Piston valve air suction non-lubricated air compressor

An air compressor and oil-free lubrication technology, which is applied in the field of air compressors, can solve the problems of occupancy, many intake check valve components, and low volumetric efficiency of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

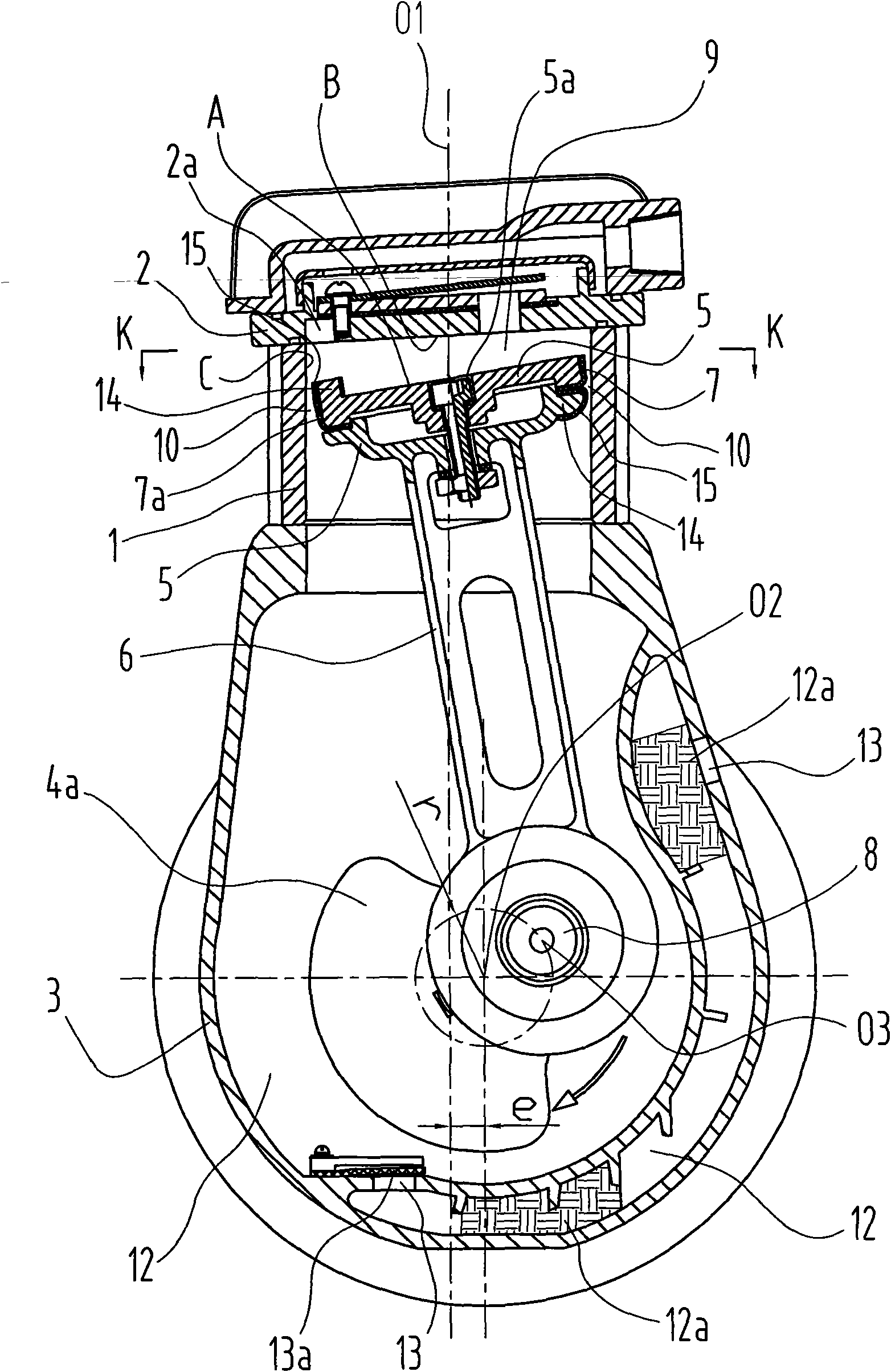

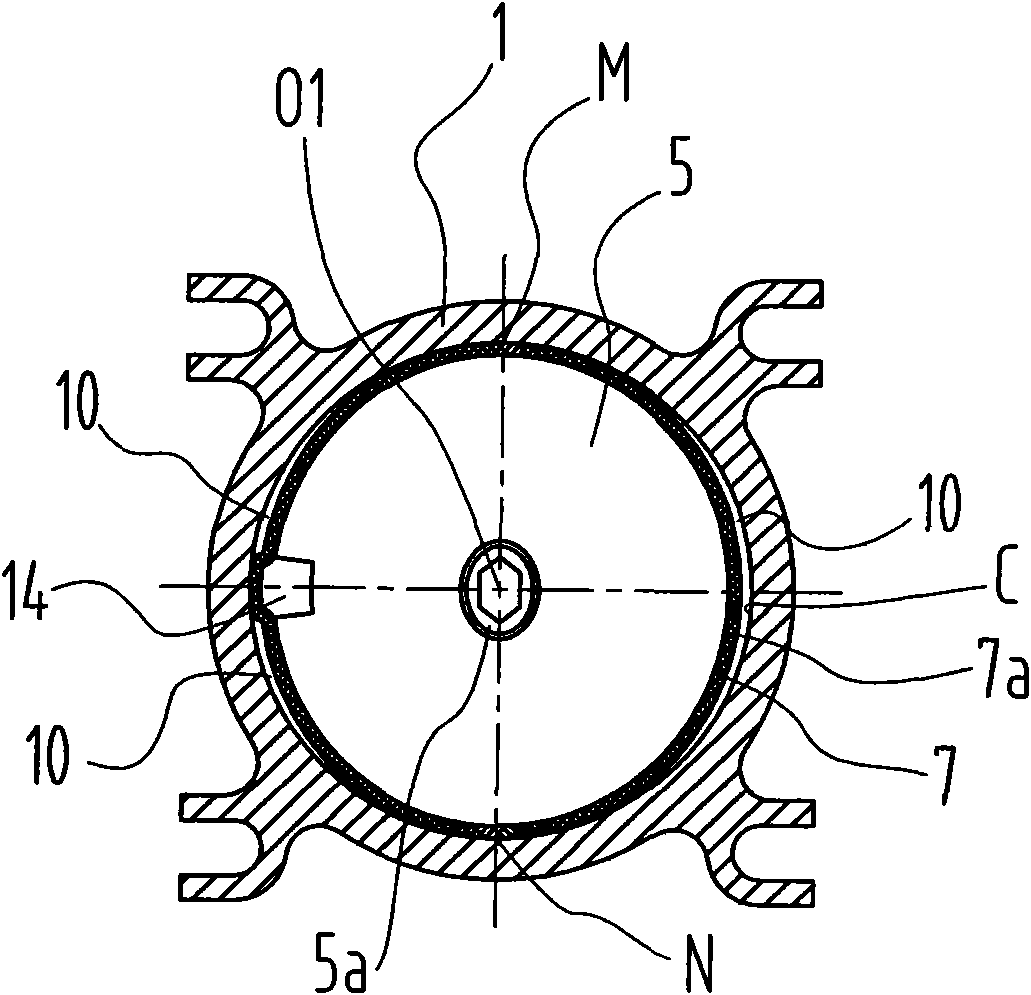

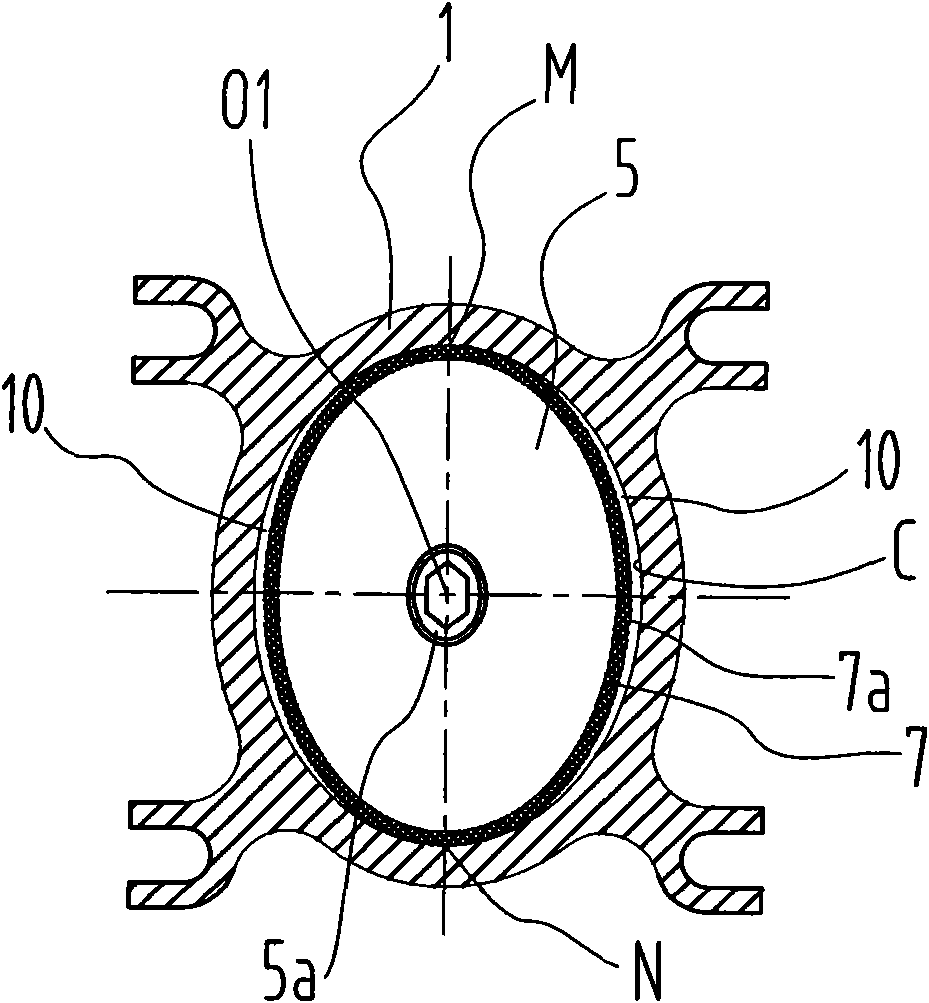

[0027] The present invention will be further described below with specific embodiment, see Figure 1-10 :

[0028] Piston valve-controlled air intake oil-free lubricated air compressor, including: cylinder 1, cylinder head 2, crankcase 3, crankshaft, crank 4, piston 5 and connecting rod 6, the piston 5 is tightly connected to the connecting rod 6 or the piston 5 and the connecting rod 6 are integrally made, and the piston 5 is equipped with a sealing ring 7 and is placed in the cylinder 1 to cooperate with the cylinder 1. The crankshaft includes a straight shaft, a crank 4 and a crank pin 8. One end of the connecting rod 6 is rotatably fitted on the crank pin 8 with a bearing structure, and the working top surface A of the piston 5, the working bottom surface B of the cylinder head 2, and the inner hole wall surface C of the cylinder 1 jointly participate in the work of enclosing the compressor. Chamber 9, and of course various seals, airway surfaces, fasteners and exhaust va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com