Flexible pyroelectric thin film device

A thermoelectric thin film and device technology, which is applied in the directions of thermoelectric device components, thermoelectric device manufacturing/processing, thermoelectric device junction lead wire materials, etc. practical problems, to achieve the effect of enhanced bonding force, reliable deposition, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

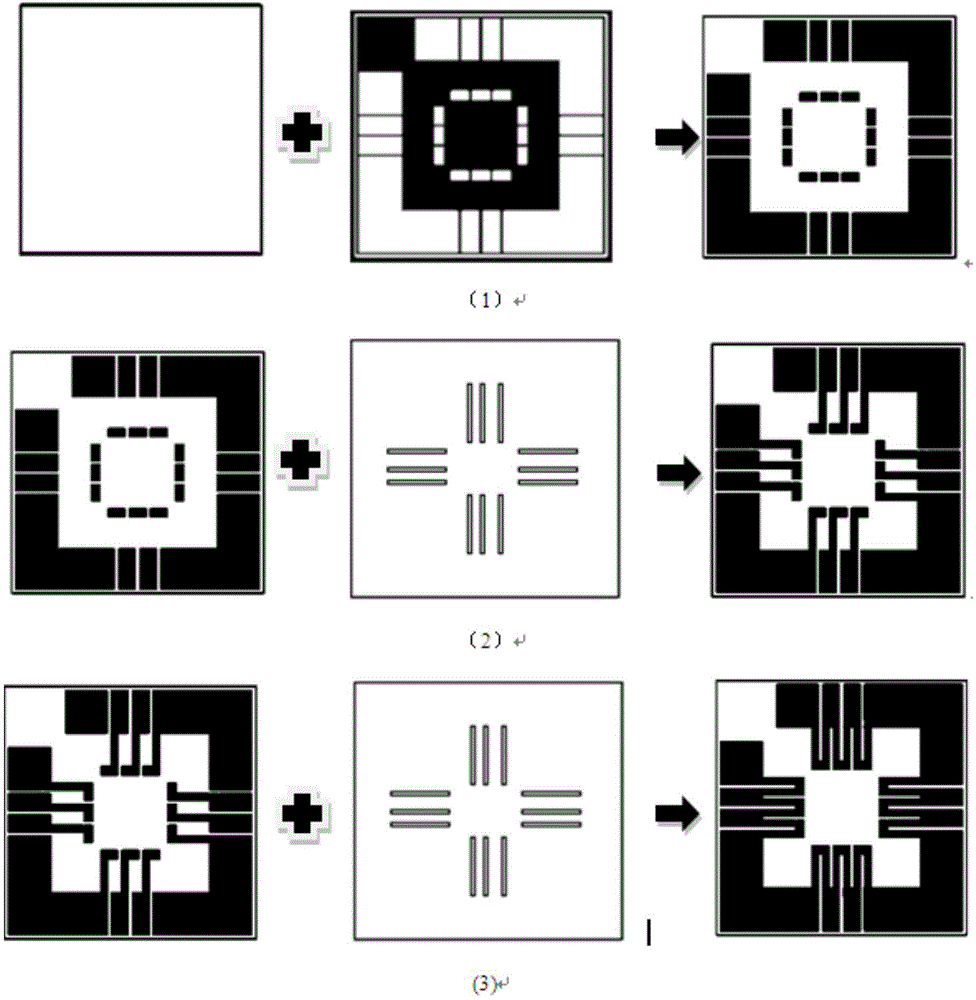

[0045] According to the preparation method in the present invention, it is sputtered at normal temperature, and the thermoelectric arm is 6mm long such as figure 1 The flexible thermoelectric thin film device shown. Its preparation process is as follows: ① use a magnetron sputtering apparatus and an electrode mask to press figure 1 Step (1) in the preparation of Cu electrode film and Ni transition layer. The parts that do not need to be sputtered are covered with an electrode mask. Under the pressure of 1.5Pa, the sputtering power of 30W, and the substrate temperature of 100°C, the copper electrode film is sputtered on the polyimide flexible substrate with a magnetron sputtering device for 2 hours. , and then sputter nickel transition layer 0.25h. ②Use a magnetron sputtering apparatus and a BST thermoelectric material mask to press figure 1 Step (2) in prepares BST (Bi 2-x Sb x Te 3 , x=1.2~2.0) thermoelectric thin film. The parts that do not need to be sputtered are co...

Embodiment 2

[0048] According to the preparation method in the present invention, a flexible thermoelectric thin film device with a sputtering temperature of 350° C. and a thermoelectric arm of 6 mm in length is prepared. The preparation process is as follows: ①Use a magnetron sputtering apparatus and an electrode mask figure 1 Step (1) in the preparation of Cu electrode film and Ni transition layer. Use an electrode mask to cover the part that does not need to be sputtered, and adjust the magnetron sputtering instrument to sputter copper on the polyimide flexible substrate under the conditions of air pressure 1.5Pa, sputtering power 30W, and substrate temperature 100°C Electrode thin film 2h, then sputter nickel transition layer 0.25h. ② Using magnetron sputtering and BST (Bi 2-x Sb x Te 3 , x=1.2~2.0) The thermoelectric material mask is pressed figure 1 Step (2) in the preparation of BST thermoelectric thin film. Use an electrode mask to cover the part that does not need to be sputt...

Embodiment 3

[0051]According to the preparation method in the present invention, a flexible thermoelectric thin-film device with a thermoelectric arm length of 8 mm, a sputtering temperature of 350° C., and annealing at 350° C. for 1 h is prepared. The preparation process is as follows: ①Use a magnetron sputtering apparatus and an electrode mask according to figure 1 Step (1) in the preparation of Cu electrode film and Ni transition layer. Use an electrode mask to cover the part that does not need to be sputtered, and adjust the magnetron sputtering instrument to sputter the copper electrode film for 2 hours under the conditions of air pressure 1.5Pa, sputtering power 30W, and substrate temperature 100°C, and then sputter Ni transition layer 0.25h. ② Using magnetron sputtering and BST (Bi 2-x Sb x Te 3 , x=1.2~2.0) The mask plate of thermoelectric material is pressed figure 1 In step (2) to prepare BST thermoelectric thin film, cover the parts that do not need to be sputtered with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com