Patents

Literature

106results about How to "Improve picking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

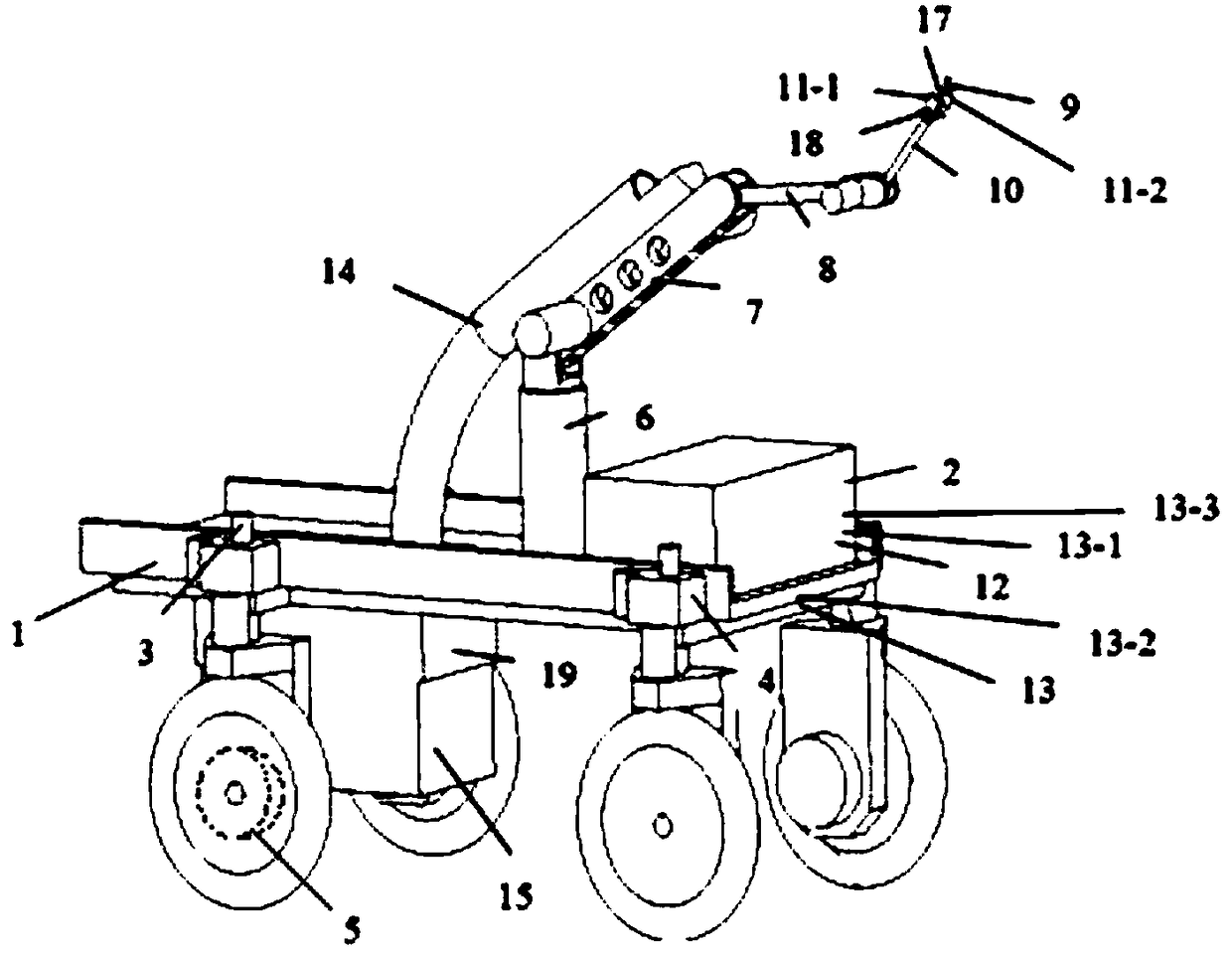

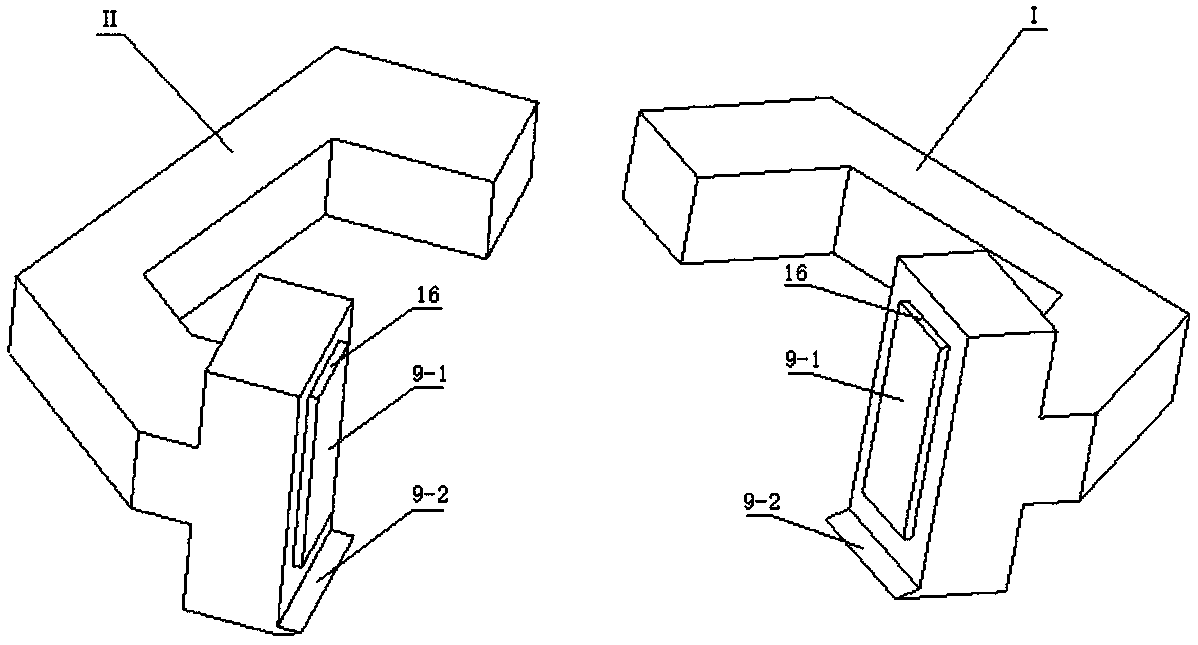

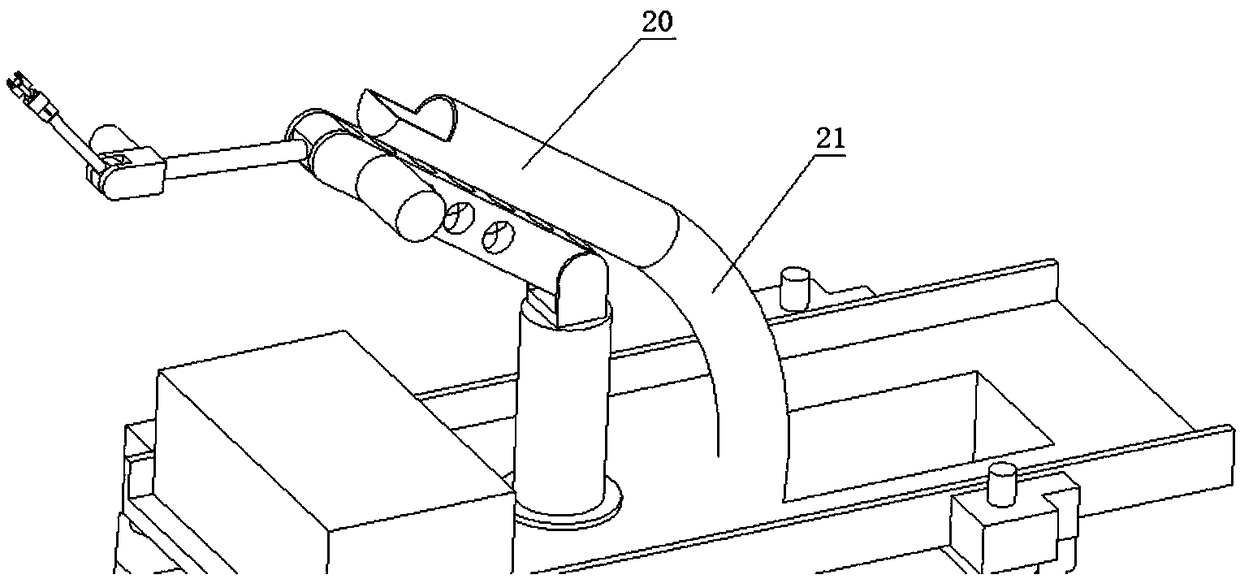

Wolfberry picking robot and control method thereof

InactiveCN105123127ARealize self-pickingRealize normal pickingPicking devicesControl mannerData acquisition

