Distributing device for automatic distribution system

A dispensing device and automatic technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of unsafe picking, high labor intensity, unsuitable distribution of mixed and fragile products, etc., to achieve the goal of picking and delivering cargo safety and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

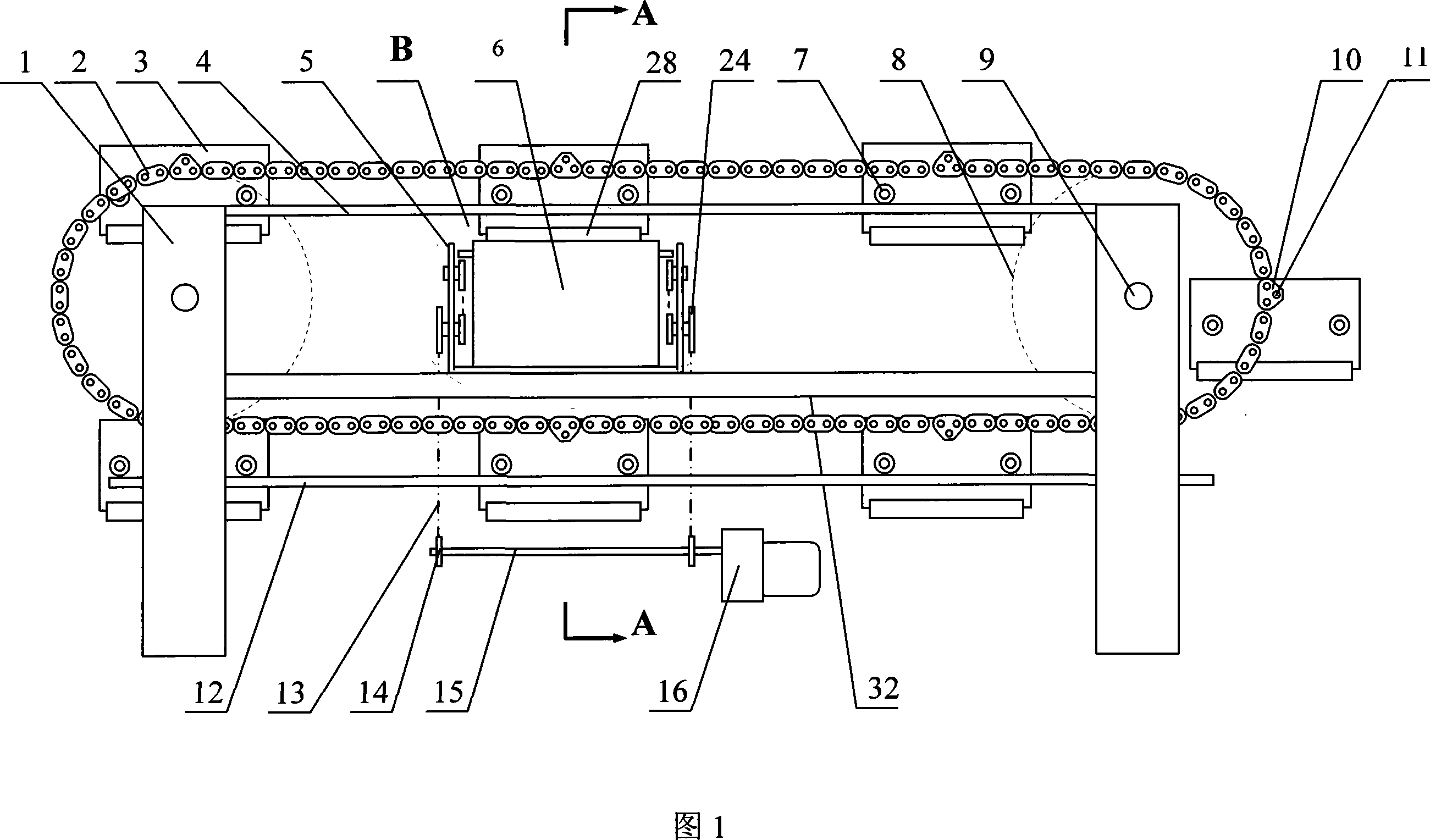

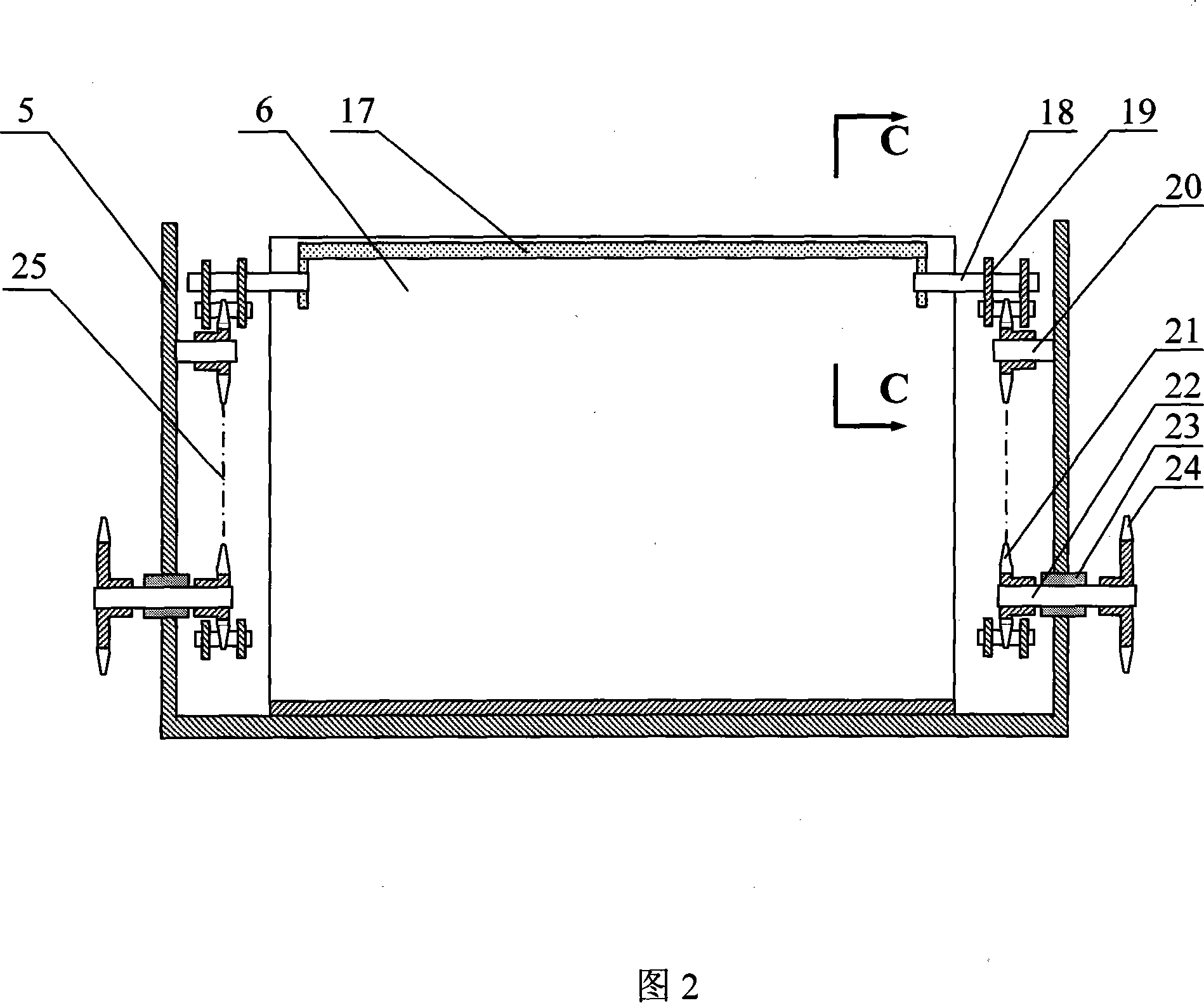

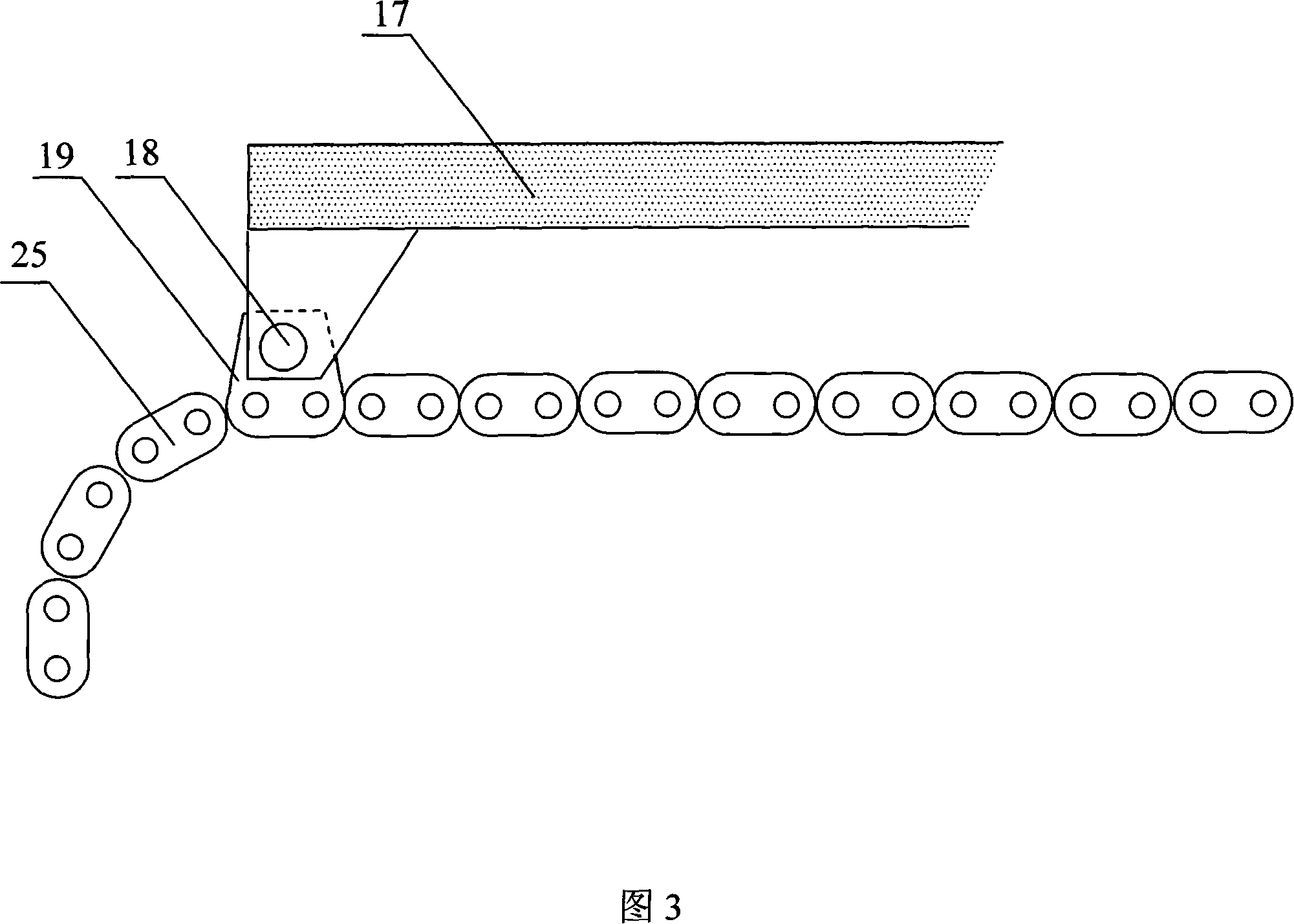

[0026] 1 to 4 show the specific structure of Embodiment 1 of the present invention.

[0027] Fig. 1 mainly shows the relative relationship between conveying and extracting two major parts. For the sake of brevity in the drawing, the conveying wheel 8 and the sliding baffle drive chain 13 are represented by dotted lines, and the sprockets and chains in each figure are also the same. Conveying part: the bracket 1 includes components such as beam 32, upper rail 4 and lower rail 