Patents

Literature

35results about How to "Reliable pickup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

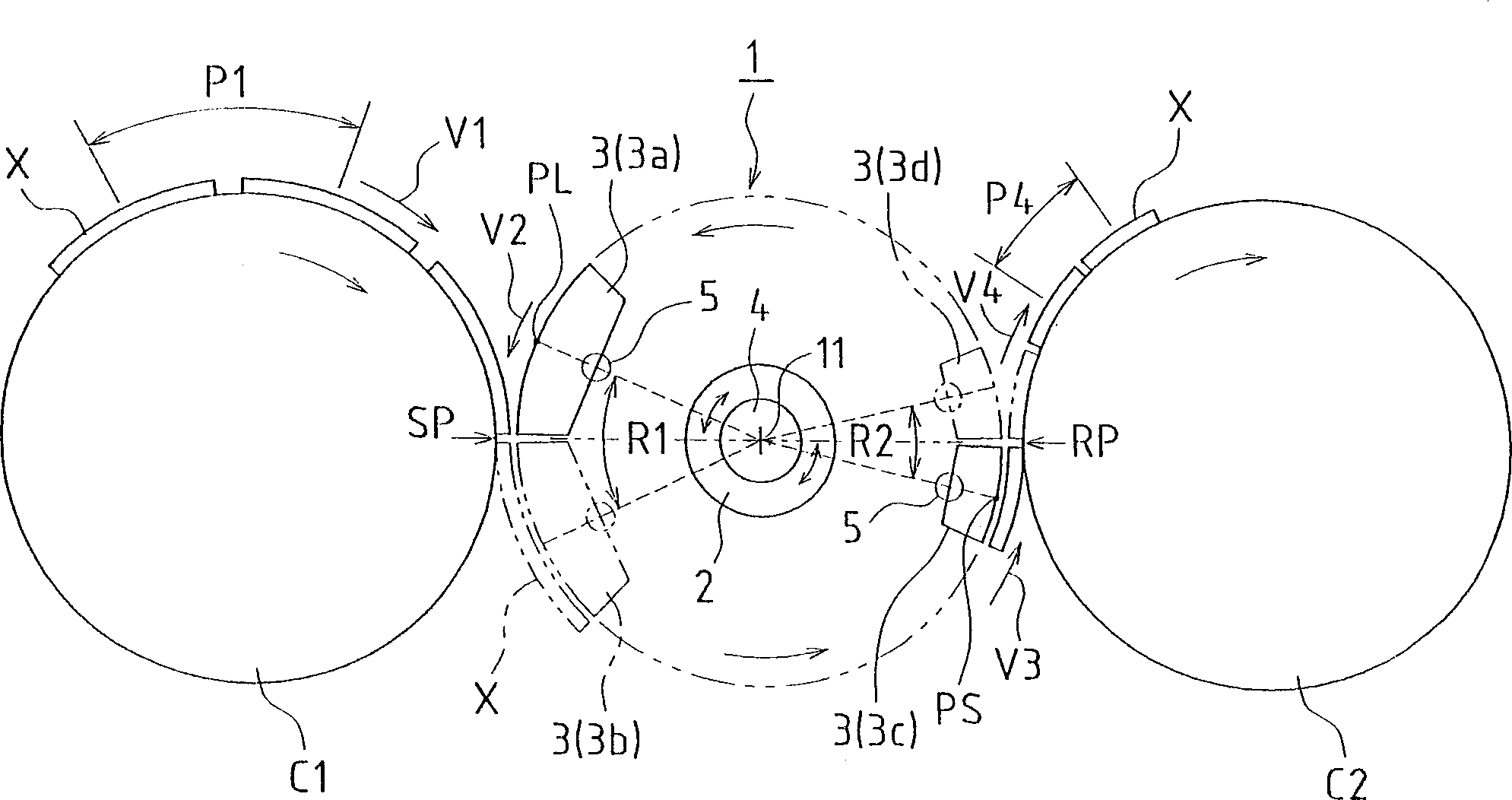

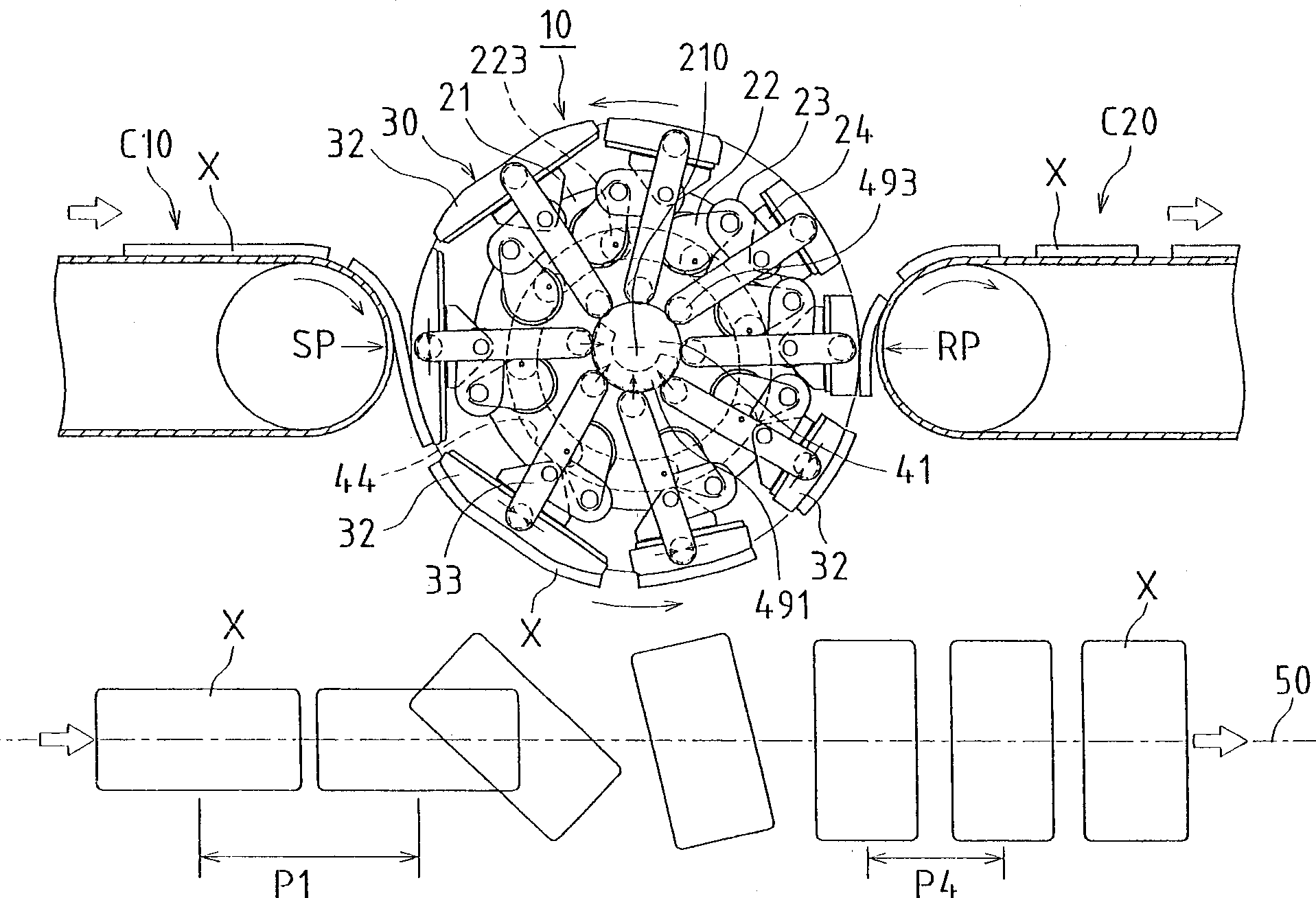

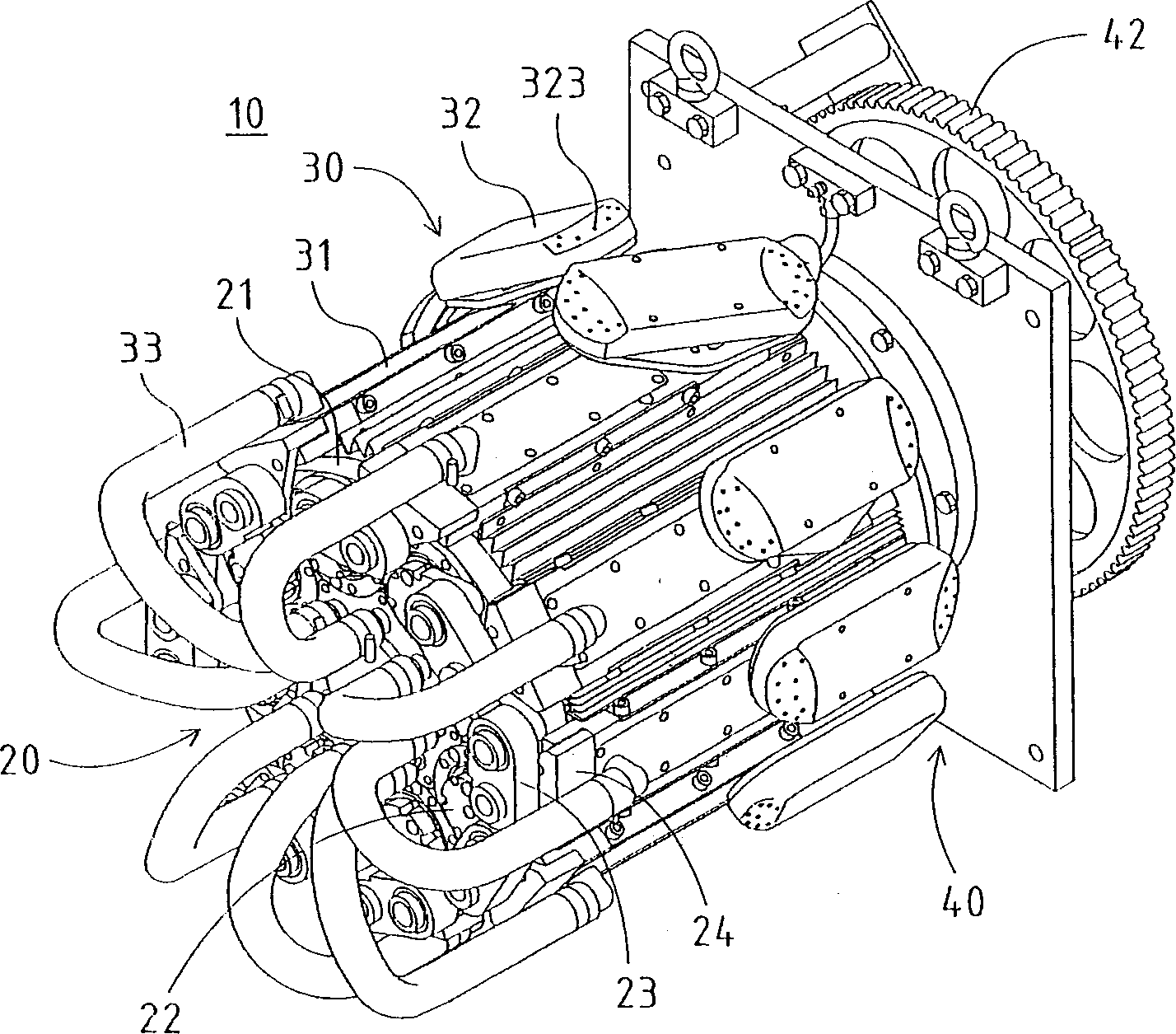

Method and device for transportation

A transportation device (10) comprising crank arms (22) installed rotatably on a drive wheel (21), link levers (23) each having one end pin-connected to the tip of each of the crank arms (22), and swing parts (30) each having the other end pin-connected to each of the link levers (23) and held at a specified distance from a rotating shaft (210) of the drive wheel (21), wherein a speed changing cam roller (223) is installed on the crank arm (22) projectedly at a position apart from the rotating center thereof, and the transmission cam roller (223) is engaged for guiding with a transmission cam groove (44) formed eccentrically with respect to the rotating shaft (210) of the drive wheel (21), whereby the tips of the crank arms (22) are swung with in one rotation frequency of the drive wheel (21), and the angular velocities of the link levers and the swing part (30) connected thereto are increased or decreased periodically relative to the angular velocity of the drive wheel (21).