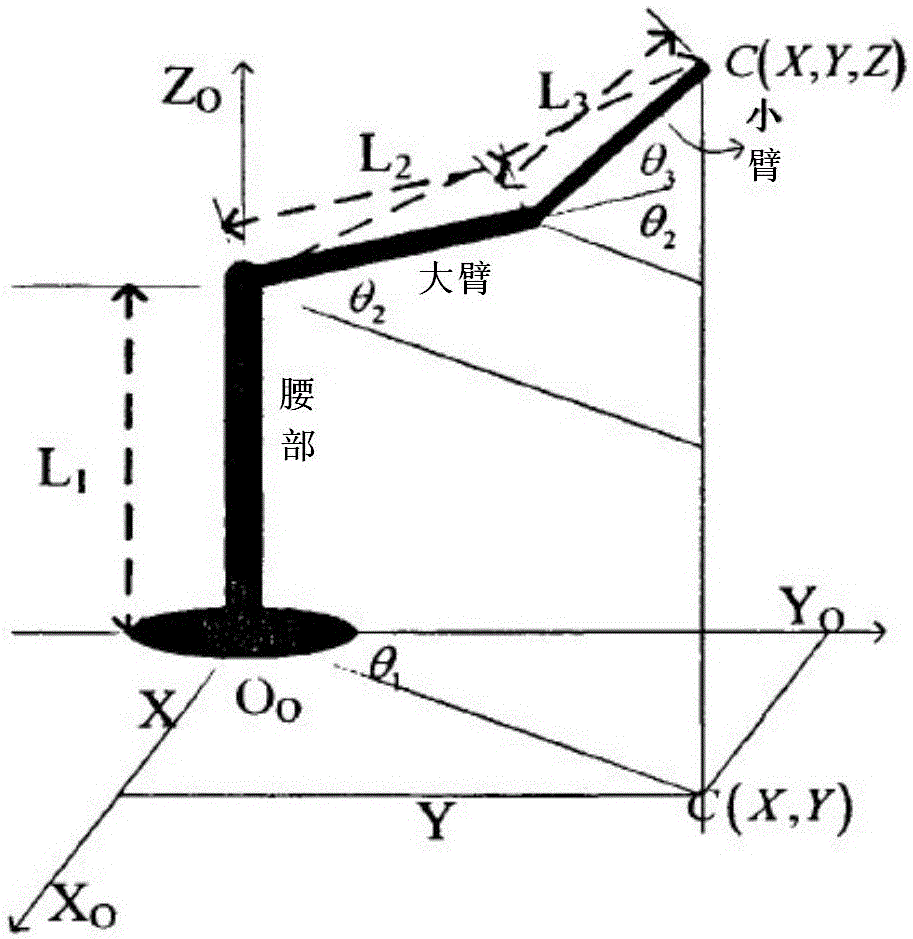

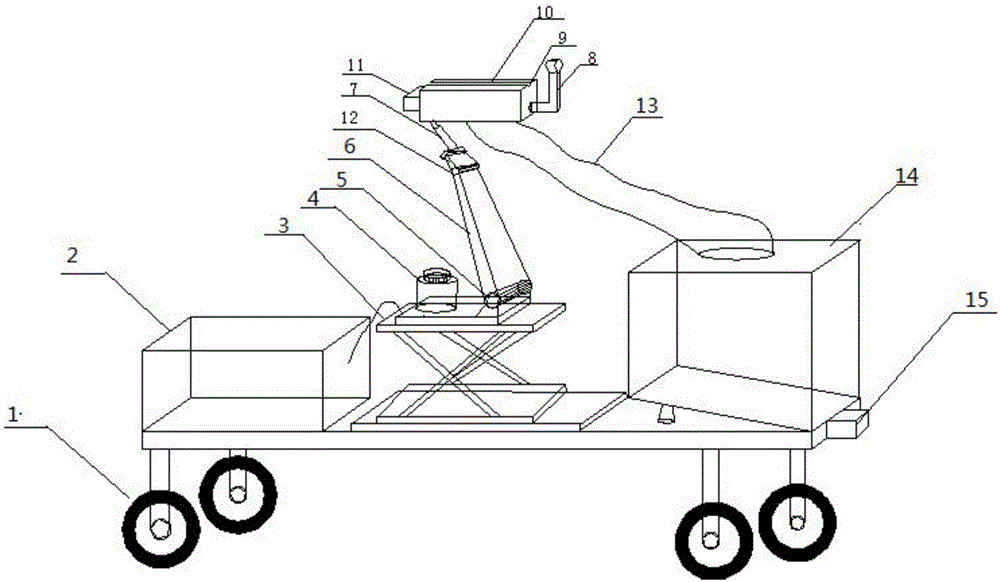

The invention discloses a wolfberry picking robot. A wolfberry picking robot system adopts a pinhole imaging technology and mainly comprises a data acquisition card and an analog-digital conversion module. A control method mainly adopts a fuzzy PID self-adaptive control way and is mainly used for controlling the vision. Hardware of the wolfberry picking robot mainly consists of a mechanical arm, a rotor structure, a picking head and various motors. By adopting the wolfberry picking robot, the automatic picking of wolfberry can be implemented, the manpower can be completely substituted, and the problem that the manual picking is subjected to the influence of the environment can be solved. The wolfberry picking robot is high in automation degree and high in picking efficiency.

Owner:BEIFANG UNIV OF NATITIES

Multifunctional soft mechanical arm for detecting ripeness of fruits

InactiveCN110039533AIncrease frictionImprove gripProgramme-controlled manipulatorGripping headsCapacitanceRipeness

The invention discloses a multifunctional soft mechanical arm for detecting the ripeness of fruits. The soft mechanical arm comprises a gripper assembly, a plurality of connectors, soft body single fingers, a soft body strain sensor and a soft body pressure sensor, wherein the plurality of connectors fixedly arranged below the gripper assembly, the soft body single finger is fixedly arranged belowthe connectors, the soft body strain sensor and the soft body pressure sensor are fixed on the inner side of the soft body single fingers, the soft body single fingers are bent and deformed under thedriving of air pressure, the soft body strain sensor is used for measuring the bending deformation of the soft body single fingers when grabbing fruits with different sizes, the soft body pressure sensor is used for measuring the change of the contact surface capacitance so as to identify the hardness of the fruits. According to the multifunctional soft mechanical arm, the size and the hardness of different fruits can be recognized through the soft body strain sensor and the soft body pressure sensor, so that the ripeness of the fruits can be well detected, and the sorting or picking tasks ofthe ripe fruits can be completed.

Owner:苏州柔性智能科技有限公司

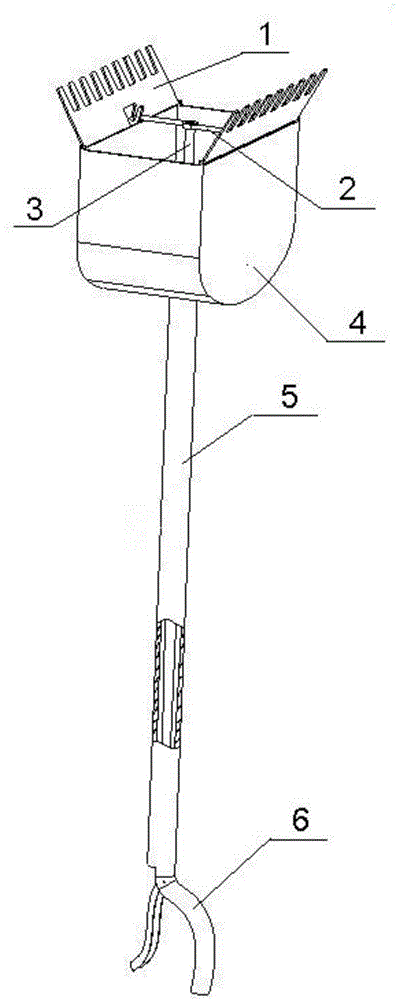

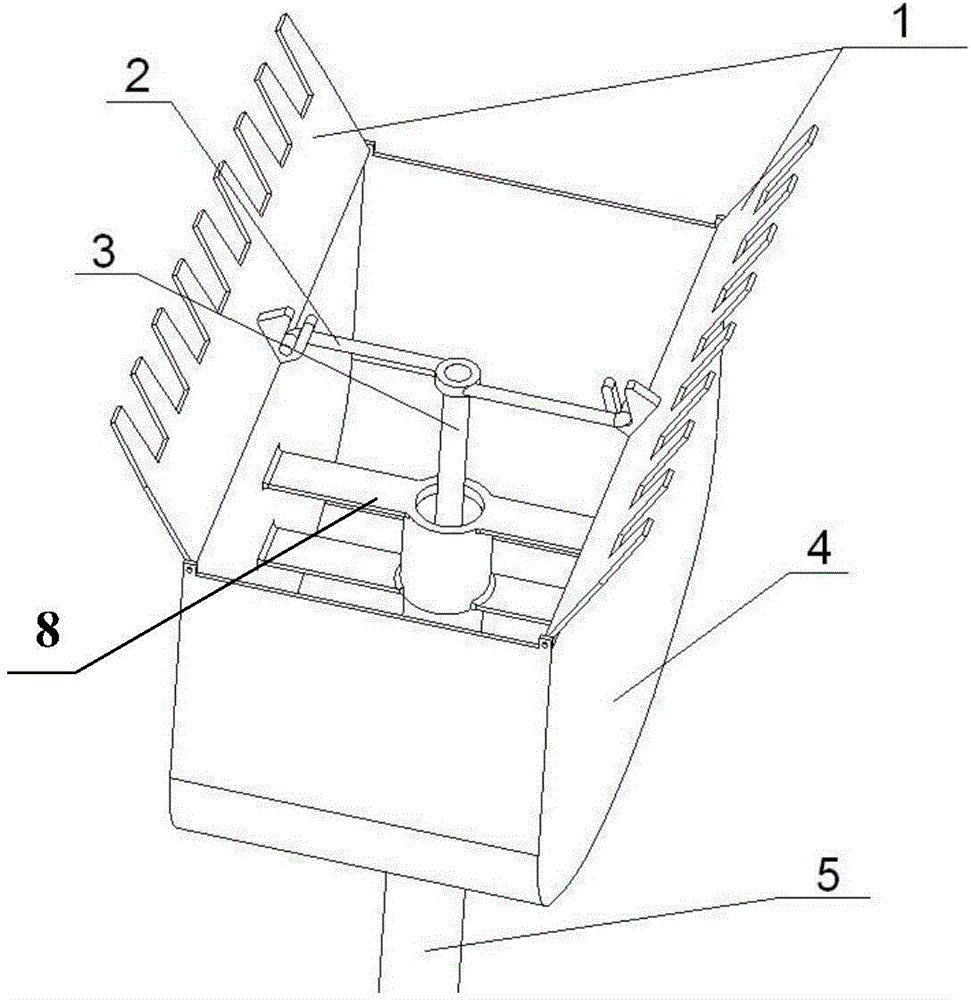

Device and method for picking ridge planting strawberries in greenhouse

InactiveCN103766073AEasy to implementSimple structurePicking devicesGreenhouseAgricultural engineering

The invention discloses a device and method for picking ridge planting strawberries in a greenhouse. The back side wall of a box body is fixedly connected with the lower part of a vertical carrying rod; the central part of the carrying rod is rotatably connected with a rocker; the lower end of the rocker extends into the box body to be fixedly connected to the rear end of a push rod positioned in the box body; the front end of the push rod is fixedly connected with one side surface of a disc positioned at the front part of the push rod; a shaft is parallel to the bottom wall of the box body and penetrates through the center of the disc; both ends of the shaft are rotatably connected with the left and the right inner side walls respectively through a stepped shaft; the middle section of the stepped shaft is a square shaft; the lower part of a first rocker arm is sheathed on the square shaft in a matching mode; the upper end of the first rocker arm is fixedly connected with one end of a second rocker arm, the other end of the second rocker arm is rotatably connected with a fence; left and right horizontal guide rails are arranged at the upper position of the fence; a slider blade moves left and right in the guide rails and is connected to the surface of the rotary disc through a linking rod; the center of the rotary disc is connected with the output shaft of a micro motor. The picking is convenient, and saves time and labor; therefore, a plurality of strawberries can be picked through one action.

