Air intake device for internal combustion engine

A technology of air intake device and internal combustion engine, which is applied in the direction of fuel air intake, combustion air/combustion-air treatment, charging system, etc., which can solve the problems that the intake noise cannot be sufficiently reduced, and achieve the goal of reducing the intake noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

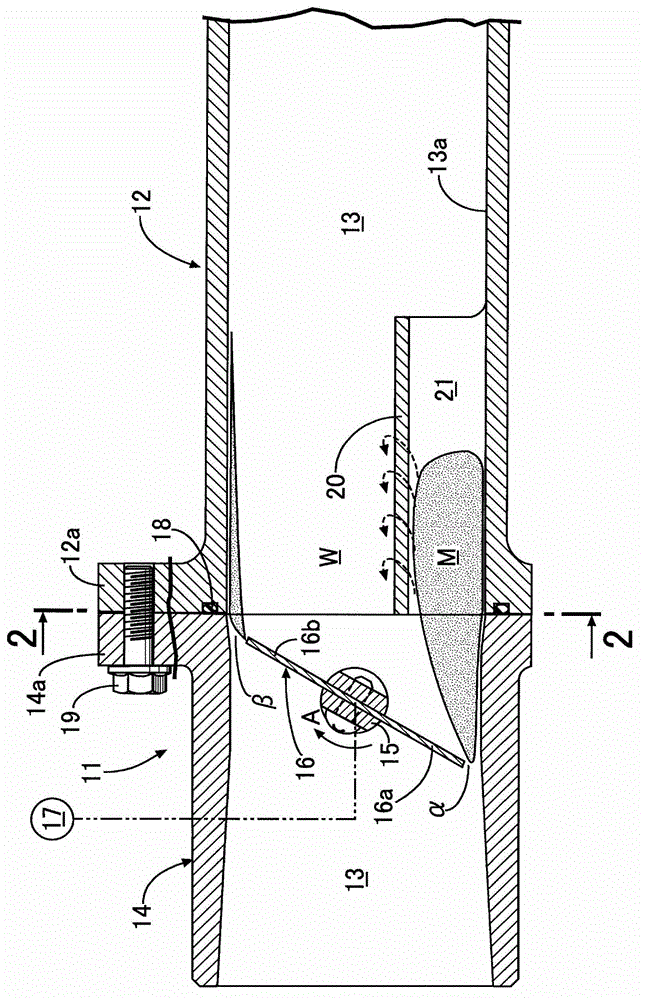

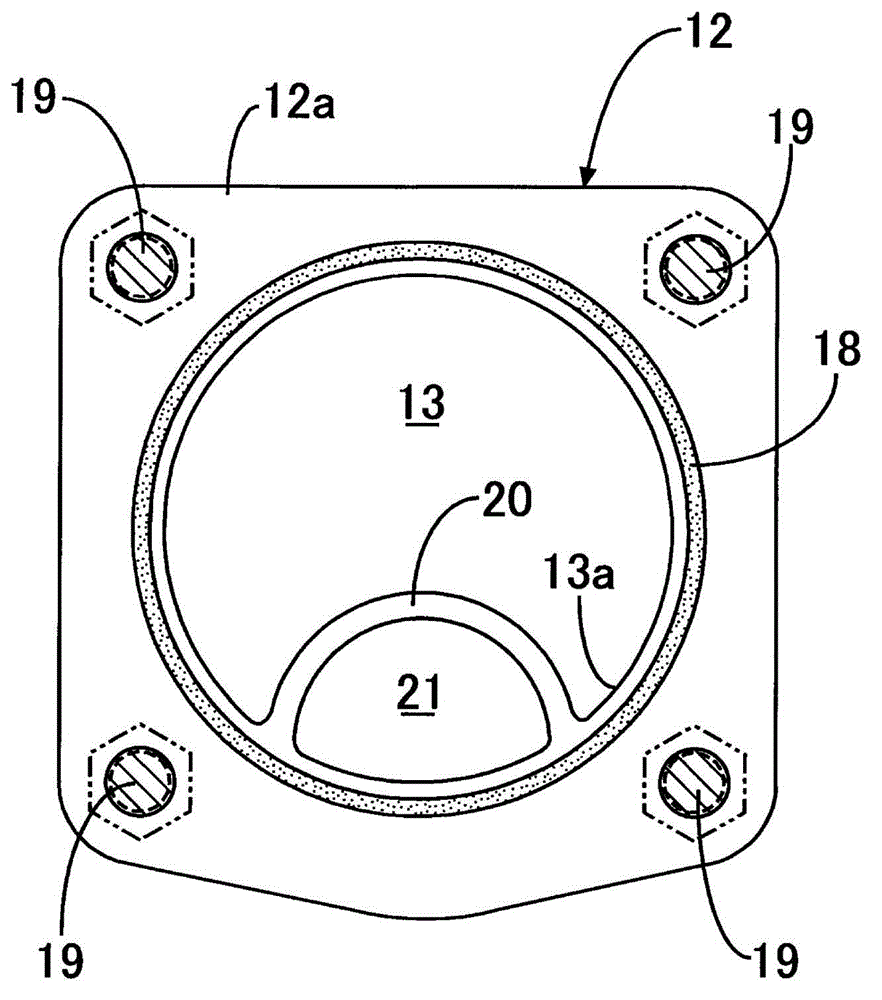

[0030] An intake device for supplying intake air to a combustion chamber of an internal combustion engine includes a throttle valve 11 on the upstream side and an intake pipe 12 on the downstream side. An air cleaner (not shown) is connected upstream of the throttle valve 11 , and a cylinder head (not shown) is connected downstream of the intake pipe 12 . An intake passage 13 through which intake air flows is formed inside the throttle valve 11 and the intake pipe 12 .

[0031] Throttle valve 11 has: throttle valve body 14, and it is penetrated for the intake passage 13 of circular section; Valve rod 15, it is set to intersect with intake passage 13; And disc-shaped spool 16, it is fixed on valve The rod 15 is driven by an electric actuator 17 to rotate within a predetermined angle range. The throttle body 14 and the intake pipe 12 are joined together by fastening flanges 14 a , 12 a formed at their opposite ends with bolts 19 . . . via an O-ring 18 .