Owner:ZUIKO CORP

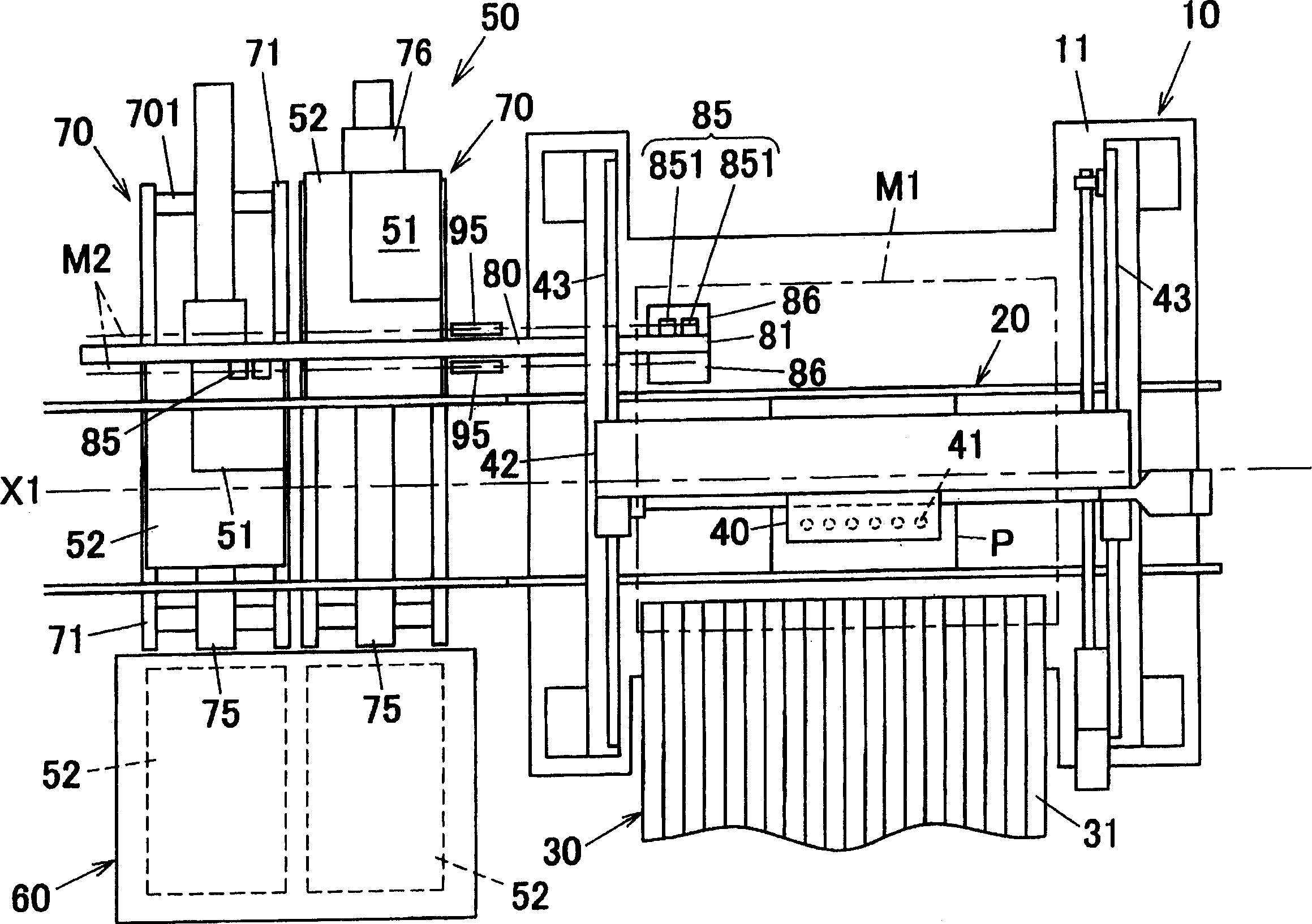

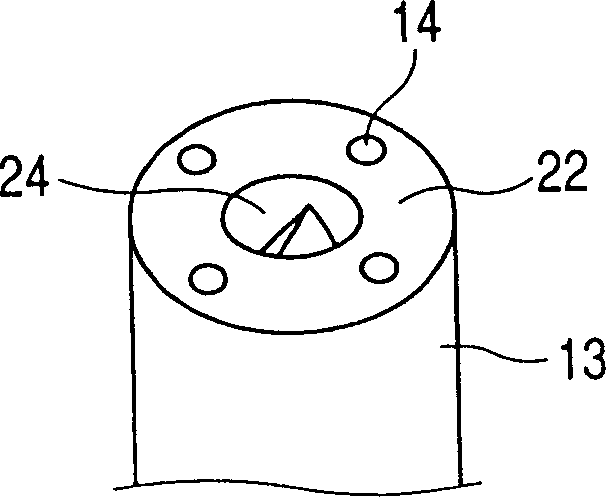

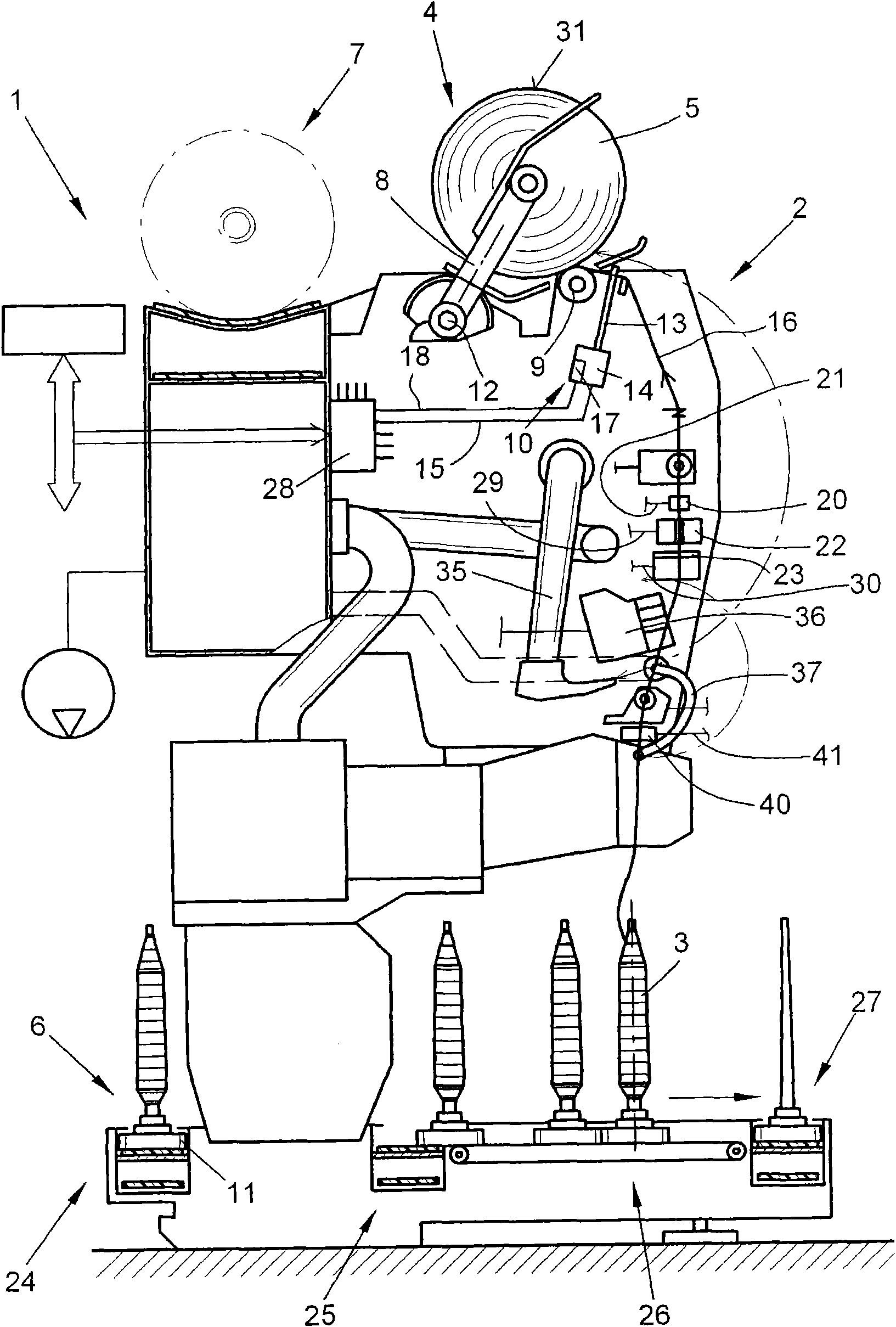

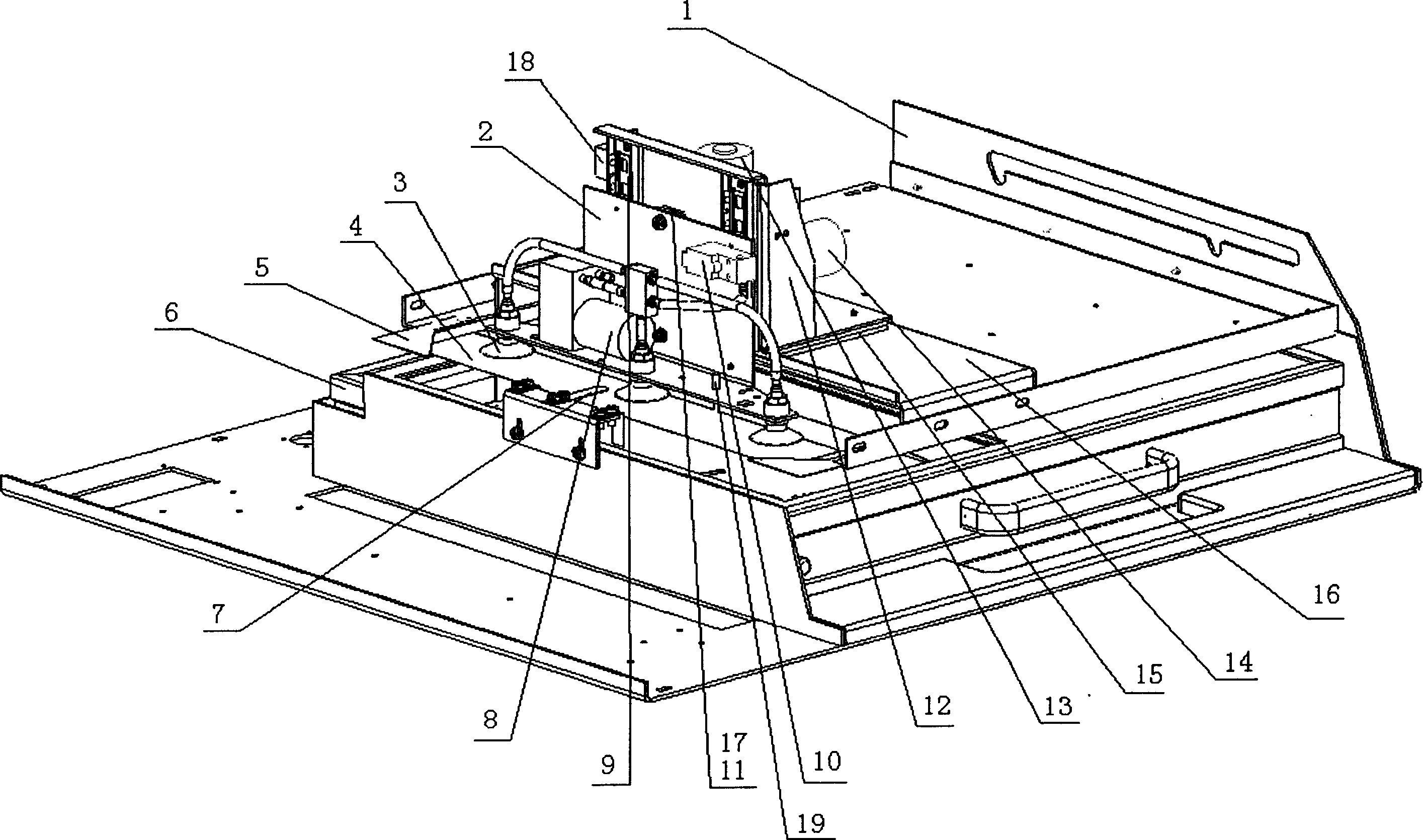

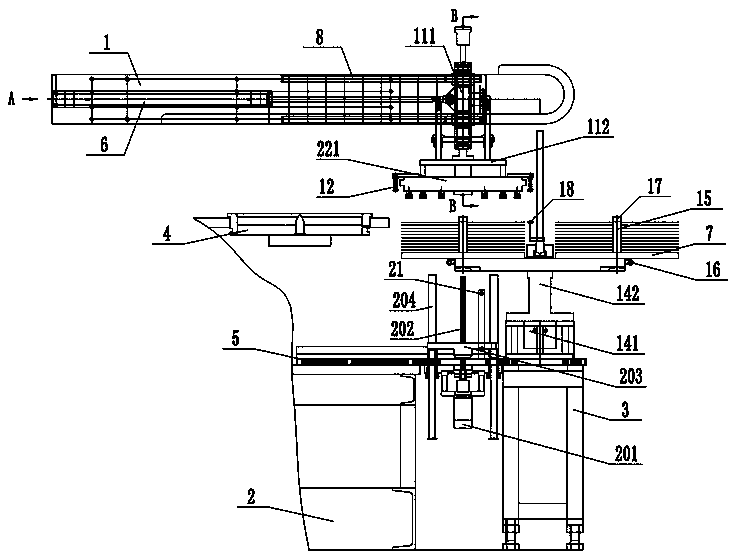

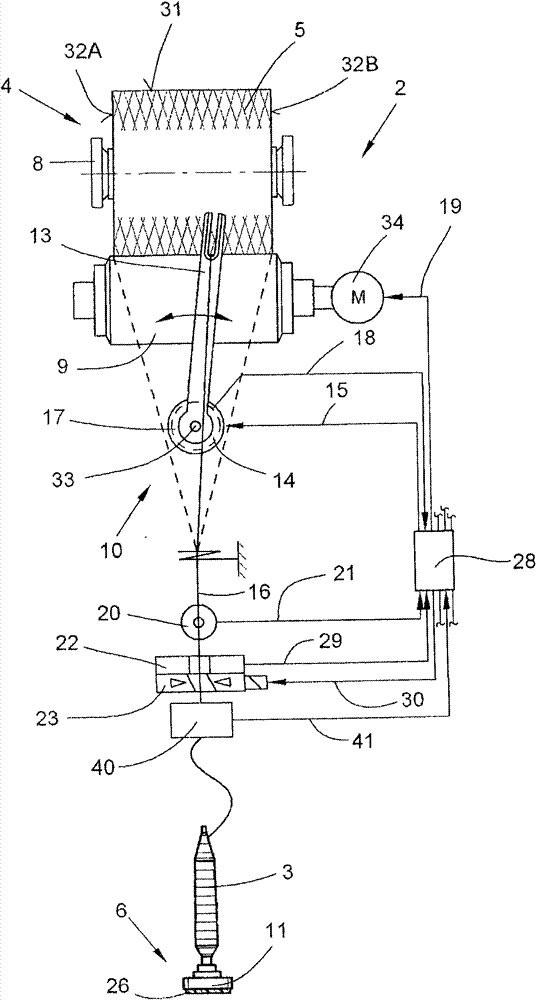

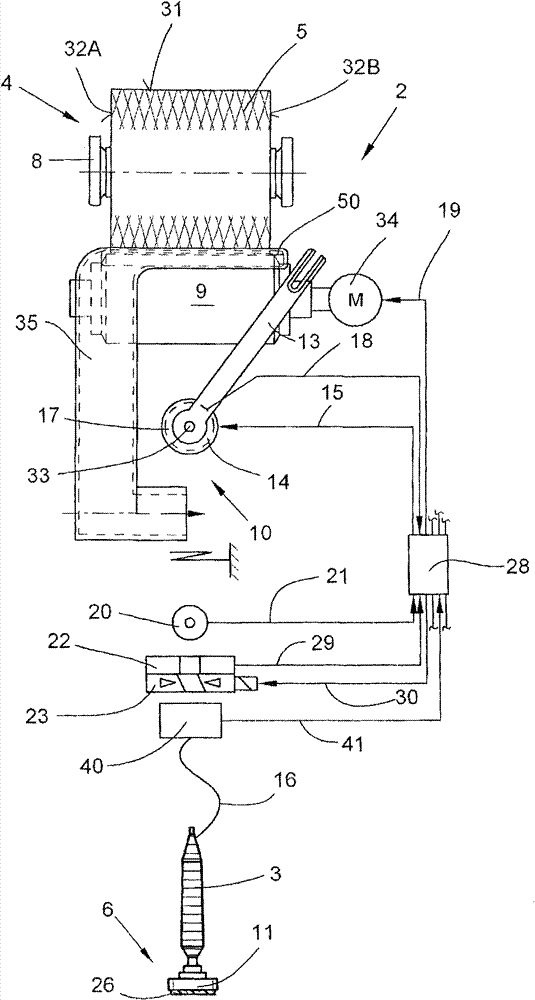

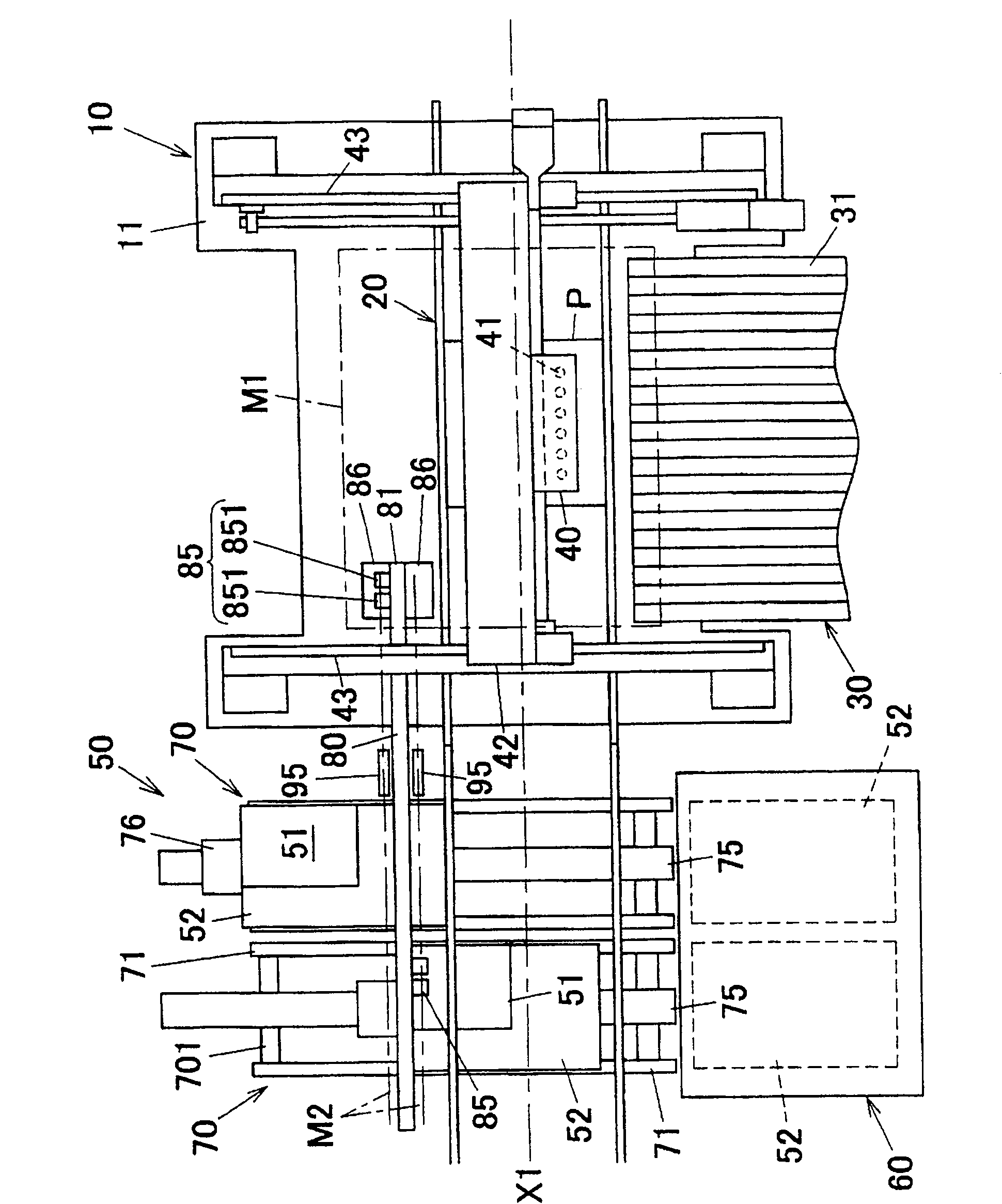

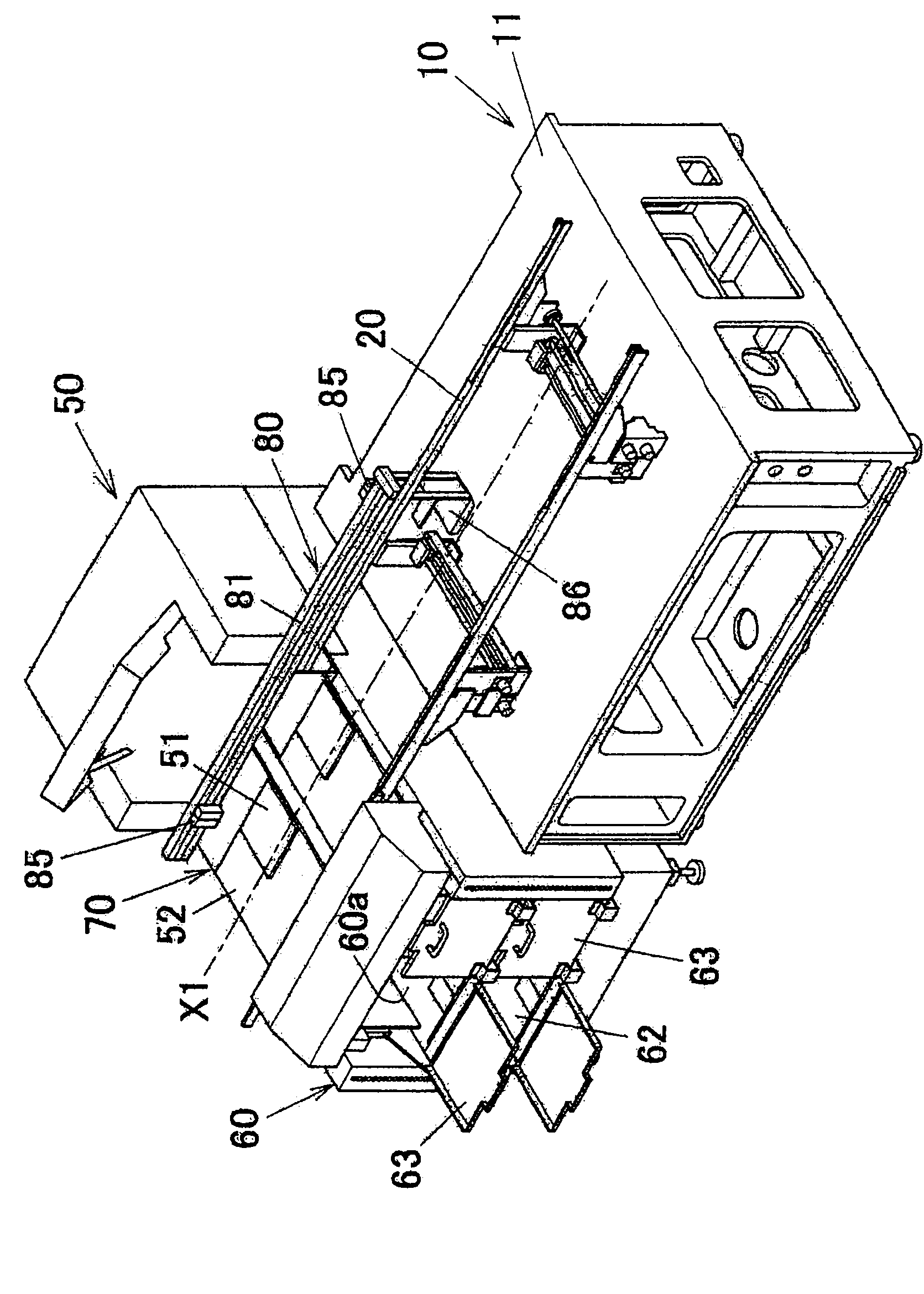

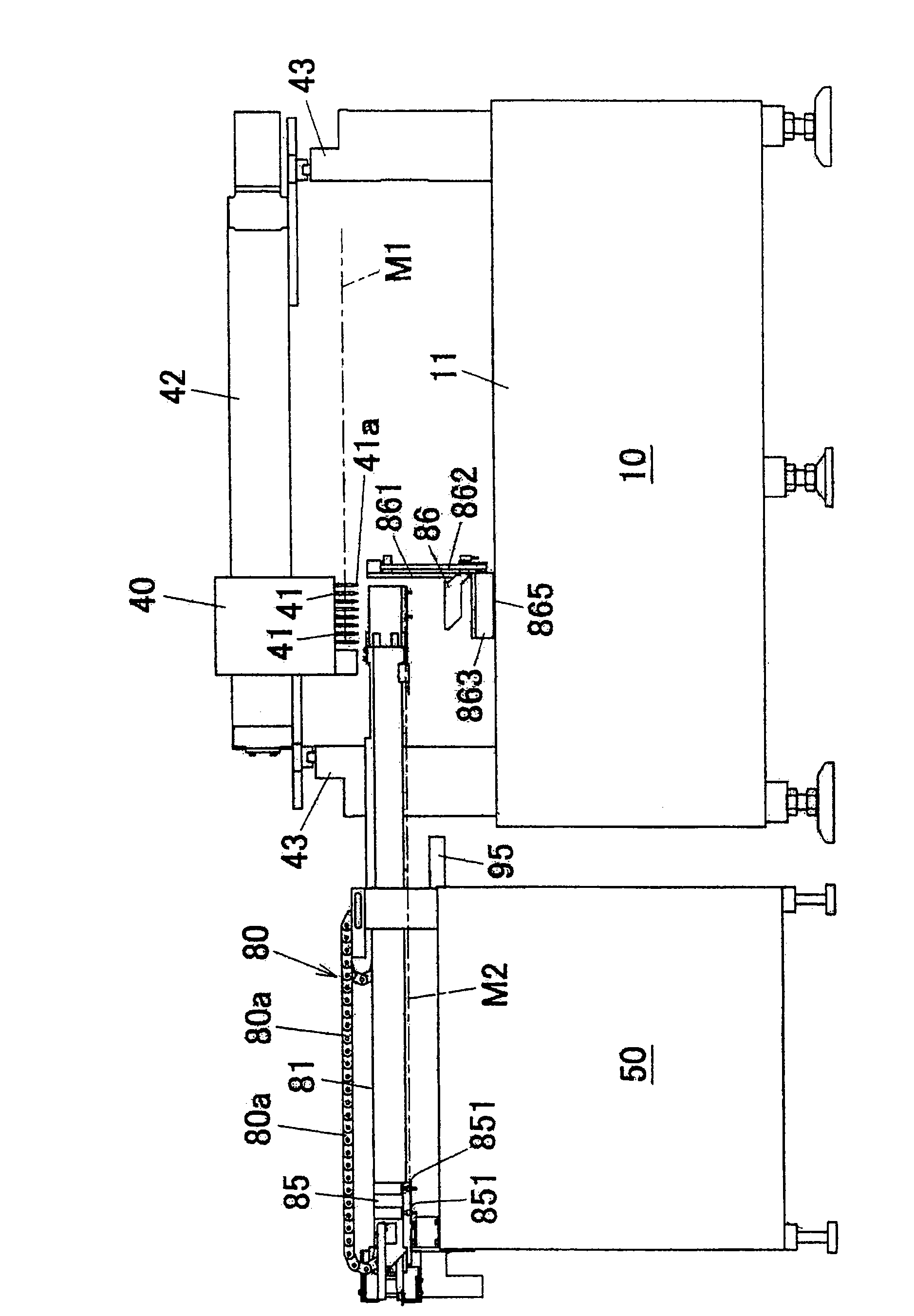

Element feeding device and mounting machine therewith

ActiveCN1705434AStable supply of electronic componentsReliable pickupElectrical componentsTransfer mechanismElectronic component

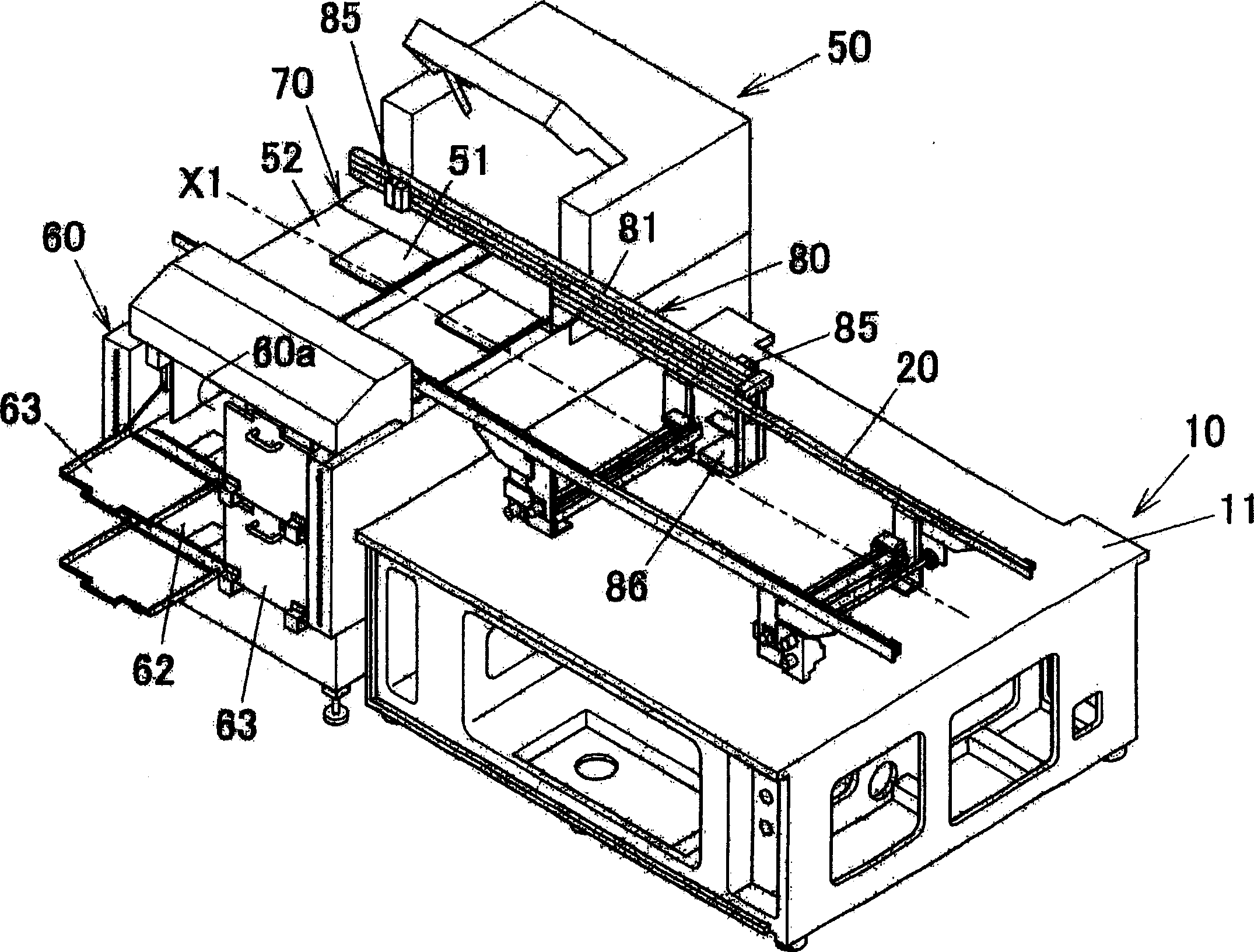

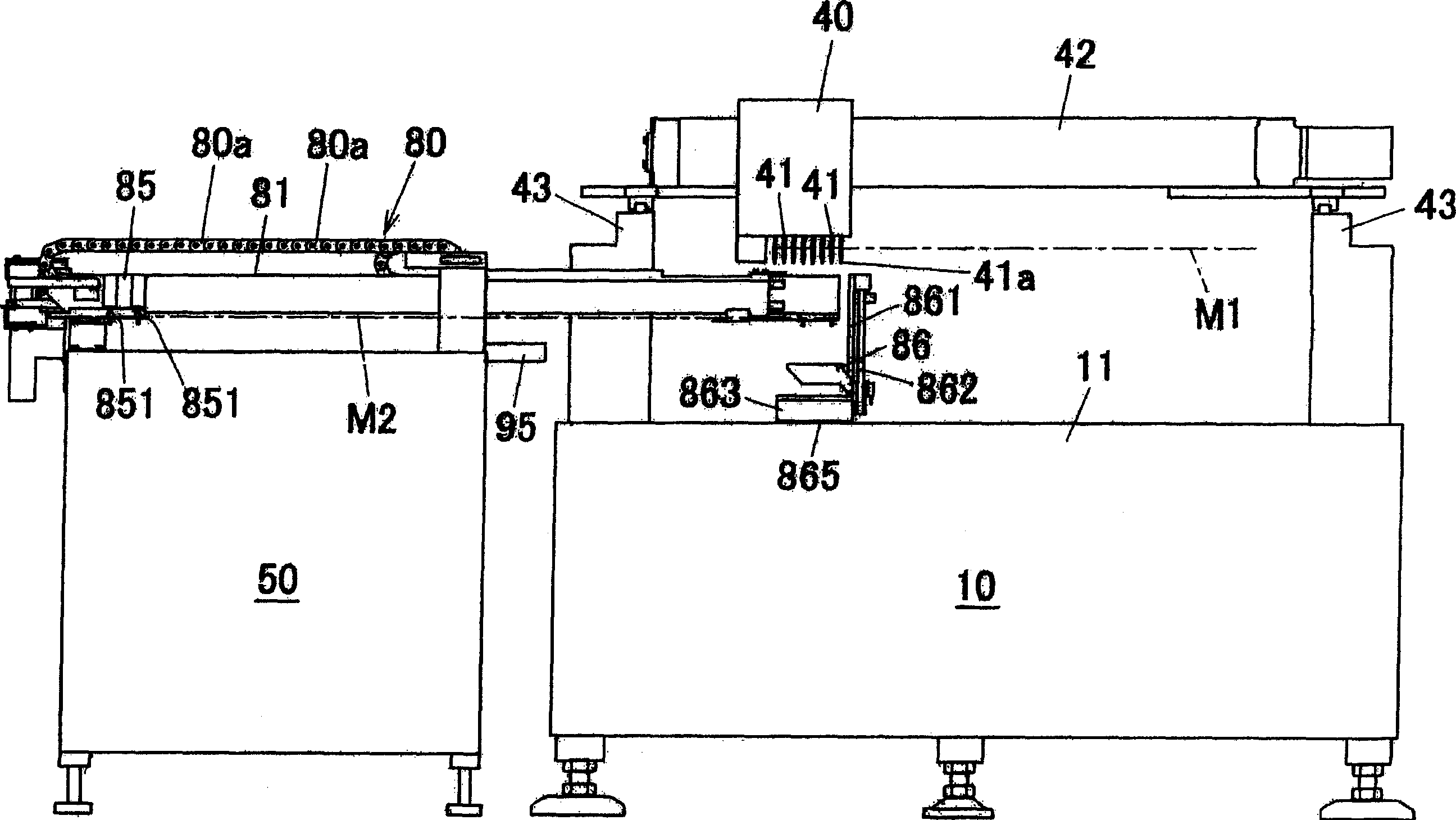

The present invention provided a component supplying apparatus that can reliably pick up electronic components and can stably supply them to a mounting machine body. The component supplying apparatus supplies the electronic components to the mounting machine body 10 for mounting the electronic components on a substrate. The component supplying apparatus comprises an accommodation section 60 for accommodating a component tray 51 for accommodating the electronic components; a component leading mechanism 70 for leading the component tray 51 from the accommodation section 60 to a pickup region; and a component transfer mechanism 80 for transferring the electronic components in a component tray at the pickup region to a component supply position for passing the electronic components to the mounting machine body 10. The component transfer mechanism 80 comprises a transfer head 851 for picking up the electronic components from the component tray 51 at the pickup region; and a transfer head travel mechanism for moving the transfer head 851 that has picked up the electronic components to a component supply position.

Owner:YAMAHA MOTOR CO LTD

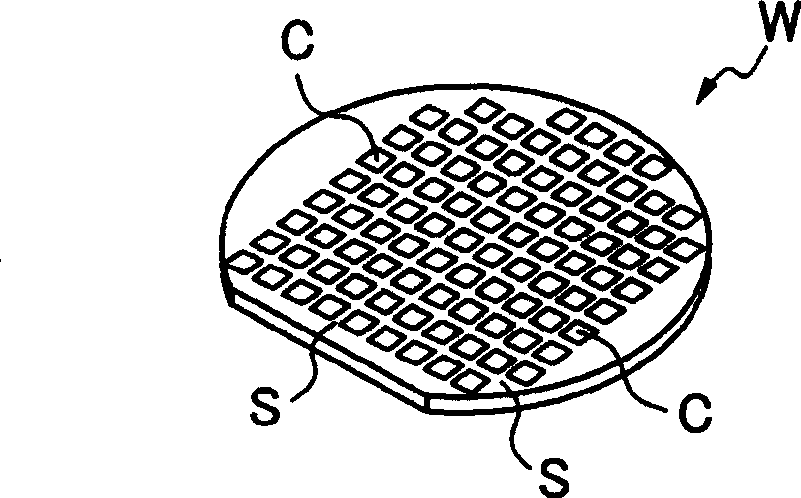

Method and apparatus for picking up work piece and mounting machine

ActiveCN1577727AMaintain a constant adsorption capacityConstant adsorption capacityLayered productsSolid-state devicesCollet

Owner:TDK CORPARATION

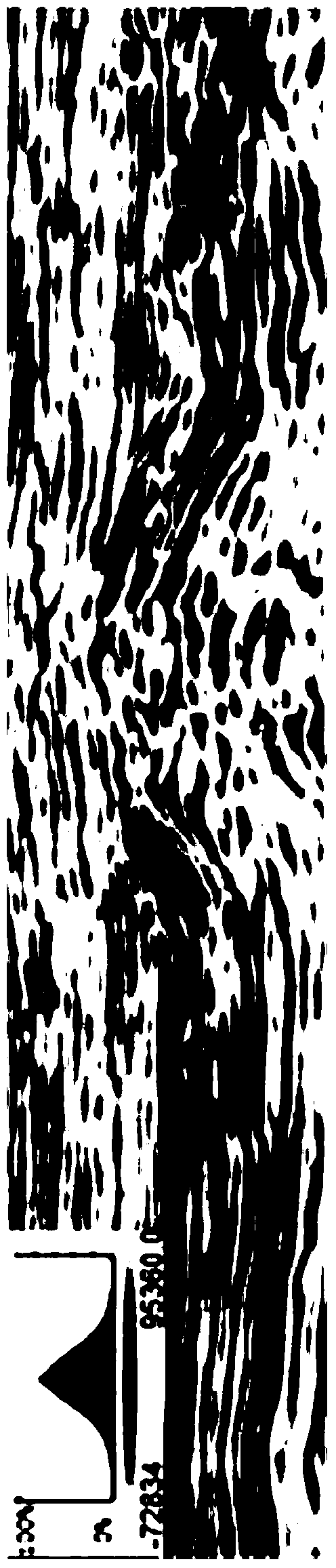

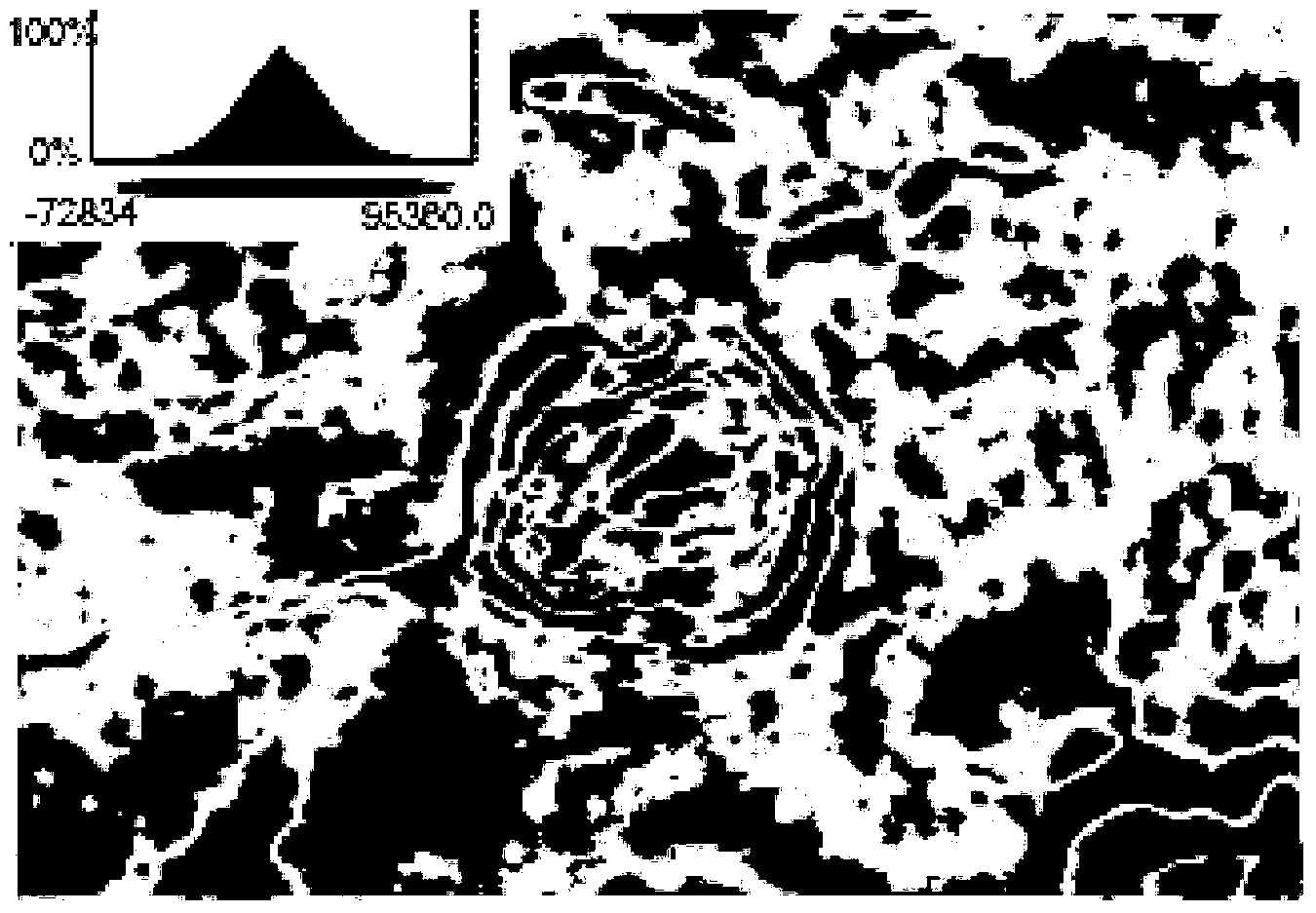

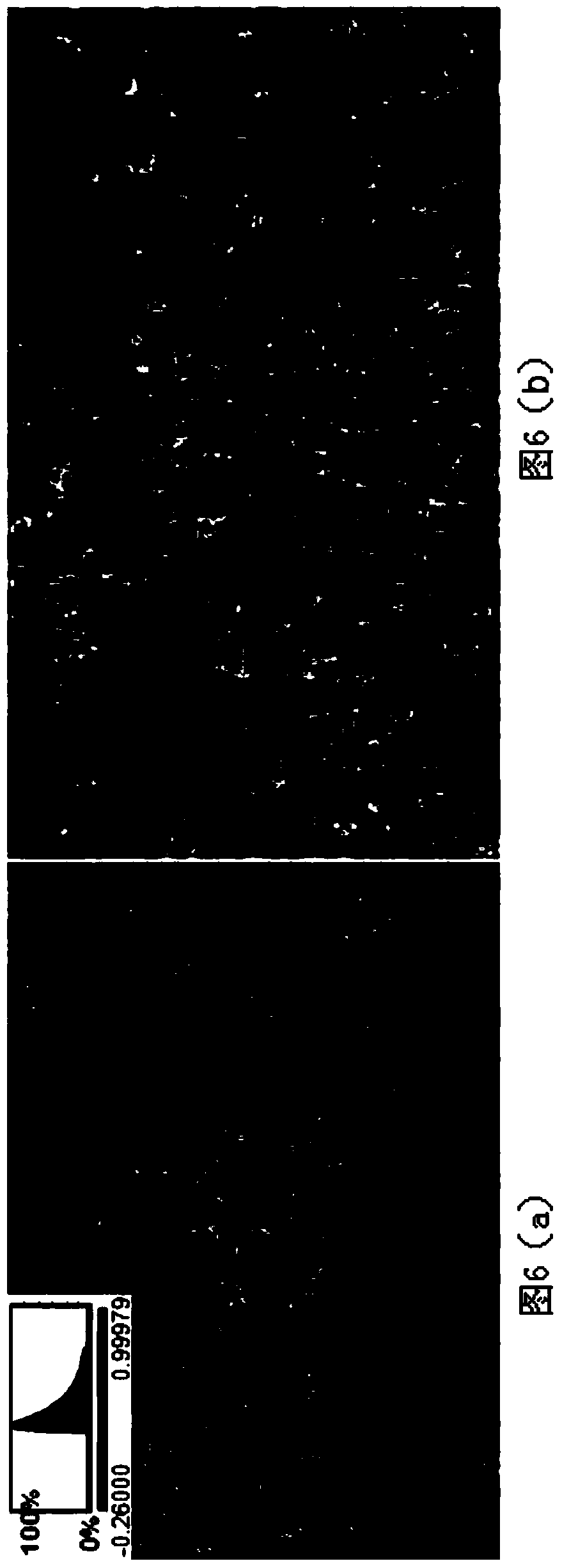

Method for depicting volcanic space distribution based on amplitude-variance cube seismic attributes

InactiveCN104007468AReliable pickupWeaken high-continuity reflexesSeismic signal processingControl functionThree dimensional display

The invention provides a method for depicting volcanic space distribution based on amplitude-variance cube seismic attributes. Strong amplitude three-dimensional seismic data are picked up to obtain volcano overflow phase data; meanwhile, volcanic vent phase data are picked up according to variance cube data, the volcanic vent phase data and the variance cube data are fused to complete the fusion depicting of an overflow phase and a vent phase. According to the method for depicting volcanic space distribution based on the amplitude-variance cube seismic attributes, the overflow phase and the volcanic vent phase are fused and displayed, three-dimensional display is achieved, and the space distribution of volcanic is visually and vividly depicted; the overflow phase and the volcanic vent phase are the two most important subphases of the volcanic, the prediction studies of a volcanic reservoir is facilitated through the fusion and display of the overflow phase and the volcanic vent phase, and the method can be widely applied to petroliferous basins related to the volcanic and especially applied to depicting of the space distribution features of the volcanic, analysis of the influences of the volcanic on the surrounding reservoirs and the control function of the volcanic activity on oil and gas accumulation.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

