Method for producing a metal oxide layer with a predetermined structure by arc evaporation

An oxide, metal technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve problems such as spark discharge interruption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

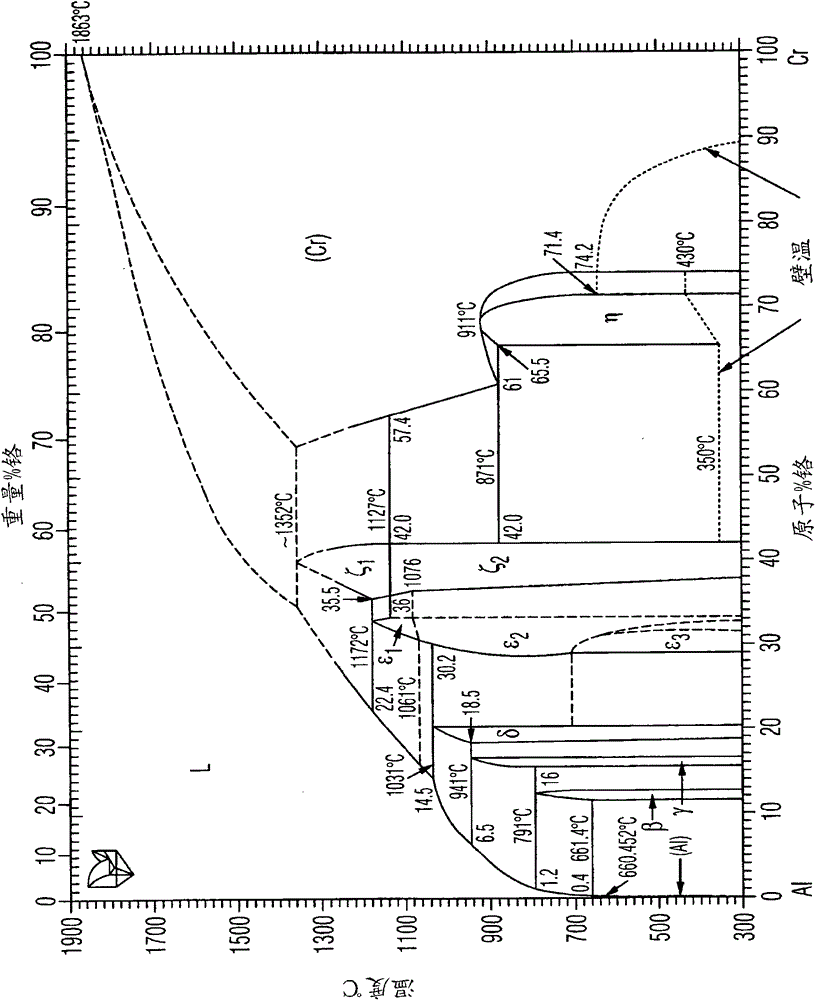

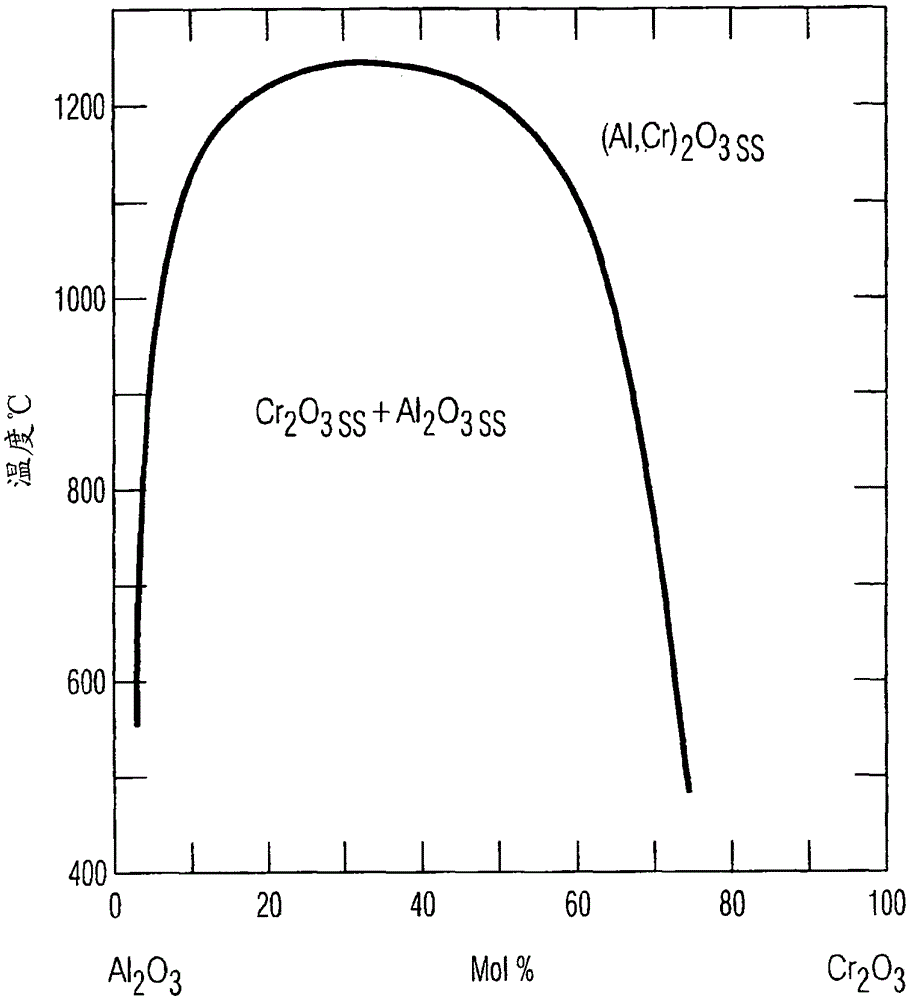

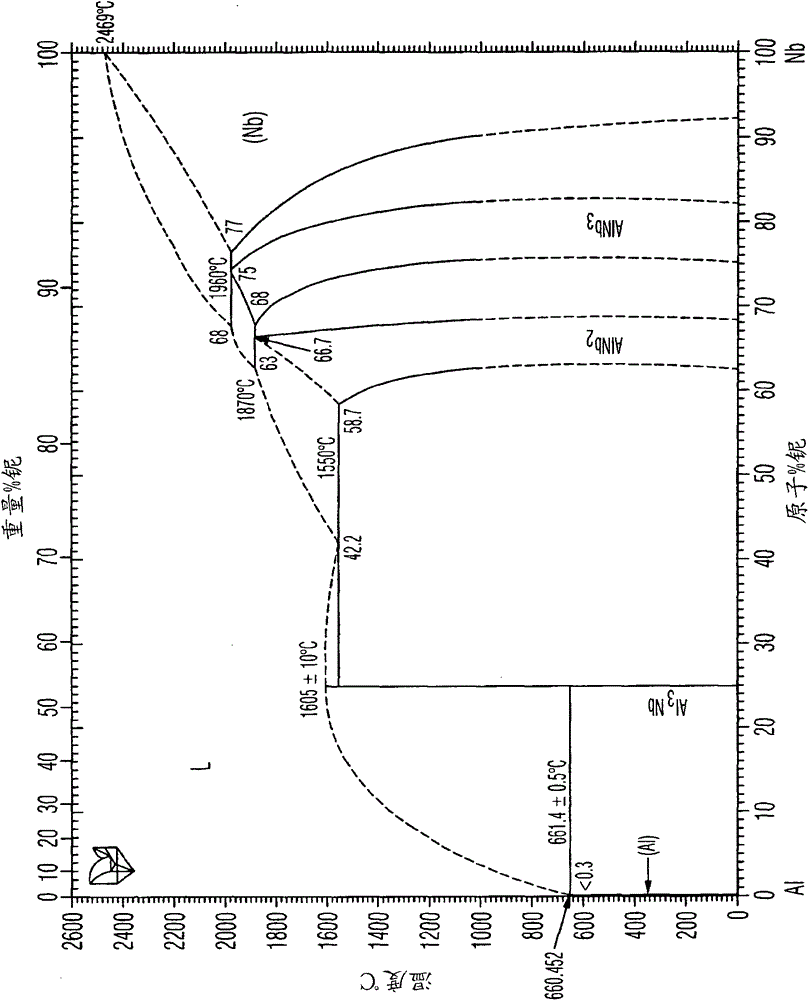

[0038]According to the invention, the structure of the oxide to be deposited can be read out on the basis of the phase diagram of the metal or semimetal components used to synthesize the oxide. This means that eg for ternary Al-Cr-O, reference is made to the Al-Cr binary phase diagram. For quaternary oxides, reference is made accordingly to the ternary phase diagram of the metal or semimetal forming the oxide. The target for arc evaporation is then formed from a metal or semimetal which is the metal or semimetal used to form the oxide of the corresponding structure to be formed. The composition of the target is selected such that the temperature of the transition to the liquid phase according to the phase diagram satisfies the formation temperature condition of an oxide having a desired structure. Oxide formation is then achieved by the reaction of the evaporated target or the target to be evaporated with oxygen.

[0039] This means that in order to produce a certain desired...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com