Method and device for measuring the resistivity of gas hydrate and hydrate-containing sediment in situ

A technology of hydrate deposits and gas hydrates, applied in the direction of material resistance, etc., can solve problems such as high logging costs, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

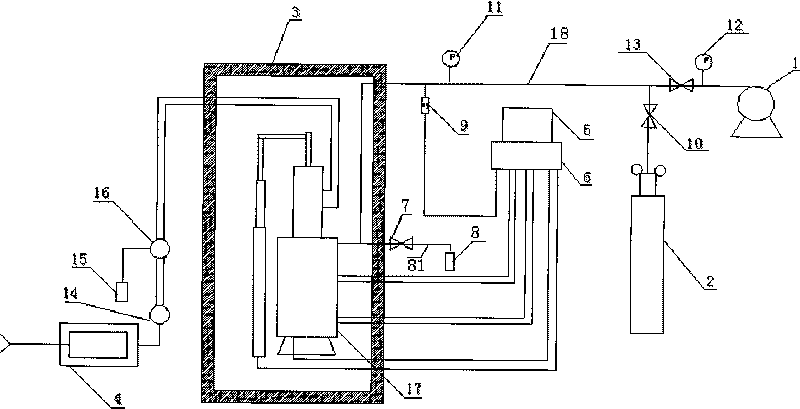

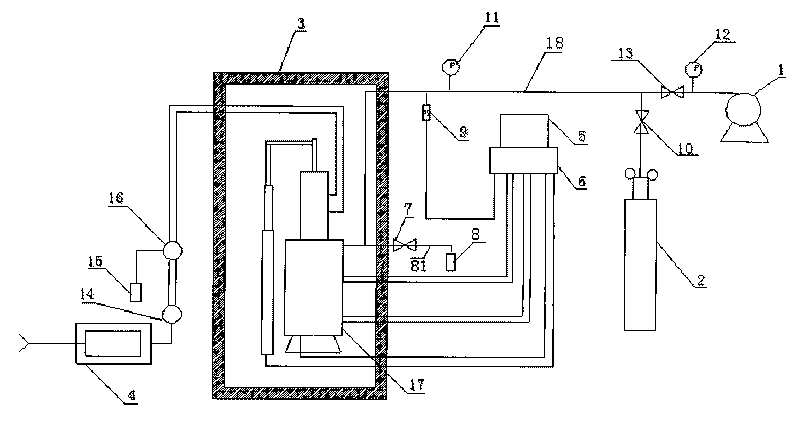

[0031] The method for measuring the resistivity of gas hydrate and hydrate-containing deposits in situ comprises the following steps:

[0032] (1) Formation of hydrates or hydrate deposits:

[0033] i) The reaction gas enters the hydrate reactor from the gas supply system;

[0034] ii) Under the reaction pressure and reaction temperature provided by the hydraulic transmission system and the temperature control system for the hydrate reactor, the reaction gas reacts with other reactants in the hydrate reactor to form hydrate;

[0035] (2) Determination of electrical resistivity properties:

[0036] i) The measurement, control and acquisition system connected to the hydrate reactor processes the measurement data of temperature, pressure, displacement, and resistance collected from the hydrate reactor, and measures the temperature, pressure, displacement, and resistance in the hydrate reactor through the Huygens bridge. The resistance R of the hydrate or hydrate-containing depo...

Embodiment 2

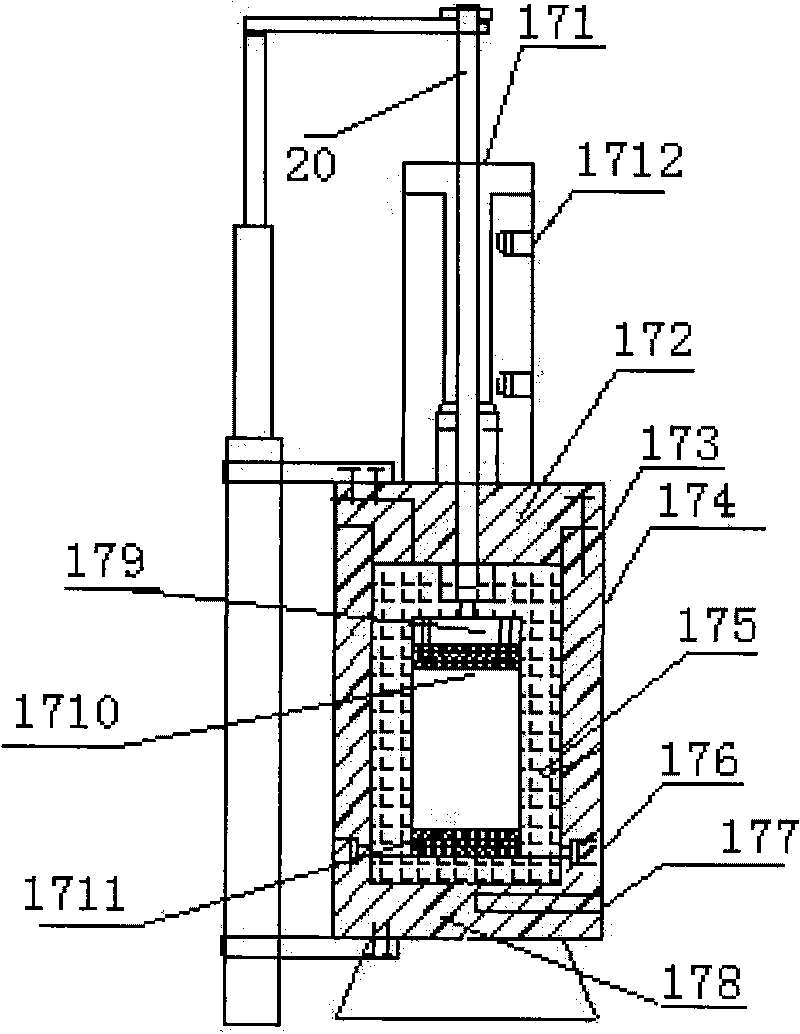

[0051] Using quartz sand, methane, and water to synthesize gas hydrate in porous media, this example is to simulate the measurement of the conductivity of the actually collected sediment samples containing gas hydrate:

[0052] Firstly, the quartz sand with a certain specification is screened, cleaned, put into the hydrate reactor 17, and at the same time, experimental water is added from the water inlet 8 to make the sand particles reach a certain saturation, and the reactor is oscillated to make the sand particles evenly distributed; Turn on the vacuum pump 1, vacuumize to remove the gas in the reactor, and then pass in the required methane gas to make the pressure reach the reaction pressure required for hydrate formation. After a period of time, the methane gas is fully dissolved in water to reach an equilibrium state , close the cylinder shut-off valve 10. Then adjust the constant temperature test chamber 3 to reduce the temperature in the reactor to the required reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com