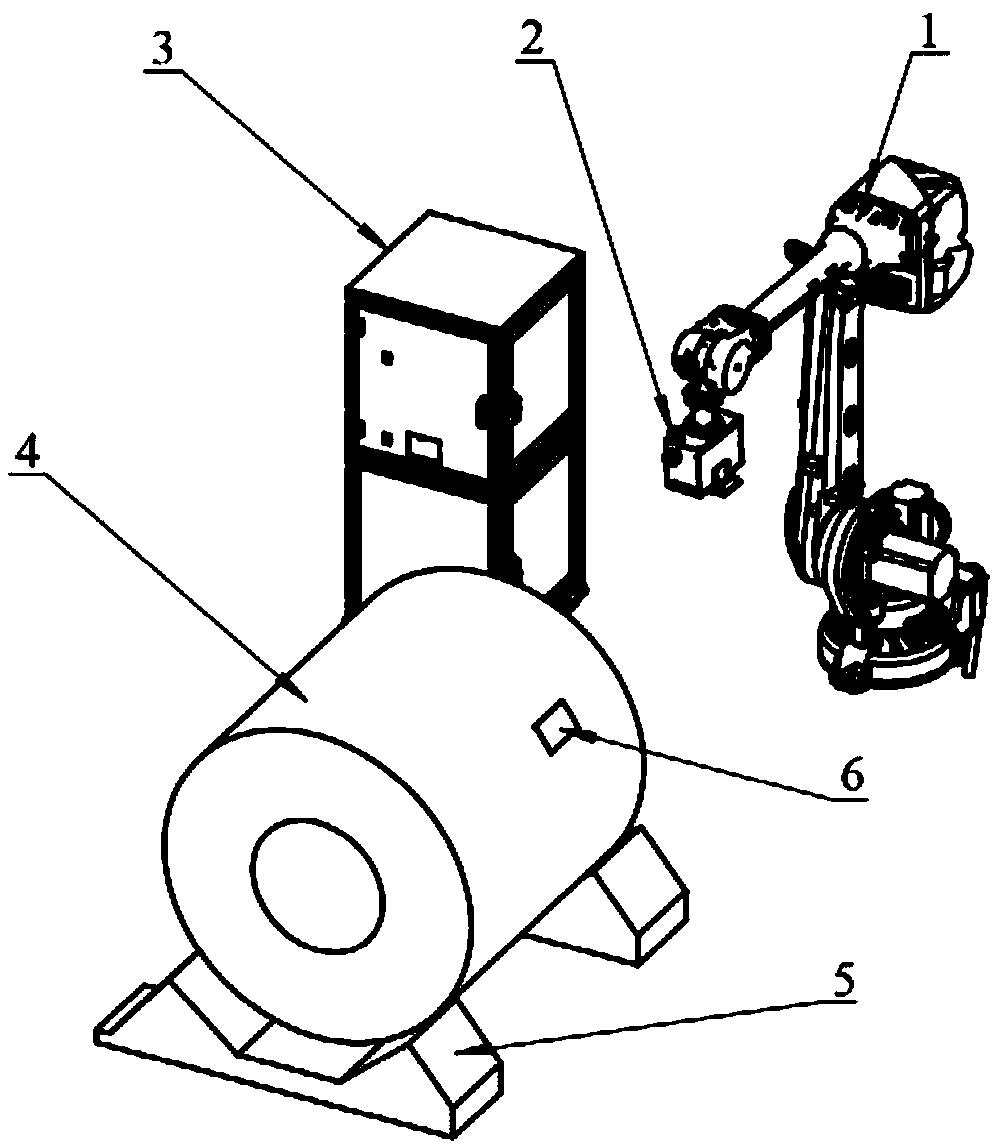

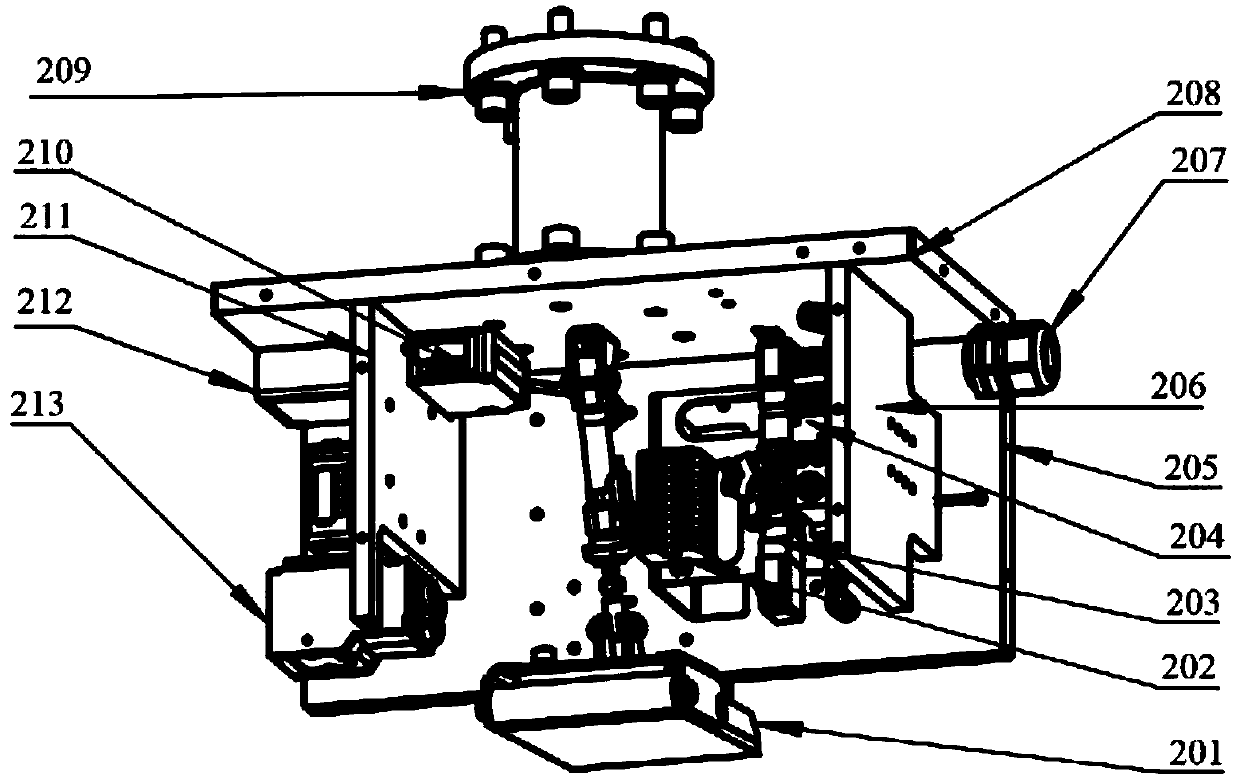

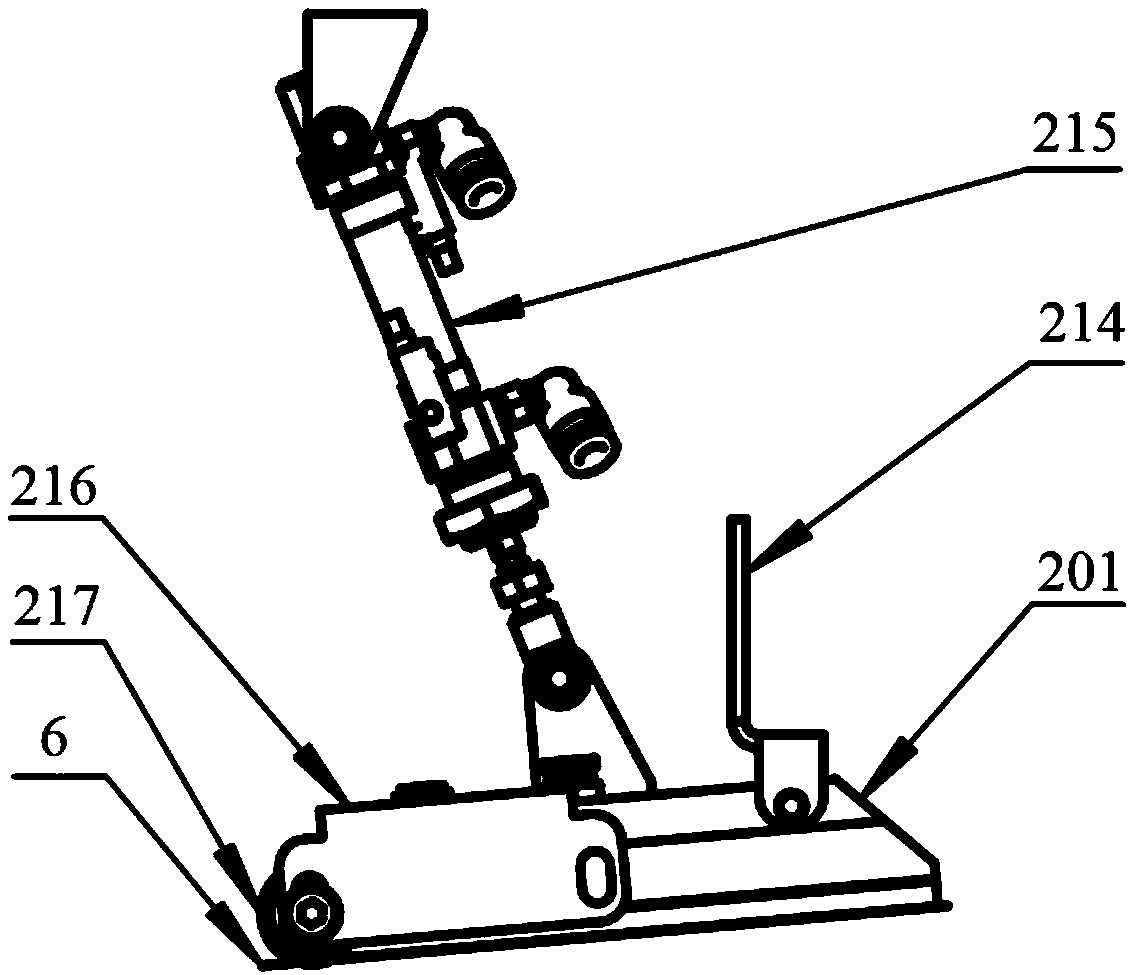

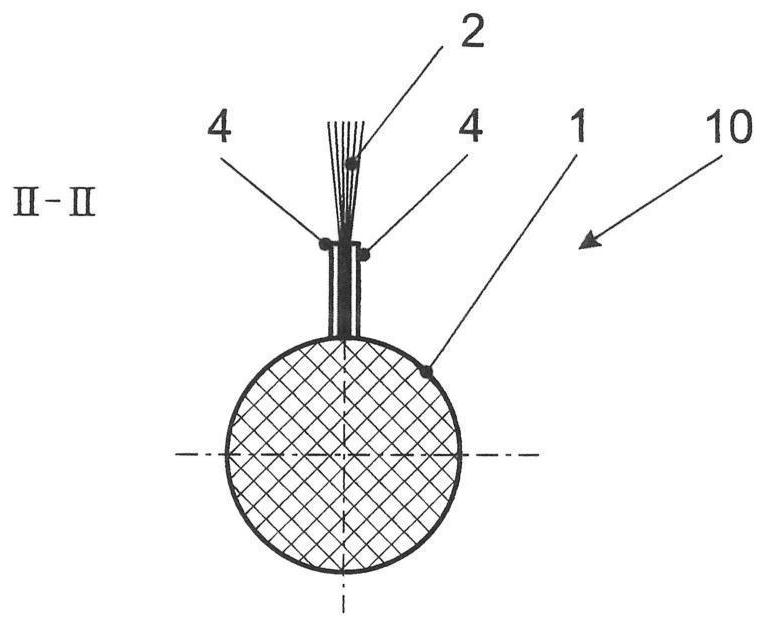

Steel coil labelling method

The invention discloses a steel coil labelling method which adopts labelling equipment. The steel coil labelling method comprises the following steps: S1, picking up labels through the labelling equipment; and S2, pasting the picked-up labels onto steel coils through the labelling equipment. The steel coil labelling method disclosed by the invention adopts special labelling equipment, can reliablyaccomplish pick-up and pasting of labels, can improve working efficiency of labelling the steel coils, is stable and reliable in work, is high in a labelling success rate, and improves the pasting effect of labelling the steel coils.

Owner:ANHUI MA STEEL AUTOMATION INFORMATION TECH

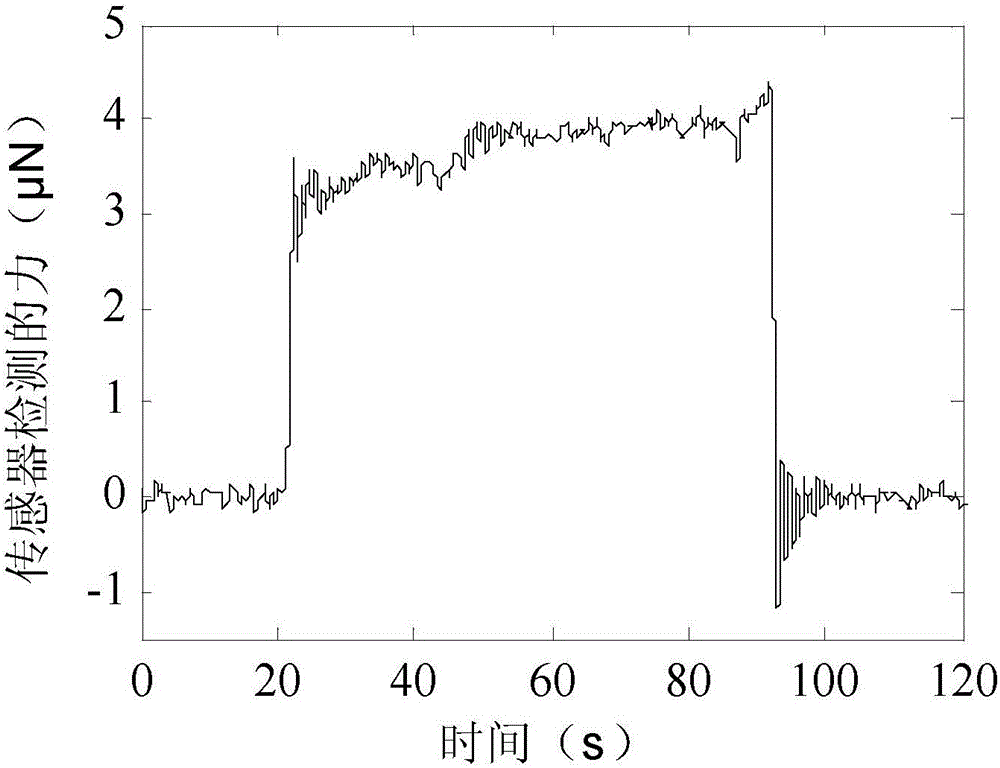

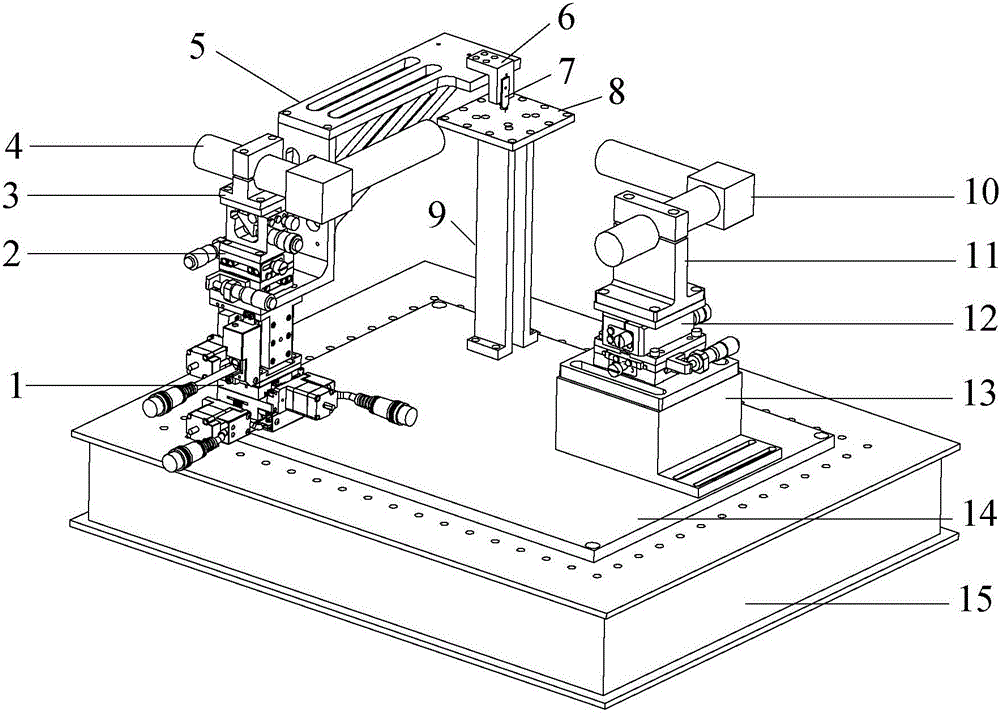

Micro/nano particle transfer method having micro force sensing and liquid drop self-calibration functions, and apparatus for realizing the same

InactiveCN104990665APick up suppleRelease suppleControlling ratio of multiple fluid flowsFluid pressure measurement using capacitance variationParticle transferEngineering

The invention, which relates to the micro / nano particle operation technology, relates to a micro / nano particle transfer method having micro force sensing and liquid drop self-calibration functions, and an apparatus for realizing the same. Therefore, a problem that capillary force detection can not be realized by using the existing capillary-force-based micro / nano particle transfer method can be solved. According to the method, one operating liquid drop is allocated at a micro / nano particle to-be-released position; an operating probe having a micro force sensing function is used for dipping and taking the liquid drop, the operating probe is moved above the micro / nano particle, and picking up of the micro / nano particle is realized by the capillary force for picking up the liquid drop; and the operating probe is moved to a to-be-released position and releasing of the micro / nano particle is realized by using the capillary force for releasing the liquid drop. According to the invention, the liquid bridge capillary force during the micro / nano particle transfer process can be detected in real time and the precision is at an nN order; on the basis of the self-calibration characteristic of the capillary force and the liquid drop, reliable releasing of the micro / nano particle can be realized; and a proper liquid drop operating condition can be created by controlling the speed of liquid drop dipping by the probe and changing the structural morphology of the end effector.

Owner:HARBIN INST OF TECH

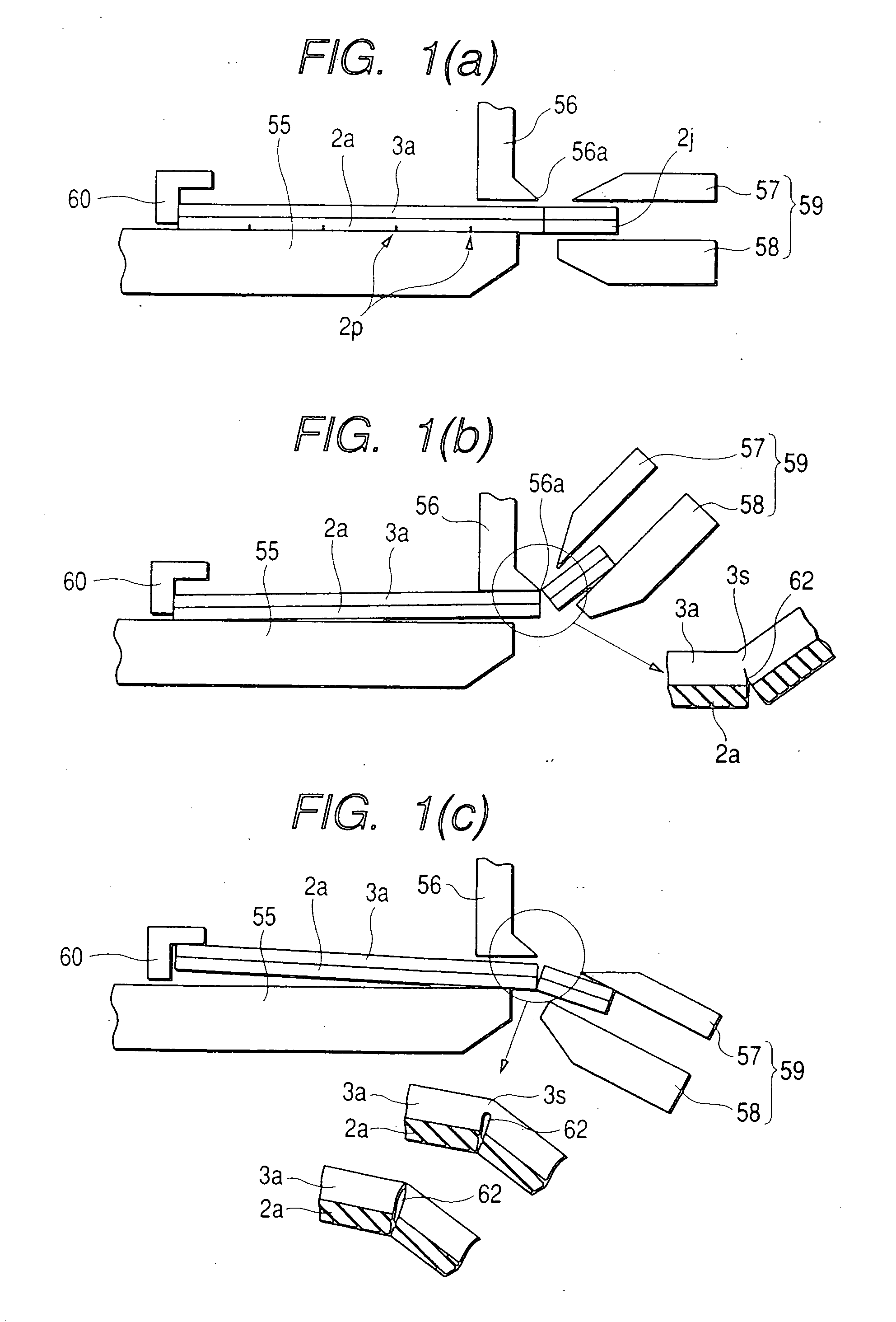

Manufacturing method of semiconductor device and semiconductor device

InactiveUS20070105283A1Satisfy flatnessReliable pickupSemiconductor/solid-state device detailsPrinted circuit aspectsDevice materialEngineering

In a dividing method according to the present invention, a wiring board formed of ceramic is forced up (upper swing) by a lower clamp claw of a clamper, and some of a protruded wiring board portion protruding from a conveying chute is pressed against a support body to perform a first division under bending stress. Thereafter, the upward-located clamper is rotatably swung (lower swing) downward to allow an upper clamp claw to press down the protruded wiring board portion, thereby performing a reverse division at the first division section again as a second division. Since the second division allows a tensile force to act on a remaining and thin non-divided resin portion, the non-divided resin portion is torn off. Thus, the perfect division is enabled. Fractionalizing is done by a one-row division and an individual division so that each semiconductor device is formed.

Owner:RENESAS TECH CORP

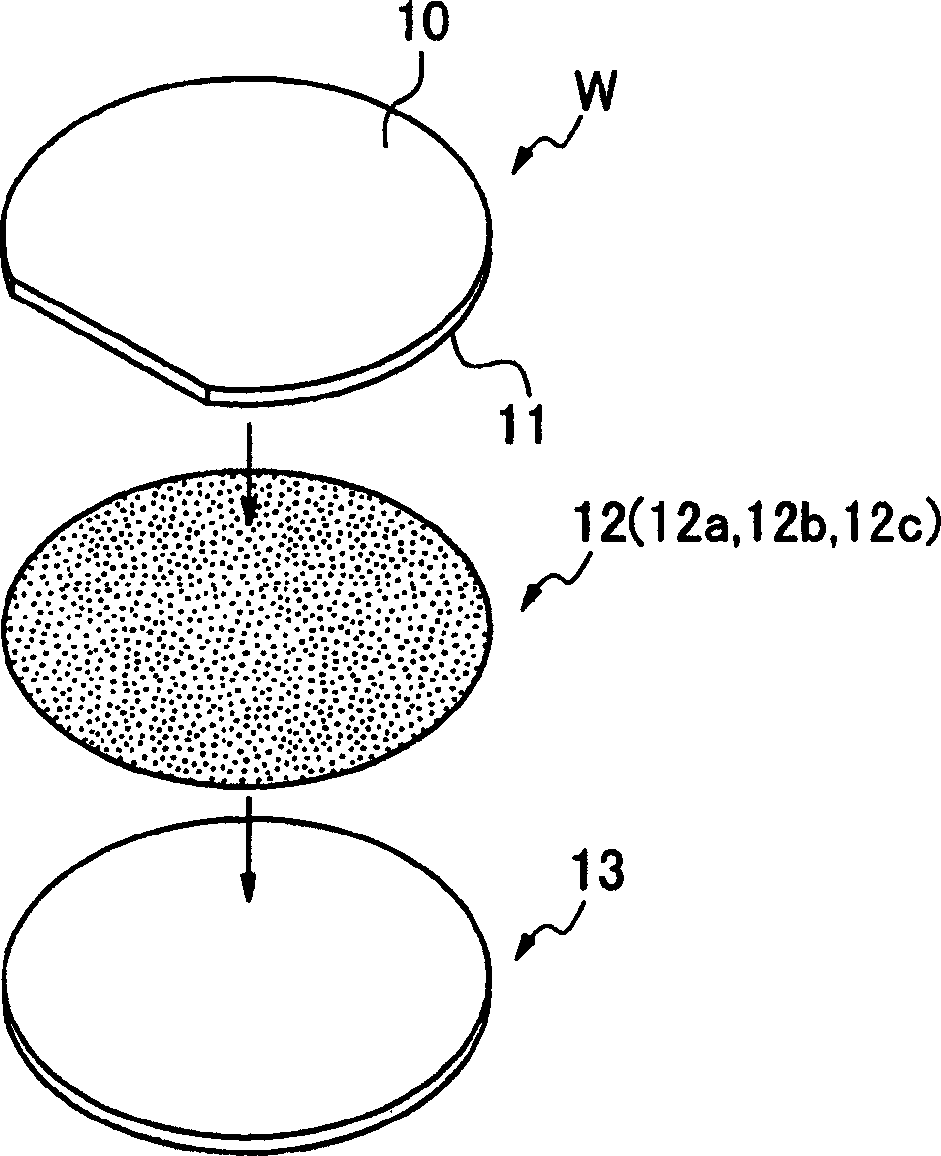

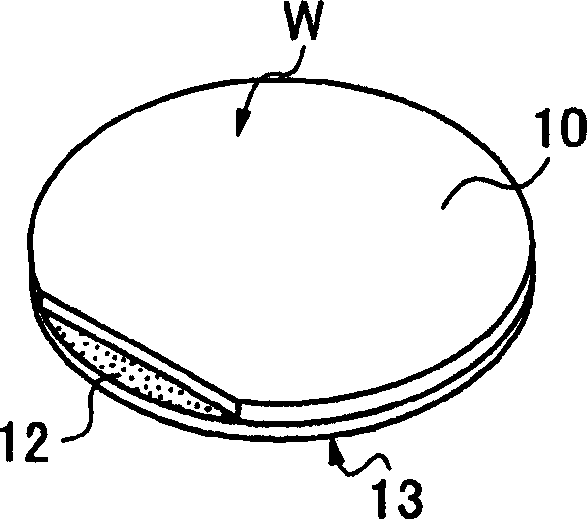

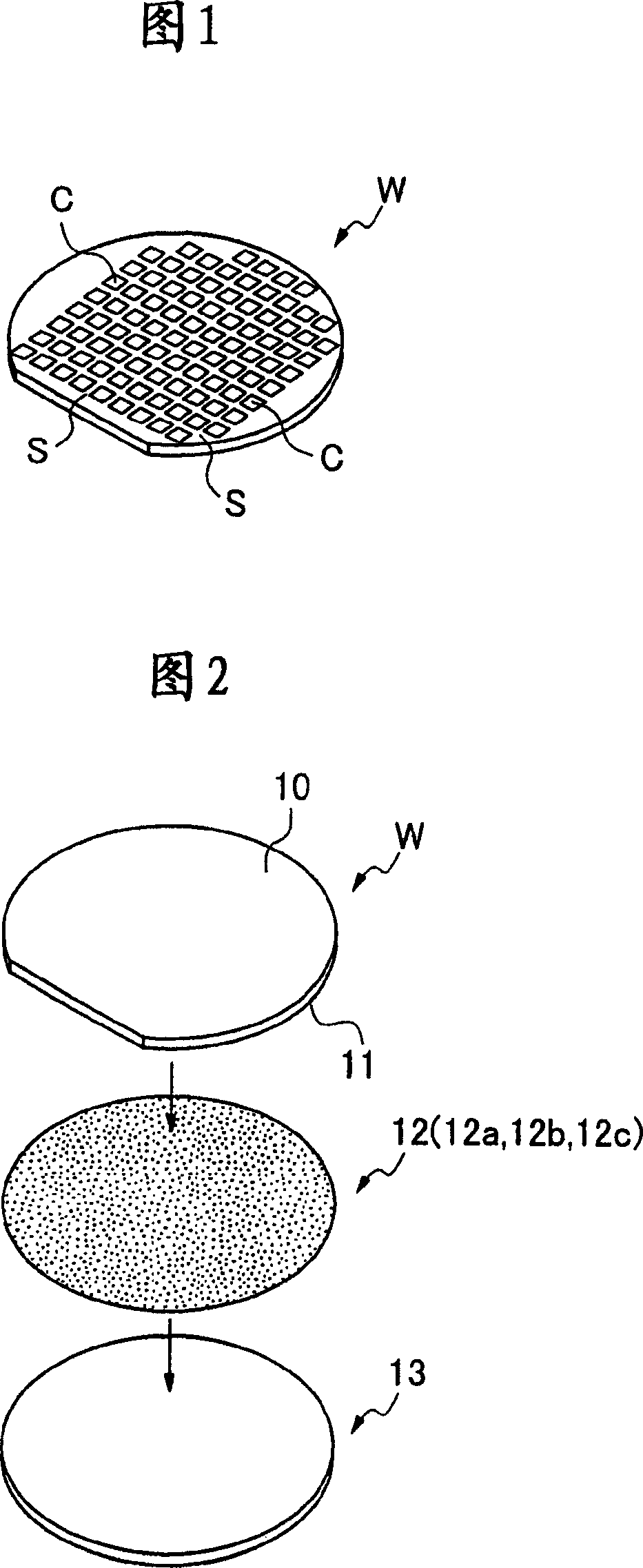

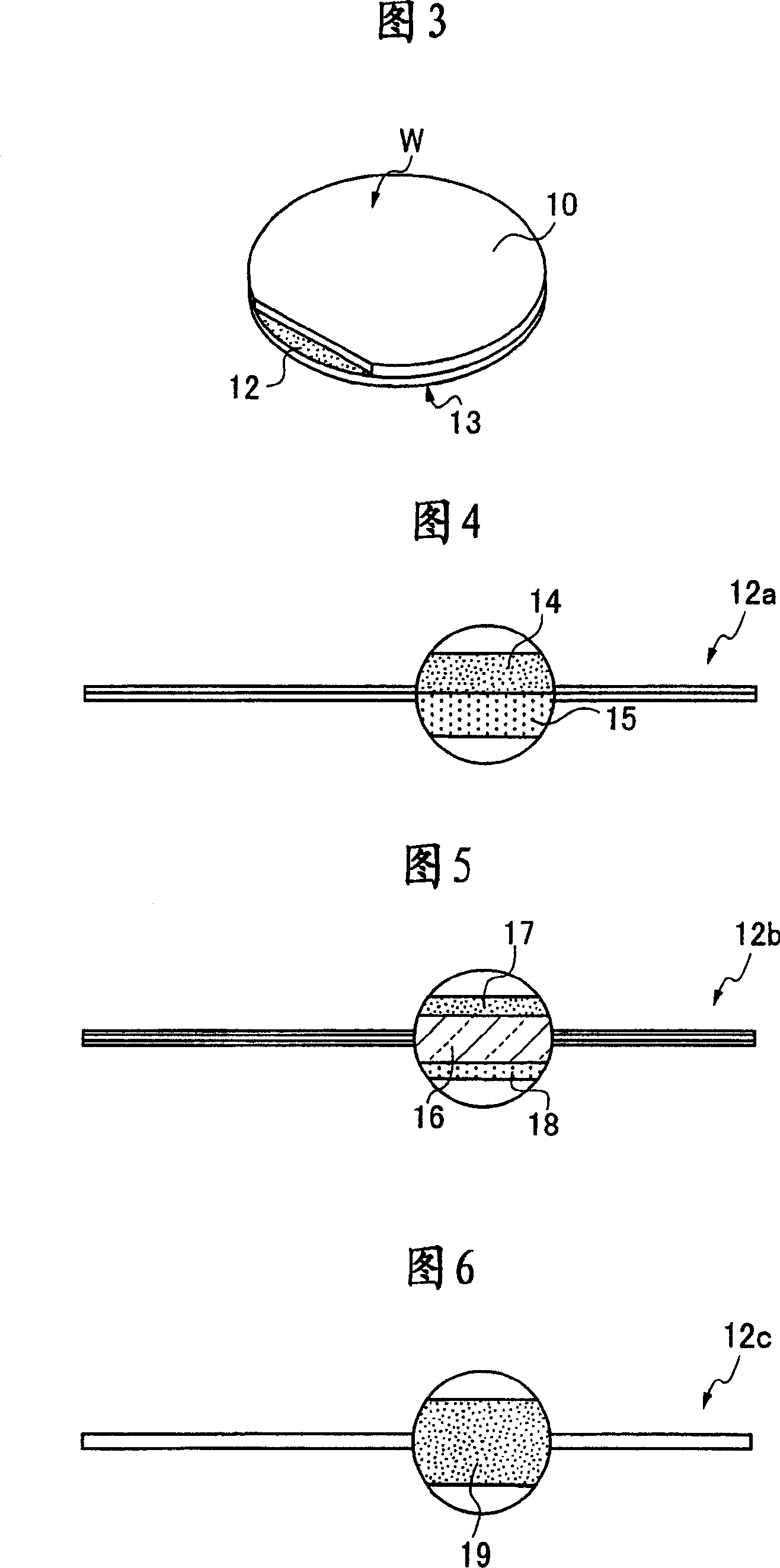

Method for manufacturing semiconductor chip

InactiveCN1592953APick up safeReliable pickupSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor packageSemiconductor chip

