Method for analyzing accelerating agent of electro coppering, and deposited electrolyte

An analytical method and accelerator technology, applied in the field of electroplating copper accelerator analysis, can solve the problems of weak electrochemical signal, low sensitivity, etc., to reduce relative errors, accurately quantify the content of sulfur-containing compounds, and achieve high convenience and accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

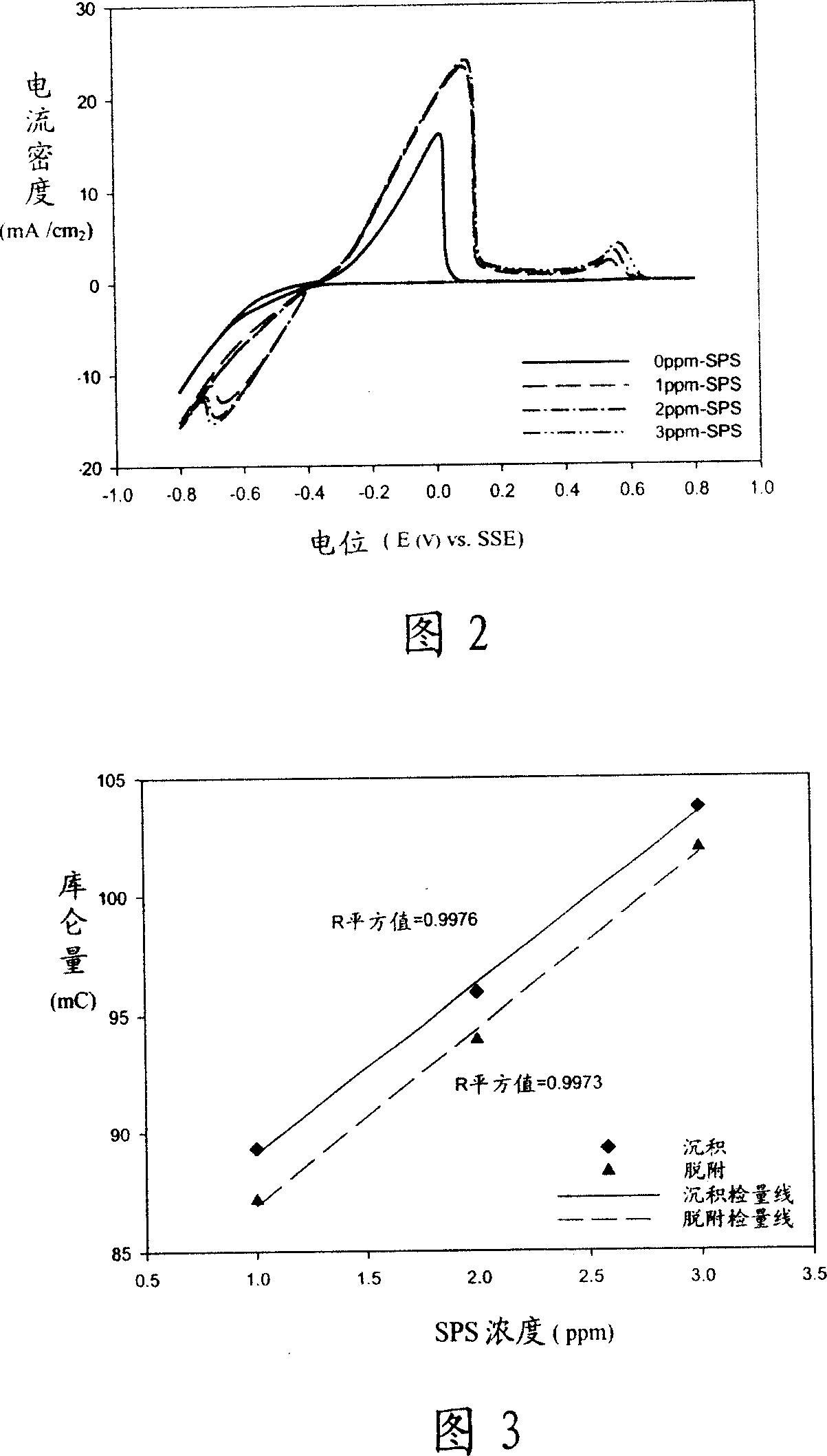

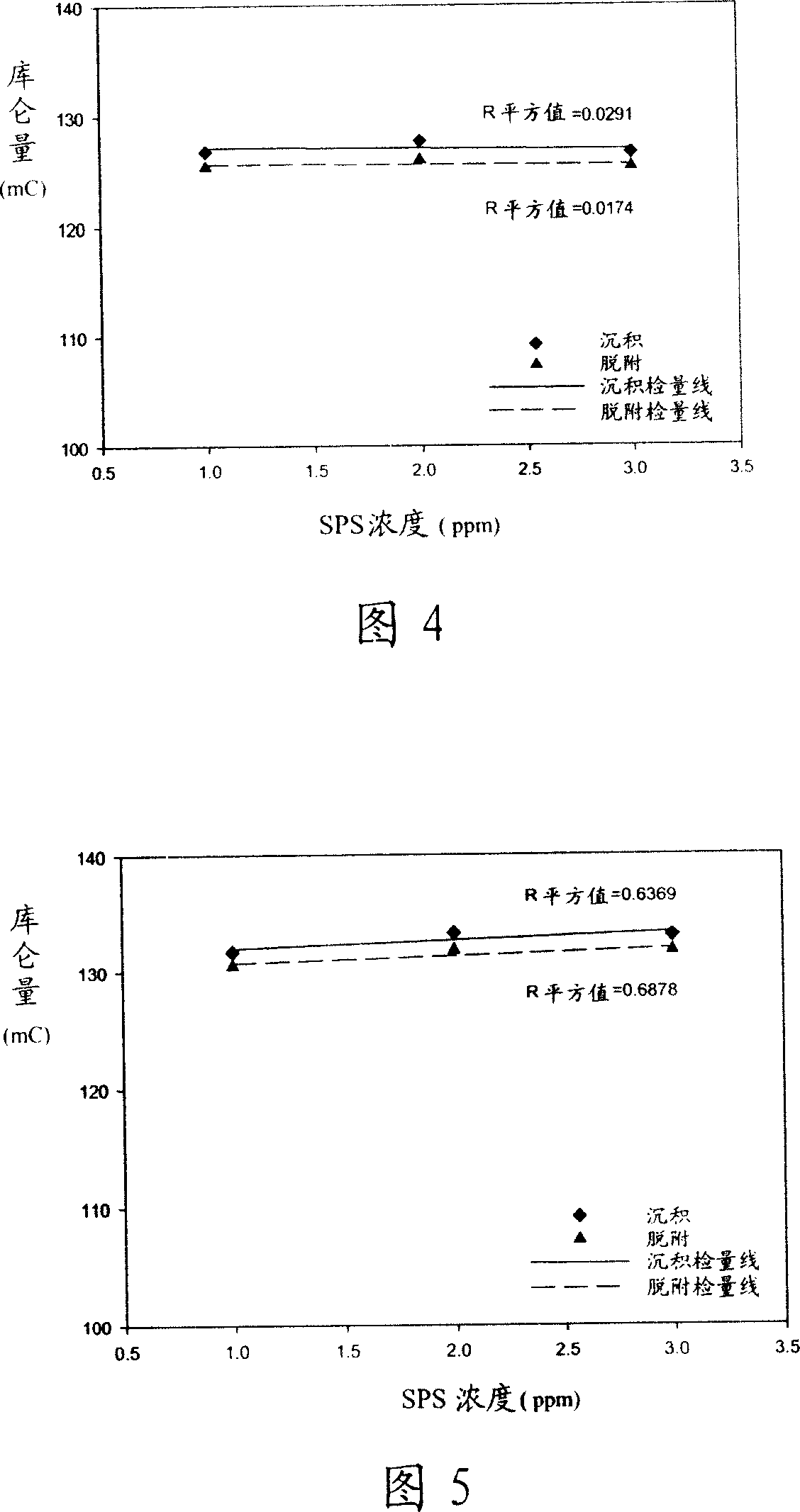

[0070] Please refer to Figure 4, which is a calibration curve diagram obtained by putting the SPS-adsorbed gold electrode into the electrolyte solution containing only sulfuric acid and copper sulfate for cyclic voltammetry scanning, and integrating the obtained polarization curve. By changing the concentration of SPS, observe whether the coulomb quantity obtained by the polarization curve integration will change with the increase of the SPS concentration. As shown in Figure 4, when the potential scan is performed in the electrolyte containing only sulfuric acid and copper sulfate, the coulomb quantity There is no obvious change with the different SPS concentrations, nor does it have a linear effect (R square value = 0.0291), so it cannot be used as the electrolyte for accelerator concentration analysis.

example 2

