Loaded non-metallocene catalyst and preparation method and application thereof

A non-metallocene and non-metallocene ligand technology, applied in the field of non-metallocene catalysts, can solve the problems of high cost of silica gel, difficulty in applying industrial production, and high temperature requirements of the loading process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

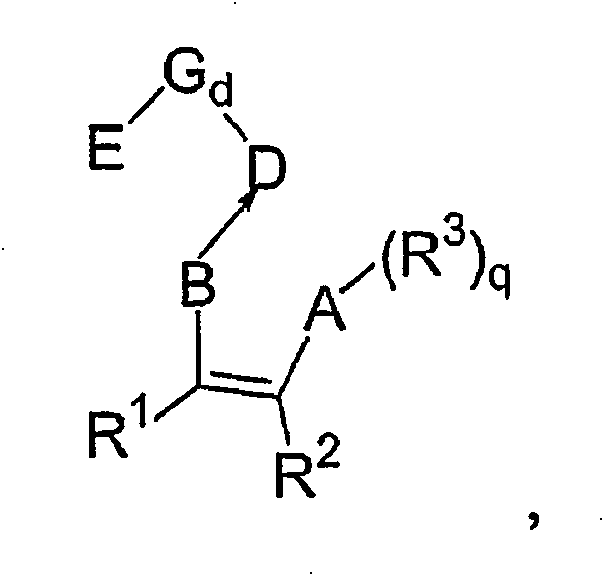

Image

Examples

preparation example Construction

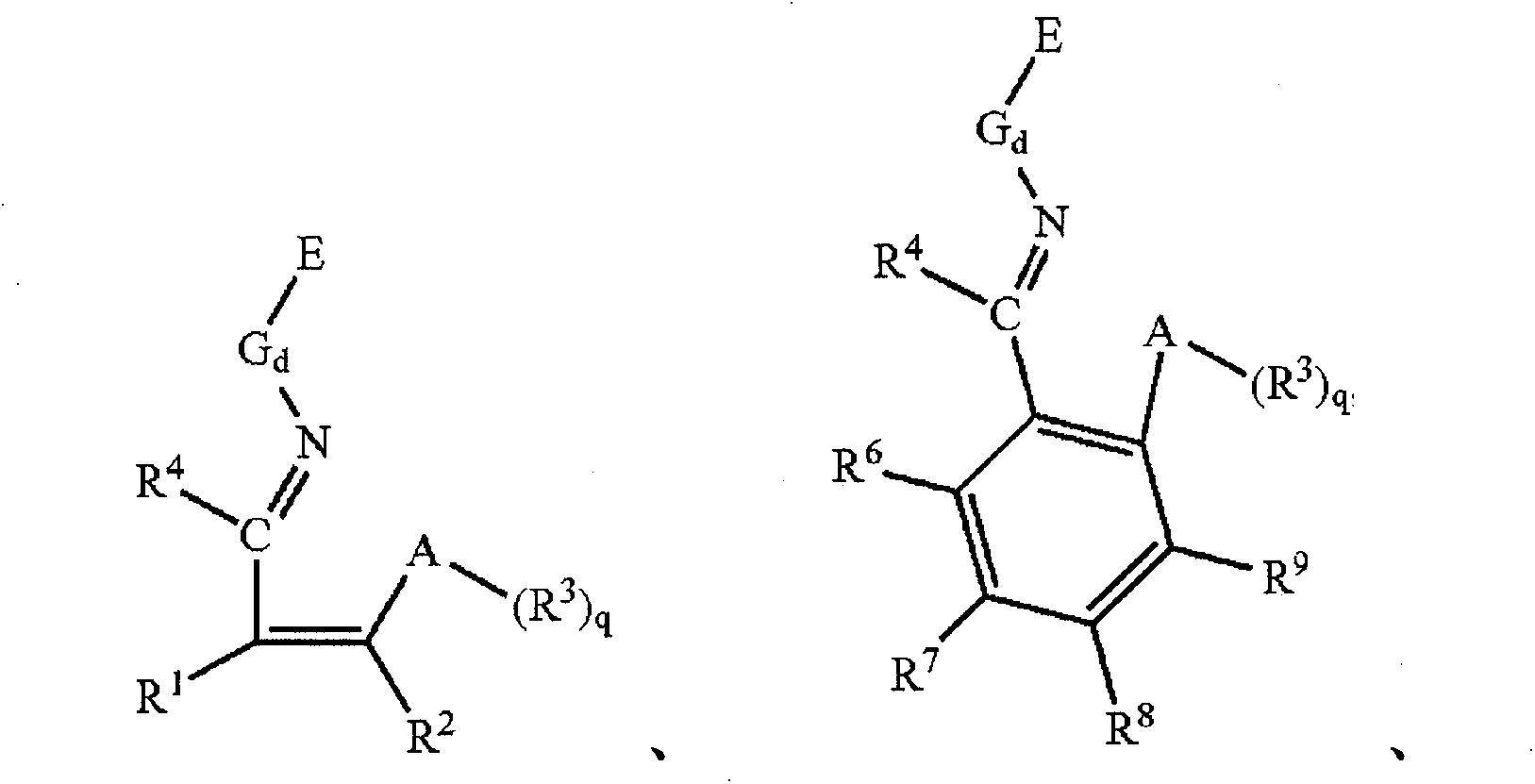

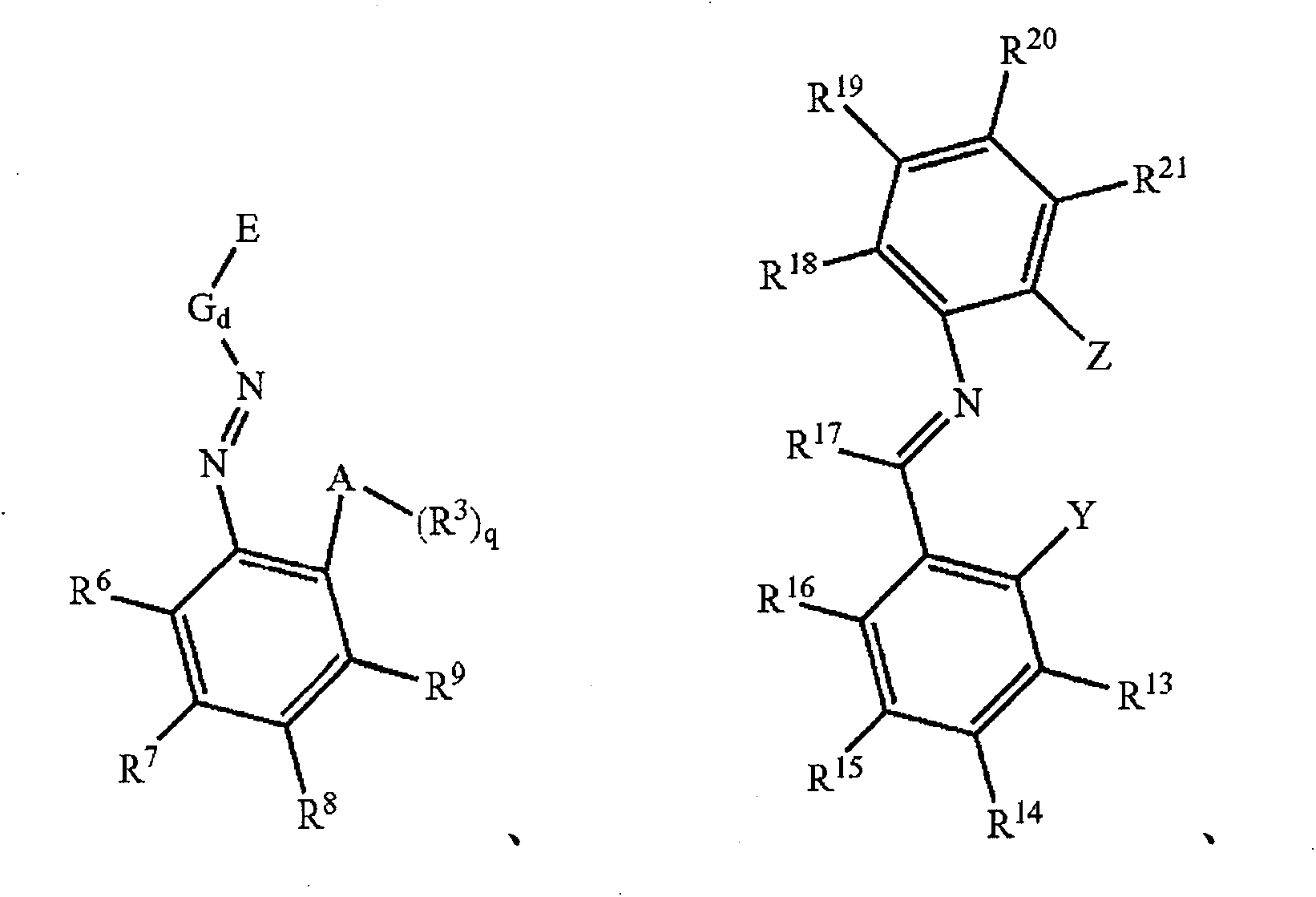

[0080] According to the present invention, it relates to a preparation method of a supported non-metallocene catalyst, comprising the following steps: dissolving a magnesium compound and a non-metallocene ligand in a solvent to obtain a magnesium compound solution; drying the magnesium compound solution, A step of obtaining a modified carrier; and a step of treating the modified carrier with a chemical treatment agent selected from group IVB metal compounds to obtain the supported non-metallocene catalyst.