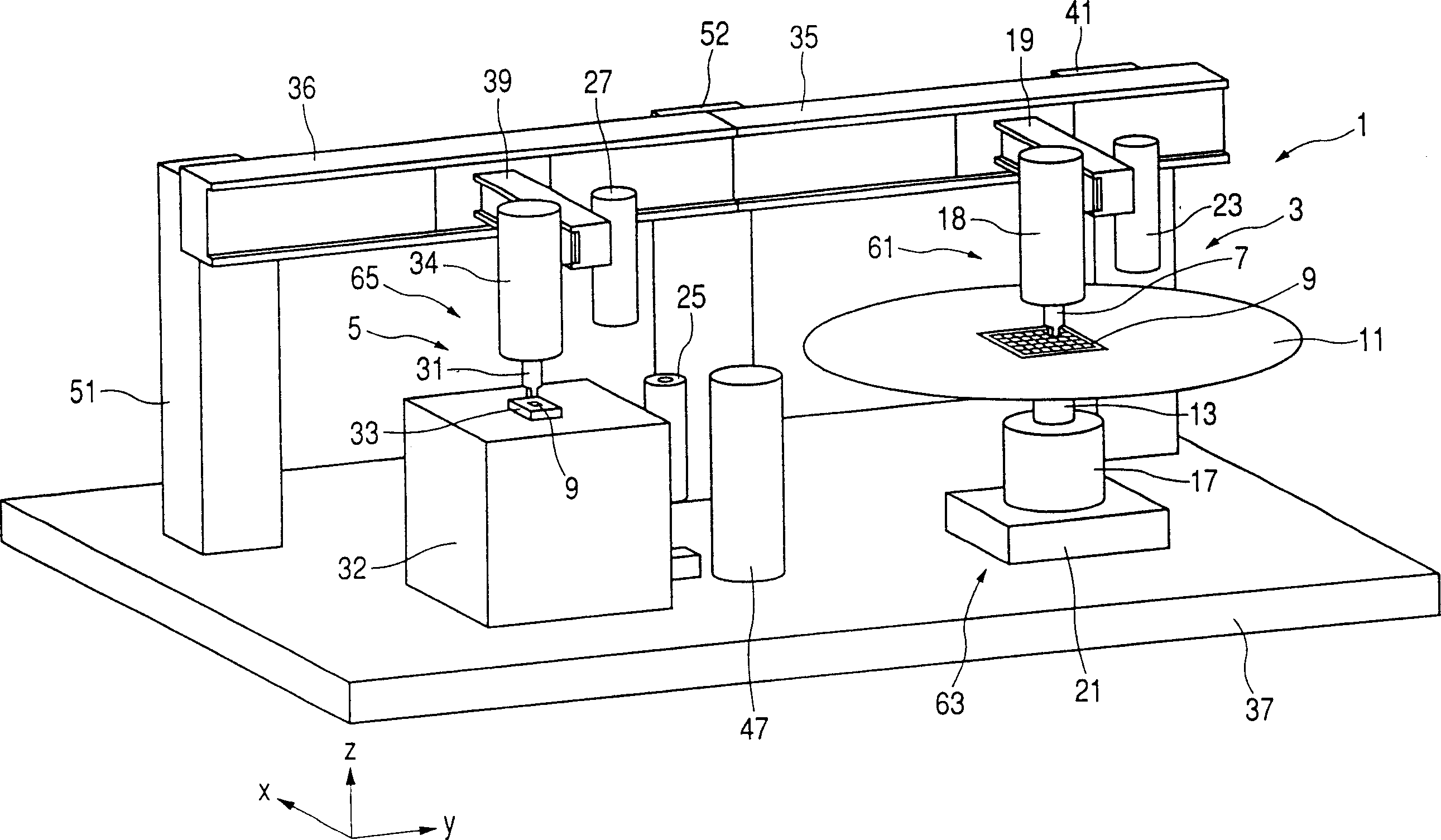

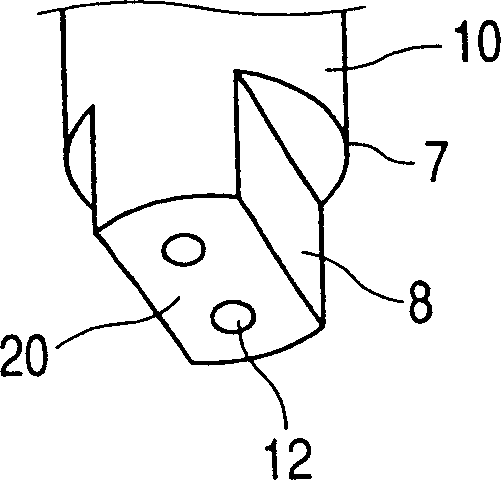

A semiconductor wafer (W) where circuits are formed in the area divided by streets is split into semiconductor chips having individual circuits. By interposing an adhesive sheet, whose adhesive force is lowered by stimulation, between the semiconductor wafer (W) and the support plate ( 13 ), the front side of the semiconductor wafer (W) is adhered to the support plate ( 13 ), thereby exposing the rear face ( 10 ) of the semiconductor wafer (W). The rear face ( 10 ) of the semiconductor wafer (W) with the support plate ( 13 ) is ground. After the grinding is finished, the semiconductor wafer (W) held with the rear face ( 10 ) up is diced into semiconductor chips (C). The adhesive sheet is given stimulus to lower the adhesive force and the semiconductor chips (C) are removed from the support plate ( 13 ). The semiconductor wafer and semiconductor chips are always supported by the support plate, avoiding damage and deformation.