Owner:JIANGSU UNIV

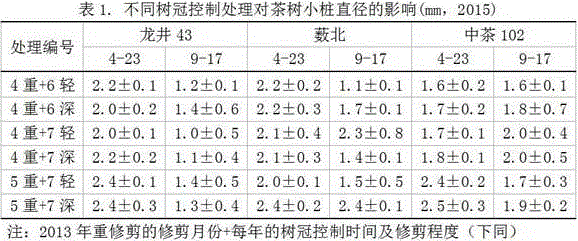

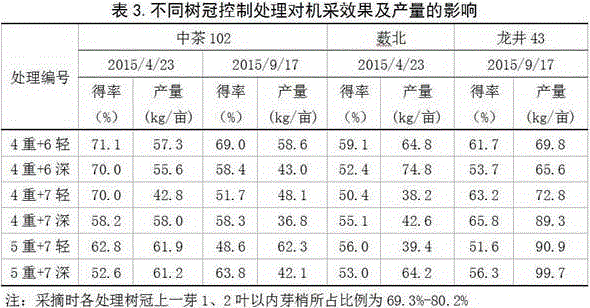

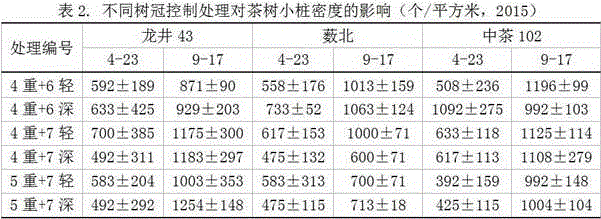

Method for building and managing famous tea mechanical plucking tea garden

ActiveCN105684820AThe skeleton level is clearEvenly distributedCultivating equipmentsPlant cultivationPlant variety

The invention provides a method for building and managing a famous tea mechanical plucking tea garden, and belongs to the technical field of plant cultivation. The method is characterized by mainly comprising the steps of tea garden selecting, tea plant variety selecting, planting, tree crown cultivating and pruning, mechanical plucking period and remaining, maintaining of plucked tea tree crowns and the like, wherein frames of tea trees of the built tea garden are clear in layer, ventilative and transparent, growing branches are thick and uniform in distribution, the tree crowns are small in surface, stumps are uniform in thickness, and the density reaches about 1000 / m<2>; young sprouts of each tea tree grow on a regular and smooth tree crown surface, bud leaves are distributed uniformly, the density is proper and can reach about 2000 / m<2>, timely plucking is conducted, the raw material yield of famous tea can reach 70%-75%, and the plucking effect is good.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

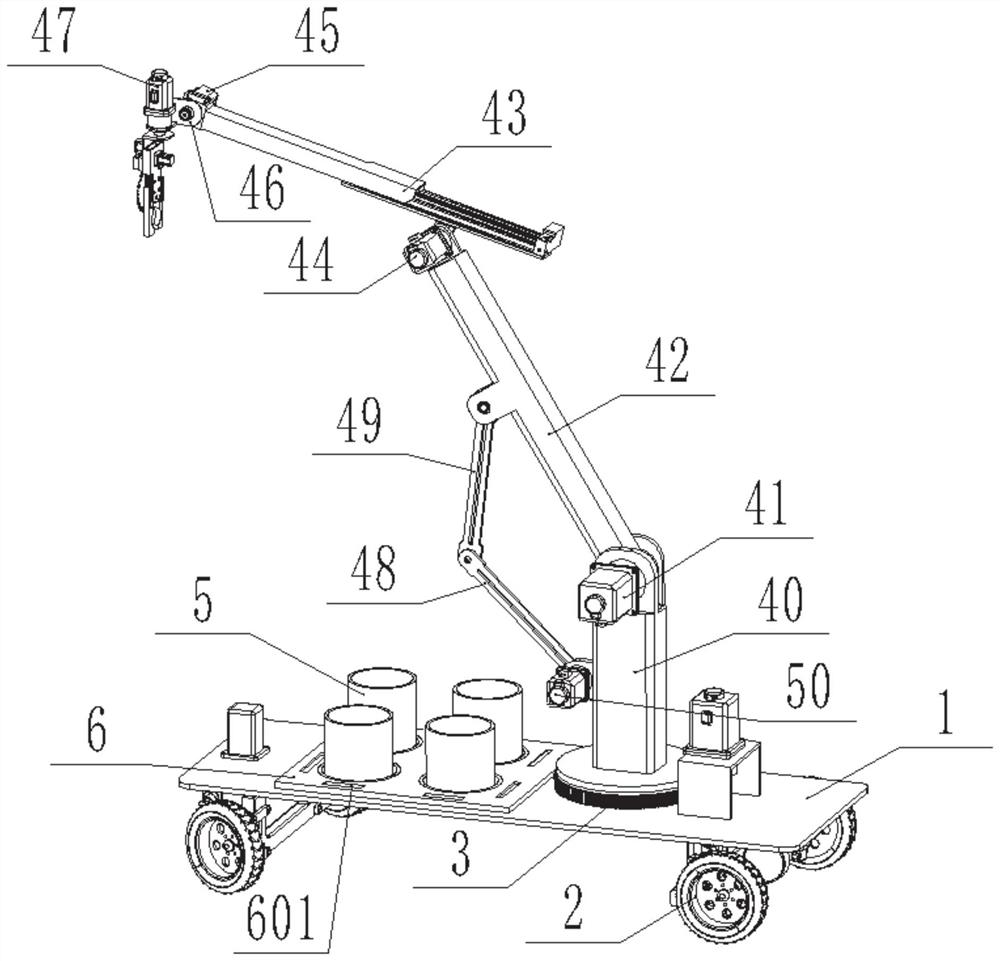

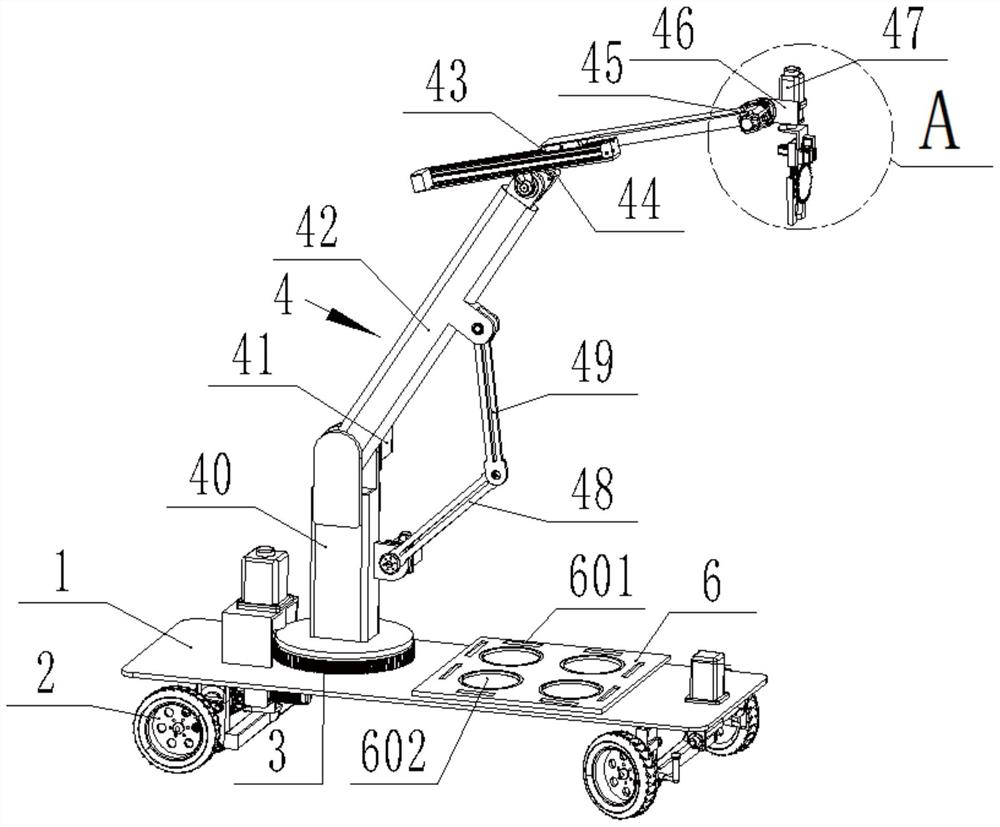

Robot and method for picking daylily

PendingCN109392462AEnsure flexibility and reliabilityImprove picking success ratePicking devicesPower controlDaylily

The invention discloses a robot and a method for picking daylily. According to the invention, a navigation walking system is adopted for navigation and positioning of the robot; a fruit picking systemis adopted for mechanical picking of the daylily; an object identification and positioning system is adopted for accurate identification and positioning in picking operation; a fruit collection device is adopted for timely collection of picked daylily; and an electric source and power control device is adopted for intelligent control to all systems. Through mechanical and electrical combination,and by combination of the growth characteristics and picking requirements of the daylily for highly-efficient picking, the manner of replacing manual labor with the robot is realized. The method provided by the invention controls the picking path of the robot for picking the daylily; three-dimensional coordinates of a feature point are obtained to be fed back to the electric source and power control device, so the feasibility and accuracy of the whole picking operation are guaranteed; and picking operation of the daylily is completed, and the picked daylily is timely collected, so the pickingand collection efficiency of the daylily is improved, the number of times of handling can be effectively reduced, and the quality of picked daylily is improved.