12, the conveyor sprocket 8 rotates around the conveyor sprocket shaft 9 set on the bracket 1, the rotary conveyor chain 2 meshes with the conveyor sprocket 8, and the cargo bucket 3 The hanging shaft 11 of the bucket on it passes through the hinged chain plate 10 of the conveyor chain 2 on the rotary conveyor chain 2 and hangs on the rotary conveyor chain 2, and rotates together with the rotary conveyor chain 2, and the roller 7 on the cargo bucket 3 makes the cargo bucket 3 horizontal It is supported on ...

Embodiment 2

[0038] In order to simplify the structure, the shape of the endless chain 25 can be changed, the two ends mesh with two larger sprockets, the up and down translation motion segment remains unchanged, and the lifting motion segment at the left and right ends changes from a straight line to an arc, see Figure 10 for details. The working principle remains the same.

Embodiment 3

[0040] 11 and 12 show the specific structure of Embodiment 3 of the present invention.

[0041] In this embodiment, the opening and closing bottom plate 28 is made into a section of circular arc or a polygonal pseudo-circular arc centered on the axis of the opening and closing bottom plate hinge support shaft 29, and is set as two symmetrical parts that are relatively opened and closed, so as to reduce the number of opening and closing bottom plates. 28 fully open the required occupied space. The structure of its extracted part is the same as that of Embodiment 1.

[0042] In Fig. 11, the cargo bucket 3 is provided with opening and closing base plate hinge shafts 29 on both sides of the paper surface direction, and the opening and closing base plate 28 is provided with an opening and closing base plate crank 31, and the upper end of the opening and closing base plate crank 31 is fixedly connected with the synchronous gear 30 and The hinge is supported on the hinge support sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com