[0081] The steps for obtaining the magnesium compound solution are specifically described below.

[0082] Specifically, the magnesium compound (solid) and the non-metallocene ligand are dissolved in an appropriate solvent (ie, a solvent for dissolving the magnesium compound), thereby obtaining the magnesium compound solution.

[0083] As the solvent, for example, C 6-12 Aromatic hydrocarbons, halogenated C 6-12 Solvents such as aromatic hydrocarbons, esters and ethers. ...

Embodiment 1

[0271] The magnesium compound adopts anhydrous magnesium chloride, the solvent for dissolving the magnesium compound and the non-metallocene ligand adopts tetrahydrofuran, and the chemical treatment agent adopts titanium tetrachloride. The non-metallocene ligand adopts the structure compound of.

[0272] Weigh 5g of anhydrous magnesium chloride and non-metallocene ligands, add tetrahydrofuran solvent and dissolve completely at room temperature, stir for 2 hours, heat to 60°C and directly vacuum-dry to obtain a modified carrier.

[0273] Then add 60ml of hexane to the modified carrier, add titanium tetrachloride dropwise for 30 minutes under stirring conditions, stir and react at 60°C for 4 hours, filter, wash with hexane twice, and use 60ml of hexane each time, Vacuum drying at room temperature to obtain a supported non-metallocene catalyst.

[0274] The proportions are: the proportion of magnesium chloride to tetrahydrofuran is 1mol:210ml; the molar ratio of magnesium chlo...

Embodiment 1-1

[0277] Basically the same as Example 1, but with the following changes:

[0278] Non-metallocene ligands use , the solvent for dissolving magnesium compounds and non-metallocene ligands was changed to toluene, and the chemical treatment agent was changed to zirconium tetrachloride (ZrCl 4 ), the magnesium compound solution was vacuum-dried at 90°C.

[0279] The proportions are as follows: the proportion of magnesium compound to toluene is 1mol:150ml; the molar ratio of magnesium compound to non-metallocene ligand is 1:0.15; the molar ratio of magnesium compound to chemical treatment agent is 1:0.20.

[0280] Supported non-metallocene catalysts are designated CAT-1-1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com