Owner:SEKISUI CHEM CO LTD +1

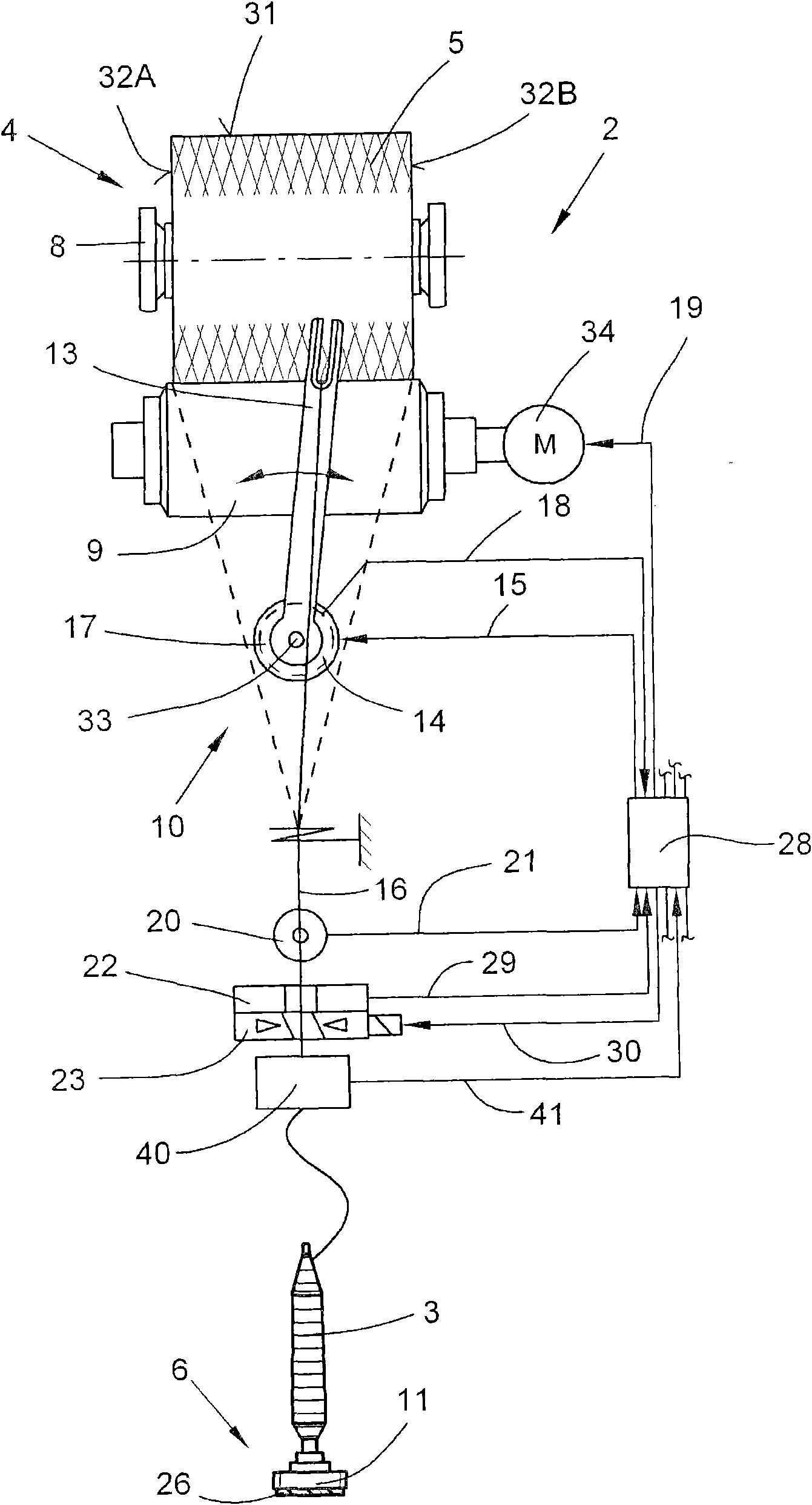

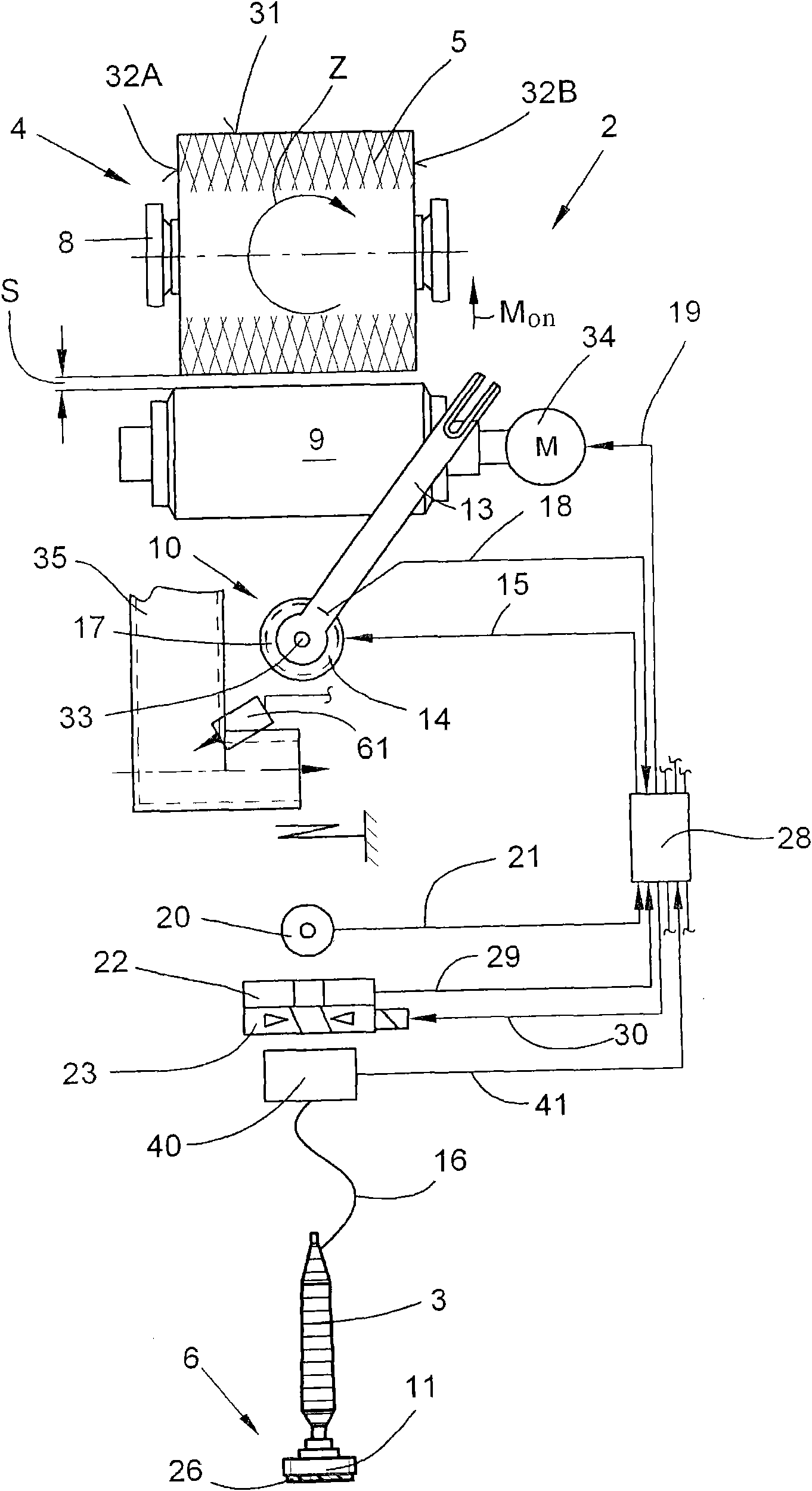

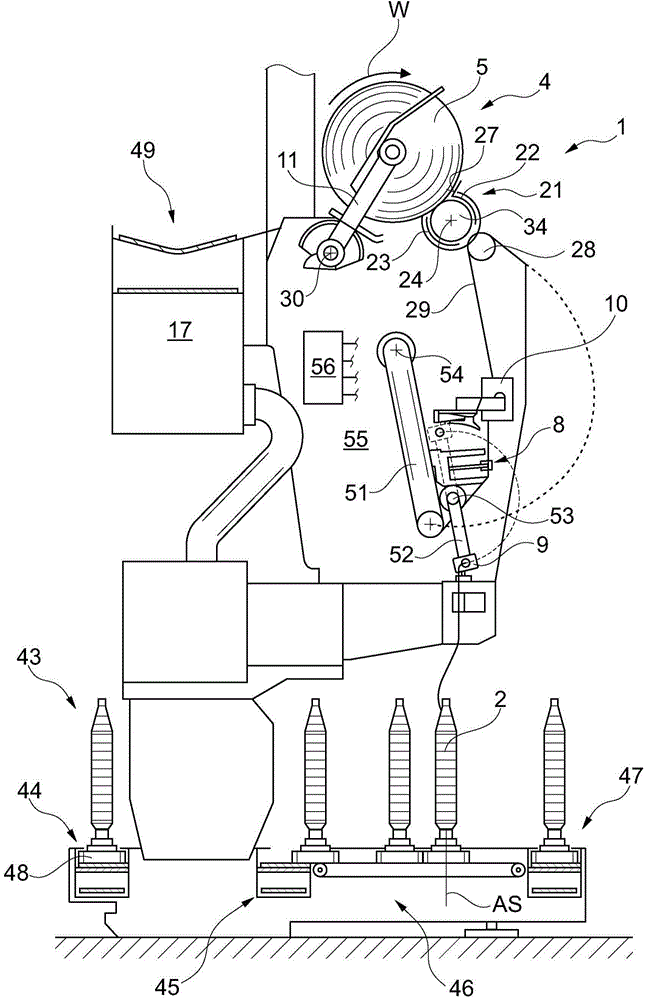

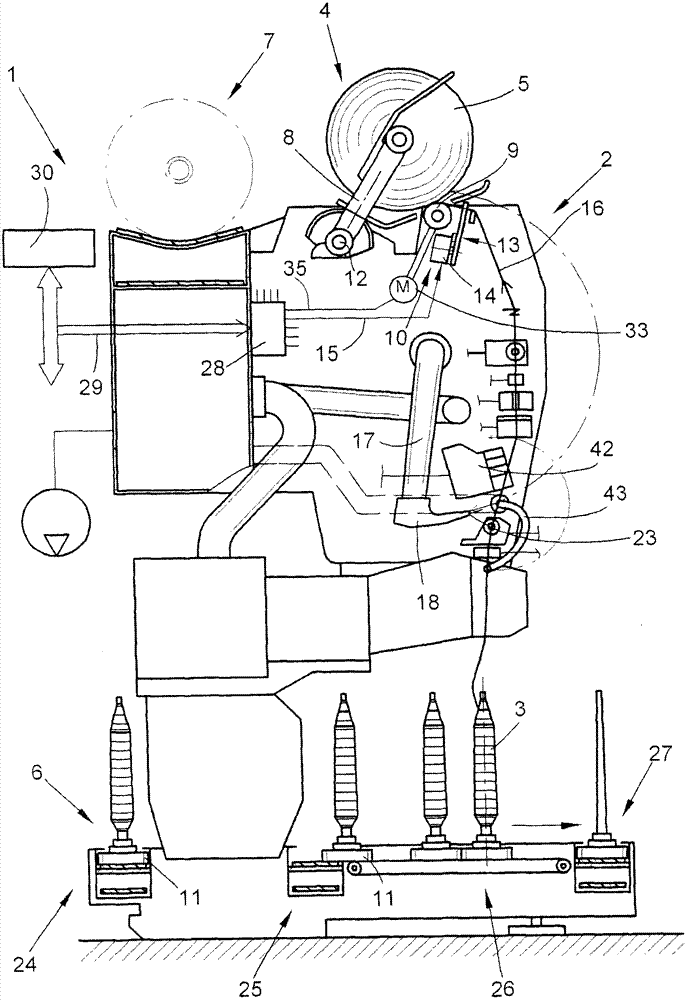

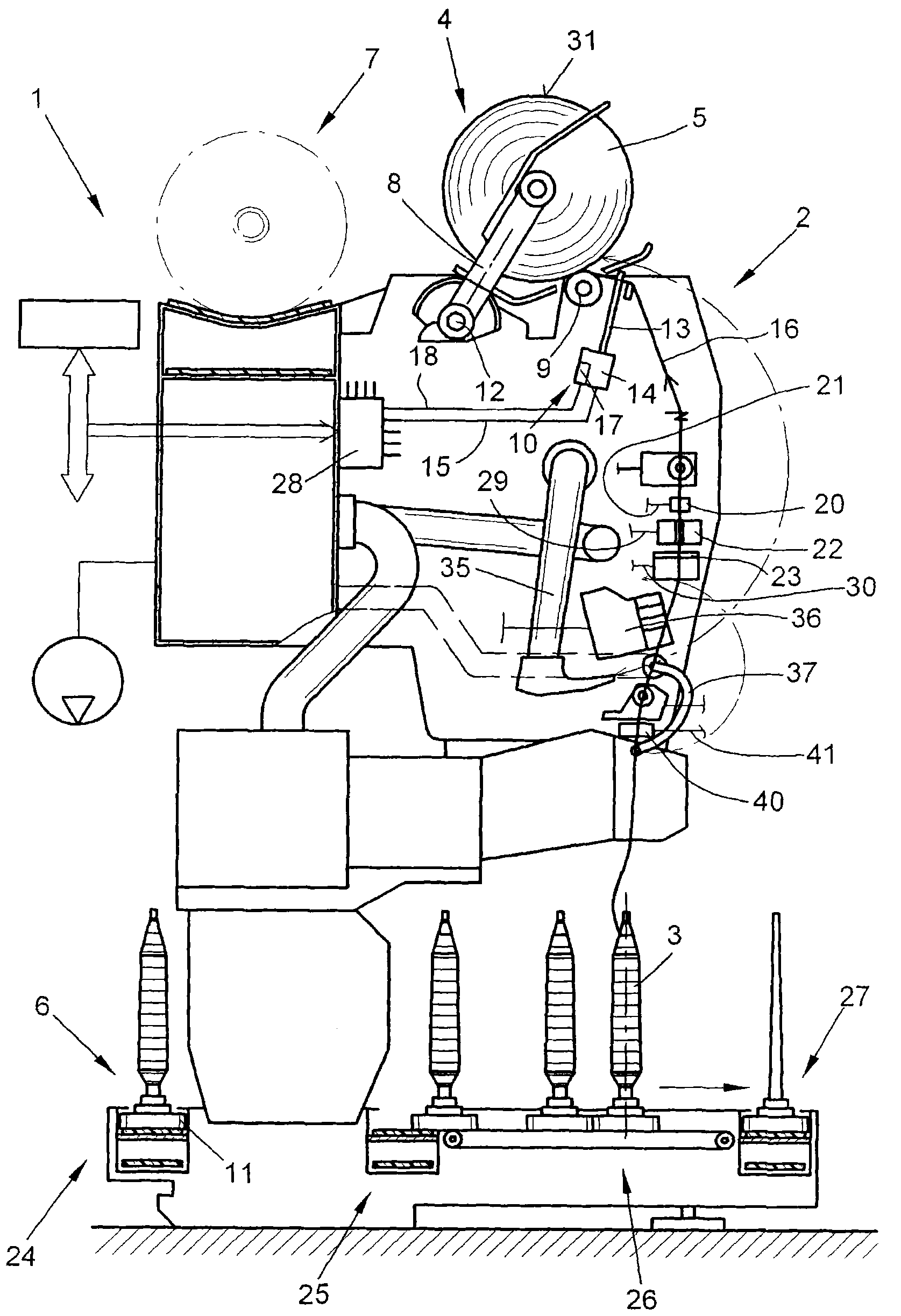

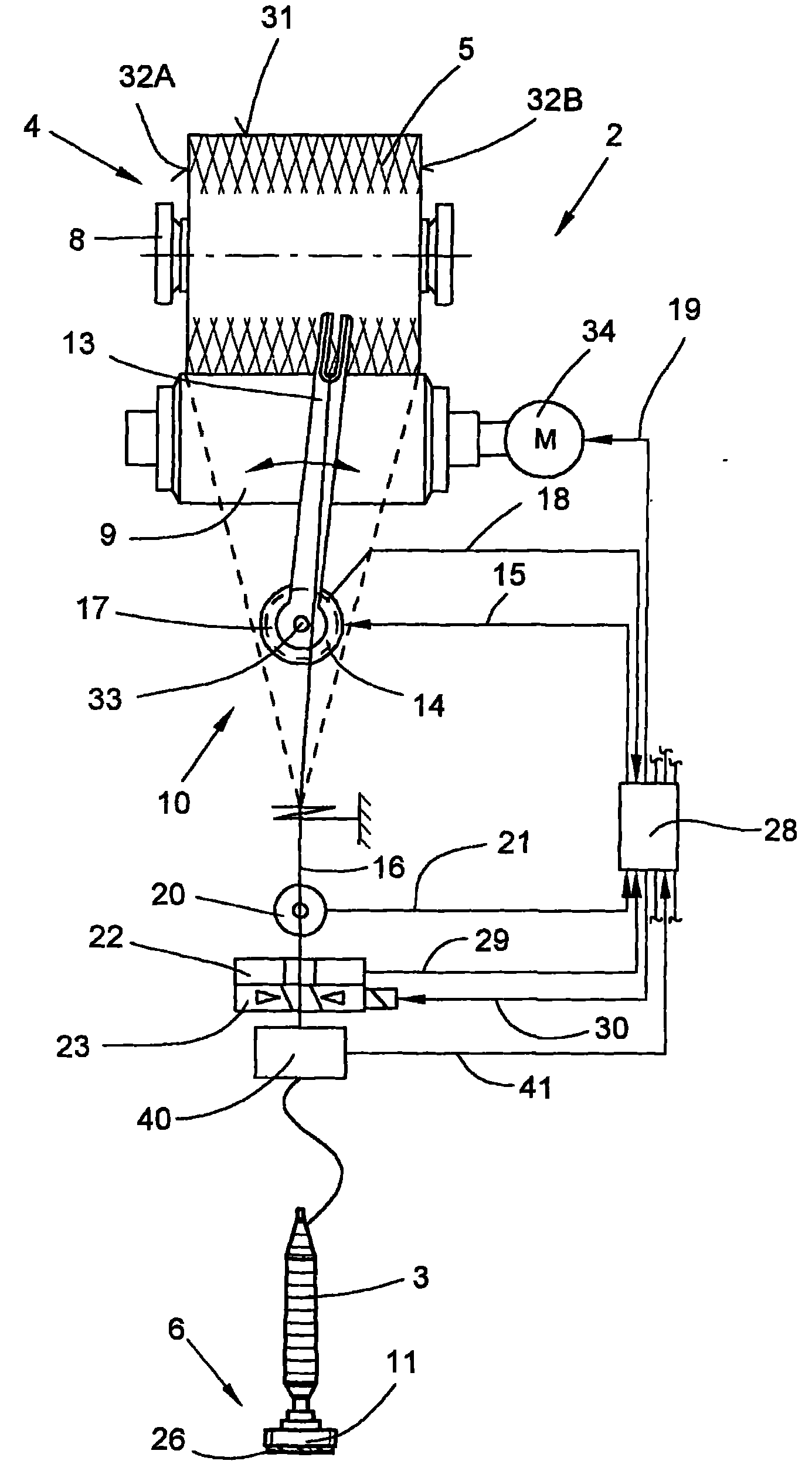

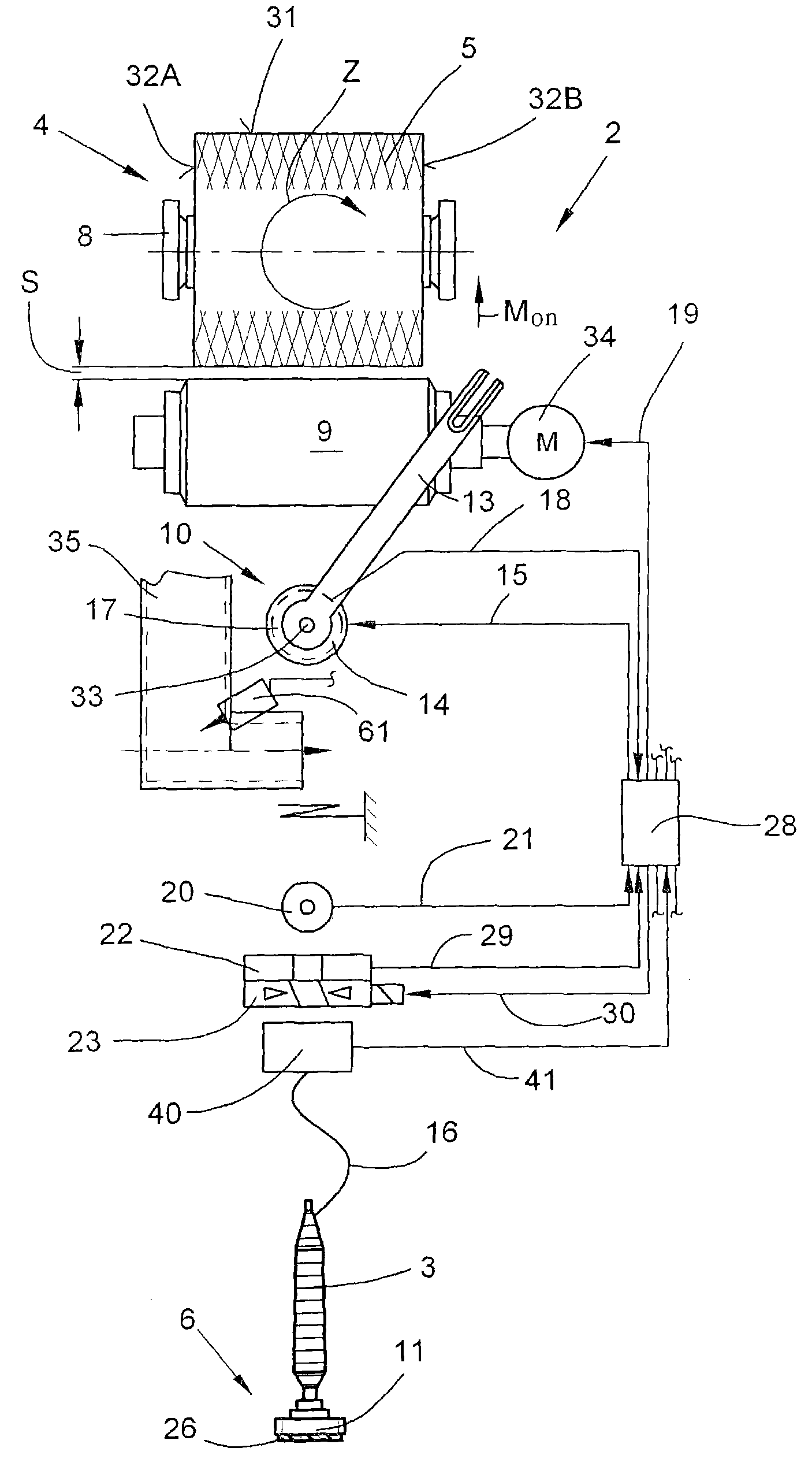

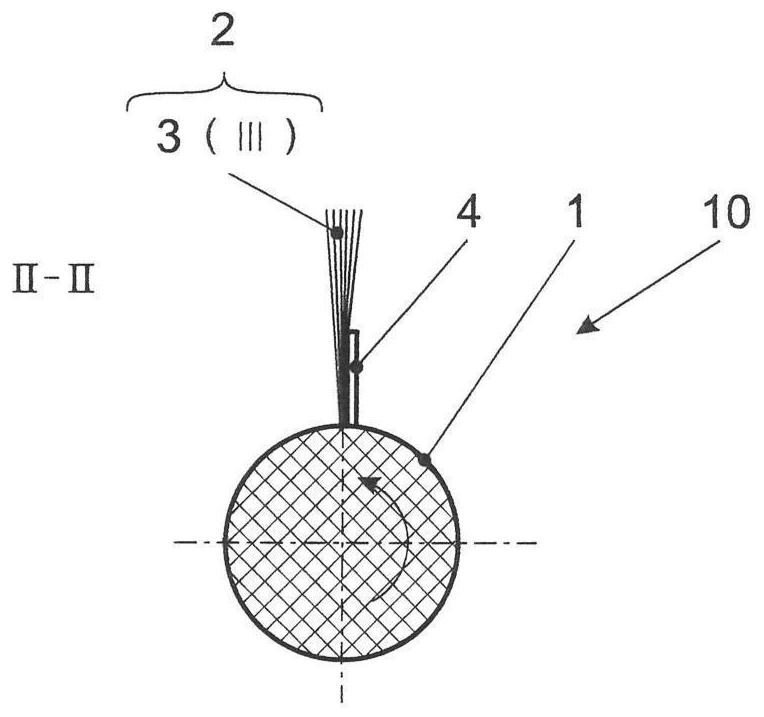

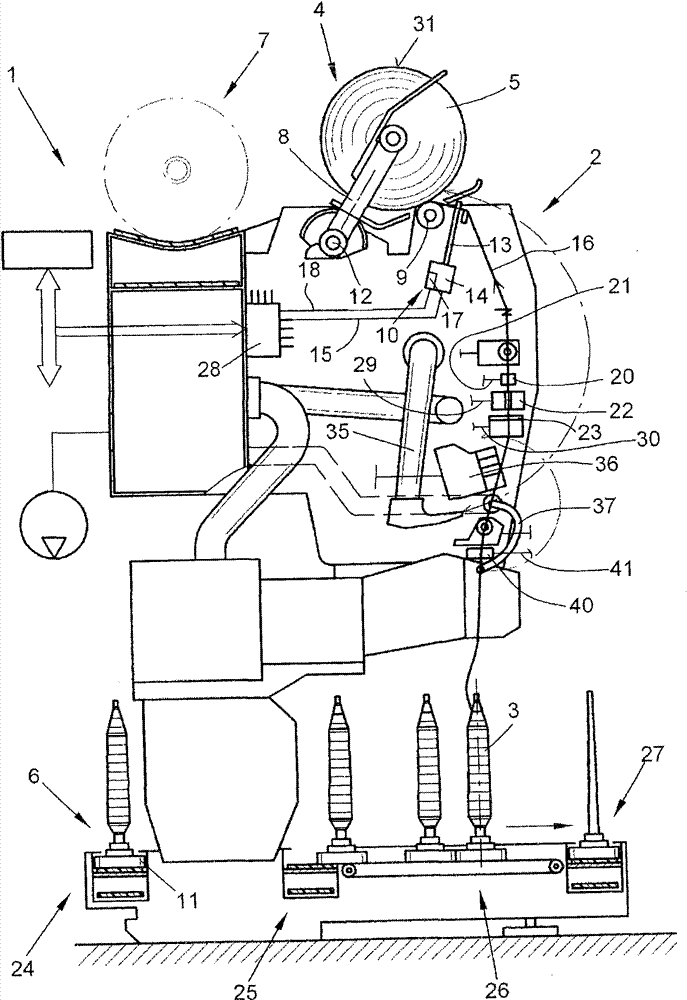

Method for operating workplaces on a textile machine for creating cross-wound spools

InactiveCN101987706AReduce negative pressureMake sure to separate slightlyFilament handlingYarnEngineering

The present invention relates to a method for operating workplaces on a textile machine for creating cross-wound spools, wherein each workplace is provided with a coiling device which comprises the following components: a spool driving roller which is used for rotating the cross wound spool through friction joint; a spool frame which is used for rotatably keeping pivotable mounting of cross wound spool and can be lifted by a torque transfer device with a limited mode; and a suction nozzle which is loaded with negative pressure and can pivot to the surface area of the cross wound spool for pneumatically picking the surface yarn which operates to the surface after coiling interruption. For picking the yarn, the cross wound spool (5) firstly rotates along a uncoiling direction (Z) through friction joint. Then a spool frame (8) is activated by a torque transfer device (60) so an air gap (S) is temporarily formed between a surface (1) of the cross wound spool (5) kept on the spool frame (8) and the spool driving roller (9) for rotating the cross wound spool (5).

Owner:SAURER GERMANY GMBH & CO KG

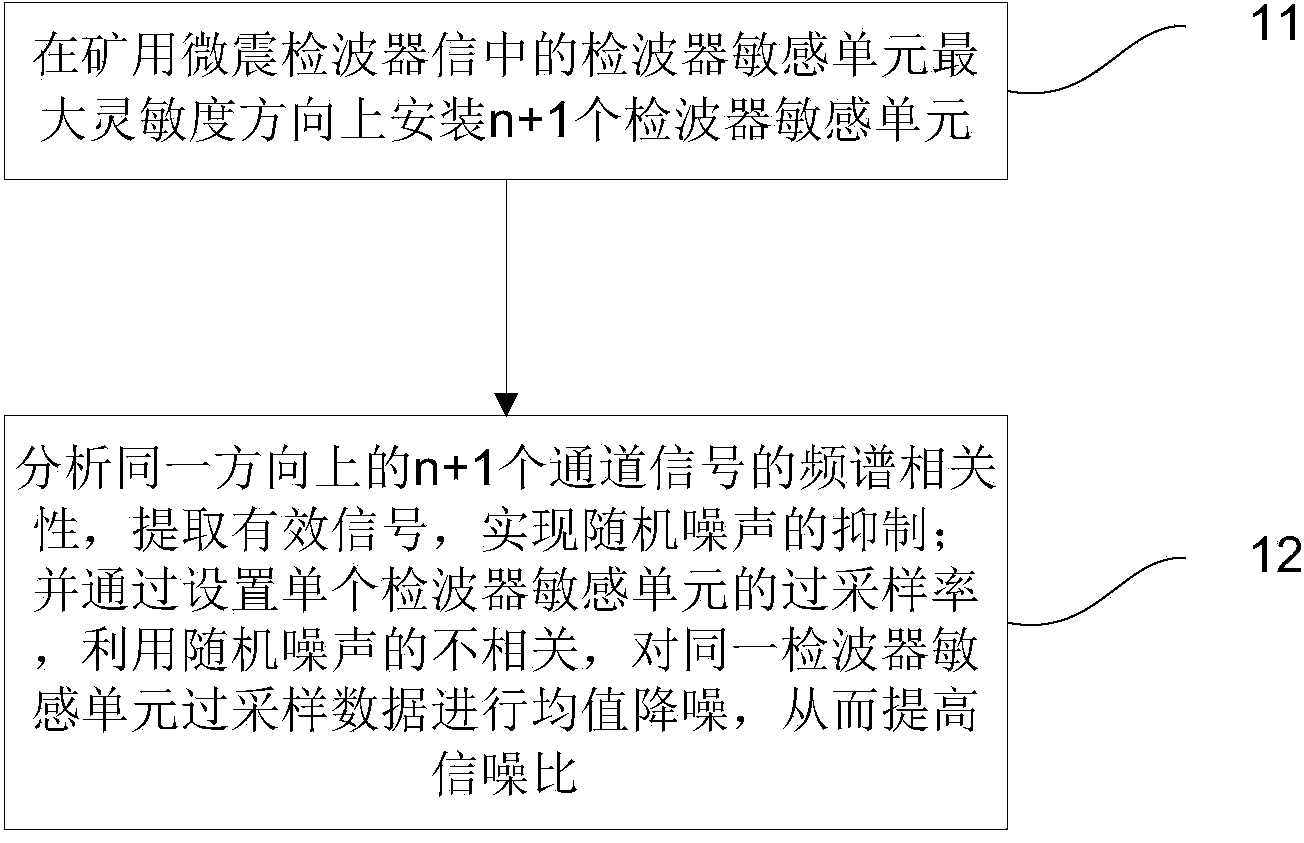

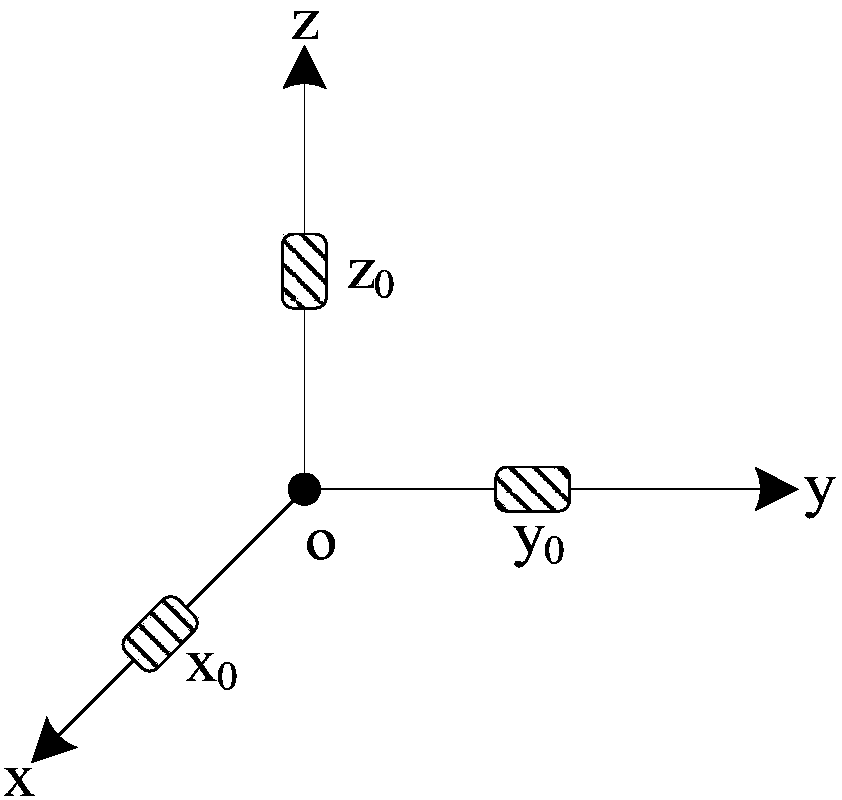

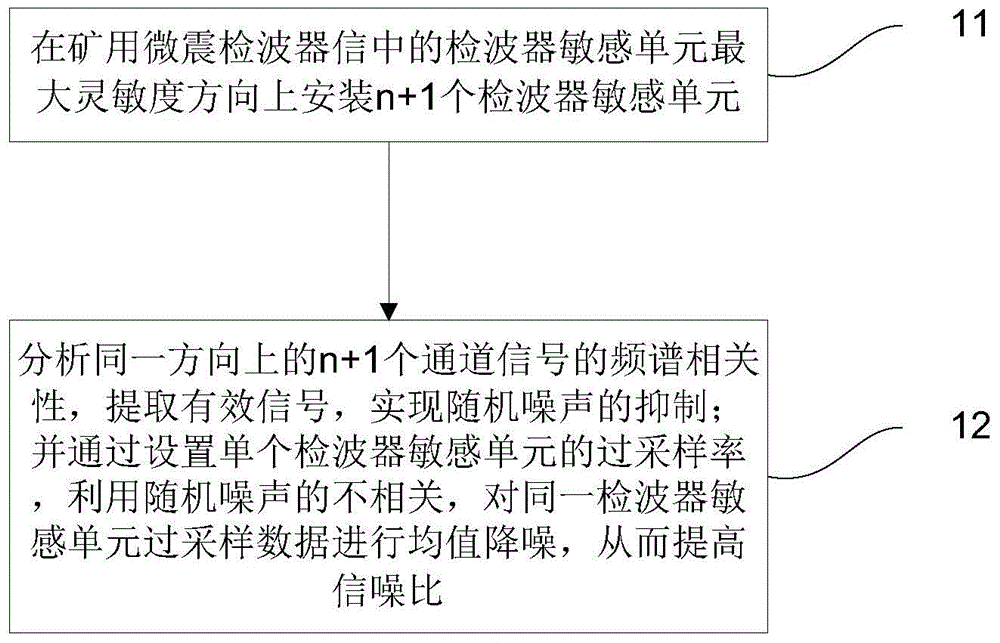

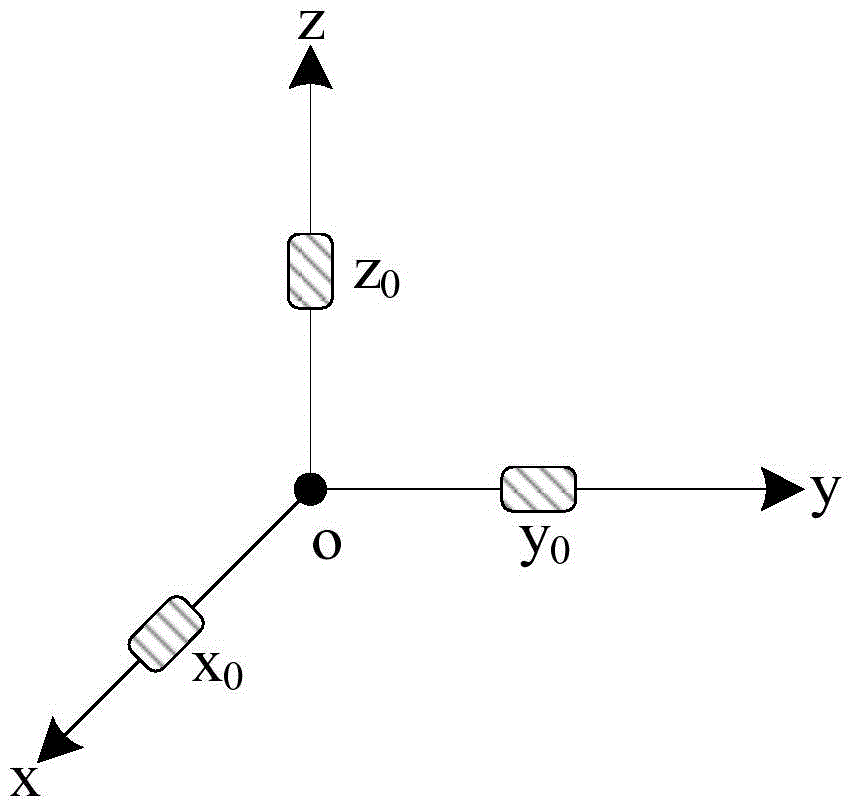

Method for improving signal-to-noise ratio of mine micro-seismic detector

ActiveCN103852784ARandom noise suppressionImprove signal-to-noise ratioSeismic signal receiversSignal-to-noise ratio (imaging)Signal-to-quantization-noise ratio

The invention discloses a method for improving the signal-to-noise ratio of a mine micro-seismic detector. The method includes the steps that n+1 detector sensing units are installed in the mine micro-seismic detector in detector sensing unit maximum sensitivity directions; the frequency spectrum correlation of n+1 channel signals in the same direction is analyzed, effective signals are extracted, and suppression on random noise is achieved; mean value noise reduction is carried out on oversampling data of the same detector sensing unit through the non-correlation of the random noise by setting the oversampling rate of each signal detector sensing unit so as to improve the signal-to-noise ratio. By means of the method, the capacity for picking up unknown source signals of parameter information such as energy and frequency is improved, interference caused by the random noise is effectively suppressed, and the signal-to-noise ratio is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Die bonding method for integrated circuit chip

InactiveCN108807191AAccurate placementReliable pickupSemiconductor/solid-state device manufacturingQuality levelEngineering

The present invention provides a die bonding method for an integrated circuit chip. Compared with the prior art, the method realizes a high-precision rapid die bonding technology through performing amaterial feeding step, an adhesive dispensing step, a die bonding step and other steps on the basis of the cooperation of die bonding movement control, adhesive dispensing and chip pick-and-place mechanism and an image recognition system. The die bonding method is applicable to a wide application range, for example, the epoxy package of scattered small chips and the die bonding of large chips of integrated circuits. Compared with a chip bonding method adopting eutectic bonding and low-temperature eutectic bonding, the die bonding method of the invention can pick up and place chips at a higherspeed more accurately and reliably, and achieve a balance between production efficiency and high quality level.

Owner:安徽先捷电子股份有限公司

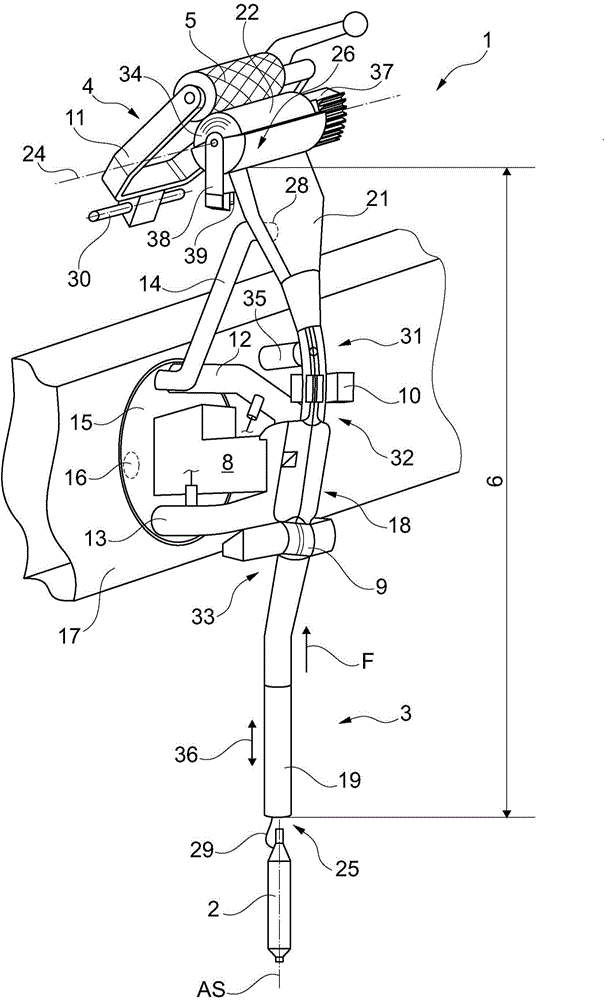

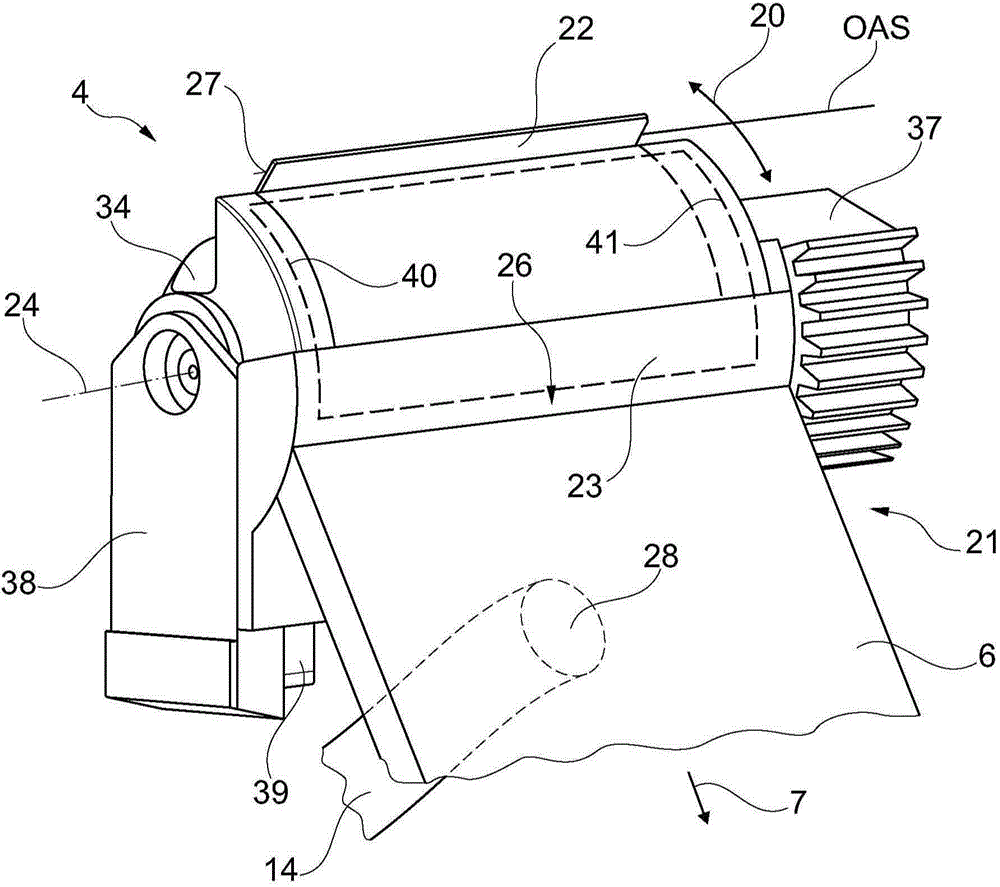

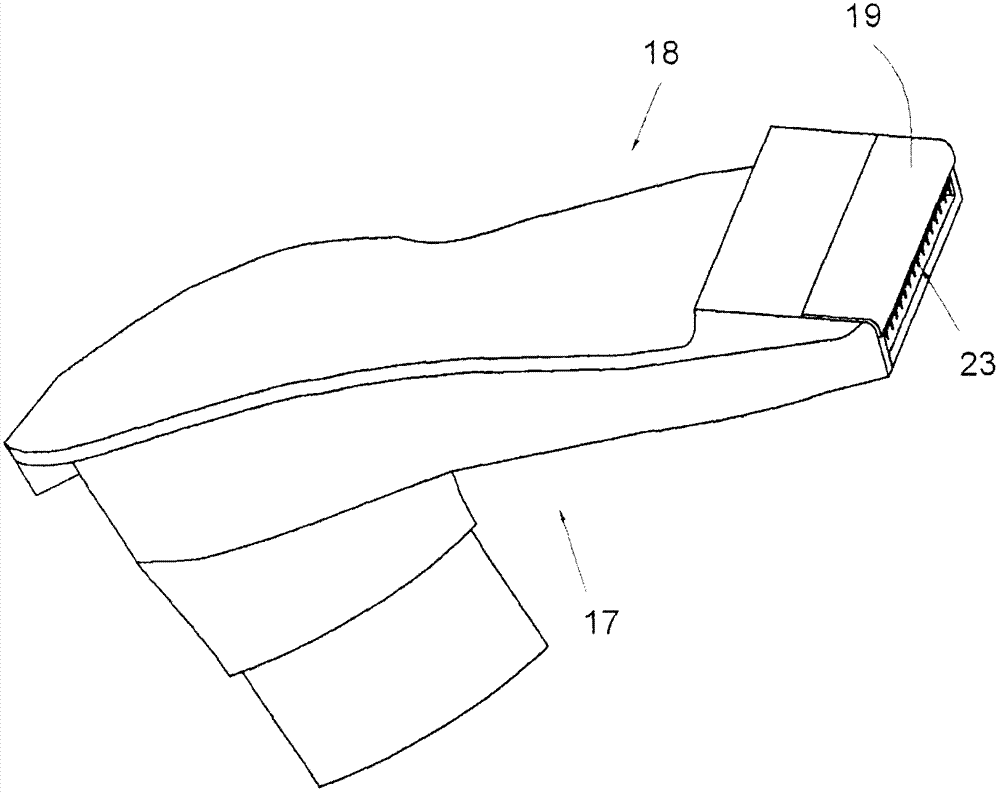

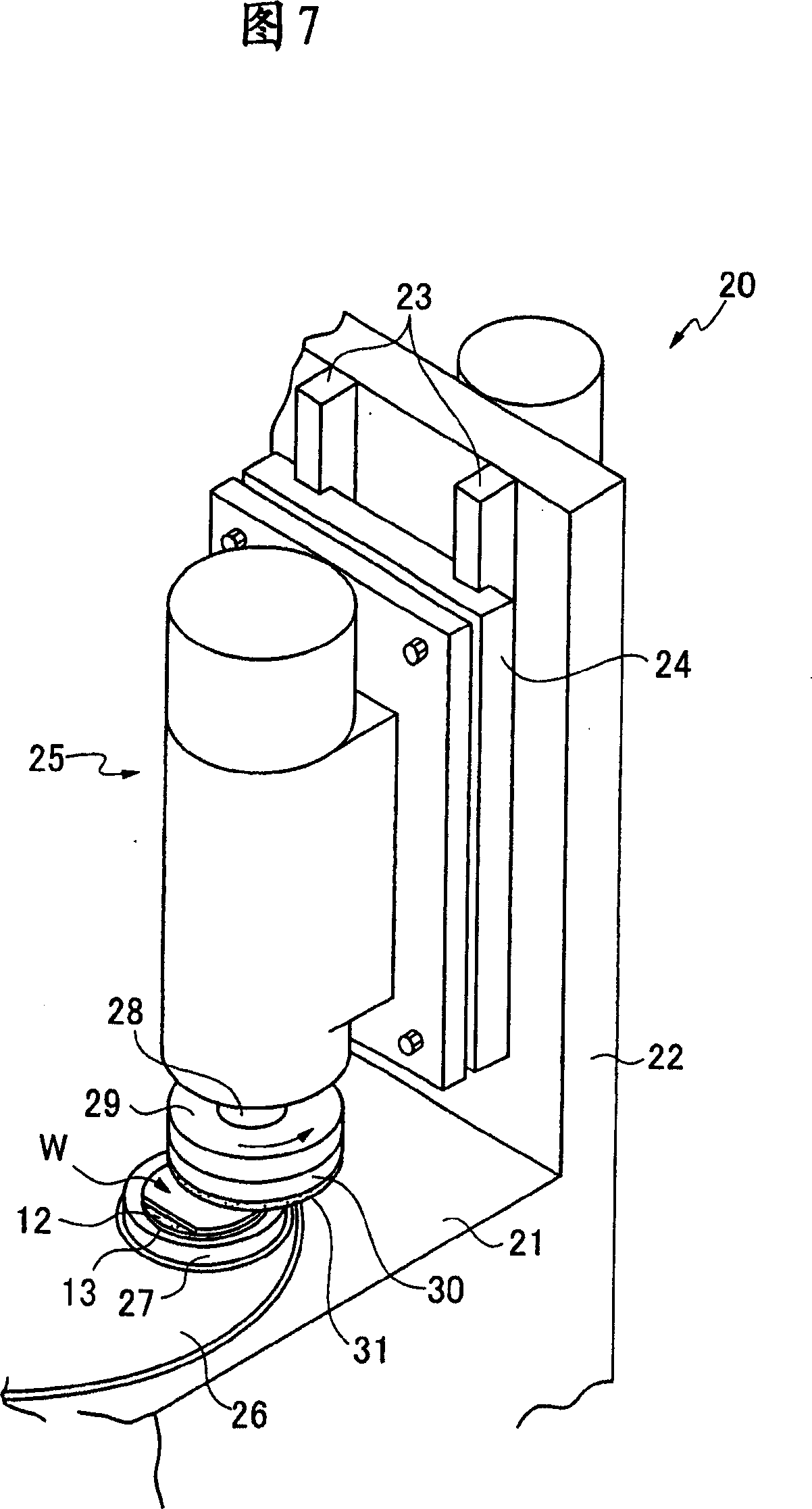

Workstation of a textile machine for creating cross-wound spools

The invention relates to a workstation (1) of a textile machine for creating cross-wound spools. The workstation comprises a creel (11), pivotably mounted for holding a winding spool (5) in a rotatable manner; a roller (34), the winding spool (5) abutting the roller during winding; and a wire suction means (21), which can be applied with a negative pressure as required to pick up a veil travelled onto the surface of the winding spool (5) after interruption of the winding. According to the invention, the wire suction device (21) is fixedly disposed in a region of a winding mechanism, and has an upper molded plate (22) and a movably mounted lower molded plate (23), the lower molded plate (23) is arranged to pivot around the roller (34), that is, forming a nozzle contour to which a negative pressure can be applied between the upper molded plate (22) and the lower molded plate (23) so as to pick up the veil on the surface region of the winding spool (5).

Owner:SAURER GERMANY GMBH & CO KG

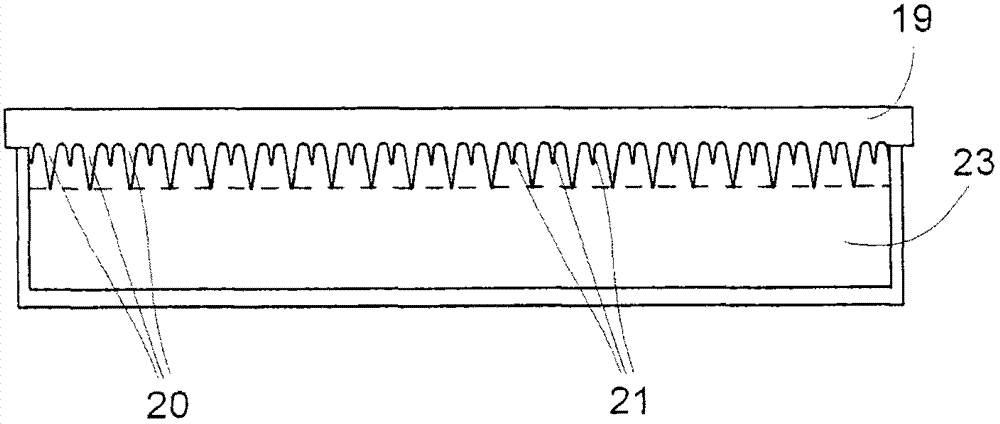

Suction nozzle for a workstation of a textile machine which produces crosswound bobbins

The invention relates to a suction nozzle for a workstation of a textile machine which produces crosswound bobbins. The suction nozzle has a suction port for the pneumatic picking of a yarn breakage or a controlled thread cut accumulated on the surface of a cross-wound bobbin end. The suction port is provided with a comb strip for fixing the bobbin end. The comb strip (19) is produced by a photo-chemical etching process and formed with large and small teeth (20, 21) of different heights. The large teeth (20) with a height (H) alternatively appear with the small teeth (21) with a height (h).