Owner:BEIFANG UNIV OF NATITIES

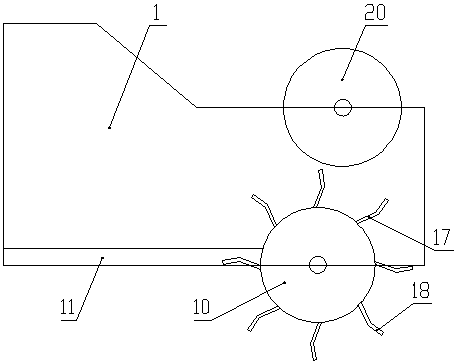

Green soy bean picking machine

The invention discloses a green soy bean picking machine which comprises a machine body. Two brush rollers are arranged at the front end of the machine body horizontally, a picking roller structure is arranged on the machine frame at the rear sides of the brush rollers, a locating roller is arranged at the bottom of the machine body and used for locating, a collecting packing auger is arranged on the machine body at the rear side of the picking roller structure, a conveyor belt is arranged at the bottom of the collecting packing auger in corresponding mode, and a flow guiding plate is arranged above the picking roller structure and the collecting packing auger. The picking roller structure comprises a mounted bearing, a roller drum support, material blocking plates, a roller drum and a plurality of long and thin steel wires. Two ends of the roller drum are arranged in the mounted bearing, the mounted bearing is fixed on the roller drum support, the material blocking plates are arranged at two ends of the roller drum, the plurality of long and thin steel wires are arranged on the roller drum surface evenly in surrounding mode, and the brush rollers and the roller drum are all driven by a hydraulic motor. The green soy bean picking machine is compact in structure, small in size and flexible to operate, improves a picking effect by knocking through the long and thin steel wires compared with manual picking and picking through needle rollers, increases picking speed, improves production efficiency, and reduces picking cost and device cost.

Owner:张鸿 +1

Auricularia auricula picking machine

PendingCN111512895AHigh degree of automationReduce manual labor intensityCultivating equipmentsMushroom cultivationEngineeringStructural engineering

The invention discloses an auricularia auricula picking machine and belongs to the technical field of production equipment of edible fungi. The auricularia auricula picking machine comprises a machineframe and an auricularia auricula picking device mounted on the machine frame, wherein the auricularia auricula picking device comprises an auricularia auricula picking tube and a driving mechanism for driving the auricularia auricula picking tube to rotate, the auricularia auricula picking tube comprises a charging opening and a discharging opening, an adjusting groove is formed in a tube wall of the auricularia auricula picking tube and is formed along an axial direction of the auricularia auricula picking tube, two sides of an opening of the adjusting groove are fixedly connected with fixed plates, strip-shaped holes are formed in the fixed plates, reinforcing plates are arranged at joints between the fixed plates and the auricularia auricula picking tube, an adjusting plate is arranged in the adjusting groove, one end of the adjusting plate is bolted with the strip-shaped holes of the fixed plates, the other end of the adjusting plate extends into the auricularia auricula pickingtube and is connected with scrapers, and the scrapers are equidistantly arrayed circumferentially along a center of the auricularia auricula picking tube. The auricularia auricula picking machine disclosed by the invention is simple and reasonable in global structure and high in degree of automation, a large volume of labor is saved, the auricularia auricula picking effect is good, and the use requirements on large-batch auricularia auricula picking are excellently met.

