Copper-electrode zinc-oxide voltage-sensitive resistor and preparation method thereof

A technology of varistors and copper electrodes, which is applied in the manufacture of varistors, resistors, and resistors, can solve problems such as the deterioration of the electrical properties of varistors and the destruction of the grain boundary barrier of varistor semiconductor components, and achieve product The effect of low cost and saving production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This example is the production process of 20K821 copper electrode zinc oxide varistor with a diameter of φ20mm. The steps are as follows:

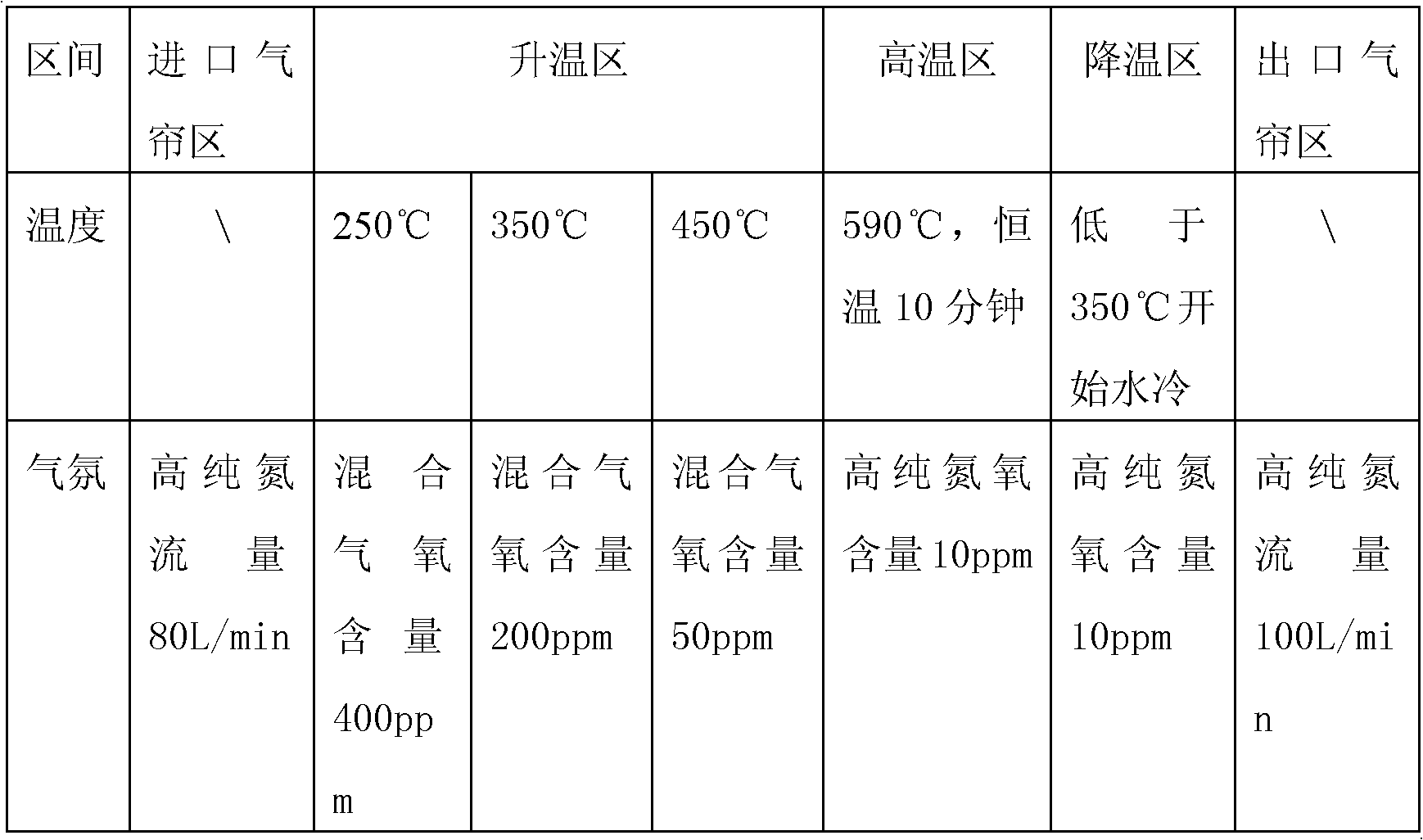

[0020] First make the pressure-sensitive ceramic body according to the traditional varistor sintering process, and then use a 200 mesh screen to print on the pressure-sensitive ceramic body with a copper content of 70%-75% and a firing temperature of 520-600°C on the pressure-sensitive ceramic body with a thickness of 8-10 μm. Low-temperature copper paste for zinc oxide varistors (can be purchased from the market), and then use a general chain-belt drying furnace. Minute process for drying. Then, after installing it with a screen, put it into a chain-type nitrogen atmosphere protection tunnel electric furnace dedicated to zinc oxide varistors, such as a tunnel furnace with a model BHTDL-100 designed by Xinbaohua Electronic Equipment Company. Copper electrodes. The process parameters of the infiltration process are shown in Table 1...