Owner:SAURER SPINNING SOLUTIONS GMBH & CO KG

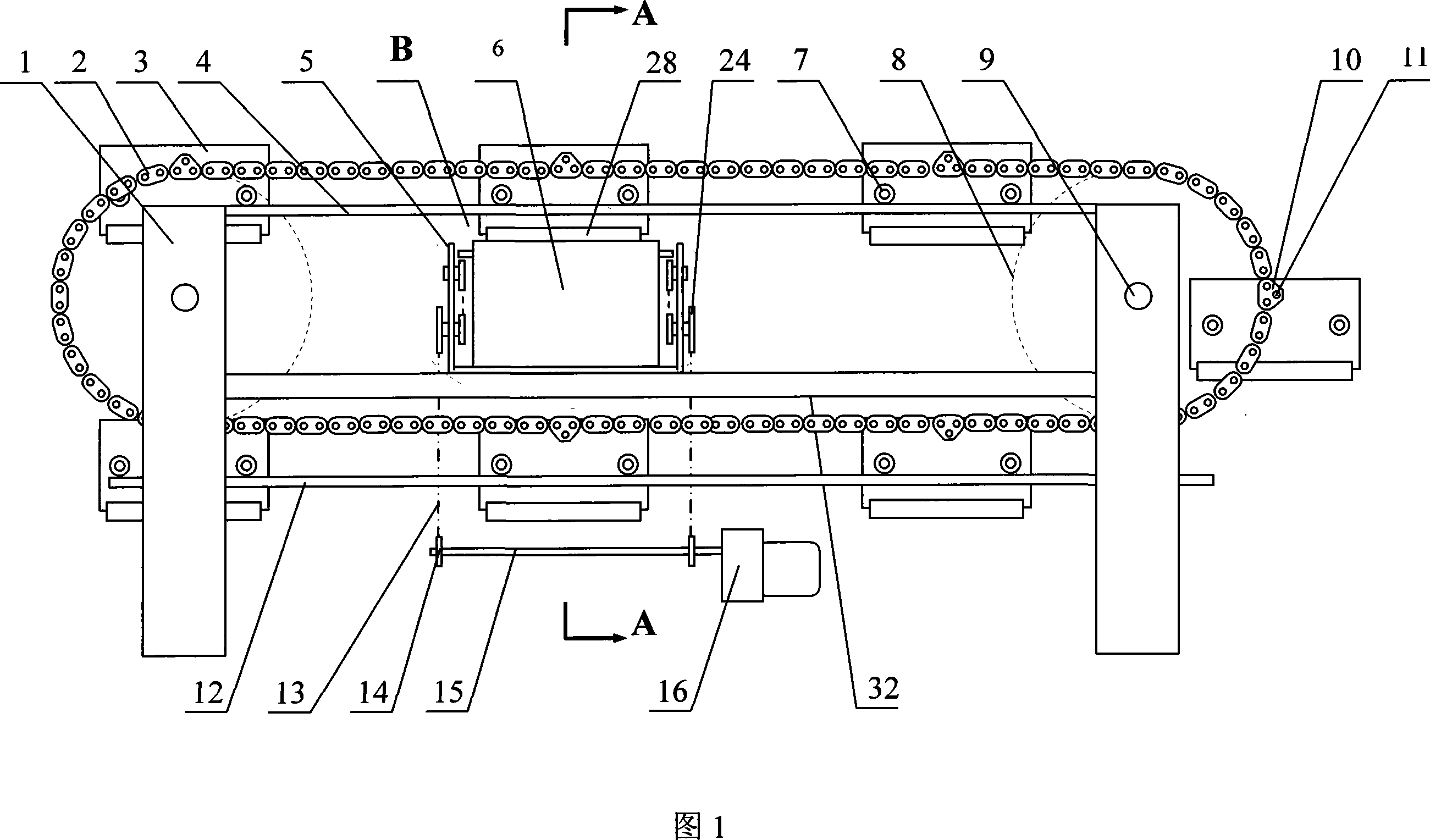

Distributing device for automatic distribution system

ActiveCN101157416AReduce labor intensitySafe pickupConveyorsConveyor partsDistribution systemSprocket

The invention discloses a distribution device of an automatic allocating cargo system, and comprises a frame, a pair of rotary conveying chains which are arranged on the frame through chain wheels, and a plurality of wagons which are arranged between the rotary conveying chains. The bottoms of the wagons are provided with switching motherboards which are provided with switching mechanisms, movable splints are arranged below the switching motherboards and four corners of the movable splints are respectively articulated on two pairs of endless chains, the size and the shape of which are respectively, mutually and correspondingly matched with each other. One side of the movable splints is corresponding to the switching mechanisms of the switching motherboards. The invention has the advantages that the goods which are allocated can be unloaded from a plurality of designation places of a conveyor at the lowest drop fall and sent out, taking goods and delivering goods are safe, rapid and reliable, thus the labor intensity of the operators can be reduced.

Owner:张家港建辰机械科技有限公司

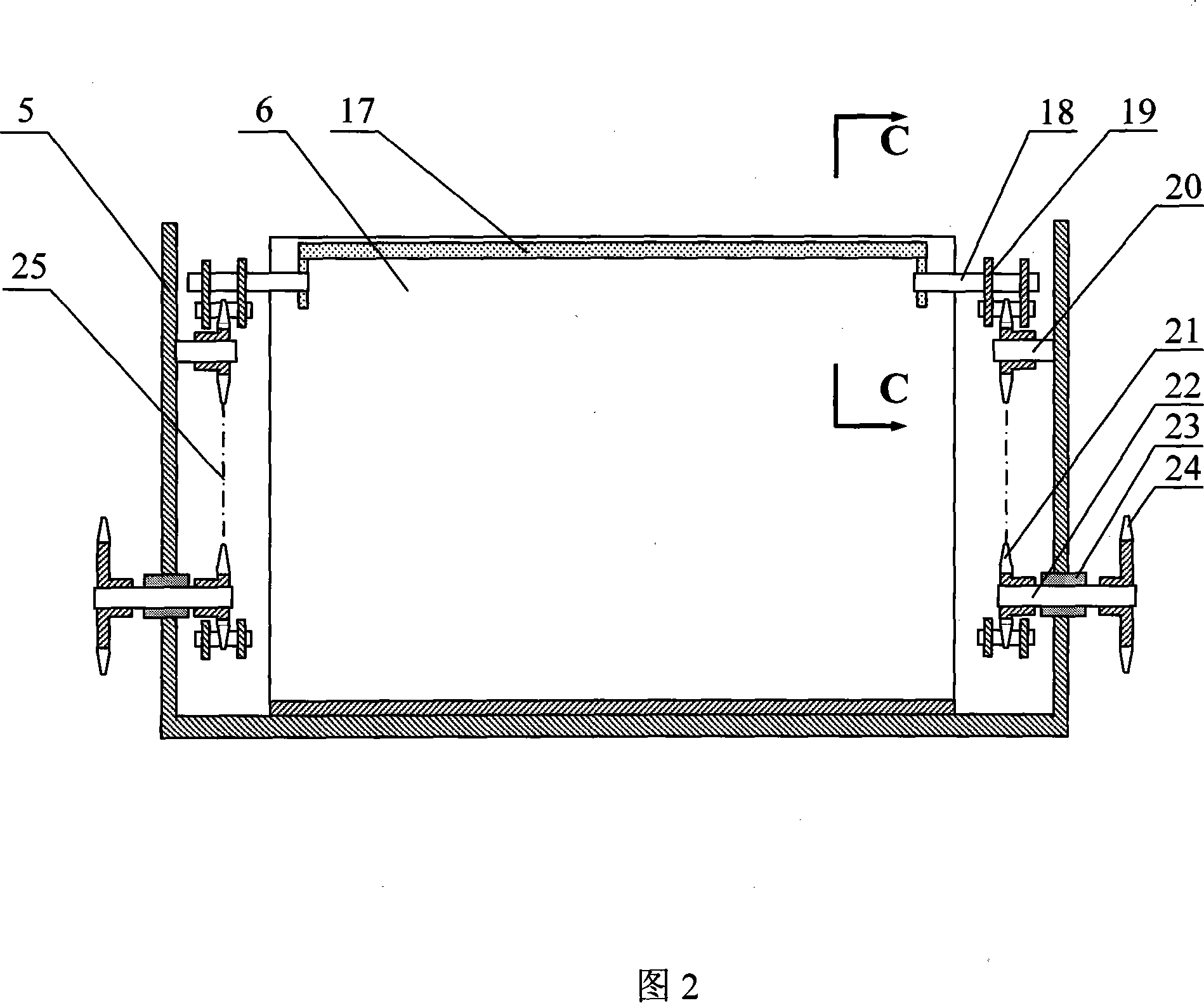

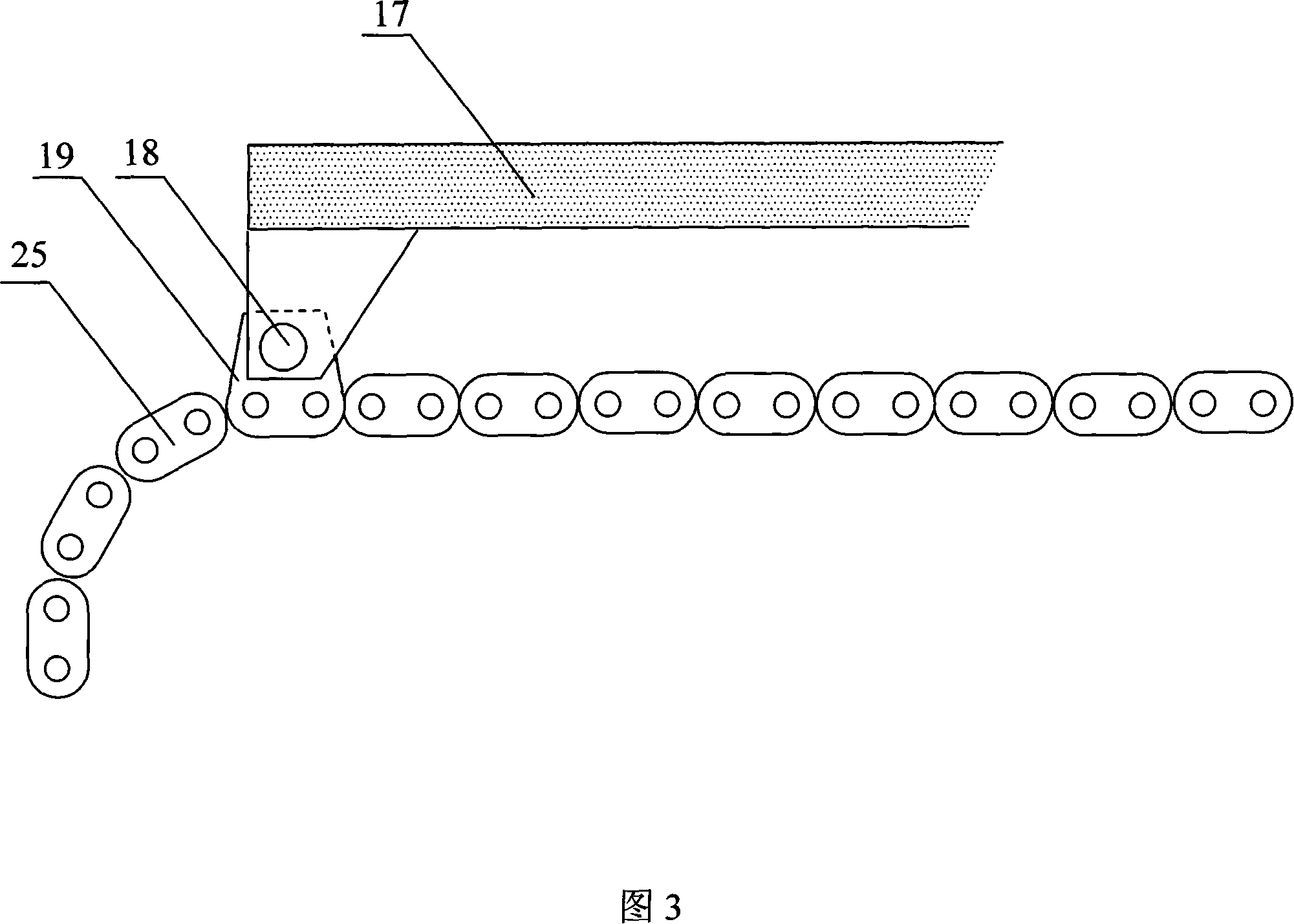

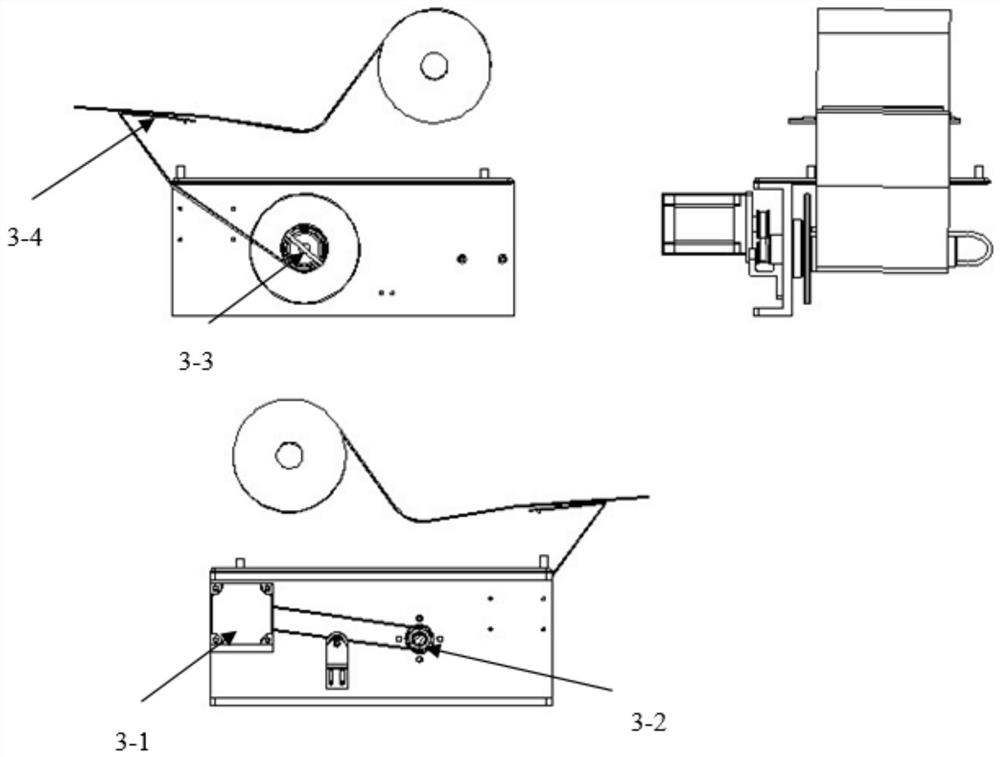

Film pick up and separating device

InactiveCN1554979AReliable pickupReliable separationCamera body detailsRadiation diagnosticsSheet filmLaser imaging

The film picking-up and separating device for laser imaging instrument includes film feeding box and its seat, film sucking and delivering device and its rack. The film sucking and delivering device rack has mounted elastic dialing piece; the film sucking and delivering device consists of sucking disc, vertical carriage, vertical sliding rail, change-over valve, gear rack, gear, horizontal carriage, vacuum pump, vertical control motor, horizontal motor, detector and stroke switch. The present invention has the features of simple structure, reliable film pick-up and few damage to film.

Owner:NEUSOFT MEDICAL SYST CO LTD

Label paper sorting and conveying device

PendingCN110371418AGuaranteed continuous sorting and pickingExactly toLabelling machinesArticle separationTrademarkEngineering

The invention relates to a label paper sorting and conveying device. The device comprises a mounting support, a rack and an auxiliary support; the mounting support is located above the rack, a horizontal moving delivery device is arranged on the mounting support, one end of the horizontal moving delivery device is provided with a negative pressure type label paper picking device, a sand wheel moldis arranged on the rack, the auxiliary support is located on one side of the rack, and is provided with a swing type dual-mandrel trademark stack bracket, a connecting table is arranged between the auxiliary support and the rack, a trademark stack lifting device is arranged on the connecting table, and the negative pressure type label paper picking device corresponds to the trademark stack lifting device up and down. The device is reasonable in structural design, and rapid and convenient to operate. Continuous and stable label paper sorting and conveying can be achieved, work efficiency can be greatly improved, and compared with the prior art, the device saves labor force, and the operation manner is safer and more reliable.

Owner:ZHENGZHOU HONGYI MACHINERY

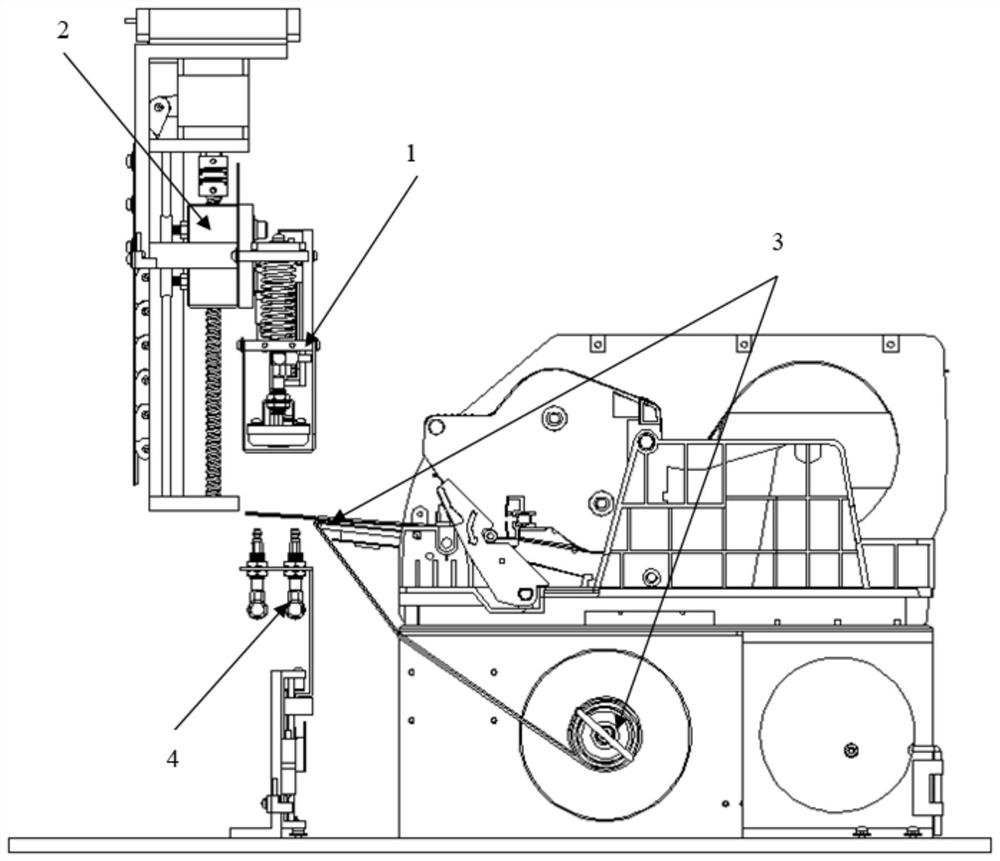

End executor of robot for steel coil labelling

The invention discloses an end executor of a robot for steel coil labelling. The end executor comprises an adapter flange, a substrate assembly arranged on the adapter flange and a labelling assemblyarranged on the substrate assembly and used for absorbing labels. According to the end executor of the robot for steel coil labelling, label picking and bonding can be reliably finished, work efficiency of steel coil labelling can be improved, work is stable and reliable, and the labelling success rate is high.

Owner:ANHUI MA STEEL AUTOMATION INFORMATION TECH

Method for operating workplaces on a textile machine for creating cross-wound spools

InactiveCN101987706BReduce negative pressureMake sure to separate slightlyFilament handlingYarnEngineering

Owner:SAURER GERMANY GMBH & CO KG

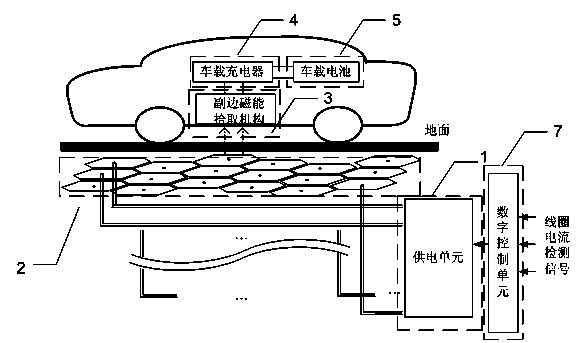

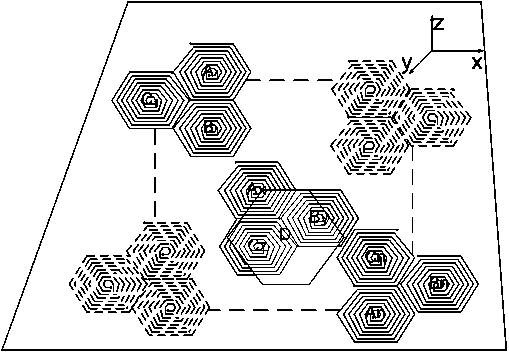

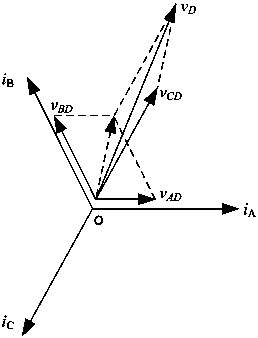

Three-phase wireless charging system and charging method for electric automobile

InactiveCN102856964BAvoid lossEfficient chargingBatteries circuit arrangementsElectromagnetic wave systemControl cellDigital control

The invention discloses a three-phase wireless charging system and a three-phase wireless charging method for an electric automobile, and belongs to a wireless power transmission system and a wireless power transmission method. The wireless charging system consists of a primary power supply device, a secondary charging device and a digital control unit, wherein the primary power supply device is arranged under the ground, the output end of the digital control unit is connected with the primary power supply device, and the secondary charging device is arranged on the automobile; a magnetic energy emitting array type coil in the primary power supply device is connected in series with a coil current detecting unit; and the output end of the coil current detecting unit is connected with the input end of the digital control unit. The system has the advantages that a primary magnetic energy emitting mechanism consists of the matrix array type coil, so that reliable charging of the electric automobile is ensured in a large range; by setting the winding direction of the primary array type coil, a zero point of secondary coil pickup voltage is avoided; and only one power supply group consisting of three adjacent primary coils closest to a secondary pickup coil supplies power is available for supplying power each time, so that other coils are prevented from running in an idle mode, and the efficiency of the whole system is improved.

Owner:CHINA UNIV OF MINING & TECH

A method of improving the signal-to-noise ratio of mine microseismic detectors

ActiveCN103852784BSuppress interferenceAvoid introducingSeismic signal receiversSignal-to-noise ratio (imaging)Frequency spectrum

The invention discloses a method for improving the signal-to-noise ratio of a mine micro-seismic detector. The method includes the steps that n+1 detector sensing units are installed in the mine micro-seismic detector in detector sensing unit maximum sensitivity directions; the frequency spectrum correlation of n+1 channel signals in the same direction is analyzed, effective signals are extracted, and suppression on random noise is achieved; mean value noise reduction is carried out on oversampling data of the same detector sensing unit through the non-correlation of the random noise by setting the oversampling rate of each signal detector sensing unit so as to improve the signal-to-noise ratio. By means of the method, the capacity for picking up unknown source signals of parameter information such as energy and frequency is improved, interference caused by the random noise is effectively suppressed, and the signal-to-noise ratio is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