Owner:厦门祺安达自动化设备有限公司

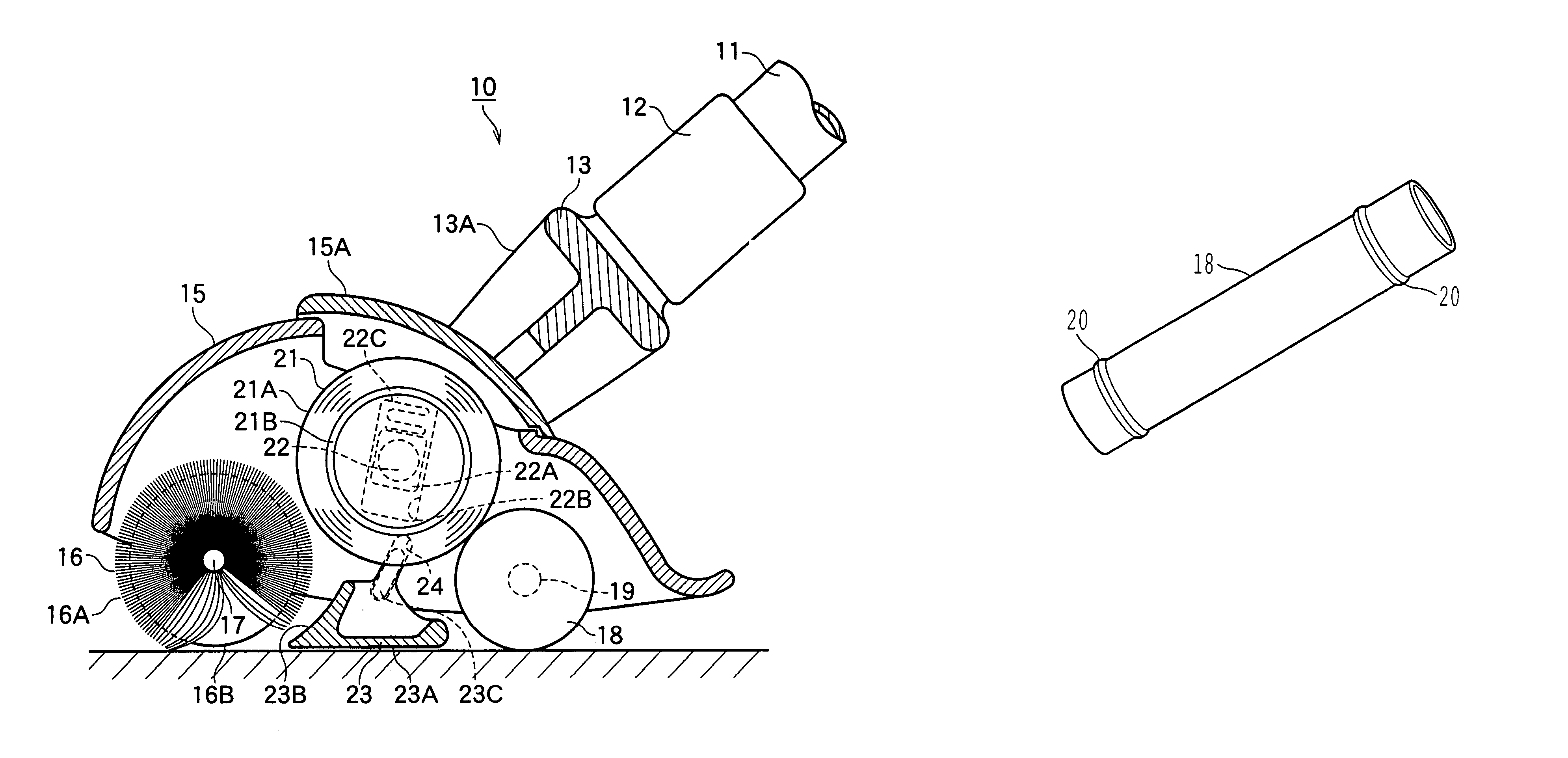

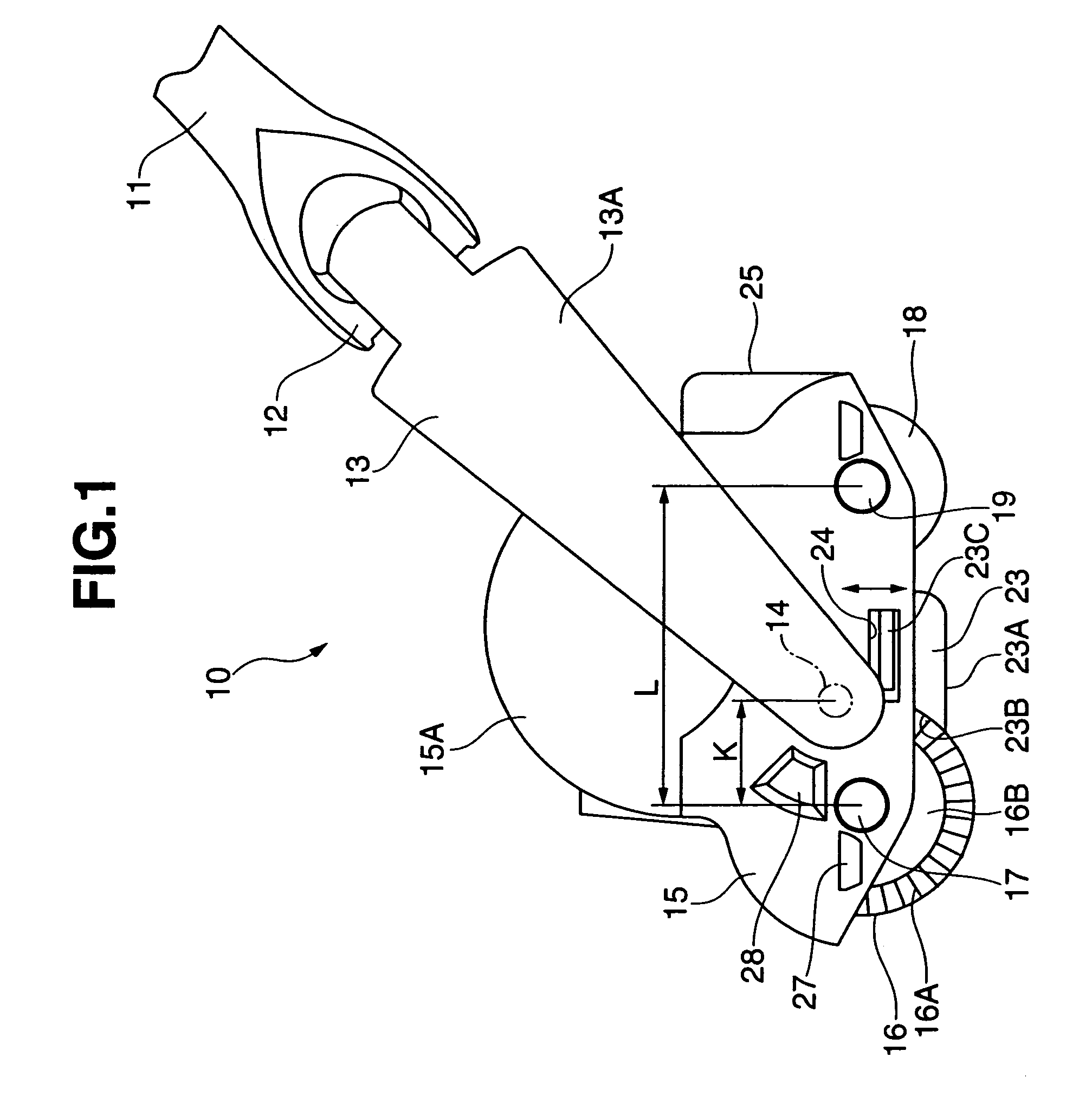

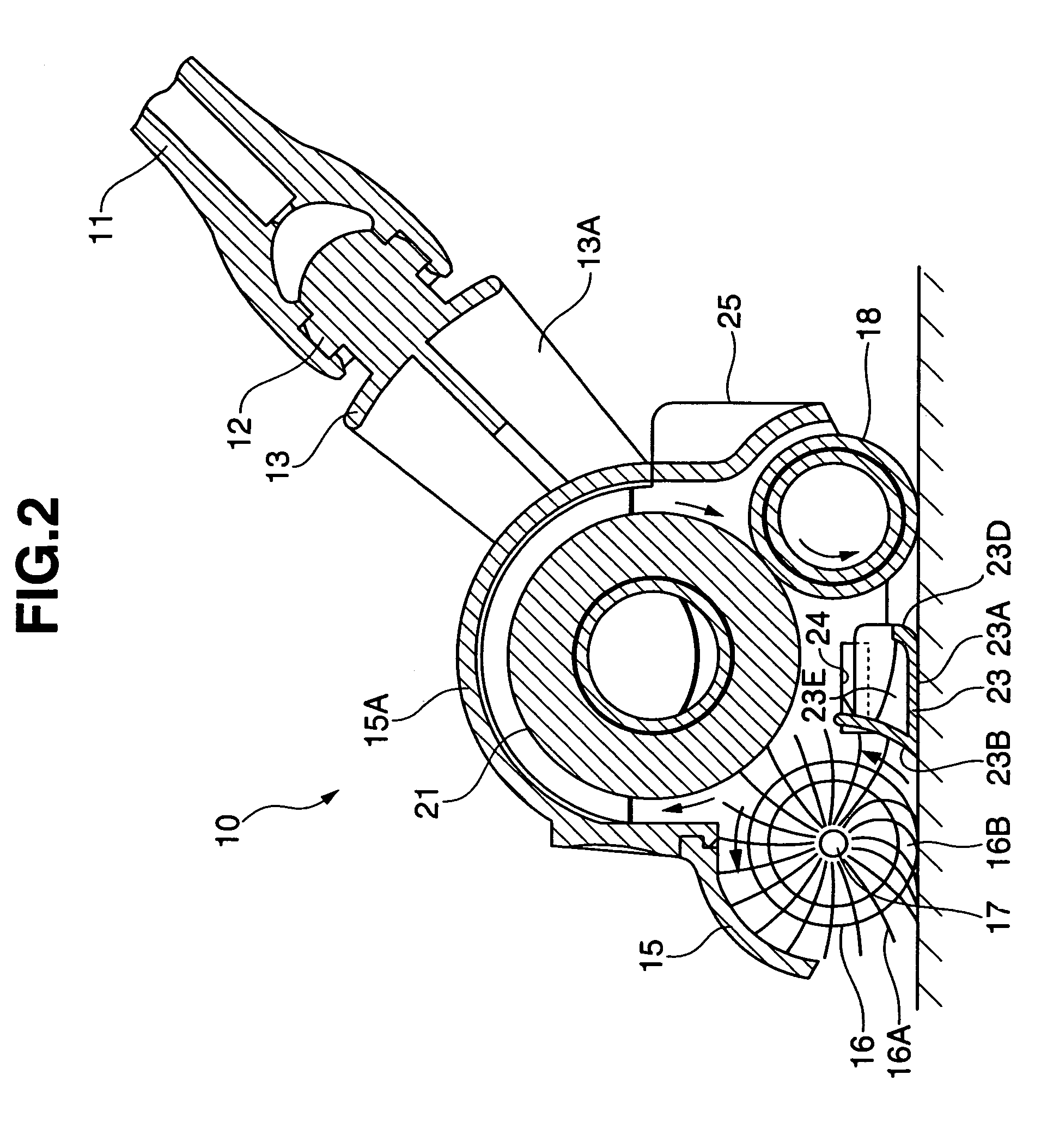

Cleaning device

InactiveUS7003840B2Clean and stableEasy to operateMechanical cleaningPressure cleaningBody rollEngineering

Owner:KAO CORP

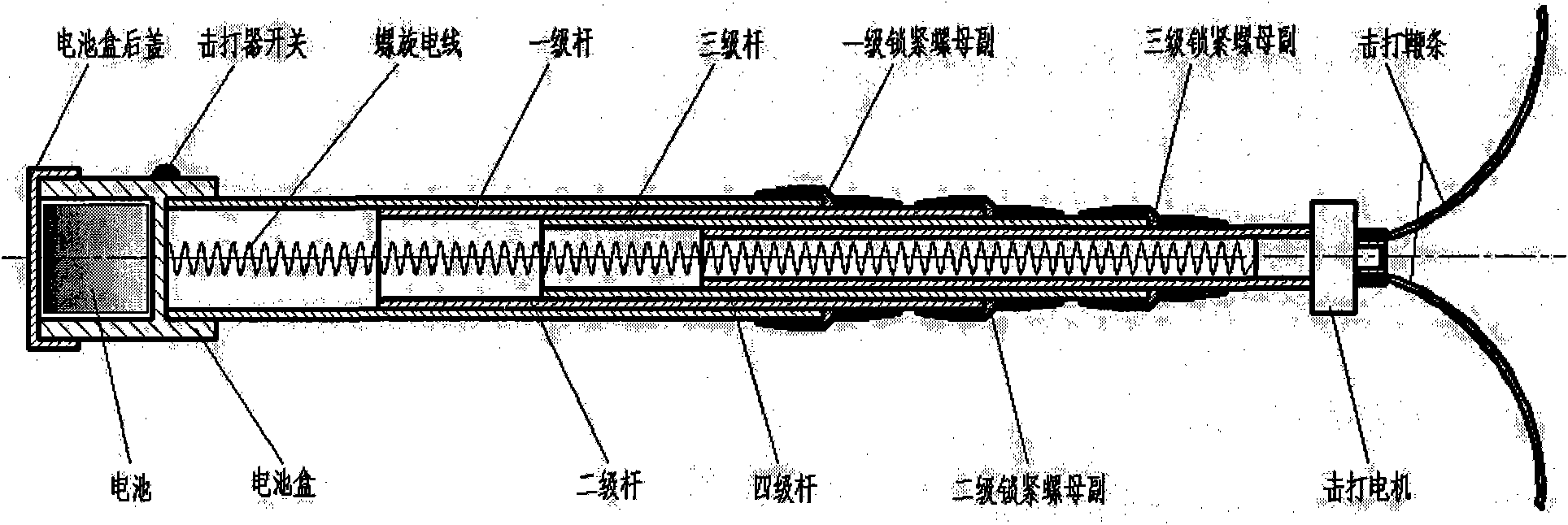

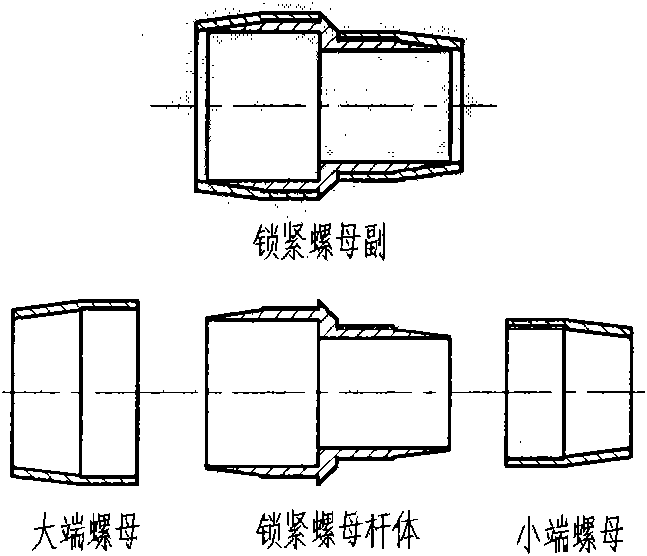

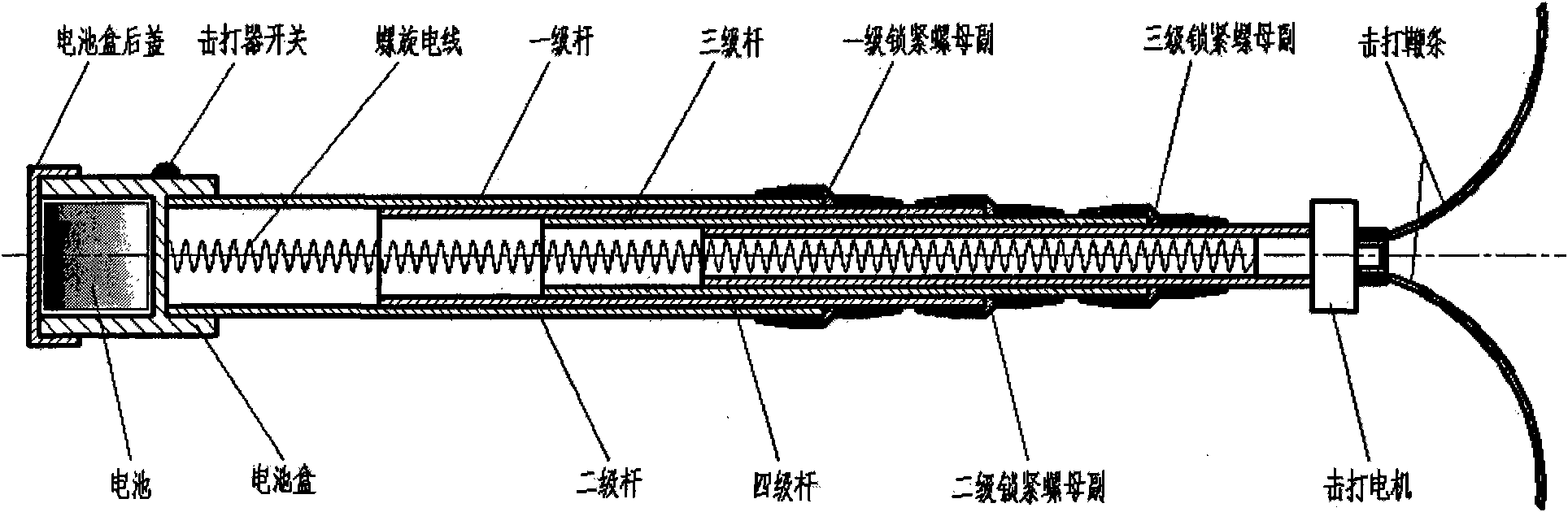

Telescopic picking rod for beating nut fruits

The invention discloses a telescopic picking rod for beating nut fruits, which comprises an over two-level telescopic rod. The telescopic rods of all levels are sleeved with each other, can be extended or retracted smoothly and are fixed or released by locking nut pairs; a battery box is arranged at the hand-held end of the picking rod; a lithium battery with high energy density is arranged in the battery box; a beater switch is embedded out of the battery box; and the working end of the picking rod is provided with a beating device which is driven by the lithium battery to beat the nut fruits. The invention is simple to operate, safe to use and convenient for carrying.