Embodiment 2

[0026] This example is the production process of 10K471 copper electrode zinc oxide varistor with a diameter of φ10mm, including the following steps:

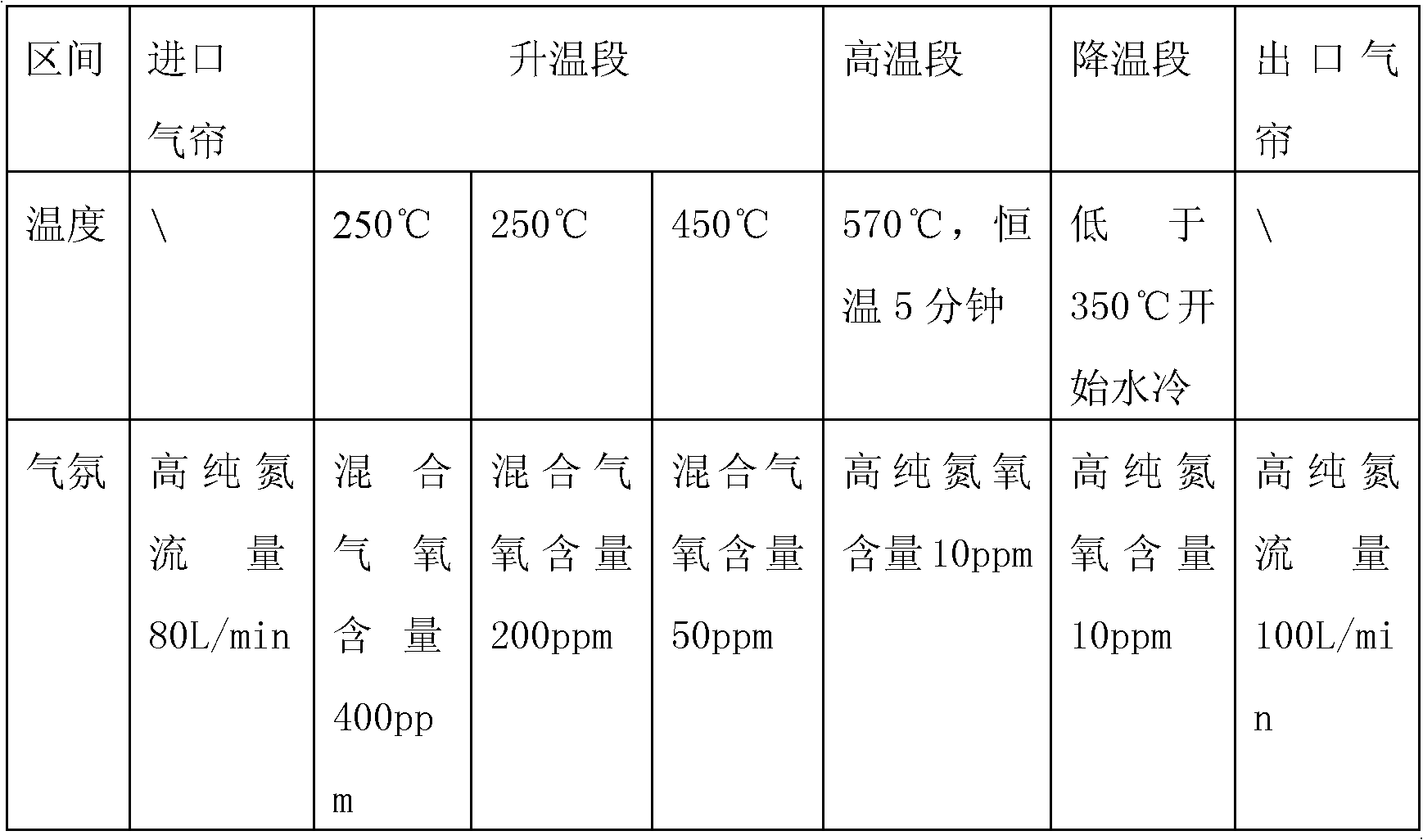

[0027] First make the pressure-sensitive ceramic body according to the traditional varistor sintering process, and then use a 200 mesh screen to print on the pressure-sensitive ceramic body with a copper content of 70%-75% and a firing temperature of 520-600°C on the pressure-sensitive ceramic body with a thickness of 8-10 μm. Low-temperature copper paste for zinc oxide varistors (can be purchased from the market), and then use a general chain-belt drying furnace. Minute process for drying. Then, after installing it with a screen, put it into a chain belt type nitrogen atmosphere protection tunnel electric furnace dedicated to zinc oxide varistors and burn infiltrated copper electrodes. The process parameters of the infiltration process are as follows:

[0028]

[0029] The entire infiltration process is carried out in an ...

Embodiment 3

[0032] This example is the production process of 7K271 copper electrode zinc oxide varistor with a diameter of φ7mm, including the following steps:

[0033] First make the pressure-sensitive ceramic body according to the traditional varistor sintering process, and then use a 200 mesh screen to print on the pressure-sensitive ceramic body with a copper content of 70%-75% and a firing temperature of 520-600°C on the pressure-sensitive ceramic body with a thickness of 8-10 μm. Low-temperature copper paste for zinc oxide varistors (can be purchased from the market), and then use a general chain-belt drying furnace. Minute process for drying. Then, after installing it with a screen, put it into a chain belt type nitrogen atmosphere protection tunnel electric furnace dedicated to zinc oxide varistors and burn infiltrated copper electrodes. The process parameters of the infiltration process are as follows:

[0034]

[0035] The entire infiltration process is carried out in an al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com