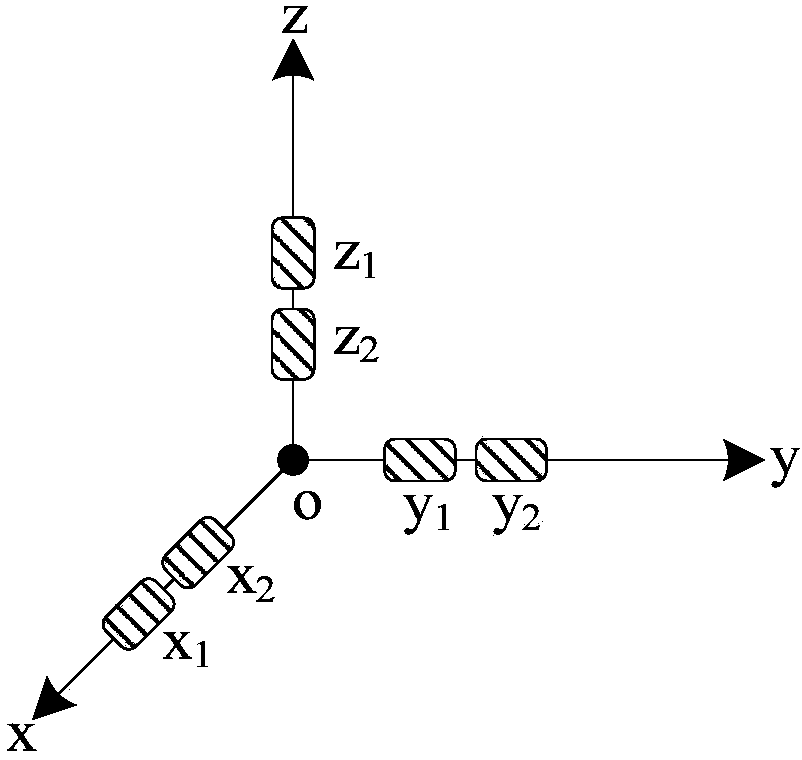

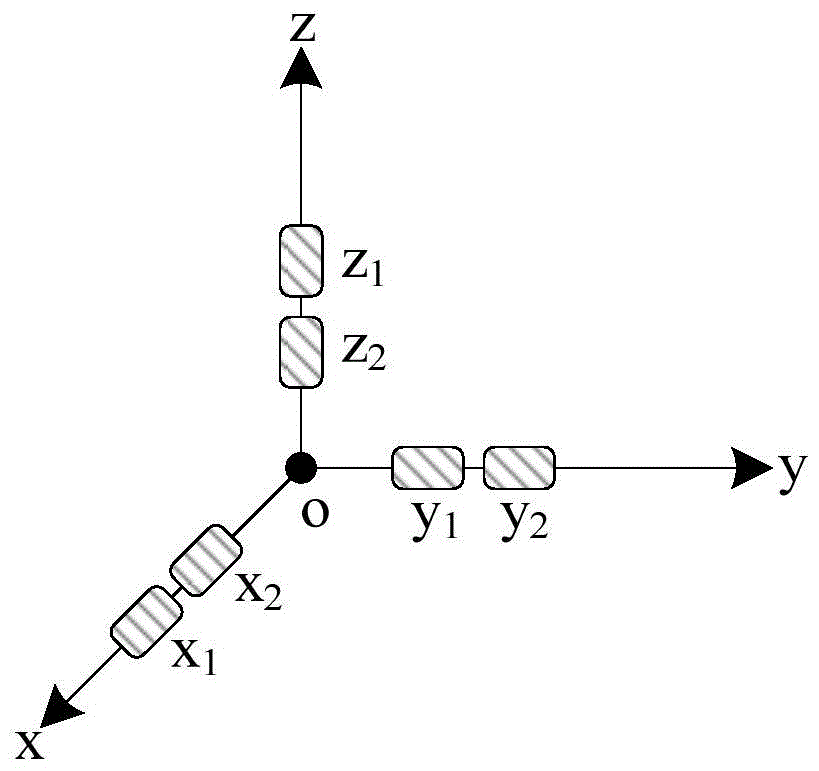

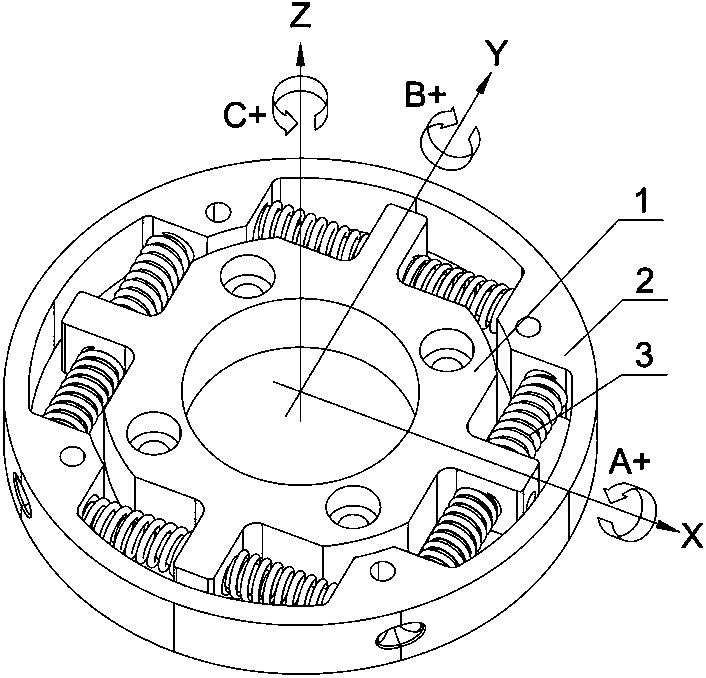

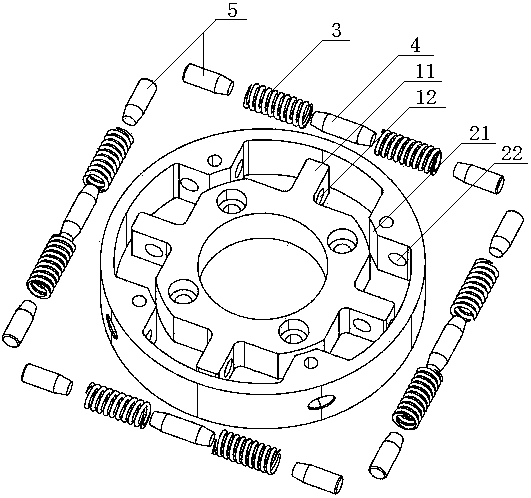

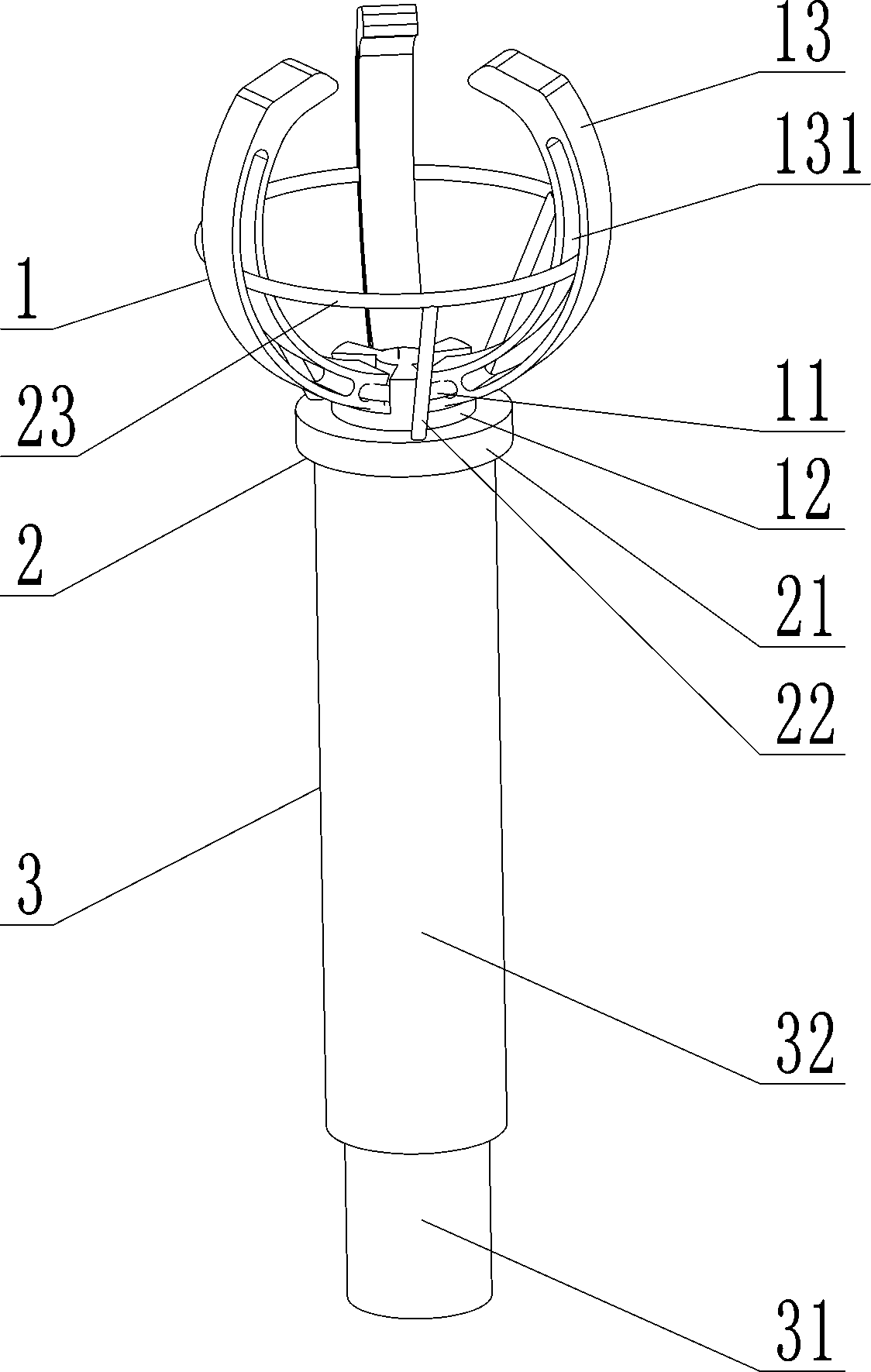

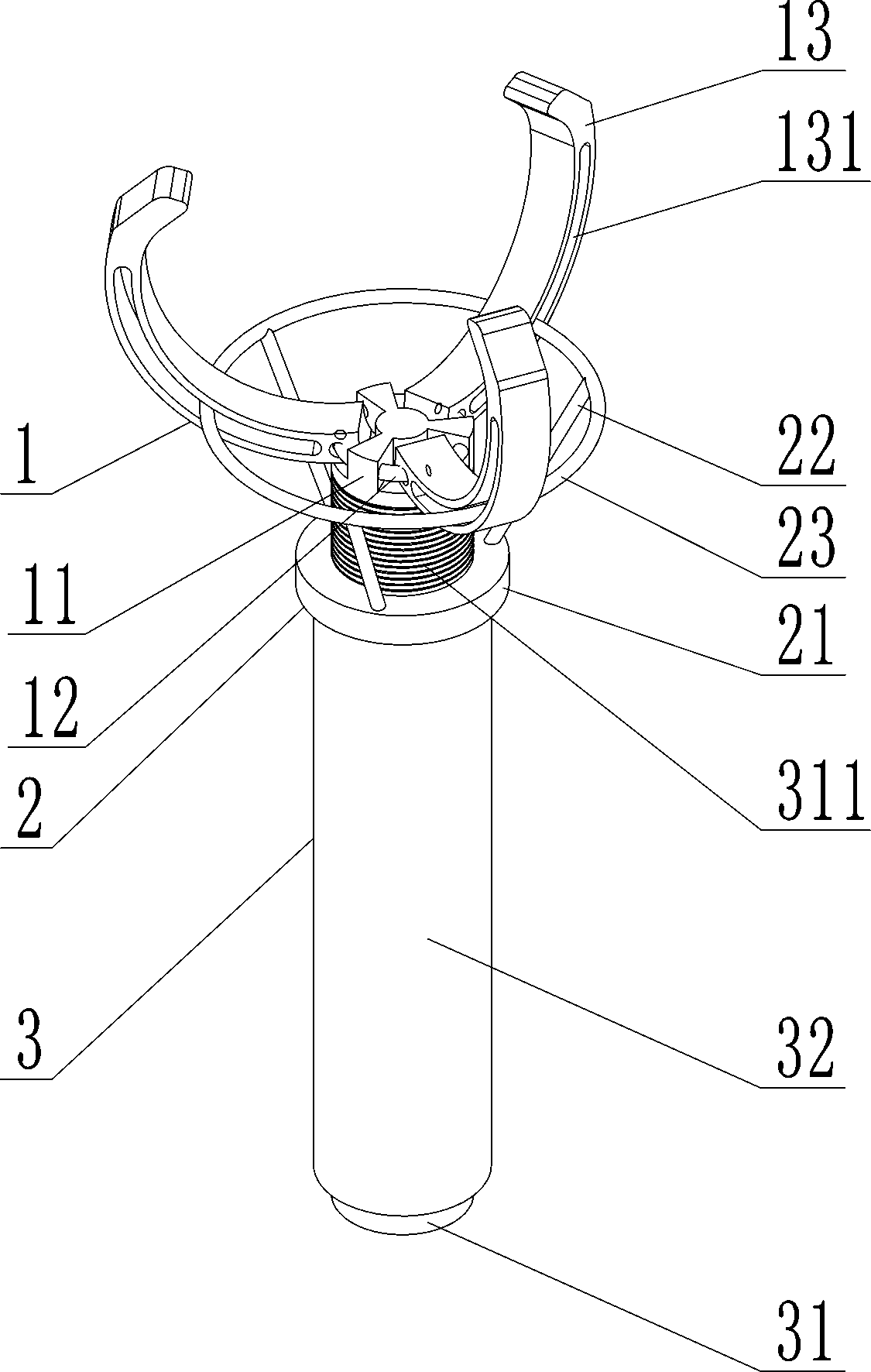

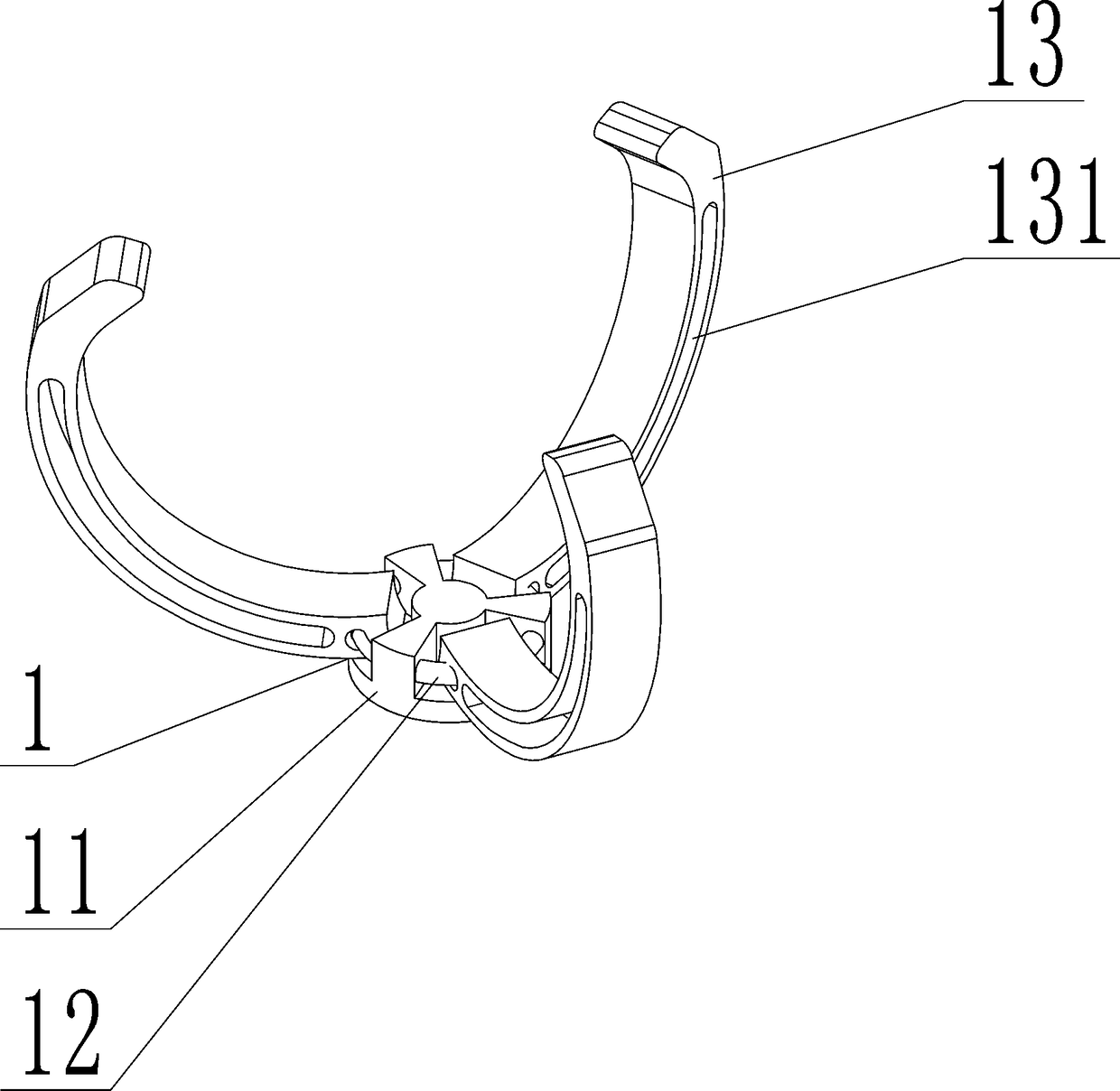

A Universal Compliance Mechanism

The invention provides a universal obedience mechanism which comprises an inner ring body, an outer ring body and elastic bodies, wherein the inner ring body is arranged in the outer ring body; the elastic bodies are arranged between the inner ring body and the outer ring body; the elastic deformation of the elastic bodies serves as the restoring tension for the relative translation, rotation andoverturning between the inner ring body and the outer ring body; gaps are reserved between the inner ring body and the outer ring body; and through the gaps, it is at least guaranteed that no interference is generated in the elastic deformation range of the elastic bodies in the stroke of relative translation, rotation and overturning between the inner ring body and the outer ring body. The universal obedience mechanism provided by the invention can not only provide translation compensation for the X-Y-Z linear directions but also provide rotation compensation for the three axial directions A-B-C corresponding to the X-Y-Z linear directions; furthermore, the reliability and the precision are high; and the application range is wide.

Owner:江苏汉格智能科技有限公司

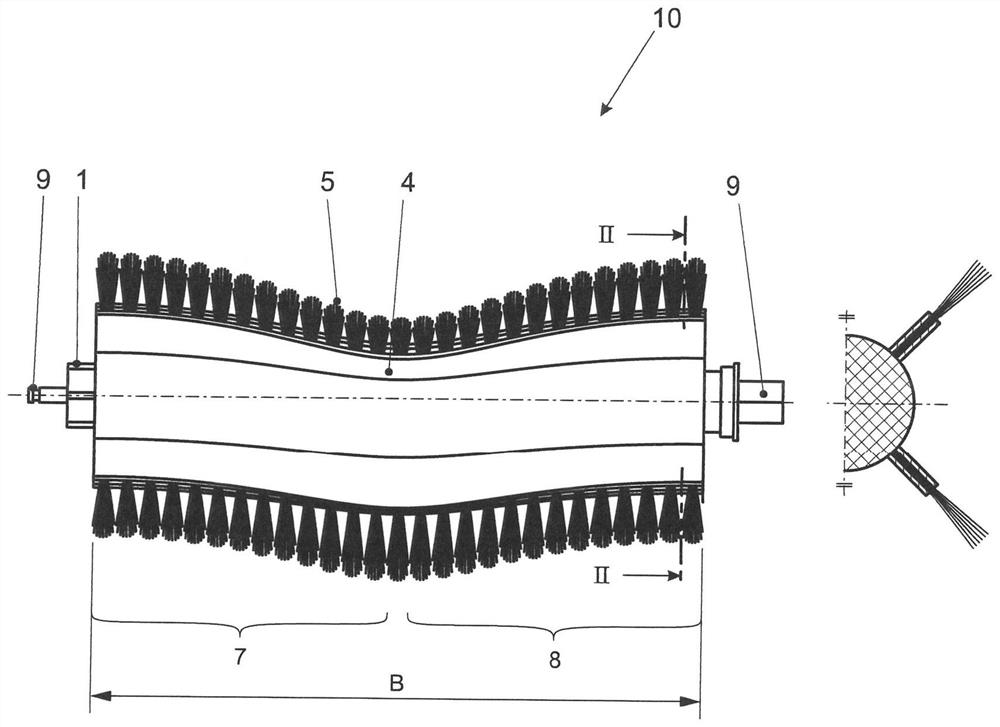

Rotatable cleaning roller and sweeping device having such a roller

InactiveCN111655106AEasy and quick cleanupReliable pickupCarpet cleanersBrush bodiesStructural engineeringFiber

Owner:CARL FREUDENBERG KG

A label peeling and picking device and method for an intelligent labeling printer

Owner:ZHONGTIE XINAN BEIJING INFORMATION SECURITY TECH

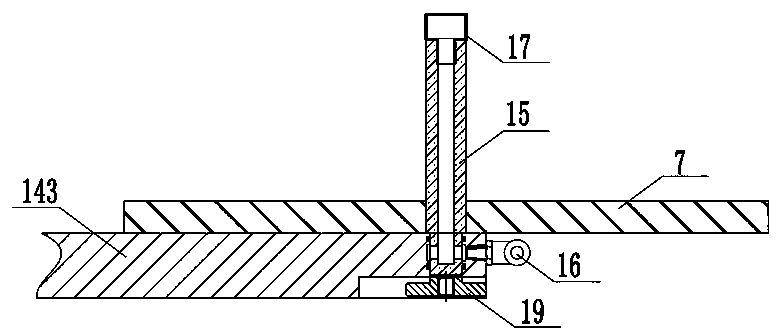

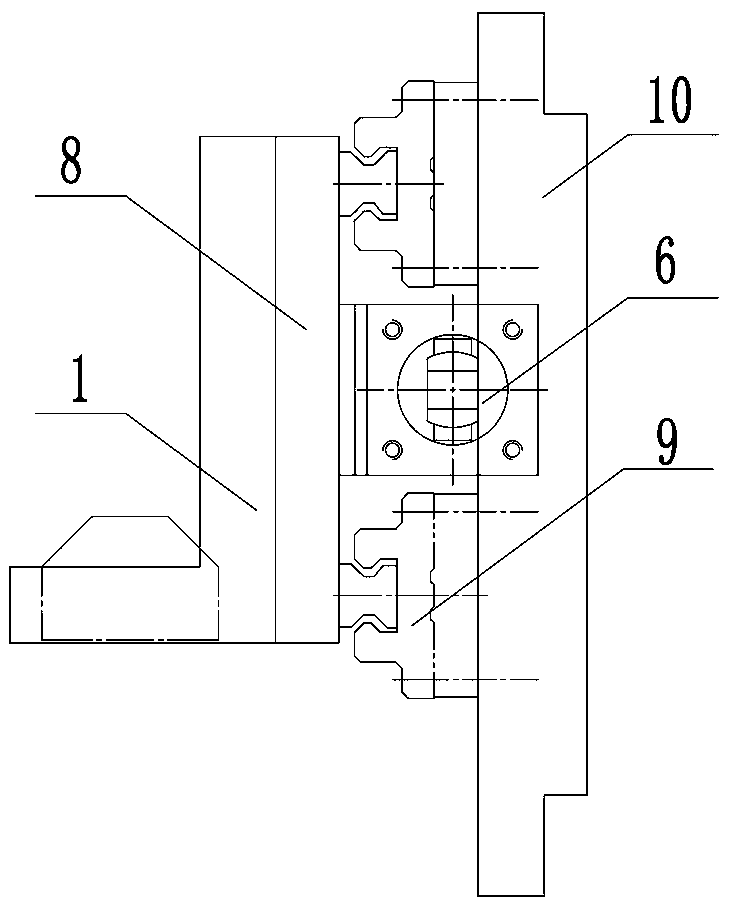

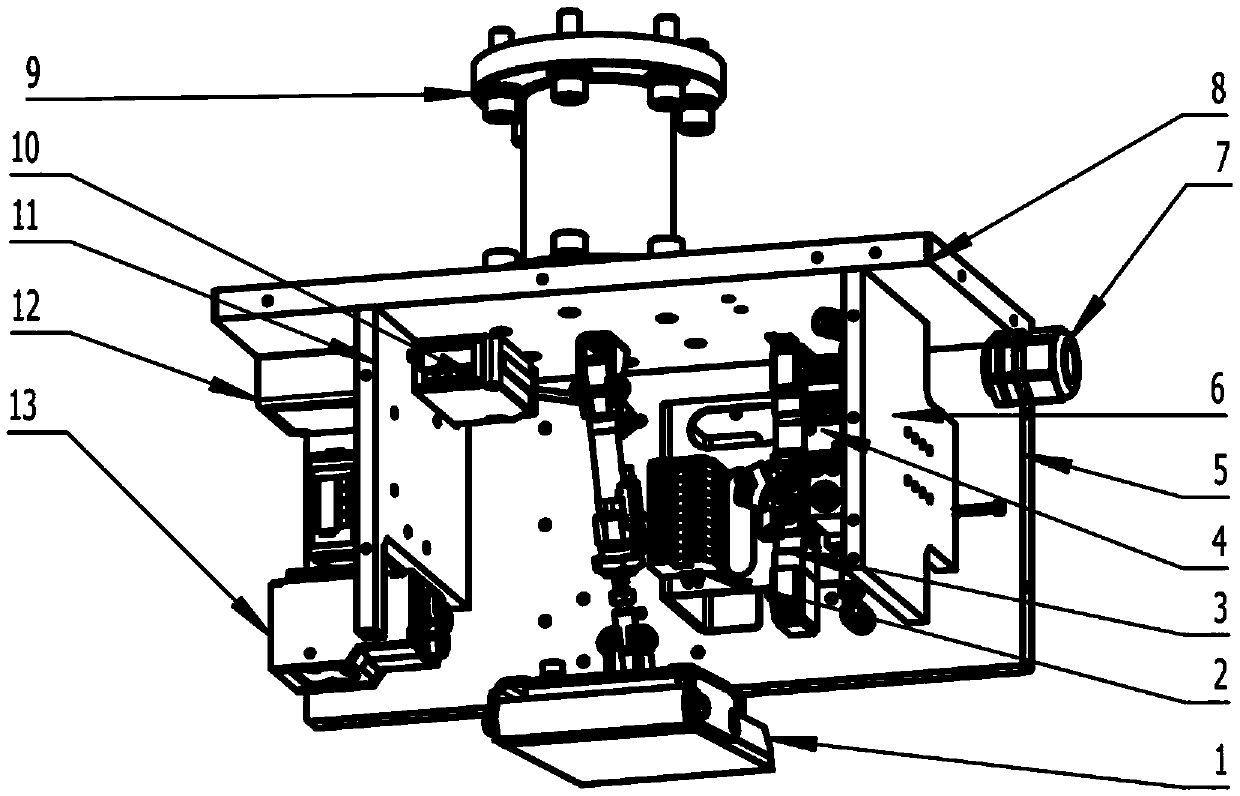

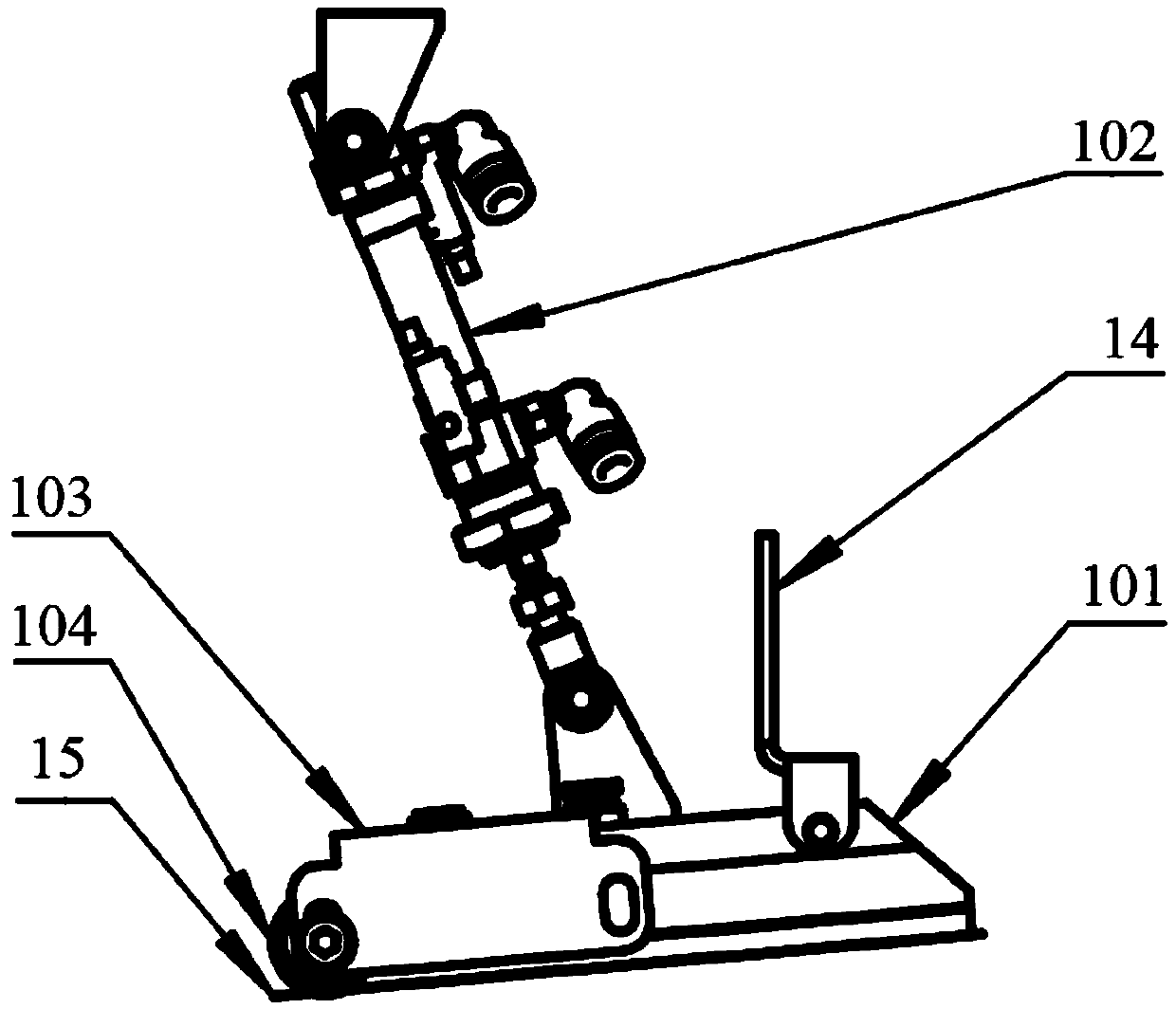

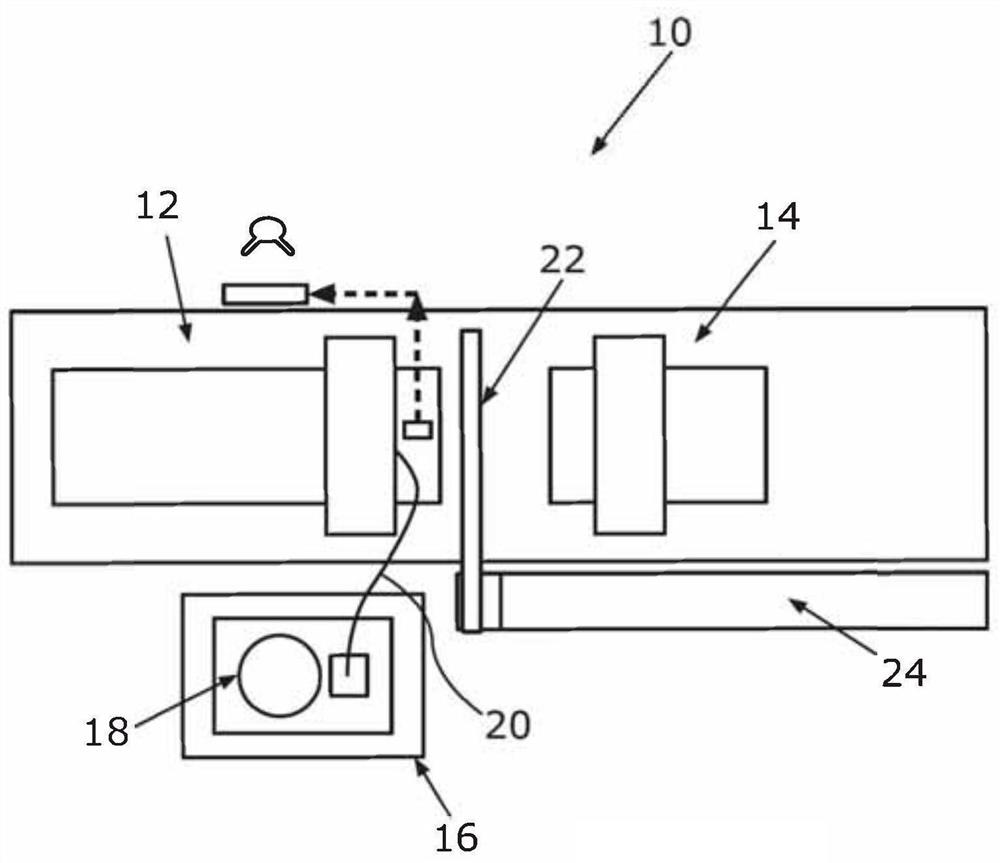

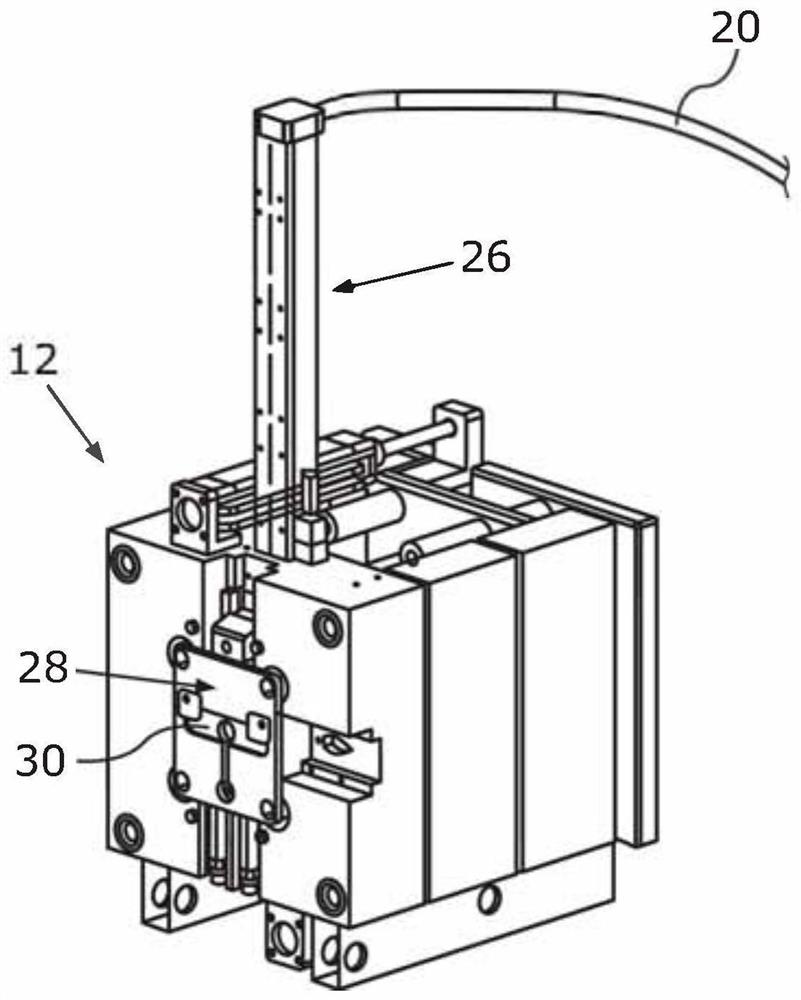

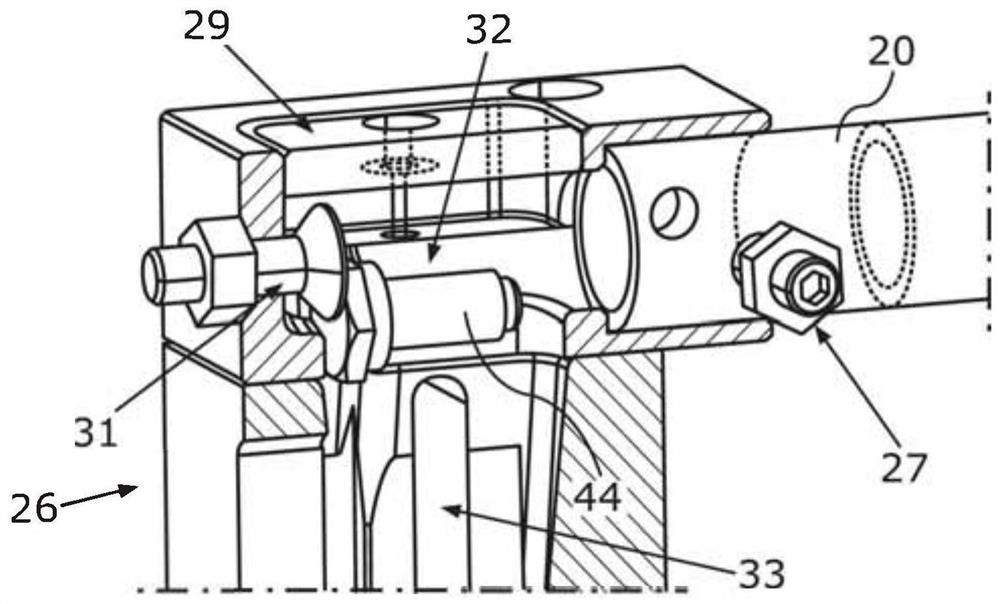

Mold half and method for producing injection molded part having at least one insert

The invention relates to a mold half (12) for an injection molding machine (10) for producing an injection molded part with at least one insert (32). The invention also relates to a method for producing an injection molded part having at least one insert (32).

