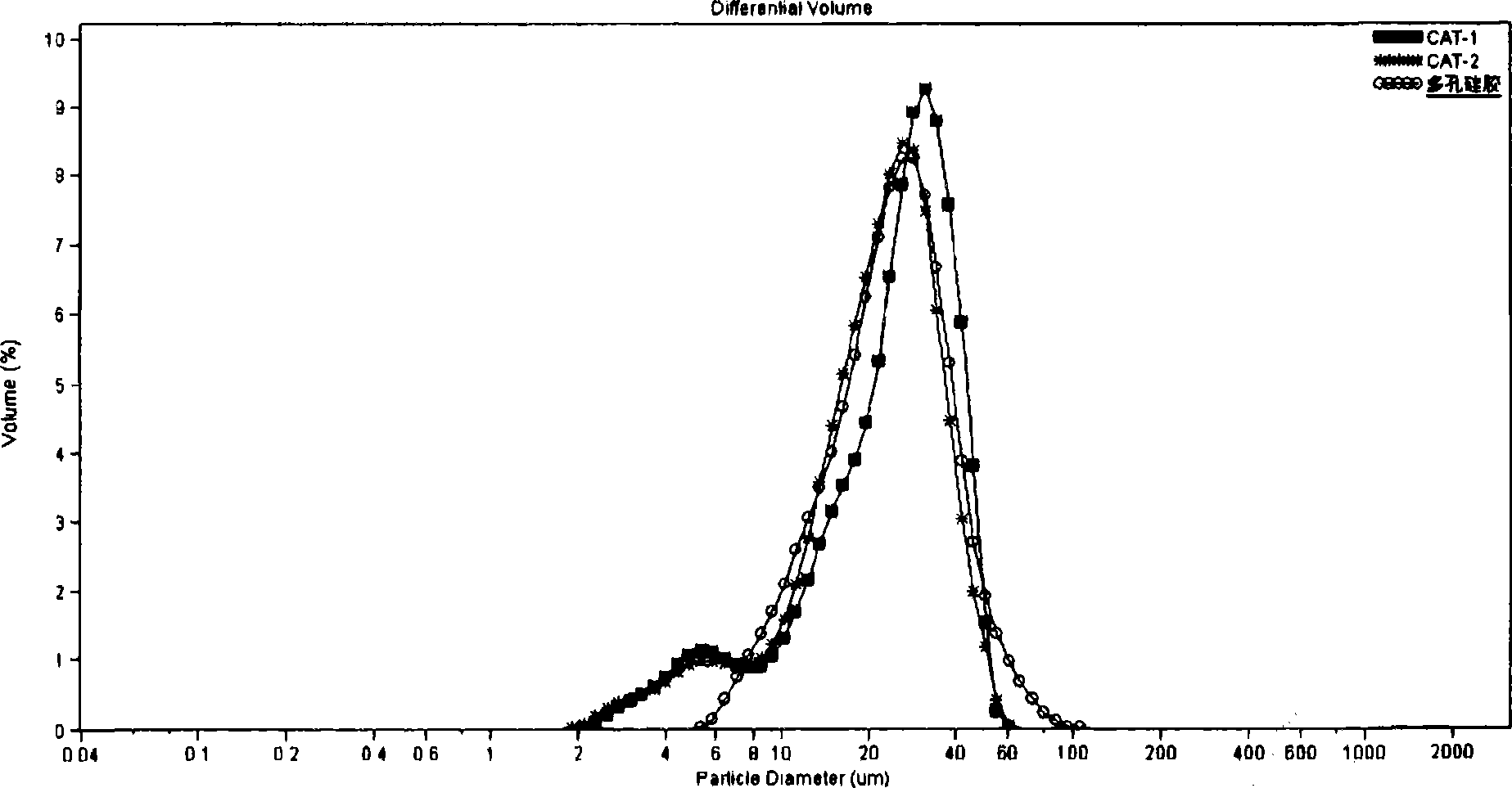

[0307] The porous carrier uses silica gel, the magnesium compound uses anhydrous magnesium chloride, the alcohol uses ethanol, and the chemical treatment agent uses titanium tetrachloride.

[0308] The silica gel was continuously calcined at 600° C. under a nitrogen atmosphere for 4 hours to be thermally activated.

[0309] Weigh 5g of anhydrous magnesium chloride, add 15ml of tetrahydrofuran and 12.5ml of absolute ethanol, heat to 60℃ to completely dissolve, add 10g of heat-activated silica gel while it is hot, stir evenly, let it stand for 12 hours, and heat it to 90℃ evenly After vacuum drying, 18.5 g of composite carrier was obtained.

[0310] Weigh 8g of composite carrier, add 76ml of hexane, add 4.0ml of titanium tetrachloride dropwise over 30 minutes under stirring conditions, stir for 4 hours at 60℃, filter, wash with hexane twice, and use 60ml of hexane each time , 25 ℃ vacuum drying to obtain the supported ca...

