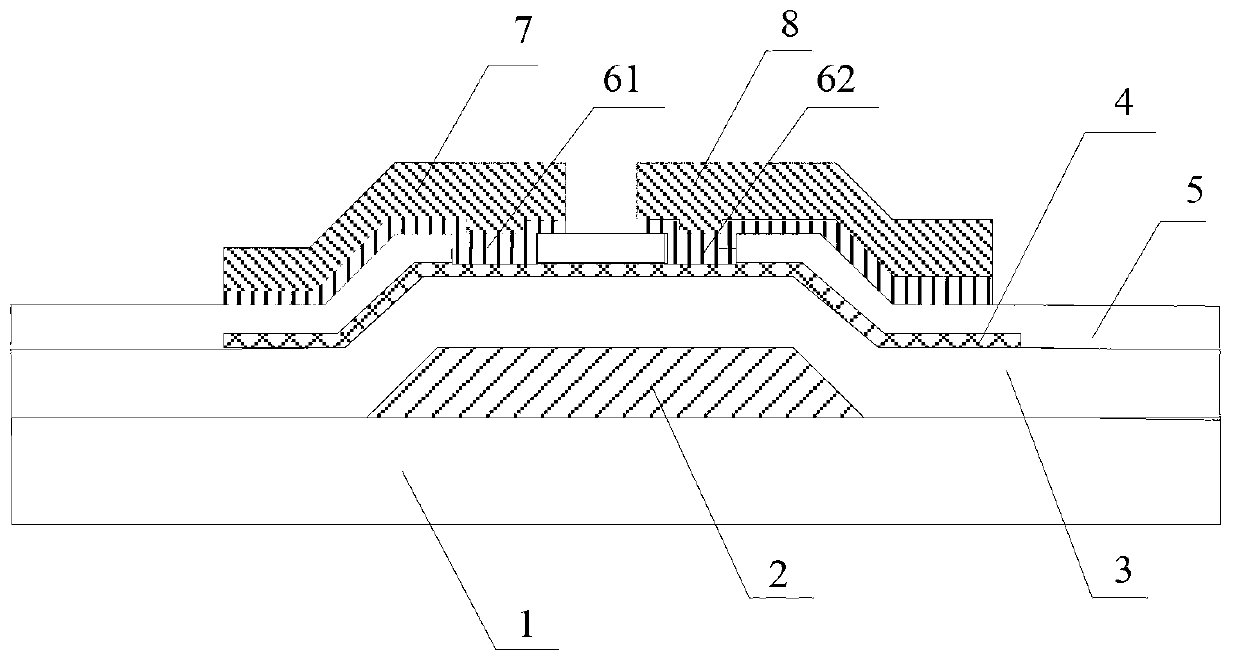

Thin film transistor and manufacturing method thereof and array substrate and display device

A technology for thin film transistors and substrates, which is applied in the fields of array substrates and display devices, thin film transistors and their manufacturing methods, can solve problems such as poor TFT performance, poor image quality, and poor Cu adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

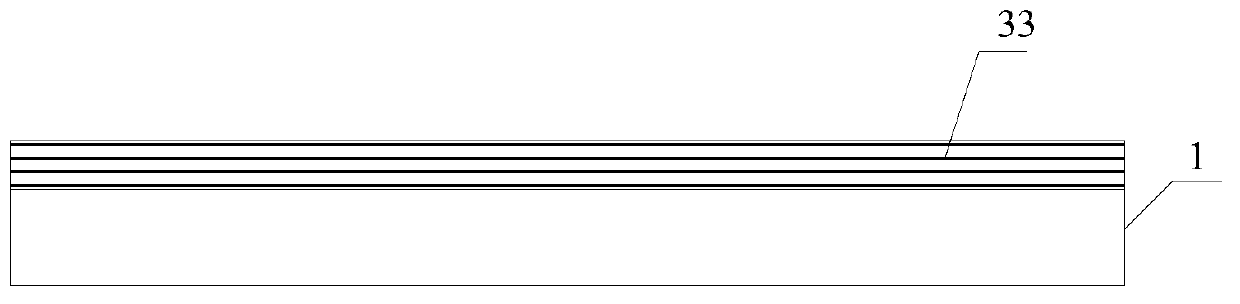

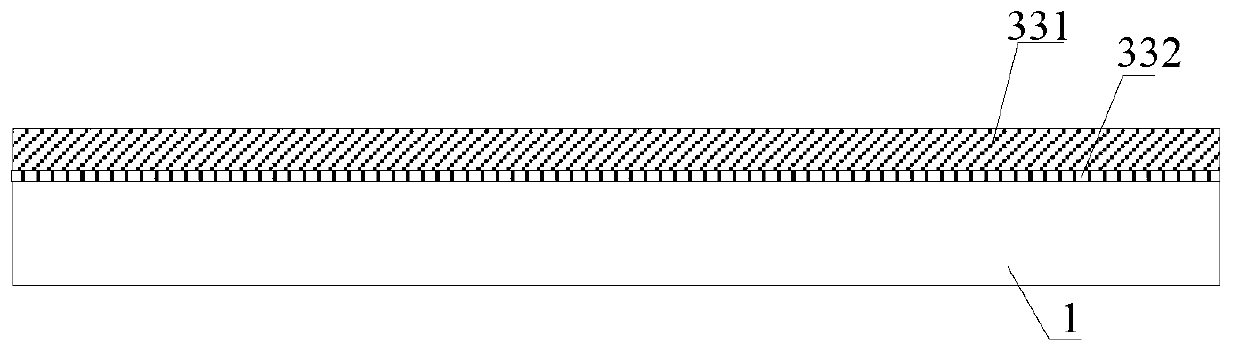

[0075] Embodiments of the present invention provide a thin film transistor and its manufacturing method, an array substrate and a display device, which are used to improve the performance of the TFT and improve the image quality.

[0076] The TFT provided by the embodiment of the present invention is preferably but not limited to be applicable to a display device under the planar electric field core technology, such as an ADS type display device. ADS is the core technology of planar electric field - Advanced Super Dimension Switch (ADS). Specifically, the electric field generated by the edge of the slit electrode (common electrode) in the same plane and the electric field generated between the slit electrode layer and the plate electrode layer (pixel electrode) form a multidimensional electric field, so that the slit electrodes in the liquid crystal cell, All aligned liquid crystal molecules directly above the electrodes can be rotated, thereby improving the working efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com