[0072] Please refer to Figure 5, which is a calibration curve diagram obtained by putting the SPS-adsorbed gold electrode into the electrolyte solution containing sulfuric acid, copper sulfate and chloride ions for potential scanning, and integrating the obtained polarization curve. As shown in Figure 5, the experimental results obtained in the electrolyte with more chlorine ions added are the same as when no chloride ions are added, and there is no linear effect (R square value = 0.6369), so it cannot be used as an accelerator concentration analysis. of electrolyte.

example 3

[0074] Please refer to Figure 6, which is to put the gold electrode adsorbed on SPS into the electrolyte solution containing sulfuric acid, copper sulfate and PEG for potential scanning, so as to observe the change of the current signal generated by the electrolyte solution added with PEG. As shown in Figure 6, as the concentration of SPS increases, the coulomb amount obtained by the polarization curve integration will decrease and show a linear relationship (R square value = 0.985), but the change of the coulomb amount is not obvious, so when electroplating Although there is a linear relationship when PEG is added to the liquid, the coulomb quantity does not change much, and it cannot be used as an electrolyte solution for accelerator concentration analysis, because if the coulomb quantity does not change much, the polarization measured when the accelerator concentration changes The curve will have the problem of insufficient accuracy, that is to say, the amount of Coulomb cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com