Multi-cylinder rotary type compressor

a rotary type, compressor technology, applied in the direction of positive displacement liquid engine, piston pump, liquid fuel engine, etc., can solve the problems of enlarged intake loss, severe vibration, and intake noise, and achieve the effect of increasing the cross-sectional area of the intake port and reducing the intake loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Reference will now be made in detail to illustrative, non-limiting embodiments of the invention, examples of which are illustrated in the accompanying drawings, wherein like reference numerals refer to the like elements throughout the drawings. The embodiments are described below to explain the invention by referring to the figures.

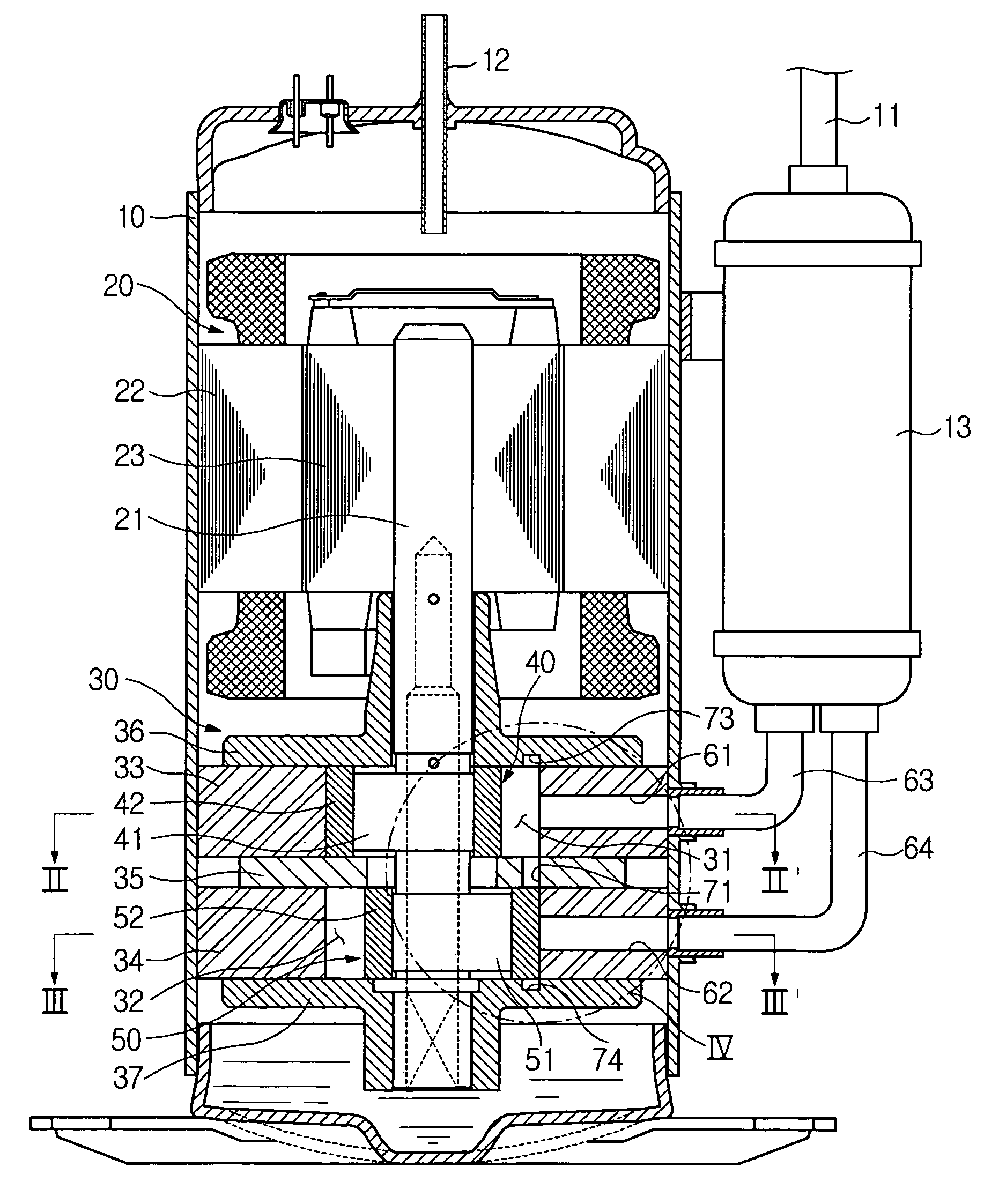

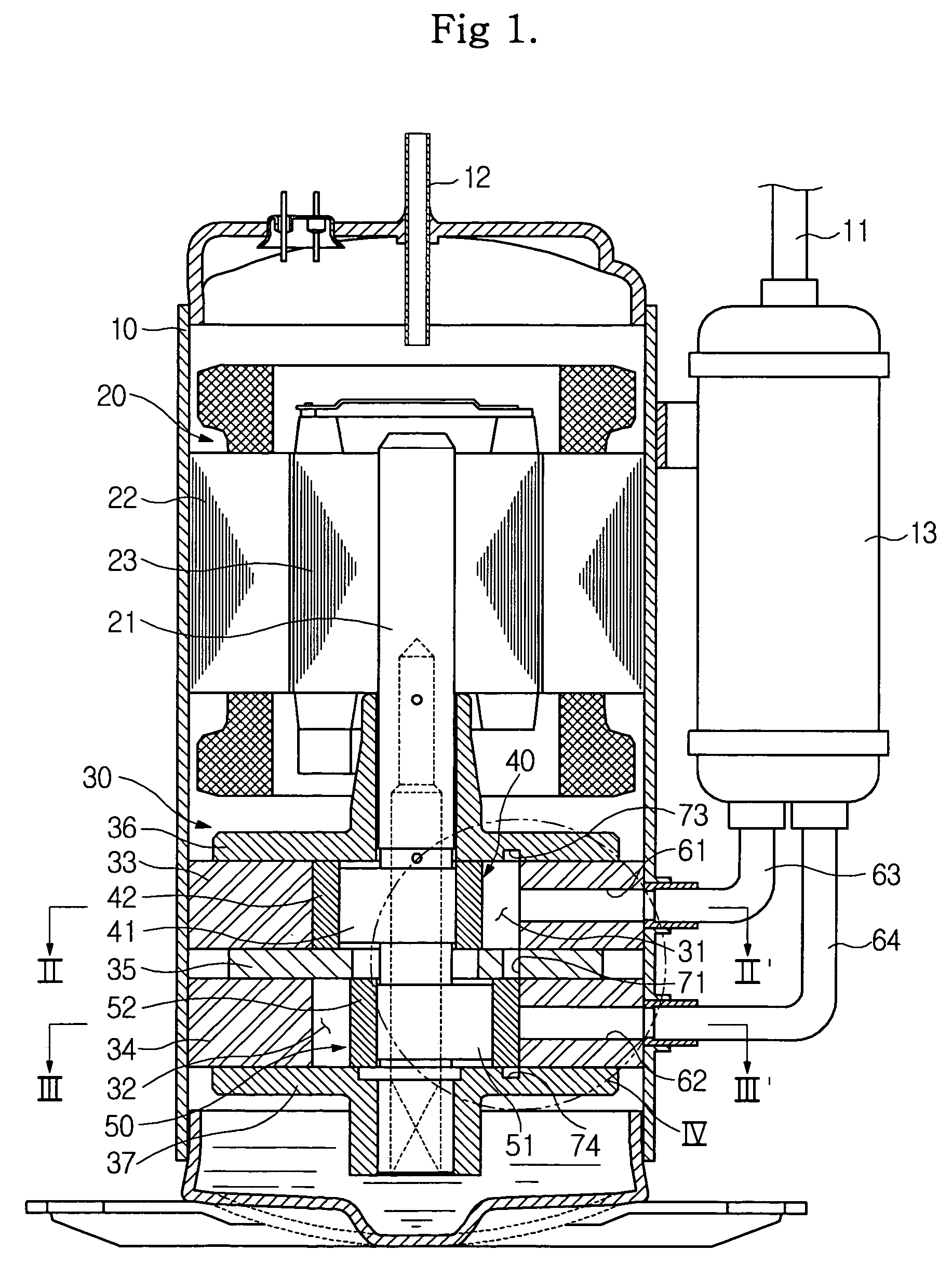

[0029] Referring to FIG. 1, a multi-cylinder rotary type compressor in accordance with one embodiment of the invention comprises a motor 20 disposed at an upper portion inside a closed container 10 to generate a rotational force, and a compressing part 30 disposed at a lower portion inside the closed container 10 while being connected to the motor 20 through a rotational shaft 21.