Owner:ZHEJIANG FORESTRY UNIVERSITY

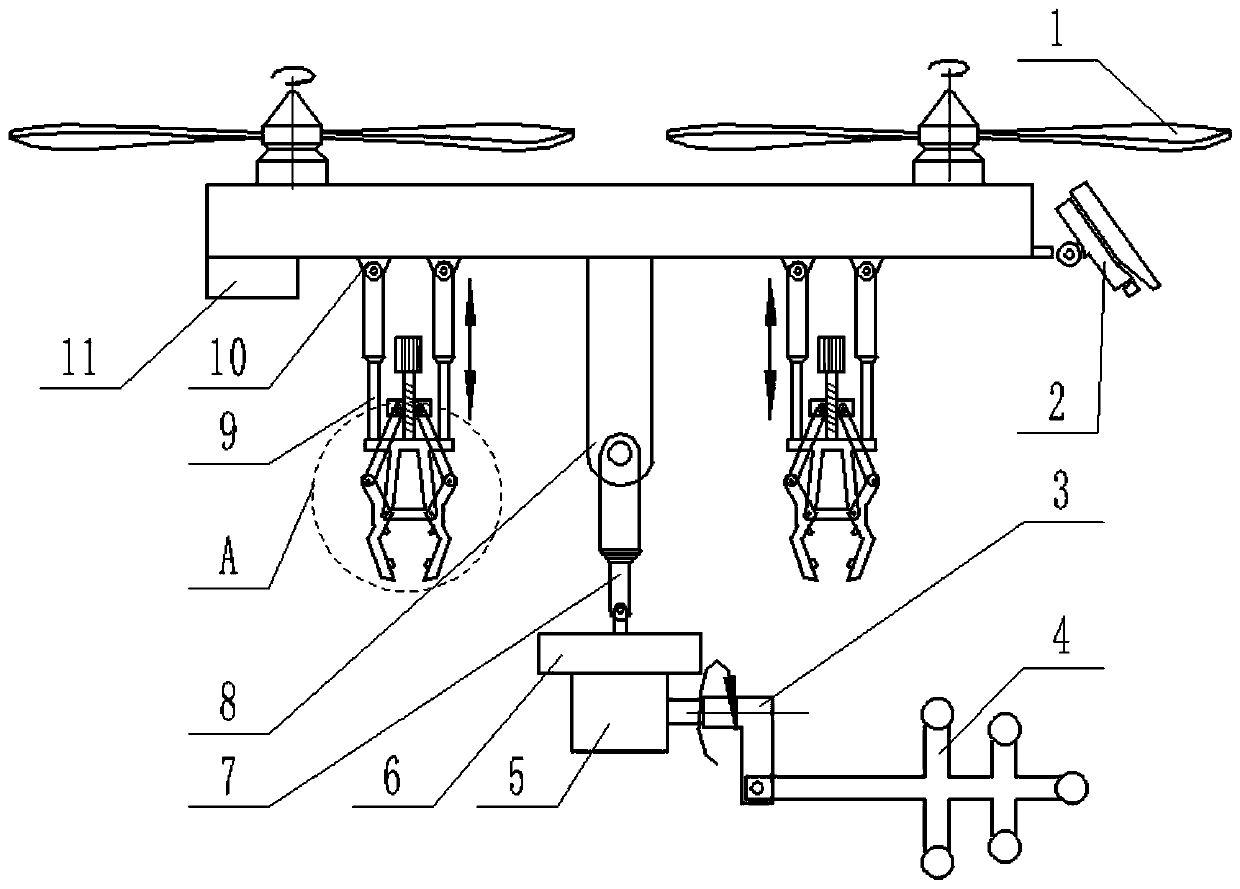

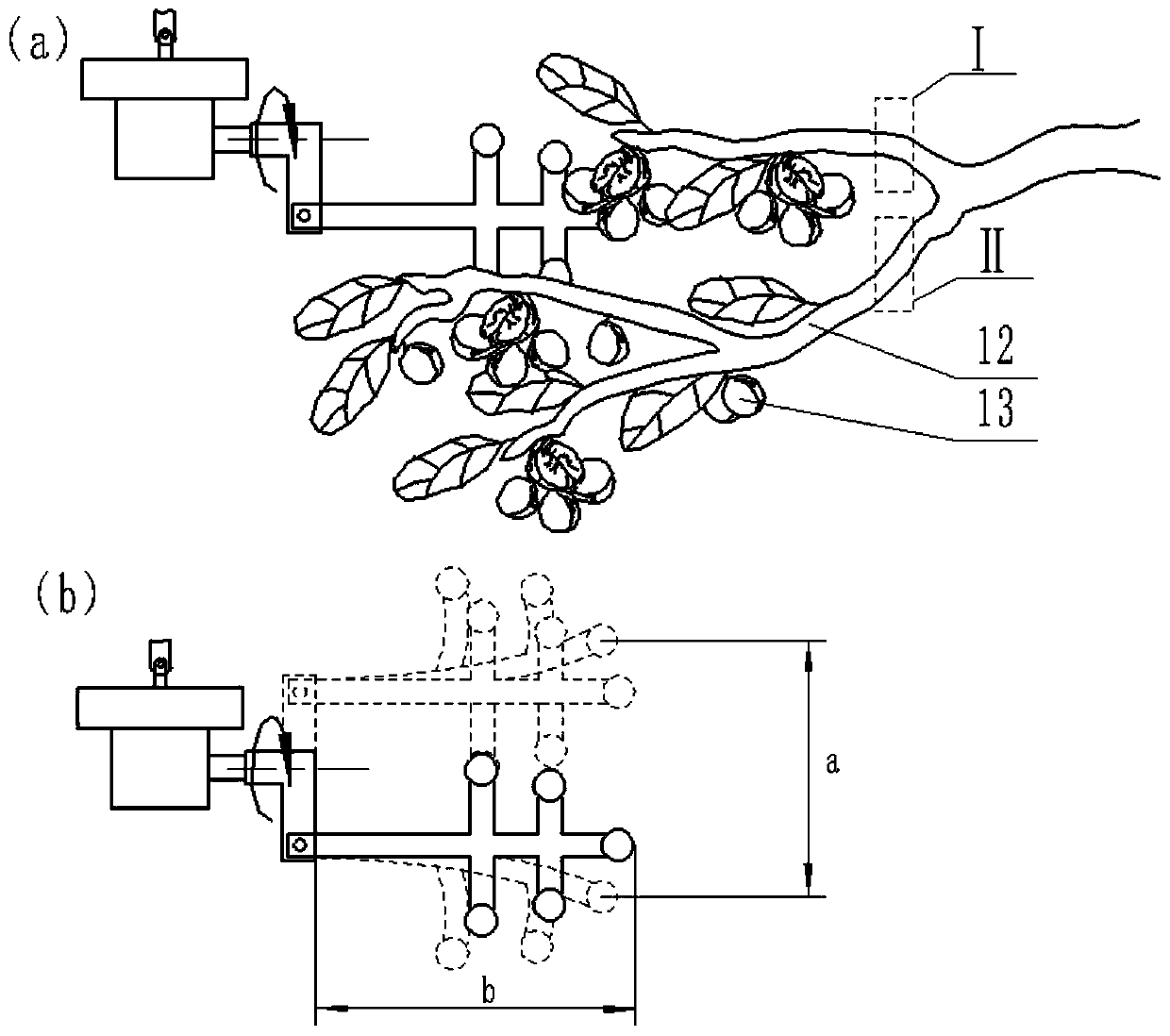

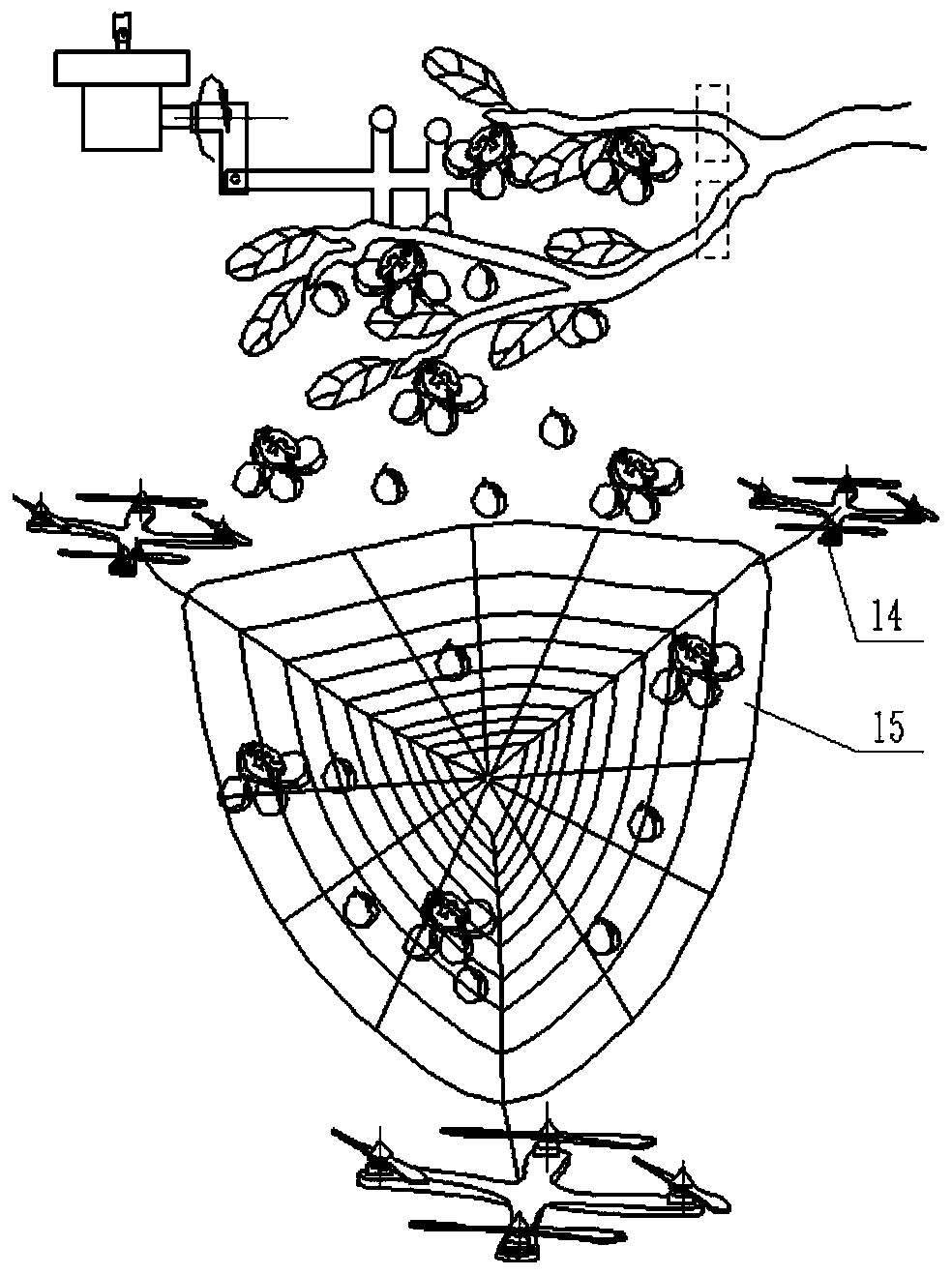

Chinese walnut picking and collecting device and method based on unmanned aerial vehicle

ActiveCN110192471AAvoid safety hazardsExtended working hoursAircraft componentsPicking devicesGlass fiberWalnut Nut

The invention discloses a Chinese walnut picking and collecting device and method based on an unmanned aerial vehicle, and belongs to the technical field of picking devices. The Chinese walnut pickingand collecting device comprises a picking unmanned aerial vehicle device, a recognizing and positioning system, a fixing device, a picking device, a collecting device and a control center. The recognizing and positioning system is located on the upper side of the picking unmanned aerial vehicle device. The fixing device and the picking device are both located on the lower side of the picking unmanned aerial vehicle device. The picking unmanned aerial vehicle device flies to a designated position according to the recognizing and positioning system, and the fixing device is composed of two stretching automatic telescopic clamping claws for clamping two branch fixing machine bodies. The eccentric variable-speed rotary striking of a glass fiber rod is realized by the picking device through aservo motor, the variable-force, variable-position and variable-angle striking of Chinese walnut branches is realized, and it is ensured that Chinese walnuts are struck down. A collecting unmanned aerial vehicle is connected with a collecting net, the struck-down Chinese walnuts fall into the collecting net, and a pressure sensor is arranged in the collecting unmanned aerial vehicle. The picking and collecting can be integrated, the picking unmanned aerial vehicle stops working in the striking process, and the electric energy consumption is reduced.

Owner:DALIAN UNIV OF TECH

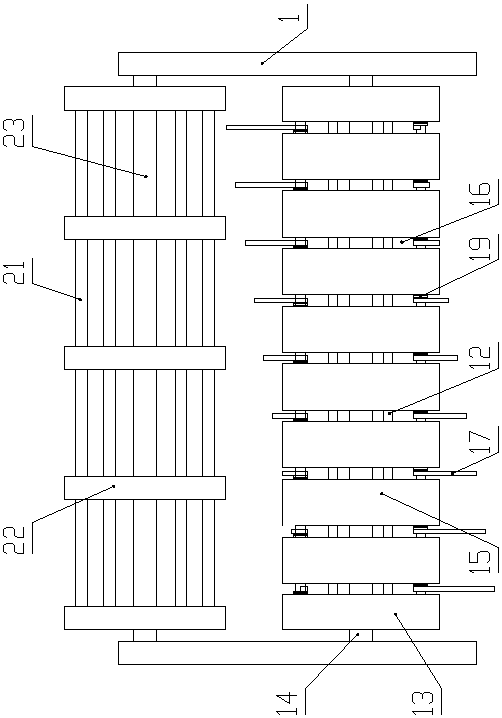

Suspension type residual film recovering and bundling combined operation machine

PendingCN107018683AReduces comb impactComb impact hasSpadesLoadersWhole bodyAgricultural engineering

The invention discloses a suspension type residual film recovering and bundling combined operation machine. The suspension type residual film recovering and bundling combined operation machine comprises a suspension type machine frame with a supporting wheel; a soil loosening device, a pickup device, a bundling device and a driving device are arranged on the machine frame; the soil loosening device is arranged at the front end of the machine frame; the soil loosening device is a row of soil loosening shovels for loosening soil; the pickup device is arranged close to the back end of the soil loosening device; the pickup device comprises a film taking comb and a rotary pickup device; the bundling device is arranged close to the back end of the pickup device. The suspension type residual film recovering and bundling combined operation machine has the characteristic of high residual film recovery efficiency, and can automatically bundle the recovered residual films to compress the volume of the recovered residual films and reduce the residual film clearing times, so that the residual films are compressed into a whole body, the recovered residual films are taken out conveniently, the operation time is prolonged and the work efficiency is improved.

Owner:HEBEI AGRICULTURAL UNIV.

