Quick reaction synthesis type high temperature atmosphere stove and method for synthesizing ceramic powder

A fast-response, atmosphere furnace technology, applied in the direction of furnaces, furnace types, lighting and heating equipment, etc., can solve the problem of being brought into reactants and products, unable to realize high-temperature furnace atmosphere protection, and unable to meet the requirements of multi-process operations, etc. problems, to avoid by-products and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

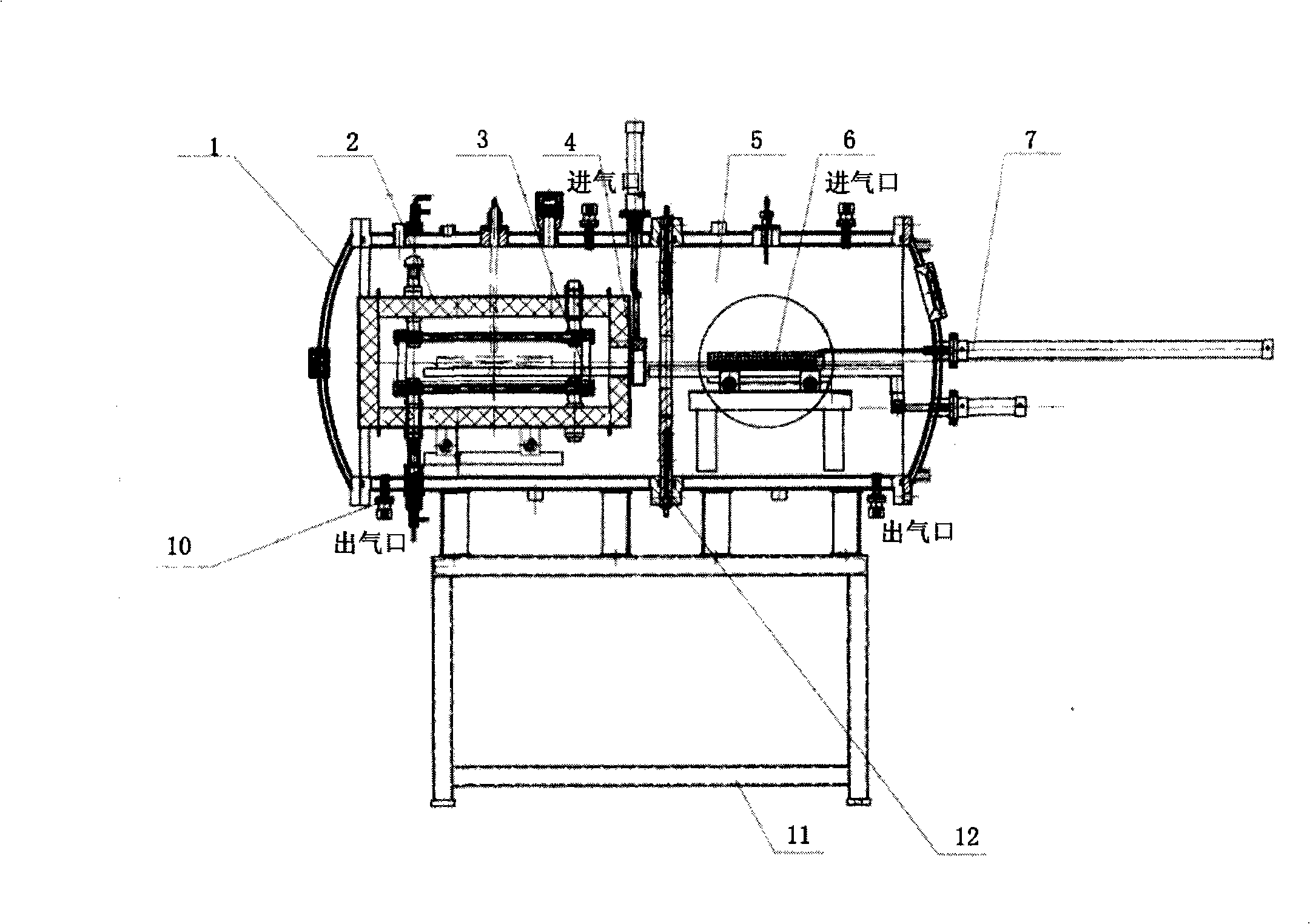

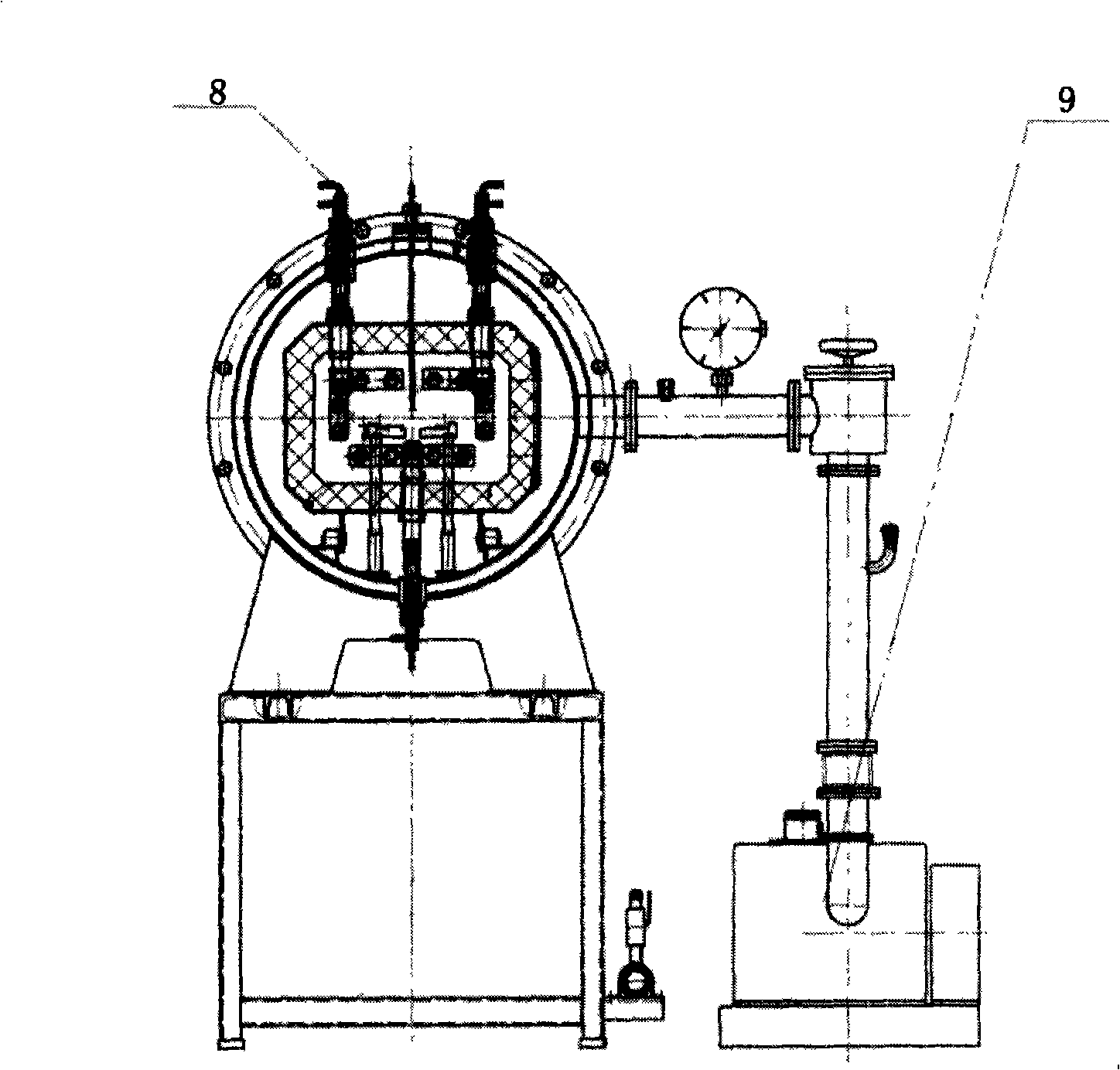

[0044] See figure 1 and figure 2 . An atmosphere furnace located on the base 11 is divided into two parts: a high-temperature atmosphere furnace 1 and a cold chamber furnace 5 by a water-cooled flange 12 with a water-cooled intermediate partition in the middle, and both the high-temperature atmosphere furnace and the cold chamber furnace have furnace doors; In the high-temperature atmosphere furnace, there is a heat-resistant stainless steel frame installed on the hearth 3, and high-quality carbon felt insulation materials are filled in the four sides of the upper, lower, left, and right frames. In the heating chamber 2, heating elements are evenly distributed on the inner walls of the upper and lower insulation materials. The heating elements are connected to the water-cooled electrode 8 composed of copper electrodes with cooling water jackets installed on the shell 1 of the high-temperature atmosphere furnace through wires. The copper electrodes in the furnace are connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com