A novel preparation method for LiFePO4/C composite positive pole material

A composite cathode material, dry process technology, applied in electrode manufacturing, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of low specific capacity, poor high-current charge and discharge performance, etc., to achieve high specific capacity, uniform particle distribution, Effects suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

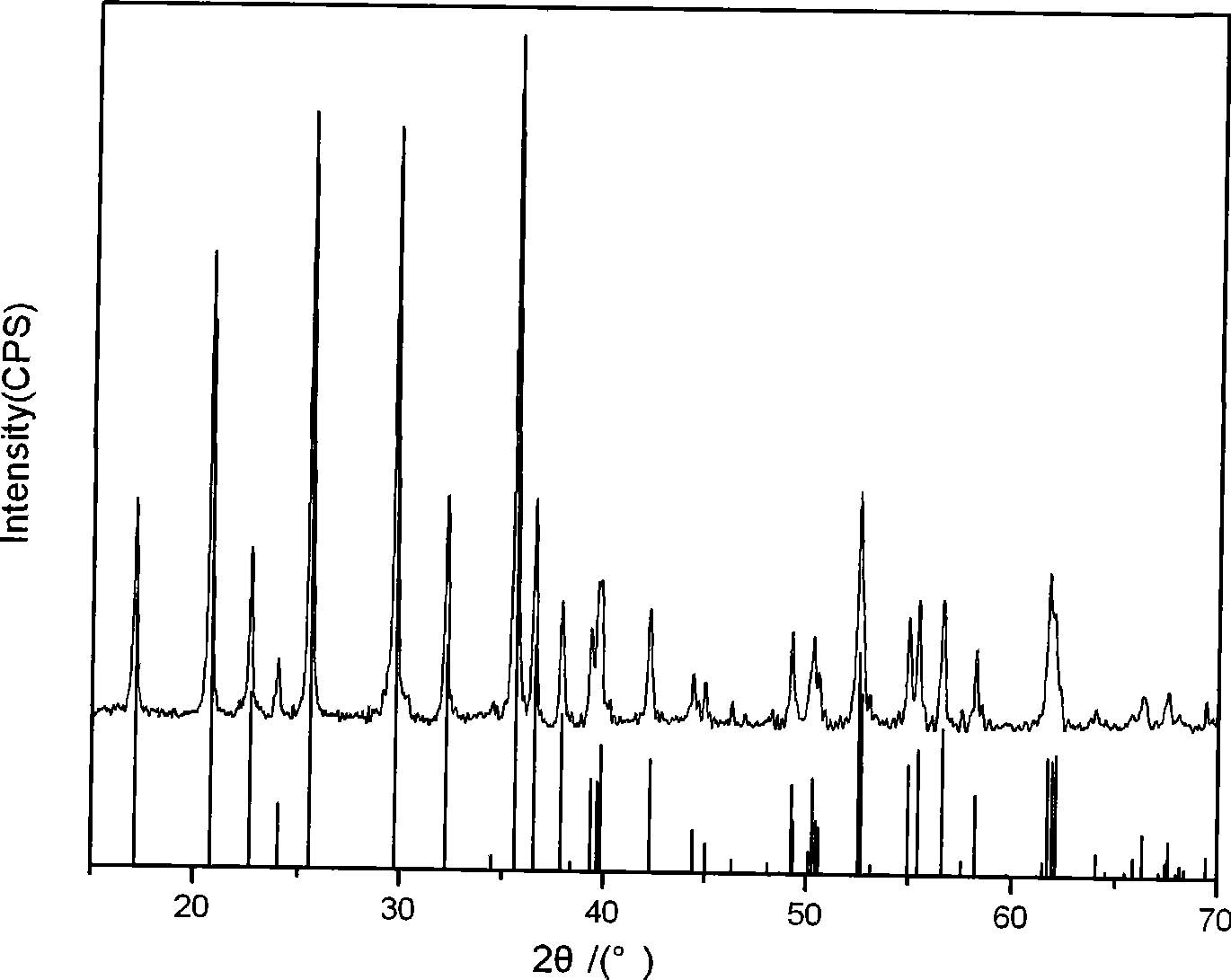

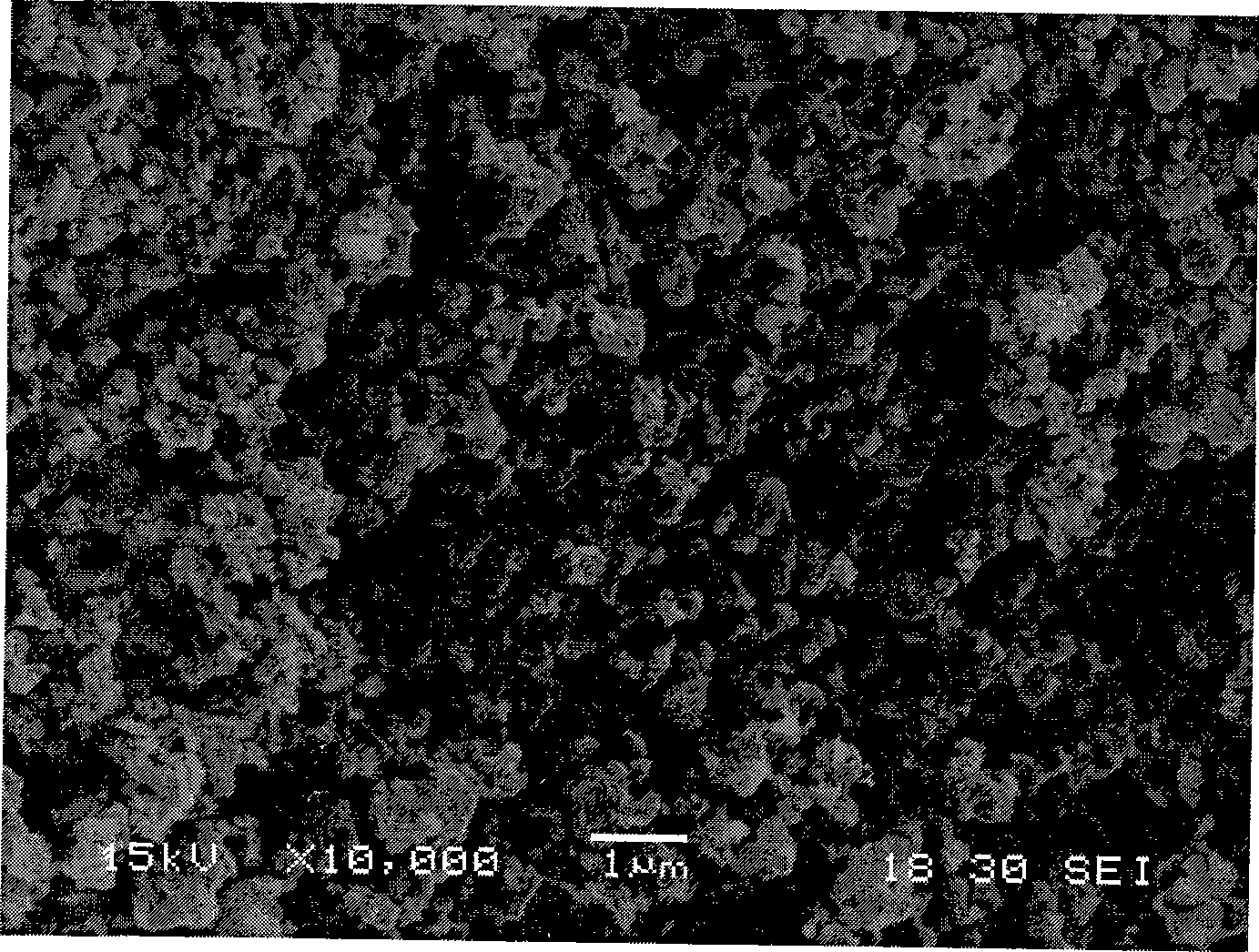

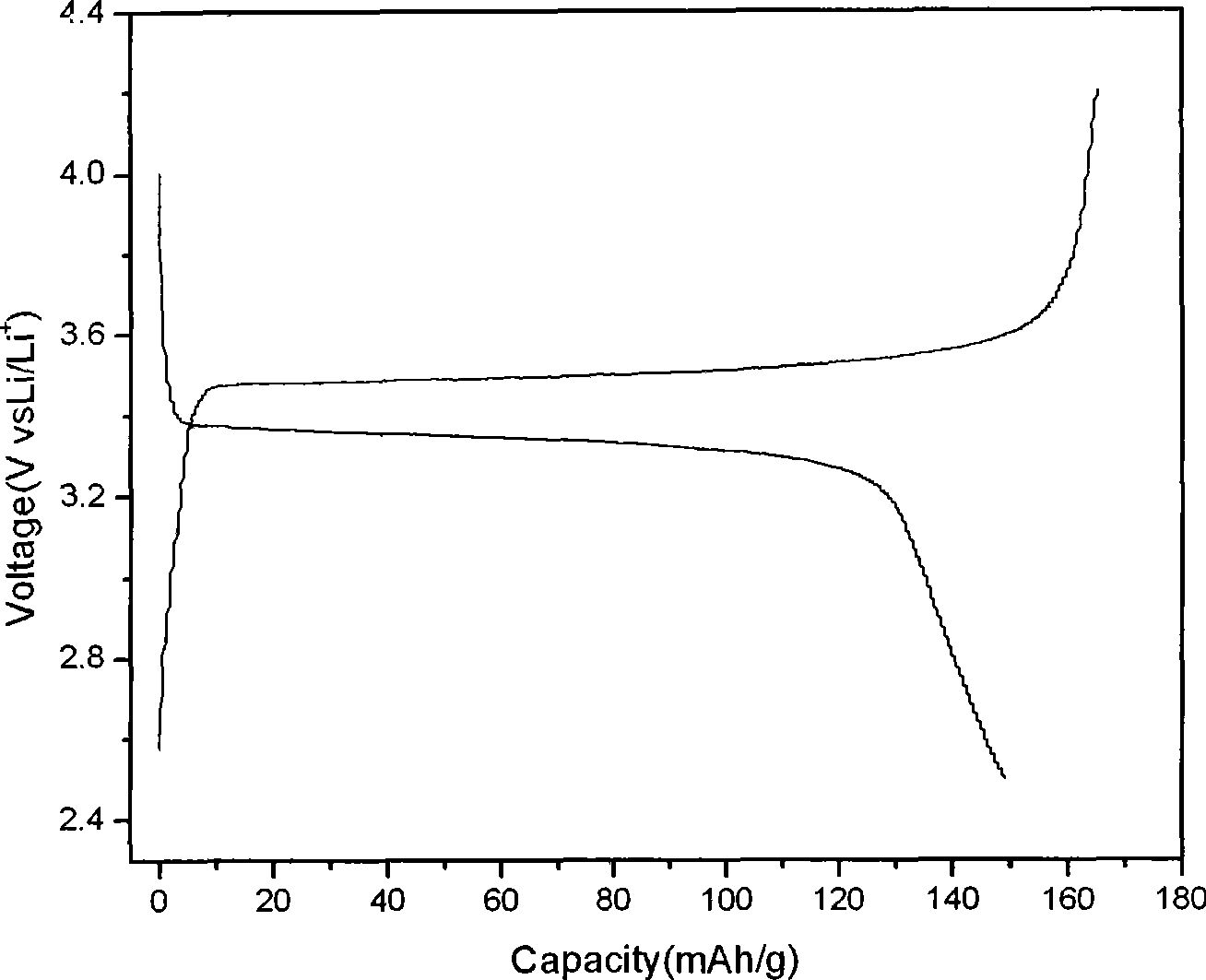

Embodiment 1

[0034] Take a certain amount of lithium acetate, iron nitrate, and diammonium hydrogen phosphate according to the stoichiometric ratio, dissolve them in deionized water to form a mixed solution with a concentration of 2mol / L, and then weigh LiFePO 4 PVA with 10% theoretical mass is added to the previous mixture and stirred evenly. Then place the reaction vessel in a water bath, set the temperature of the water bath to 80°C, and the stirring rate to 100r / min. When the solution appears turbid, start ultrasonic dispersion. The ultrasonic dispersion time is 5 minutes each time, and the ultrasonic interval is 10 minutes. Ultrasonic 3 