[0032] When the valve...

no. 3 approach

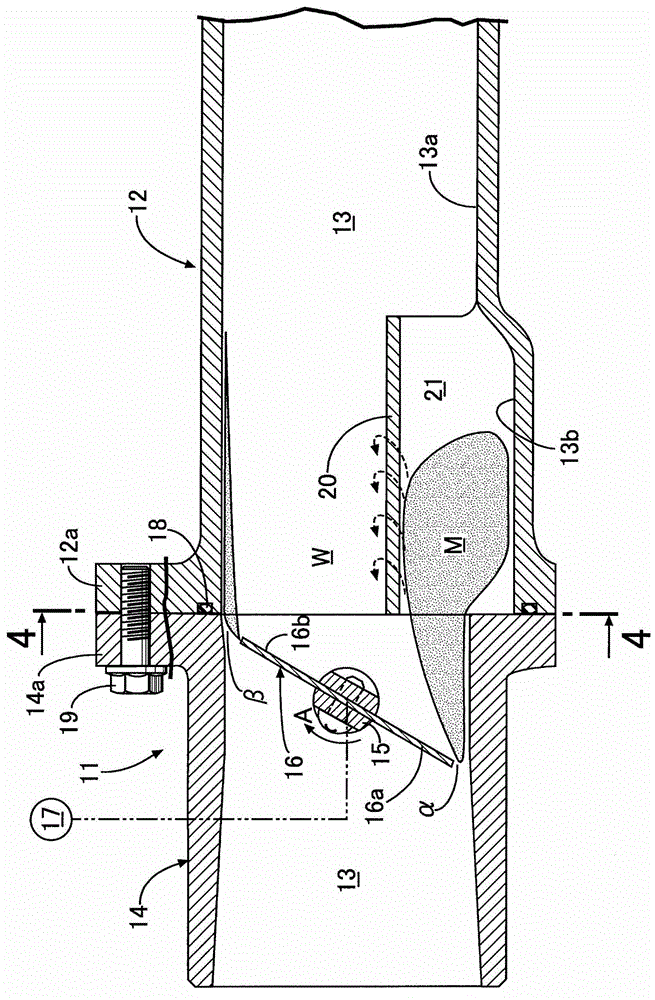

[0042] The third embodiment is a modification of the second embodiment in which the recess 13b is provided in the intake passage 13. In the second embodiment, the cross section of the first partition 20 is arc-shaped, while in the third embodiment The plate 20 is formed in a trapezoidal shape in section. In addition, the central portion of the flat second partition plate 22 arranged above the first partition plate 20 is connected to the central portion of the first partition plate 20 , and both ends of the second partition plate 22 are connected to the wall surface of the intake passage 13 . 13a connection.

[0043] As a result, since the rigidity of the first partition 20 is increased by the second partition 22, the first partition 20 is prevented from vibrating due to the air flow, and the generation of secondary intake air due to the vibration of the first partition 20 can be suppressed. noise. Moreover, two second flow paths 23, 23 with triangular cross-sections are form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com