Method and device for transportation

A technology of conveying direction and conveying parts, which is applied in the field of conveying, and can solve the problems of insufficient high-speed and stable conveying of articles, wrinkling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

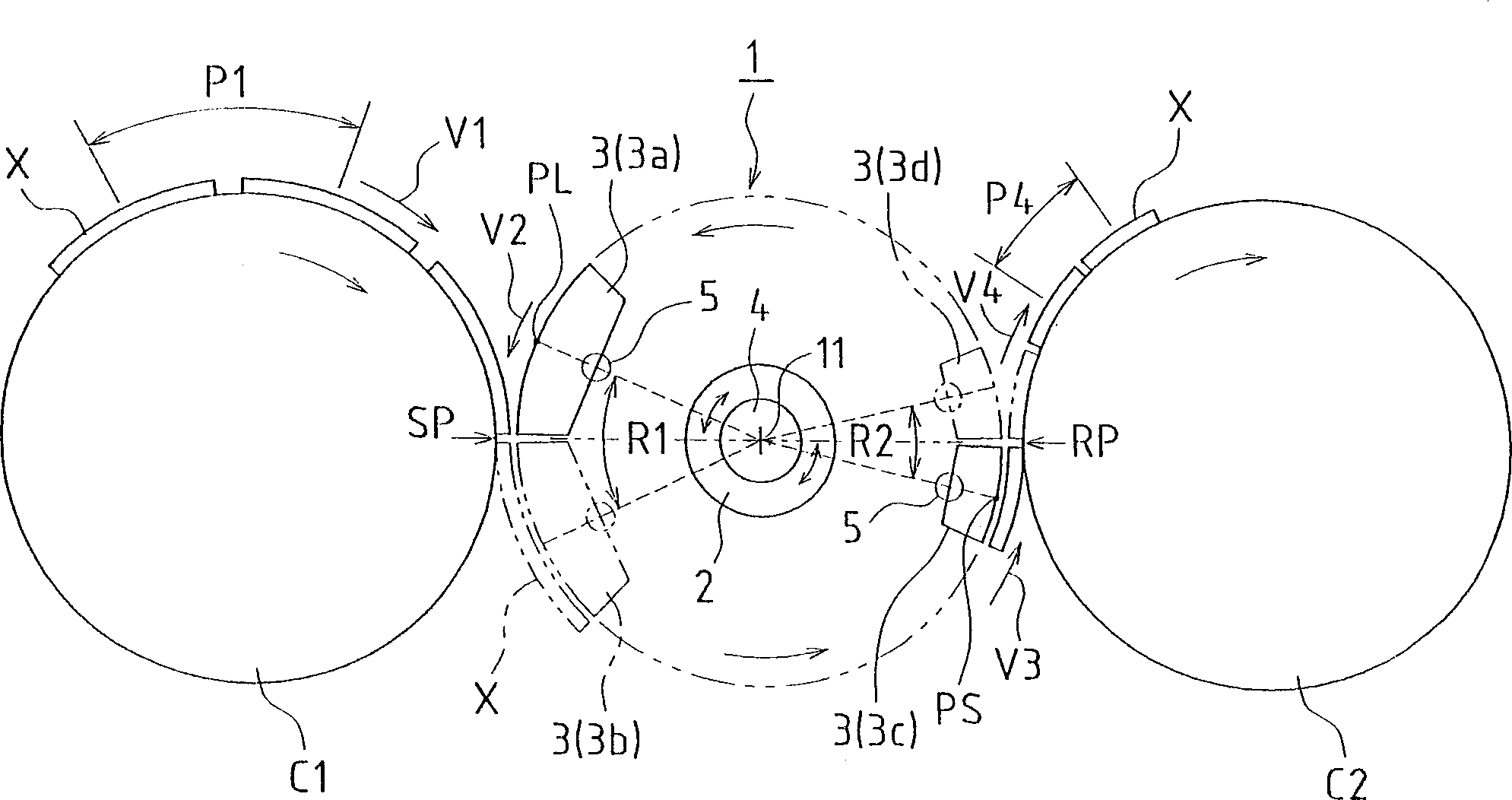

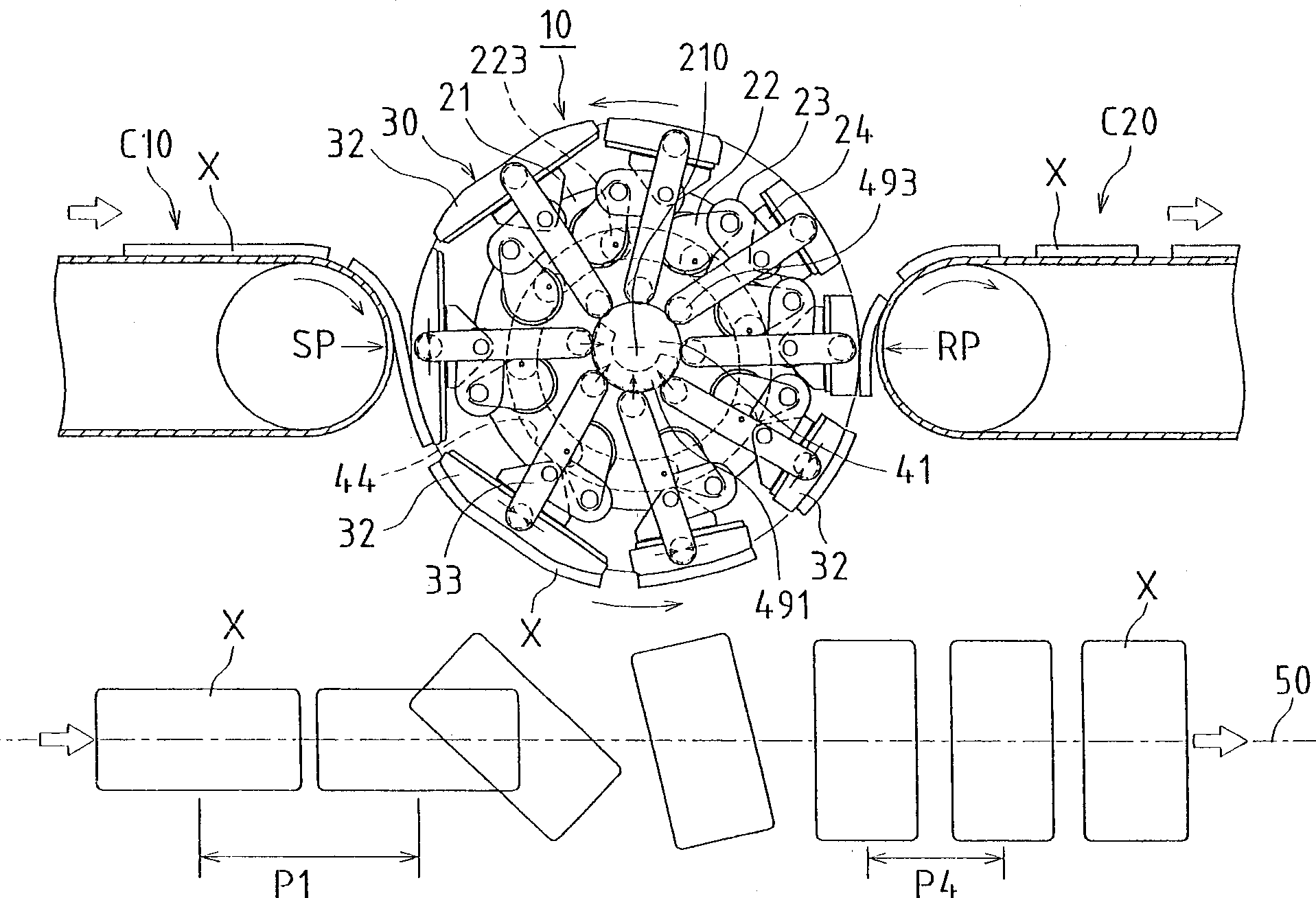

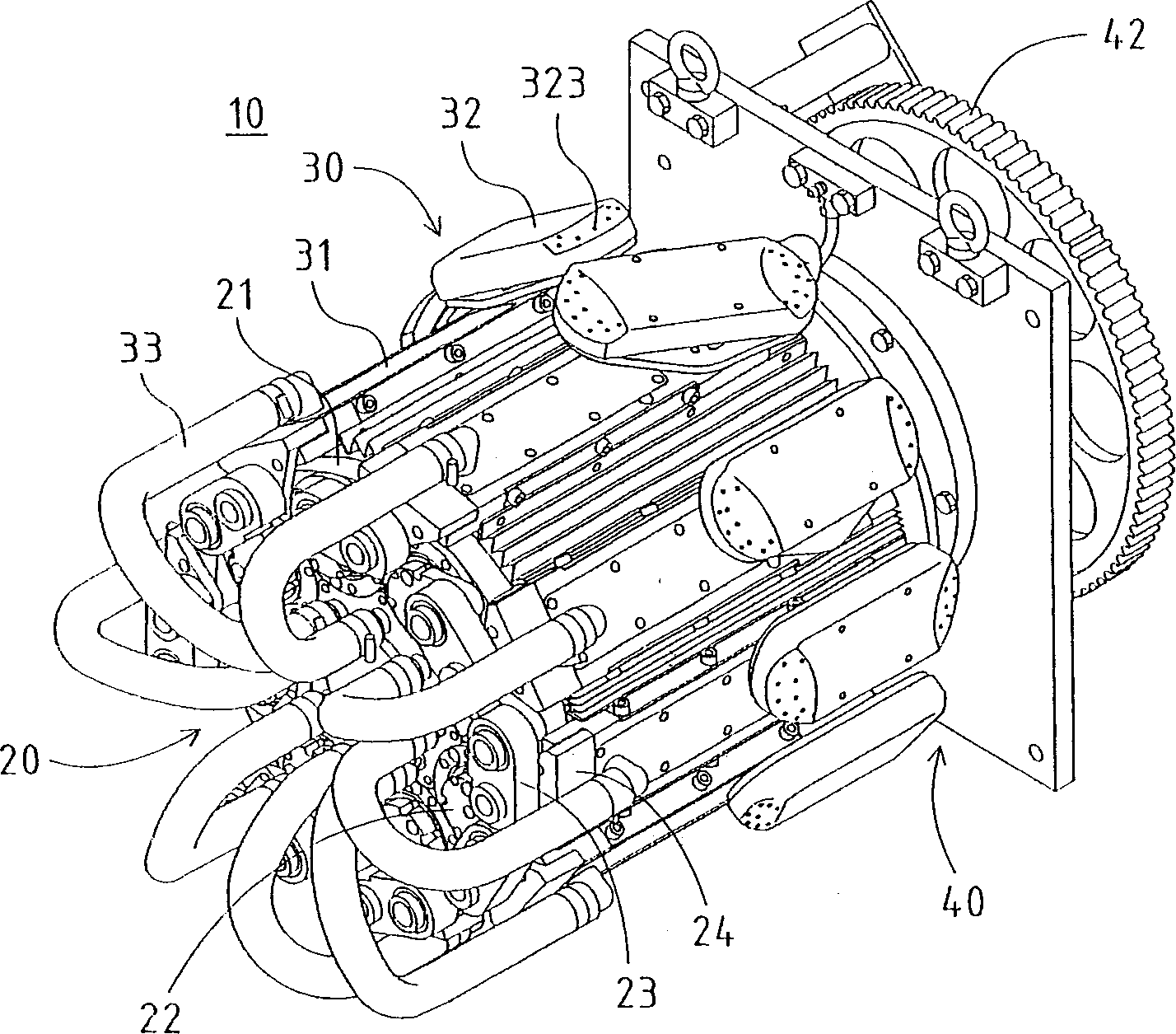

[0038] An embodiment of the present invention will now be described with reference to the drawings.

[0039] Figure 2 to Figure 4 The operation and general structure of the delivery device 10 according to the invention is shown. The conveying device 10 includes a substantially cylindrical rotor that can rotate around a rotating shaft 210 and is disposed between the previous conveyor belt C10 and the rear conveyor belt C20 . Both the shown front conveyor belt C10 and the rear conveyor belt C20 carry light and soft workpiece X (such as hygienic products such as sanitary napkins) on the air-permeable conveyor belt, and use vacuum suction to absorb workpiece X and continuously convey it Artifact X. The part that attracts the workpiece X is not limited to vacuuming but can be any other attracting part, which is electrostatic attraction. The conveying parts of the previous stage and the latter stage can be drums or other devices instead of conveyor belts.

[0040] In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com