Fuel tank insert part weld molding method and fuel tank

A technology for fuel tanks and components, which is applied in the field of cladding and forming of embedded components, to achieve the effect of reliable cladding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

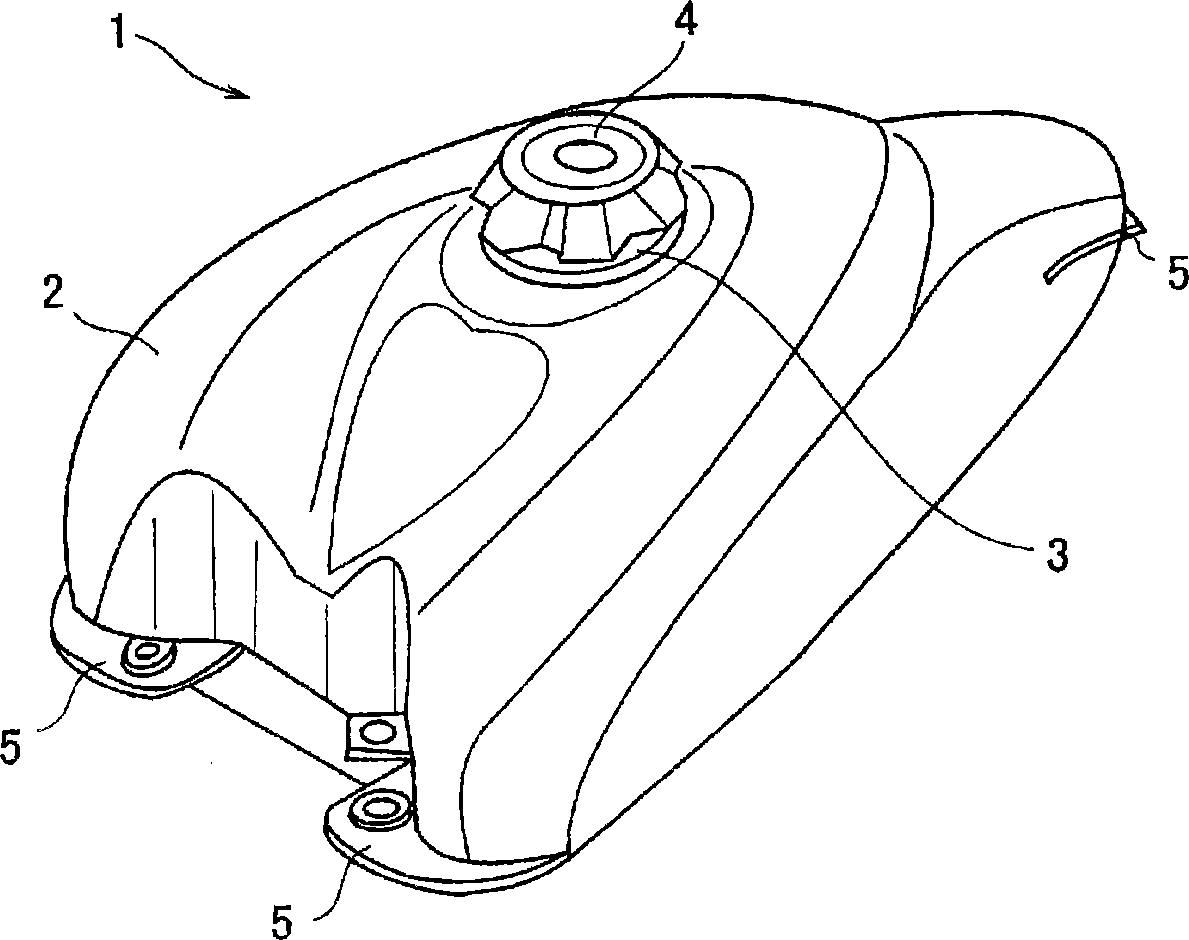

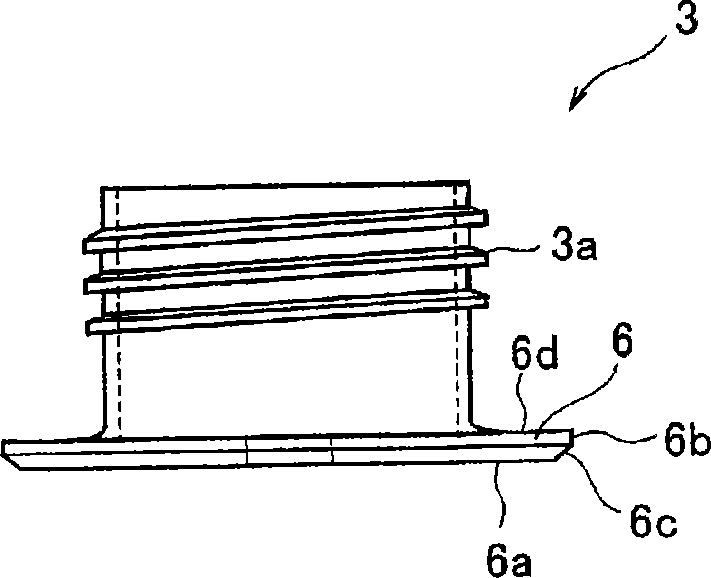

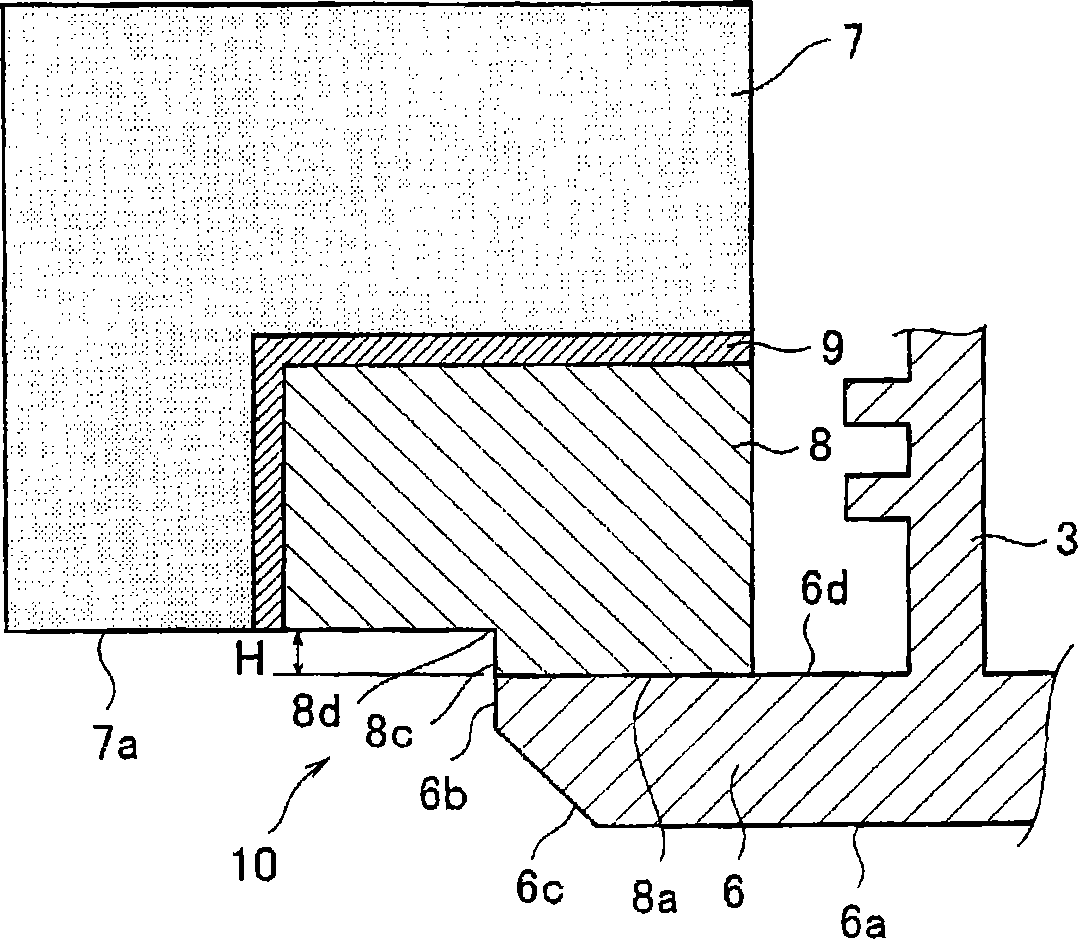

[0045] Embodiments of the present invention will be described below based on the drawings. here, figure 1 It is a perspective view of a fuel tank for a motorcycle to which the method of welding an insert member according to the present invention is applied, figure 2 is a side view of the fill port body, image 3 It is a schematic cross-sectional view of a mold structure for carrying out the first embodiment of the insert part welding molding method of the present invention, Figure 4 is an action explanatory diagram of the first embodiment, Figure 5 It is a schematic cross-sectional view of a mold structure for implementing a second embodiment of the method of welding an insert part of the present invention, Figure 6 It is an action explanatory diagram of the second embodiment.

[0046] Such as figure 1 As shown, a fuel tank 1 for a motorcycle to which the method for welding an insert of the present invention is applied has an insert member, that is, an oil filler ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com