times, until the solution is evaporated to dryness to obtain the precursor, take out the precursor and place it in an infrared drying oven with the power adjusted to 250W, and dry for 10 hours to obtain a dry precursor solid, which is ground into powder for sintering. The heat treatment process increases from room temperature to 600 °C at a rate of 5 °...

Embodiment 2

[0036] Take a certain amount of lithium hydroxide, iron nitrate, and ammonium dihydrogen phosphate according to the stoichiometric ratio, dissolve them in deionized water to make a solution with a concentration of 1.5mol / L, and then weigh LiFePO 4 CTAB with 5% theoretical mass was added to the previous mixture and stirred evenly. Then place the reaction vessel in a water bath, set the temperature of the water bath to 70°C, and the stirring rate to 200r / min. When the solution appears turbid, start ultrasonic dispersion. The ultrasonic dispersion time is 6 minutes each time, and the ultrasonic interval is 15 minutes. Ultrasonic 2 times, until the solution is evaporated to dryness to obtain the precursor, take out the precursor and place it in a microwave oven, control the microwave power to 300W and heat for 15 minutes to obtain a dry precursor solid, which is then ground into powder for sintering. The heat treatment process increases from room temperature to 600 °C at a rate of...

Embodiment 3

[0038] Take a certain amount of lithium dihydrogen phosphate and iron nitrate according to the stoichiometric ratio, dissolve them in deionized water to make a solution with a concentration of 1mol / L, and then weigh LiFePO 4 10% PEG (average molecular weight: 380-400) and 5% sucrose in theoretical mass, these two mixed carbon sources are added to the previous mixed solution and stirred evenly. Then put the reaction vessel in a water bath, set the temperature of the water bath to 90°C, and the stirring rate to 150r / min. When the solution appears turbid, ultrasonically disperse it for 15 minutes. Finally, until the solution is evaporated to dryness to obtain the precursor, take out the precursor and place it side by side. In an infrared drying oven with the power adjusted to 500W, dry for 6 hours to obtain a dry precursor solid, which is then ground into powder. The heat treatment process increases from room temperature to 700 °C at a rate of 10 °C / min, and then naturally cools ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com