Method and device for operating station of textile machine for manufacturing cross-wound spools and station for executing the method

A technology of cross-winding bobbins and textile machines, applied in the direction of transportation and packaging, thin material handling, conveying filamentous materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

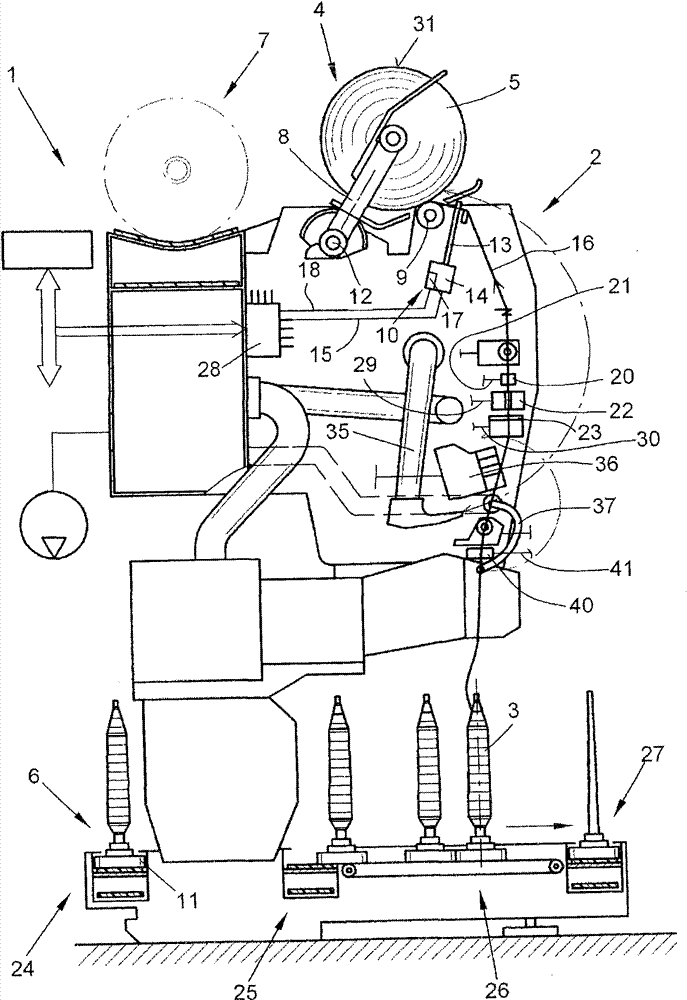

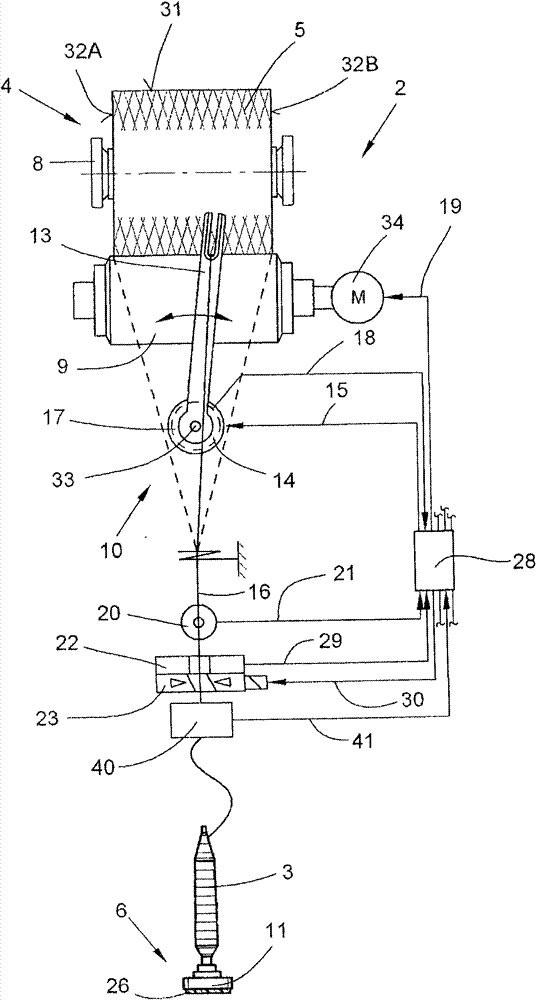

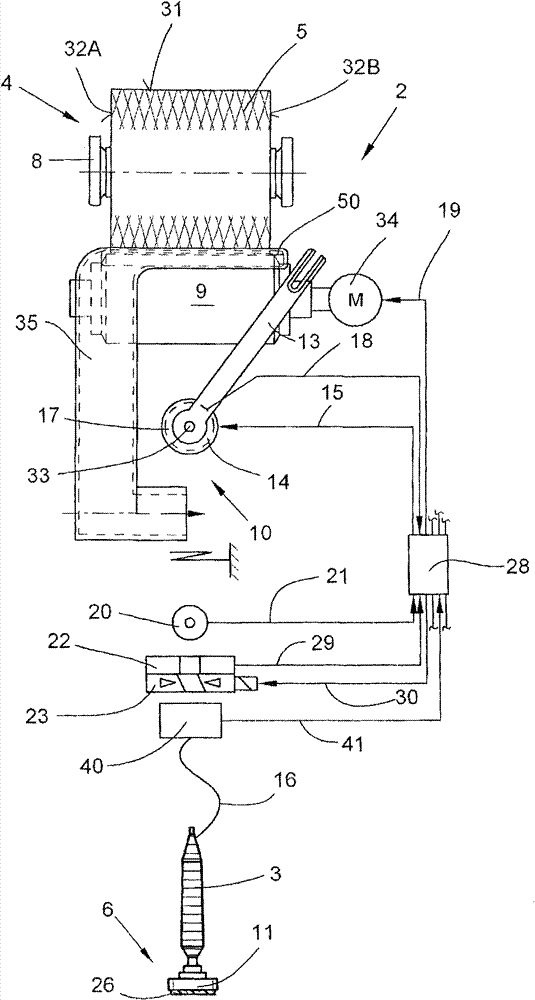

[0031] figure 1 A station 2 of a textile machine 1 for producing cross-winding bobbins, which in the present example is a so-called automatic cross-winder, is shown schematically in side view.

[0032] As is known, such an automatic crosswinder 1 each has a plurality of identically constructed stations 2 between its (not shown) end frames. As is also known and therefore not described in detail, at these winding stations 2 the spinning cop bobbins 3 produced on the ring spinning machine are rewound into bulky cross-wound bobbins 5, cross-wound After the bobbin 5 has been completed, it is transferred to a cross-wound bobbin conveyor 7 arranged along the longitudinal length of the machine by means of a service unit (not shown) such as a cross-wound bobbin changer and conveyed to the side bobbin loading station or similar.

[0033] Furthermore, such an automatic crosswinder 1 usually also has a supply device in the form of a bobbin and sleeve transport system 6 .

[0034] In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com