Embodiment 1-1

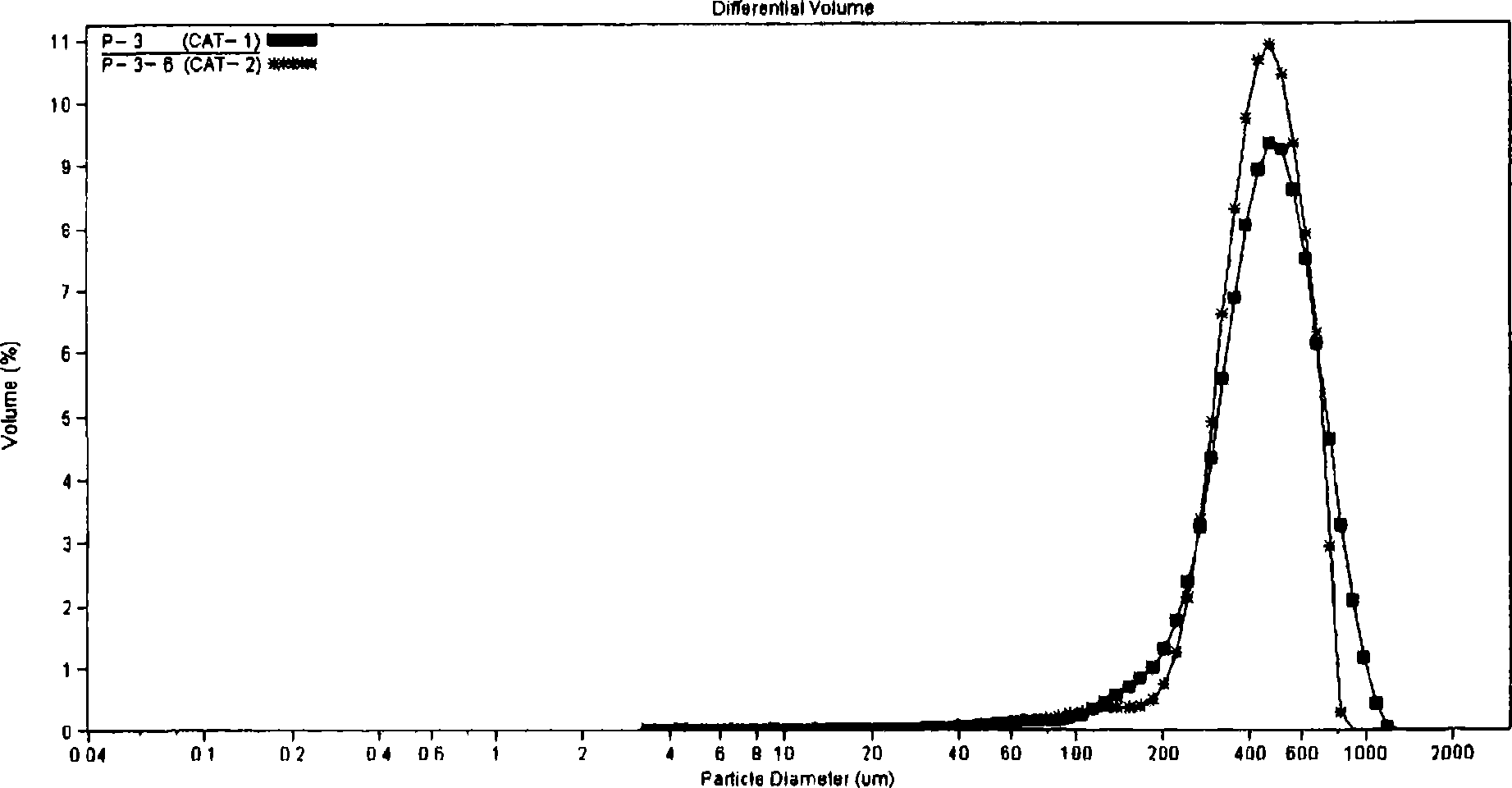

[0313] It is basically the same as embodiment 1, but has the following changes:

[0314] The porous carrier uses aluminum oxide. The aluminum oxide was fired continuously at 700°C under nitrogen atmosphere for 6 hours.

[0315] Magnesium compound changed to magnesium bromide (MgBr 2 ), butanol is used for alcohol, and titanium tetrabromide (TiBr 4 ).

[0316] The ratio is that the molar ratio of magnesium bromide to tetrahydrofuran is 1:5; the molar ratio of magnesium bromide to butanol is 1:3.5; the mass ratio of magnesium bromide to porous carrier is 1:1.4; titanium tetrabromide and composite The carrier ratio is 7.64 mmol: 1 g.

[0317] The solvent for the preparation of the supported catalyst was changed to decane.

[0318] The supported catalyst is denoted as CAT-1-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com