[0030] The motor 20 includes a cylindrical stator 22 fixed to an inner surface of the closed container 10, and a rotor 23 rotatably installed inside the stator 22 while being coupled at the center of the rotor 23 to the rotational shaft 21.

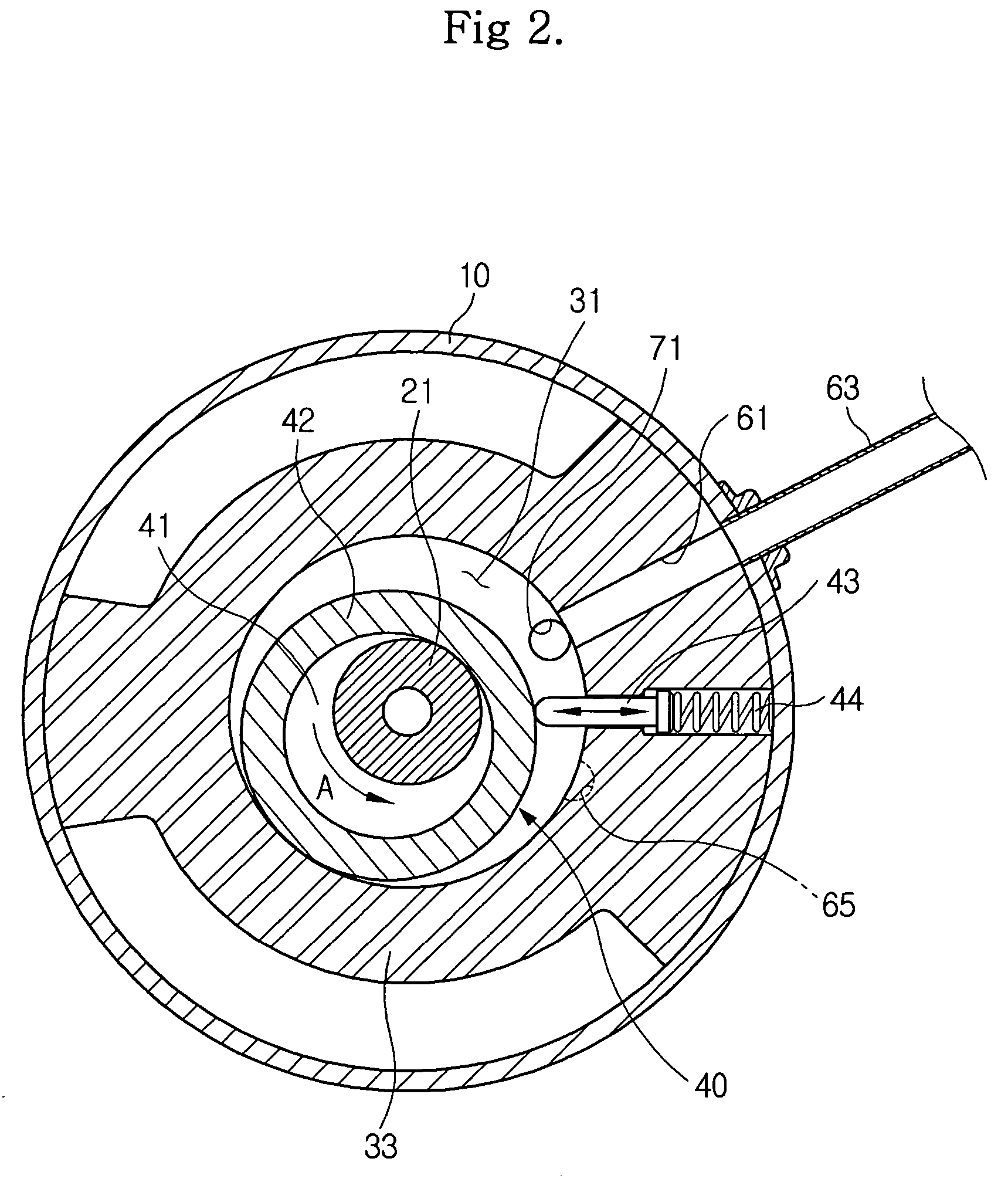

[0031] As shown in FIGS. 1 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com