Method and Apparatus For Feeding Wire to a Welding Arc

a welding arc and wire technology, applied in the field of welding, can solve the problems of too much heating of workpieces, unstable process, and difficult control of arc length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] While the present invention will be illustrated with reference to a particular welding system using particular components, it should be understood at the outset that the invention may also be implemented with other systems, components, and modules, and be used in other environments.

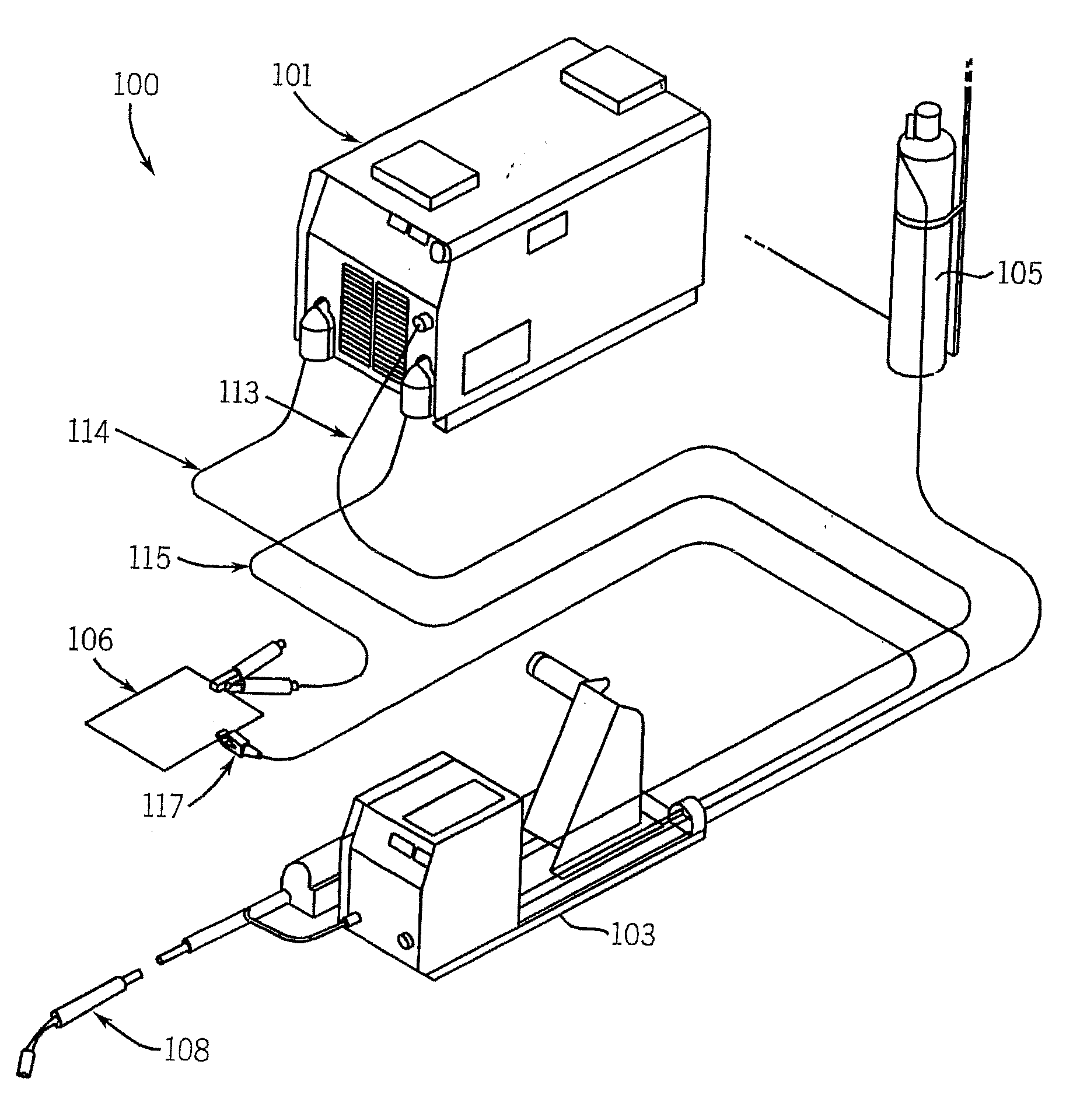

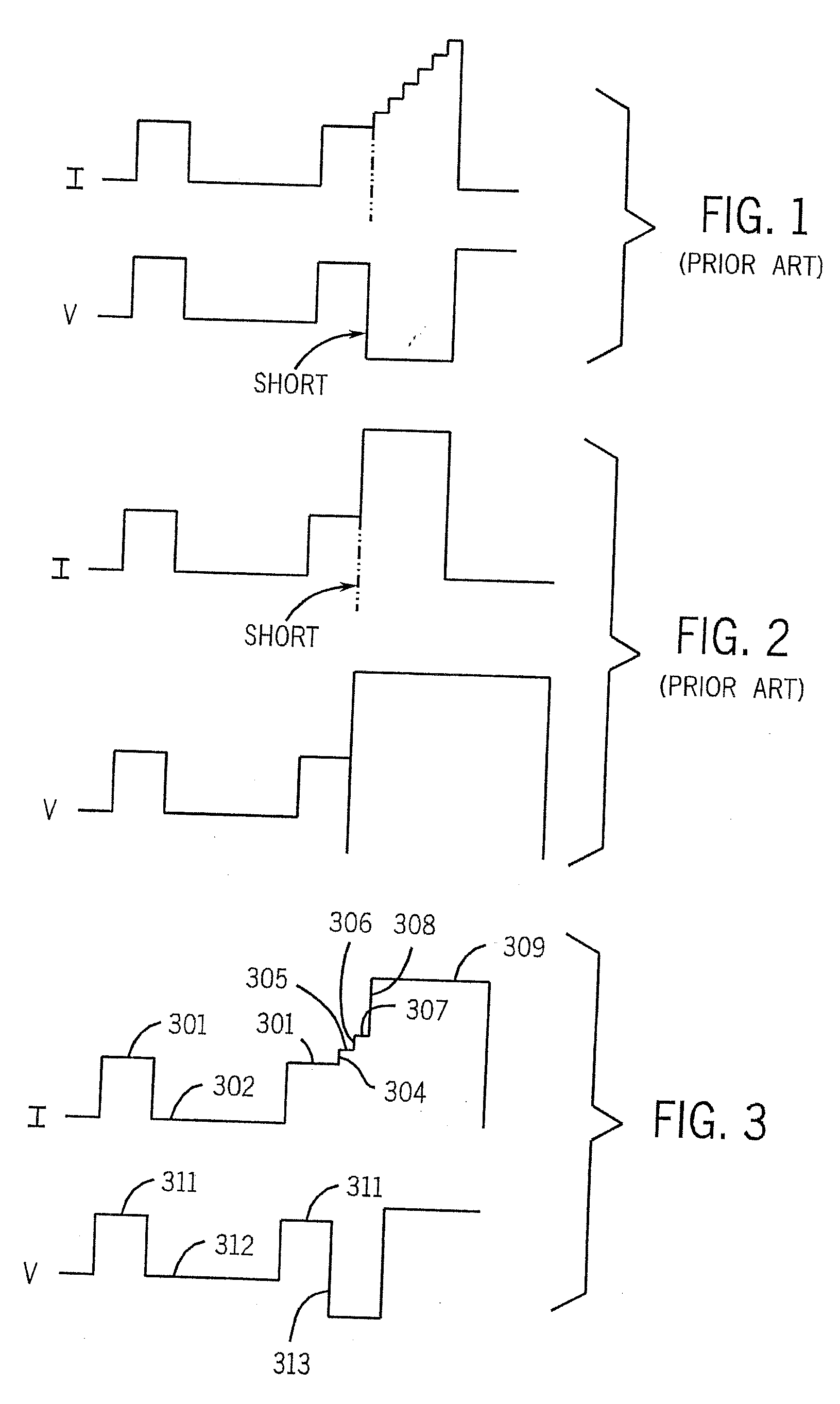

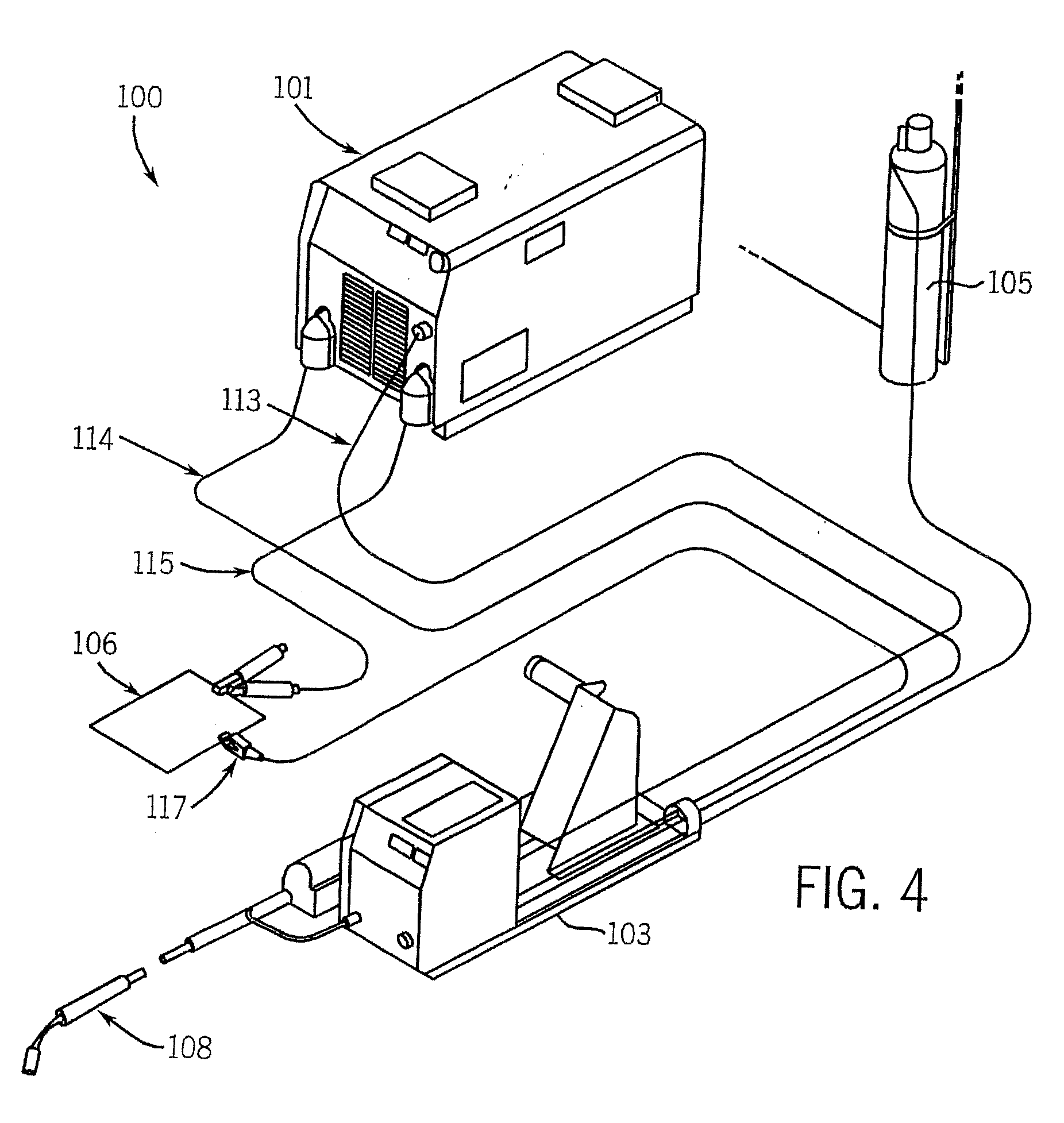

[0029] Generally, the present invention is a method and apparatus for controlled short circuit or pulse welding that includes mechanical control of transitions between the arc and short circuit states. In various embodiments the process includes a pulse mode or transfer. Control of energy to the weld is effected using the output current or voltage magnitude, wave shape, time, etc. Thus, the transitions are caused to occur by controlling the wire movement, and current can be coordinated with, the transitions to reduce spatter, instability, or other undesirable features, by, for example, changing the current as the transition occurs, or in anticipation of the transition. Alternatives include using t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| movement | aaaaa | aaaaa |

| deposition rates | aaaaa | aaaaa |

| arc length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com