Filter and manufacturing method therefor

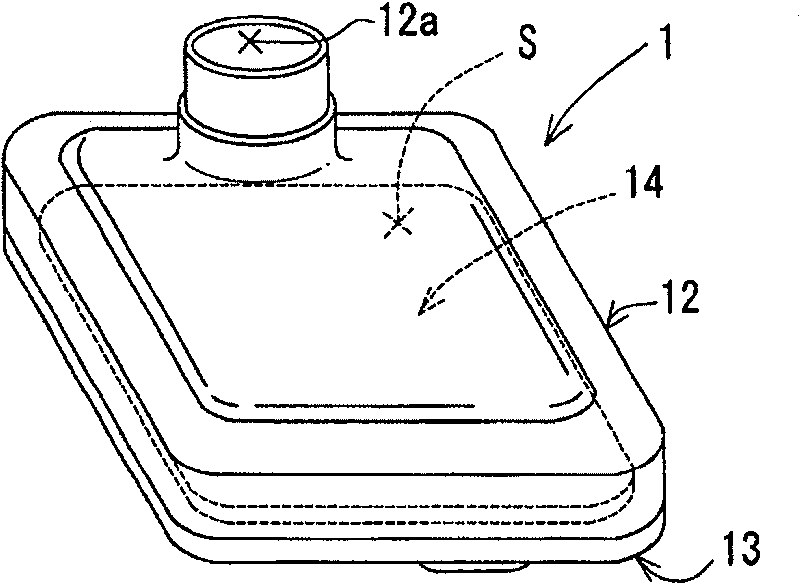

A technology of filters and filter chambers, applied in chemical instruments and methods, fixed filter element filters, filtration separation, etc., can solve problems such as melting, product performance deterioration, unwelded parts and over-welded parts, etc., to achieve Effect of suppressing shedding, improving aesthetics, and suppressing entry into the filter chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

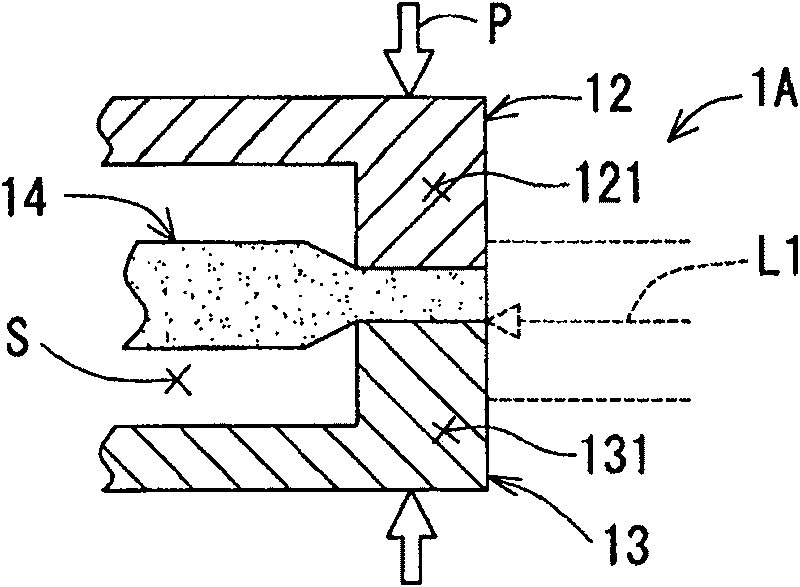

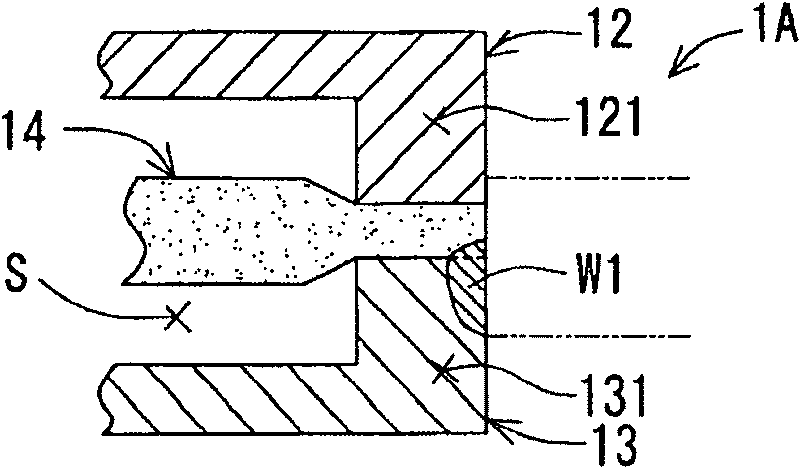

[0184] Next, the filter 1A according to the first embodiment will be described. First, the manufacturing method of this filter 1A is described, as figure 2 As shown, in the state where the edge portion of the element 14 is clamped between the butt end 121 of the upper case member 12 and the butt end 131 of the lower case member 13, each case is pushed along the butt direction P by an external force. The members 12, 13 are pressurized. At this time, the edge portion of the element 14 becomes a low-density state. Then, in this pressurized state, laser light L1 is irradiated from the side toward the outer surface of the element 14 and the outer surface of the front end side of the mating end portion 131 of the lower case member 13 .

[0185] In addition, the mounting position of the edge portion of the element 14 with respect to each case member 12 , 13 is set at a position where it is not exposed outward from the outer surface of the mating end portion 121 , 131 of each case ...

Embodiment 2

[0189] Next, the filter 1B according to the second embodiment will be described. In this filter 1B, as in Figure 4 As shown, on the upper housing member 12, an outer wall portion 124 connected to the butt end portion 121 thereof and extending in the butt direction P is provided. In addition, as in the above-mentioned first embodiment, in the state where the edge portion of the element 14 is sandwiched between the butt end portions 121, 131 of the respective case members 12, 13, the respective case members 12, 13 are pushed toward each other by external force. Pressurize in docking direction P.

[0190] At this time, the inner peripheral surface of the outer wall portion 124 abuts against the base end side outer surface of the mating end portion 131 of the lower case member 13 on the abutting surface extending along the mating direction P, and at the same time, a predetermined The gap faces the outer surface on the front end side of the mating end portion 131 of the lower ca...

Embodiment 3

[0196] Next, the filter 1C according to the third embodiment will be described. In this filter 1C, as Figure 6 As shown, similarly to the above-described second embodiment, the welded portion W1 for the element is formed by the laser L1, and the welded portion W2 for the case is formed by the laser L2 at the same time.

[0197] In the above filter 1C, such as Figure 7 As shown, a concave portion (indicated as a “fitting portion” according to the present invention) is provided on the outer wall portion 124 of the above-mentioned case member 12 . In addition, the base end side of the mating end portion 131 of the lower housing member 13 is formed in a flange shape protruding outward, and at this position, the convex portion 132 (according to In the present invention, it is referred to as "part to be mated").

[0198] The recessed portion 122 and the protruding portion 132 are arranged on the side of the filter chamber S of the casing welded portion W2. The mating width (the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com