Owner:LISA DRAXLMAIER GMBH

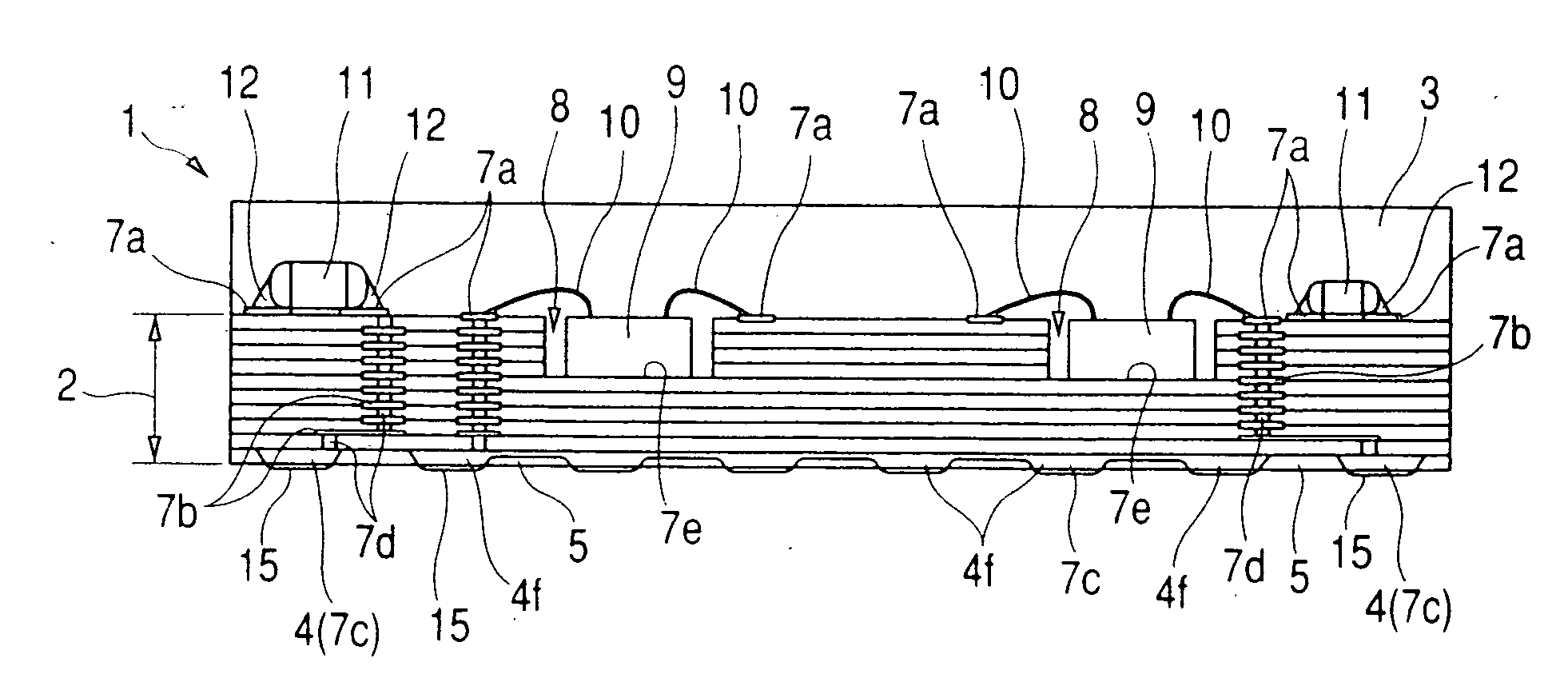

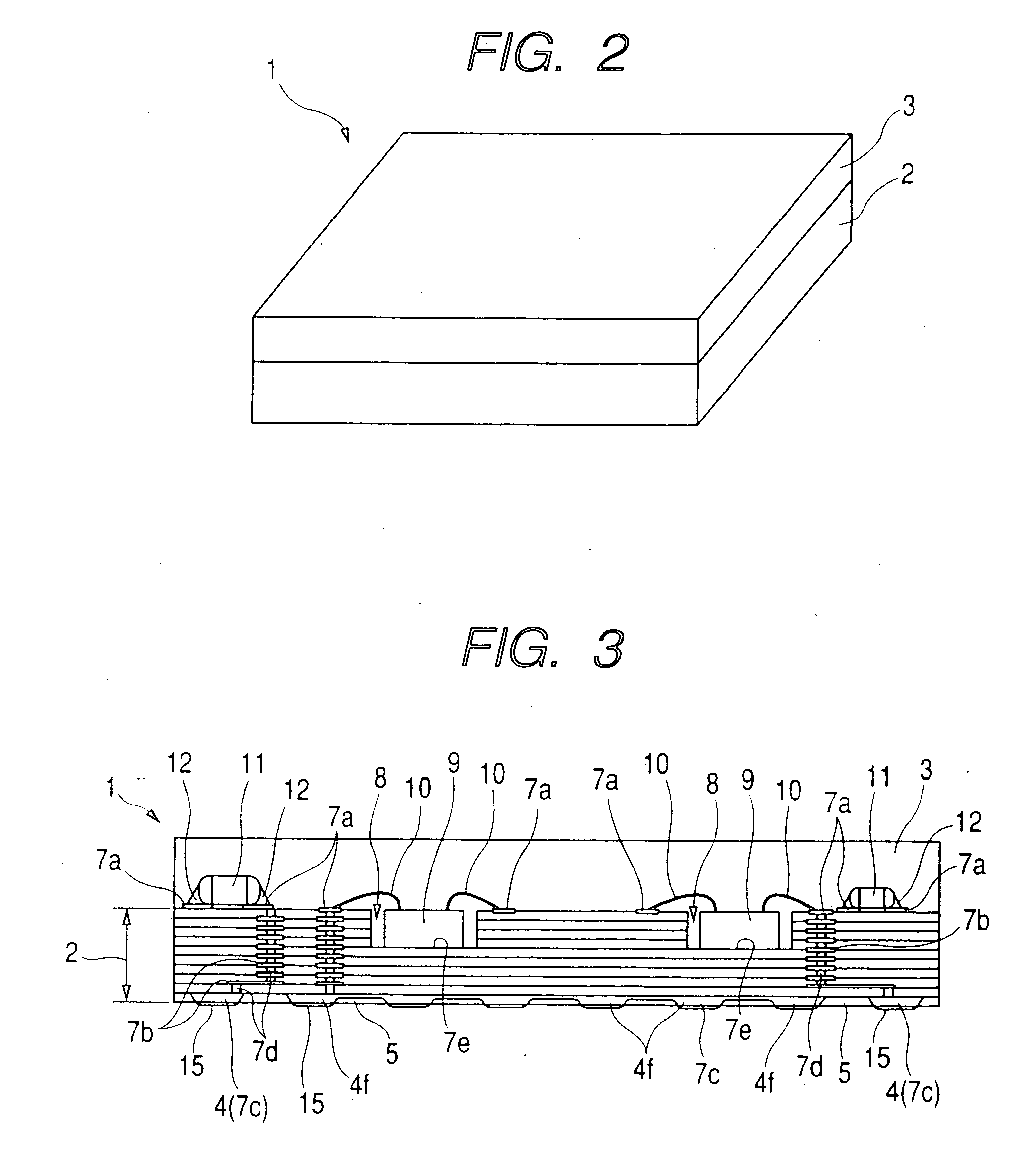

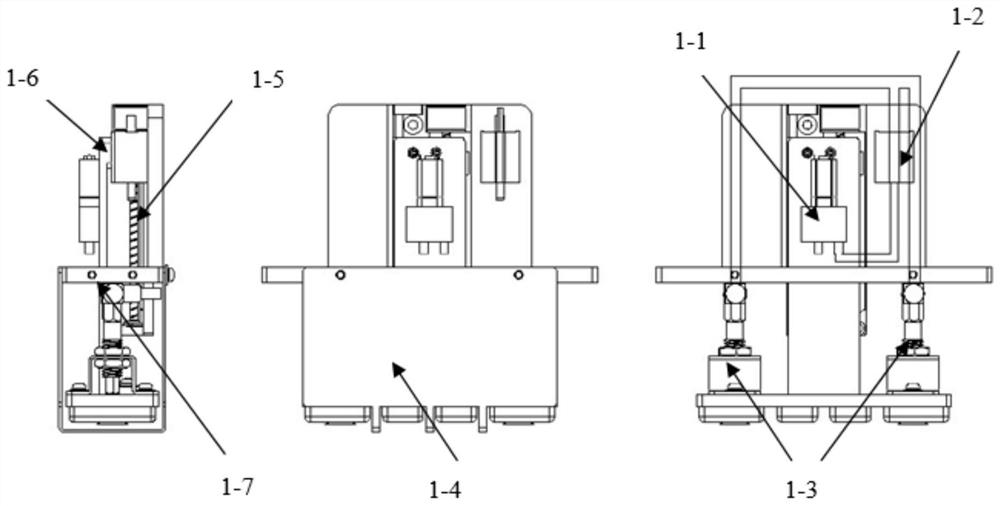

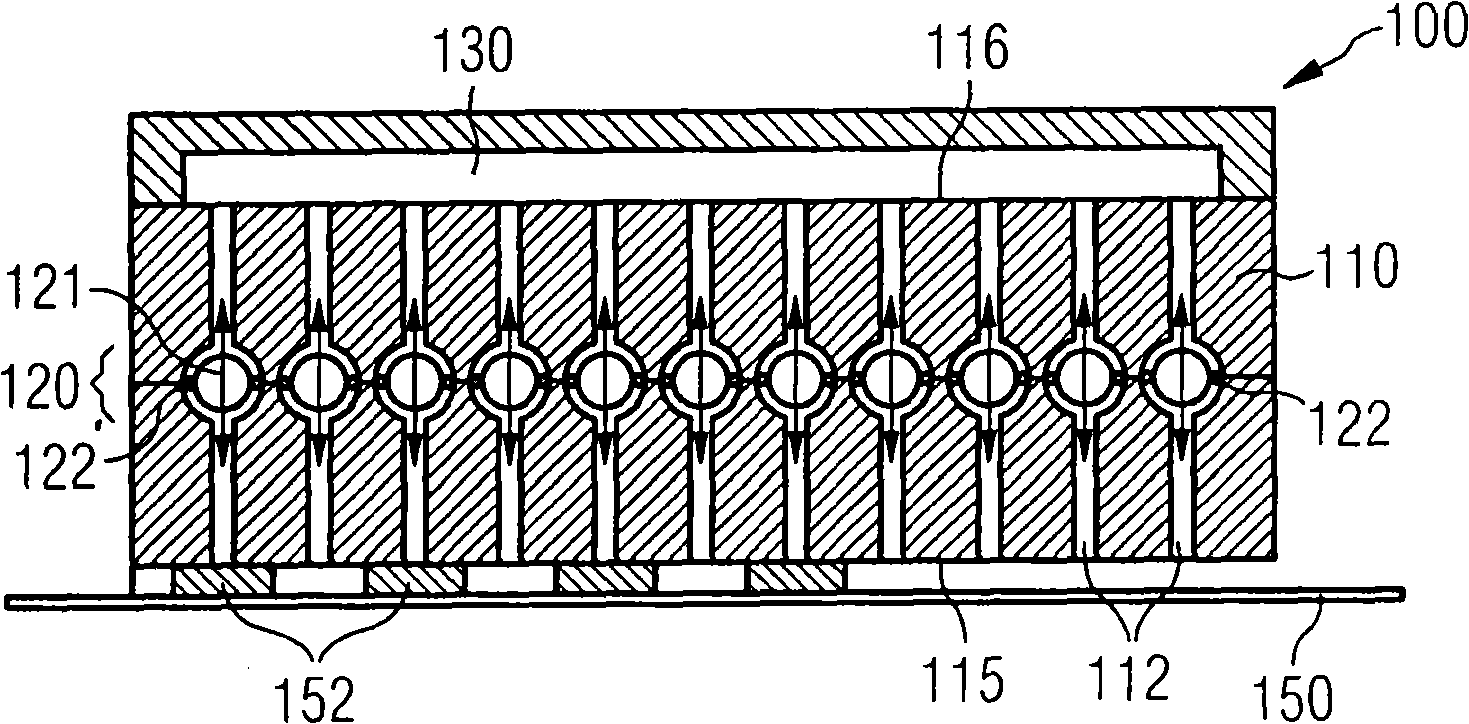

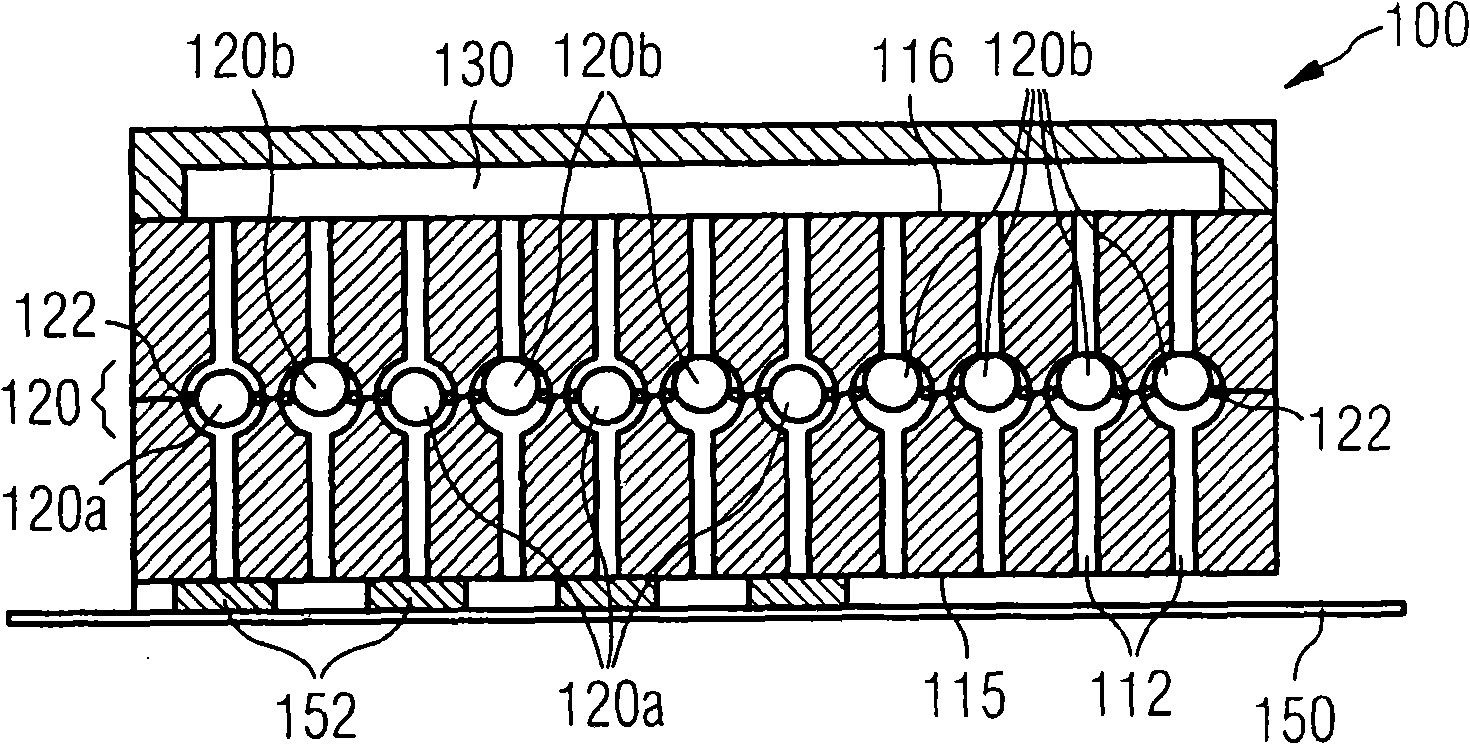

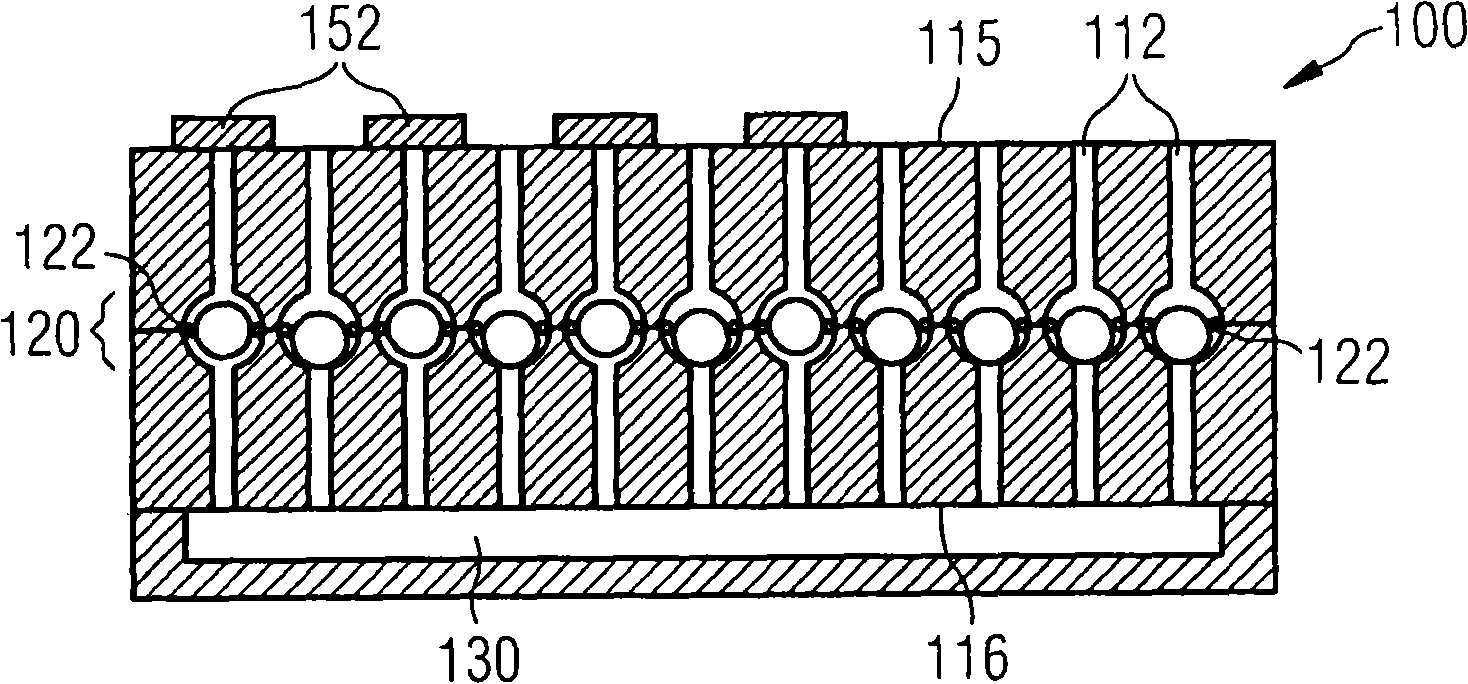

Containment of a number of electronic components with suction channels with a pneumatic adjustment element

InactiveCN101409250AImprove picking efficiencyReliable pickupSemiconductor/solid-state device manufacturingElectrical componentsEngineeringSemiconductor chip

A device for simultaneous accommodation of electronic components. The devie is specifically use for accommodation of a plurality of semiconductor chips from a chip unit. The chip unit has a support film and a semiconductor chip attached to the support film. The device has a base unit with multiple suction channels that extend from a front side of the base unit to a rear side of the base unit. Multiple pneumatic adjustment units i.e. passive components, are assigned to the respective suction channels. Each adjustment unit is equipped such that an air flow through the respective suction channel is partially blocked when the strength of the air flow exceeds a predetermined threshold value. An independent claim is also included for a method for simultaneous accommodation of electronic components. The method adopts the component accommodation deivce.

Owner:SIEMENS ELECTRONICS ASSEMBLY SYST LLC

Method for manufacturing semiconductor chip

InactiveCN100334689CPick up safeReliable pickupSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor packageSemiconductor chip

A semiconductor wafer (W) where circuits are formed in the area divided by streets is split into semiconductor chips having individual circuits. By interposing an adhesive sheet, whose adhesive force is lowered by stimulation, between the semiconductor wafer (W) and the support plate ( 13 ), the front side of the semiconductor wafer (W) is adhered to the support plate ( 13 ), thereby exposing the rear face ( 10 ) of the semiconductor wafer (W). The rear face ( 10 ) of the semiconductor wafer (W) with the support plate ( 13 ) is ground. After the grinding is finished, the semiconductor wafer (W) held with the rear face ( 10 ) up is diced into semiconductor chips (C). The adhesive sheet is given stimulus to lower the adhesive force and the semiconductor chips (C) are removed from the support plate ( 13 ). The semiconductor wafer and semiconductor chips are always supported by the support plate, avoiding damage and deformation.

Owner:SEKISUI CHEM CO LTD +1

Method and device for operating station of textile machine for manufacturing cross-wound spools and station for executing the method

The method involves providing a bobbin frame (8) for rotatably holding a cross-wound bobbin (5), where the cross-wound bobbin includes two bobbin edges. A single-motor drive (14) of a thread laying device (10) is controlled in adjustment with a position of a free thread end of a thread (16) connected to the cross-wound bobbin in an event of interruption in winding, such that a finger thread guide (13) of the thread laying device displaces the free thread end in a direction of one of the bobbin edges and positions the free thread end with defined length outside of the bobbin edge. An independent claim is also included for a workstation comprising an angular sensor.

Owner:SAURER GERMANY GMBH & CO KG

Grabbing device

InactiveCN109129387AOvercome costsOvercome or in some occasions it is not convenient for people to work directly with handsGripping headsBiomedical engineering

Owner:秦亮赪

Element feeding device and mounting machine therewith

The present invention provided a component supplying apparatus that can reliably pick up electronic components and can stably supply them to a mounting machine body. The component supplying apparatus supplies the electronic components to the mounting machine body 10 for mounting the electronic components on a substrate. The component supplying apparatus comprises an accommodation section 60 for accommodating a component tray 51 for accommodating the electronic components; a component leading mechanism 70 for leading the component tray 51 from the accommodation section 60 to a pickup region; and a component transfer mechanism 80 for transferring the electronic components in a component tray at the pickup region to a component supply position for passing the electronic components to the mounting machine body 10. The component transfer mechanism 80 comprises a transfer head 851 for picking up the electronic components from the component tray 51 at the pickup region; and a transfer head travel mechanism for moving the transfer head 851 that has picked up the electronic components to a component supply position.

Owner:YAMAHA MOTOR CO LTD

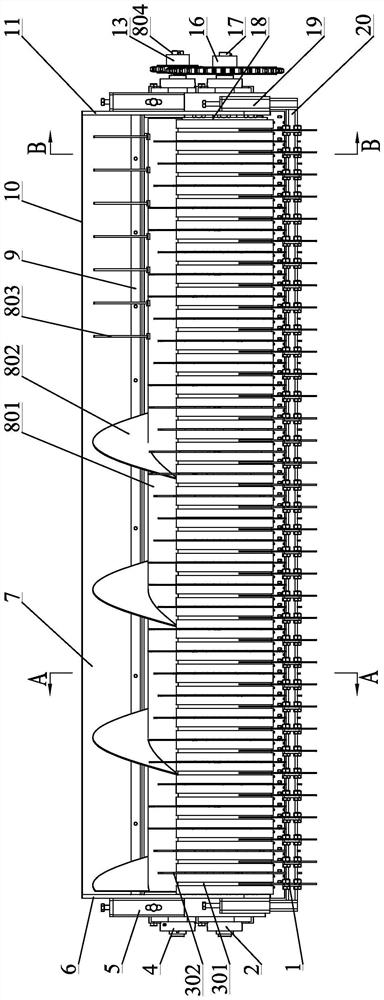

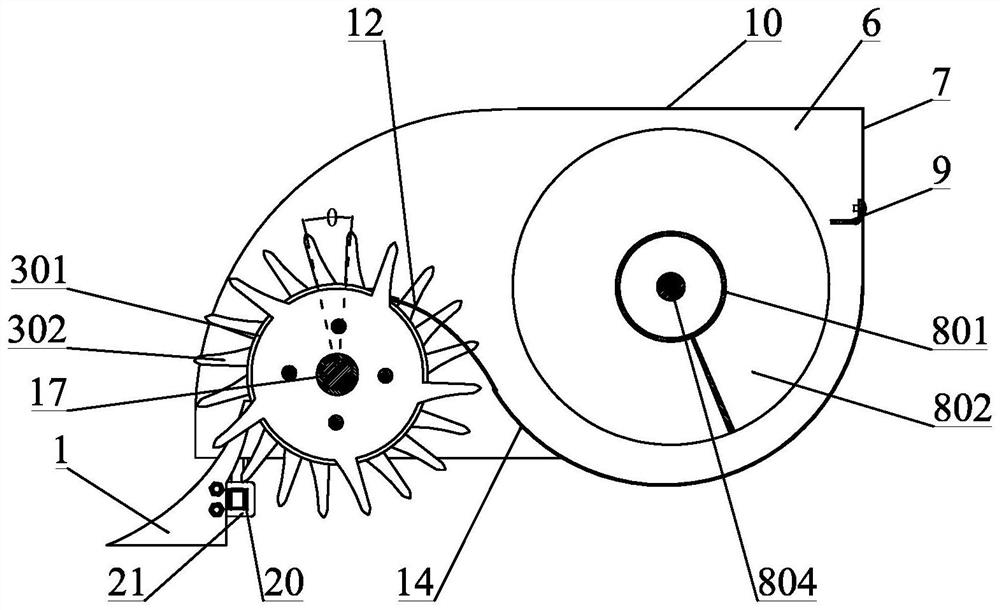

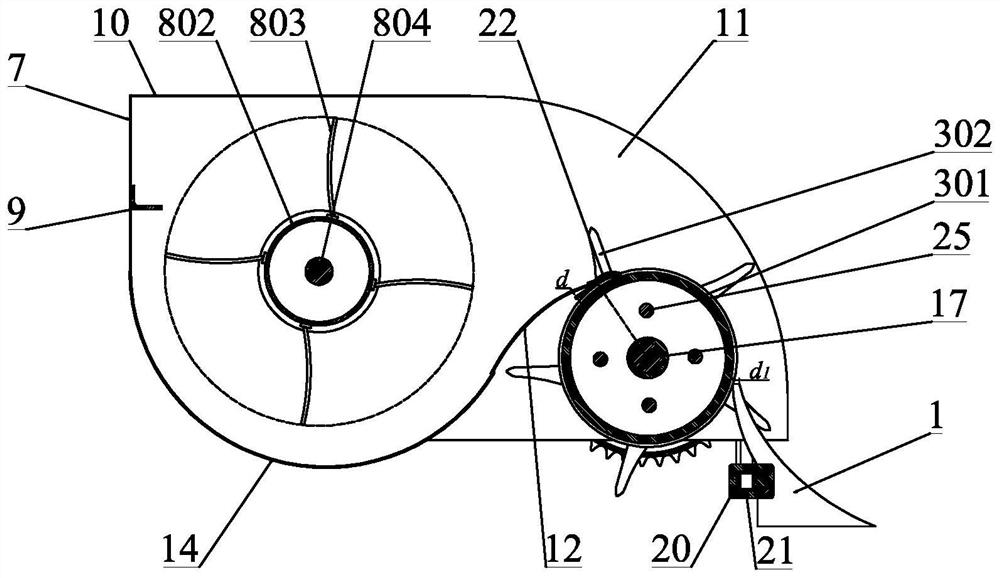

Fixed tooth and movable tooth combined step-by-step peanut picking device

PendingCN114557185AAvoid frictionImprove picking effectFood processingDigger harvestersAgricultural engineeringStructural engineering

The invention discloses a fixed tooth and movable tooth combined step-by-step peanut picking device, and belongs to the technical field of peanut harvesting machinery. Comprising fixed teeth, a picking roller, a seedling unloading plate, a sieve plate, a shell and an auger, the two ends of a roller shaft of the picking roller are fixed to a left side plate and a right side plate of the shell through picking roller bearing seats, a row of fixed teeth are arranged below the working front end of the picking roller, each fixed tooth is provided with an arc-shaped working face, and the end, close to the picking roller, of each fixed tooth is tangent to the circumference of the picking roller; the auger is arranged behind the picking roller through an auger bearing seat, a sieve plate is arranged below the auger, and the sieve plate is connected with a seedling unloading plate which is in transition connection with the picking roller and is matched with the auger to form a kinematic pair. The peanut picking process is divided into two steps, the fixed teeth go deep into the earth surface by a certain depth to shovel up peanut plants, then the peanut plants are driven by the picking roller to move upwards, and the picking and pushing process is completed. Peanut plants are unloaded by the seedling unloading plate and then slide into a rear auger.

Owner:JILIN AGRICULTURAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com