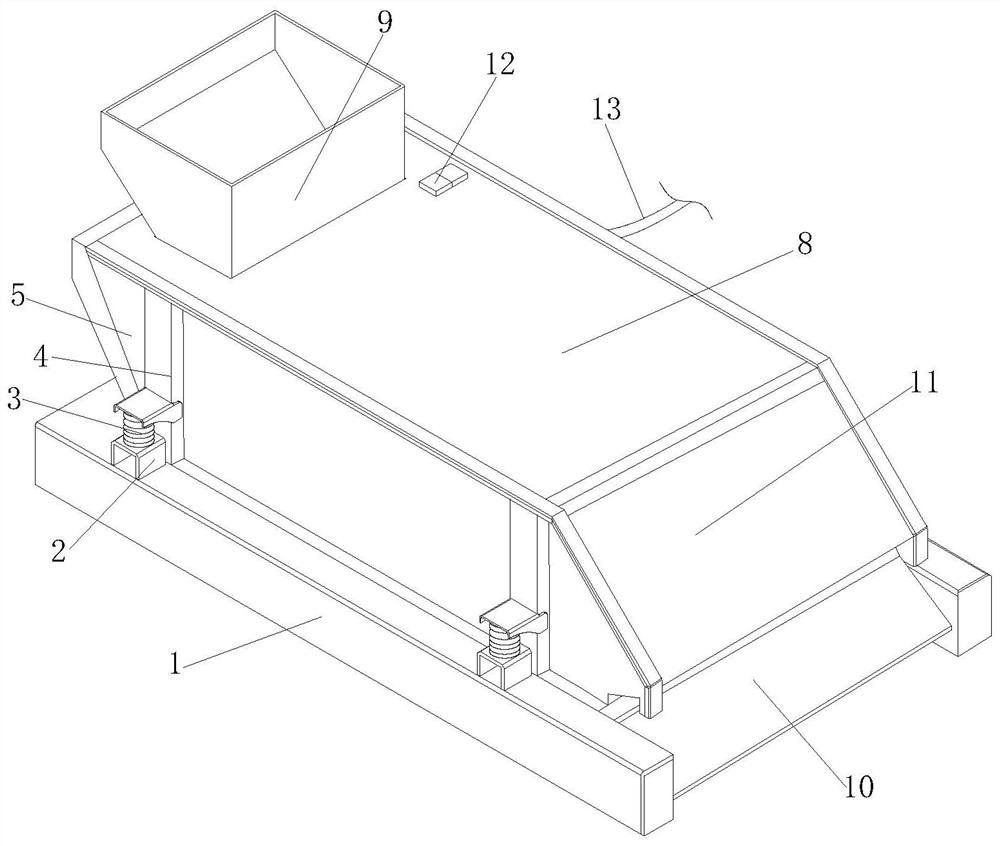

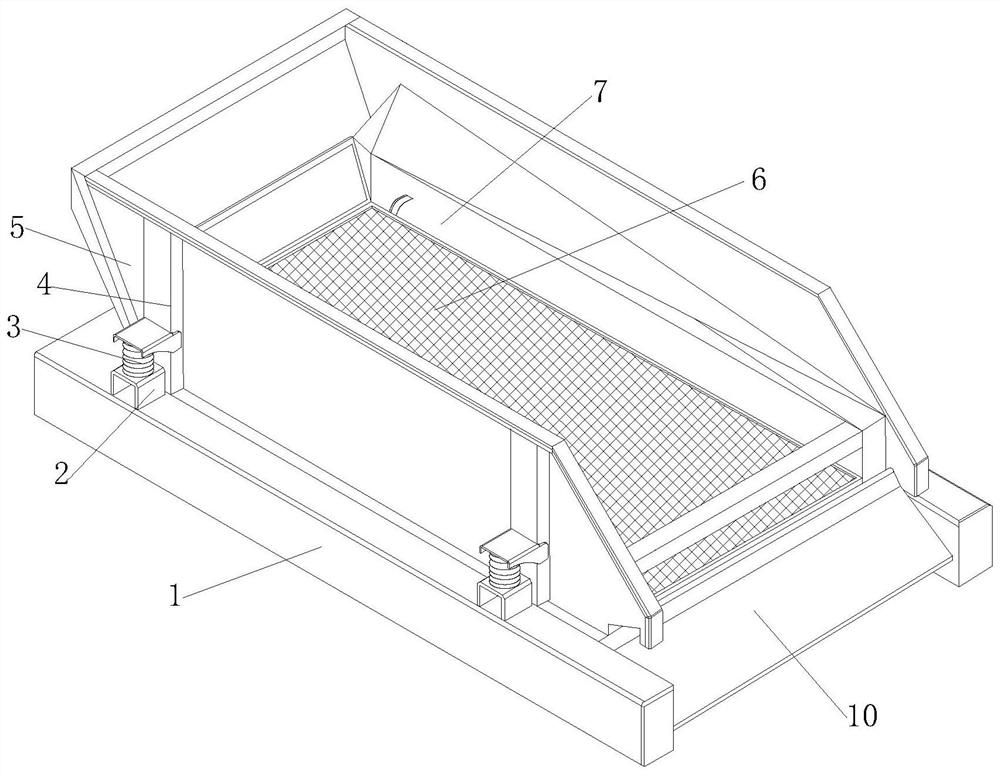

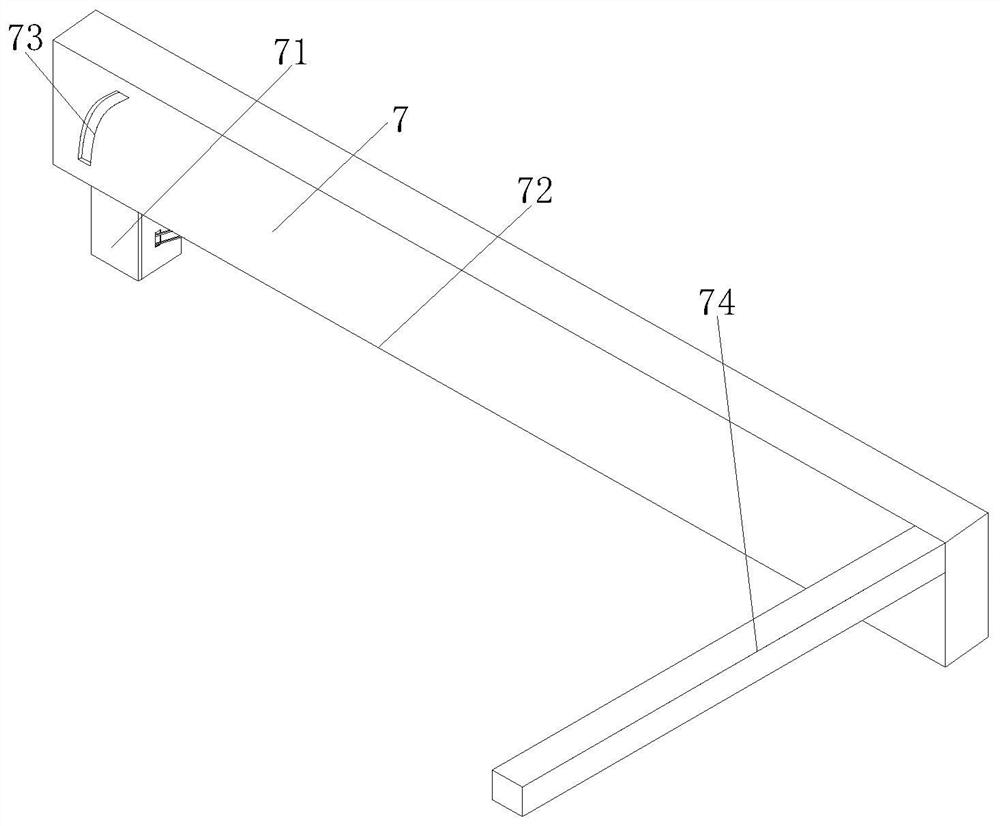

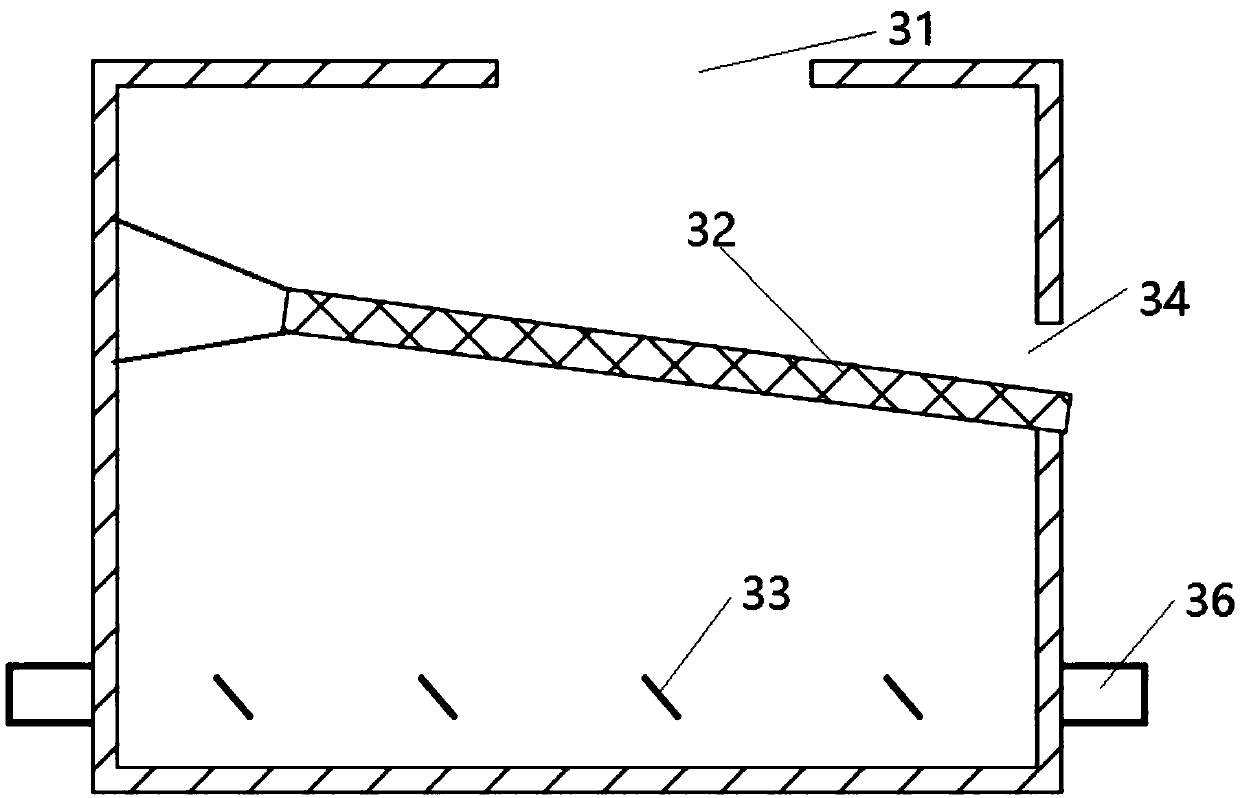

Powder separation equipment for sorting traditional Chinese medicinal materials

InactiveCN111871778ASimple structureSolve the problem of shattering and affecting product qualitySievingGas current separationTransmission beltStructural engineering

The invention discloses powder separation equipment for sorting traditional Chinese medicinal materials. The powder separation equipment comprises a bottom frame, a support block, a damping spring, abracket, a frame seat, a screen, an intermittent shaking mechanism, a top plate, a discharging hopper, a material guide plate, a cover plate, a control switch and a power line. According to the powderseparation equipment, the intermittent shaking mechanism is arranged in an optimized manner, a rotary disc enables a push column to push the screen to slightly shake in a sliding groove in a reciprocating manner up and down through a groove frame, meanwhile, a transmission belt drives fan blades to rotate, generated airflow is blown out through an air outlet cover, powder is blown away from tablets, and the sorting effect is further enhanced; and the discharging hopper is optimally arranged, the upper side and the lower side of the rotary disc are intermittently matched with an upper rack anda lower rack respectively under the action of a motor, a sliding frame drives a material blocking plate to reciprocate on a supporting plate frame, and therefore the material blocking plate intermittently reciprocates at the bottom of the hopper frame, materials are intermittently and quantitatively discharged, material accumulation is avoided, and the sorting efficiency of the traditional Chinese medicinal materials is improved.

Owner:泉州市亚创科技有限公司

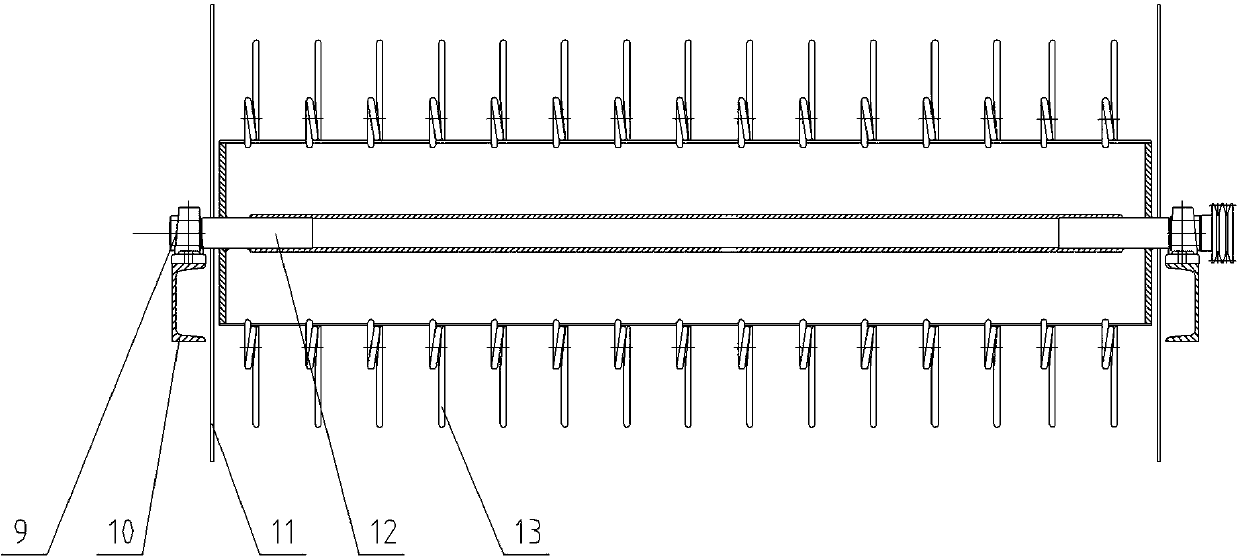

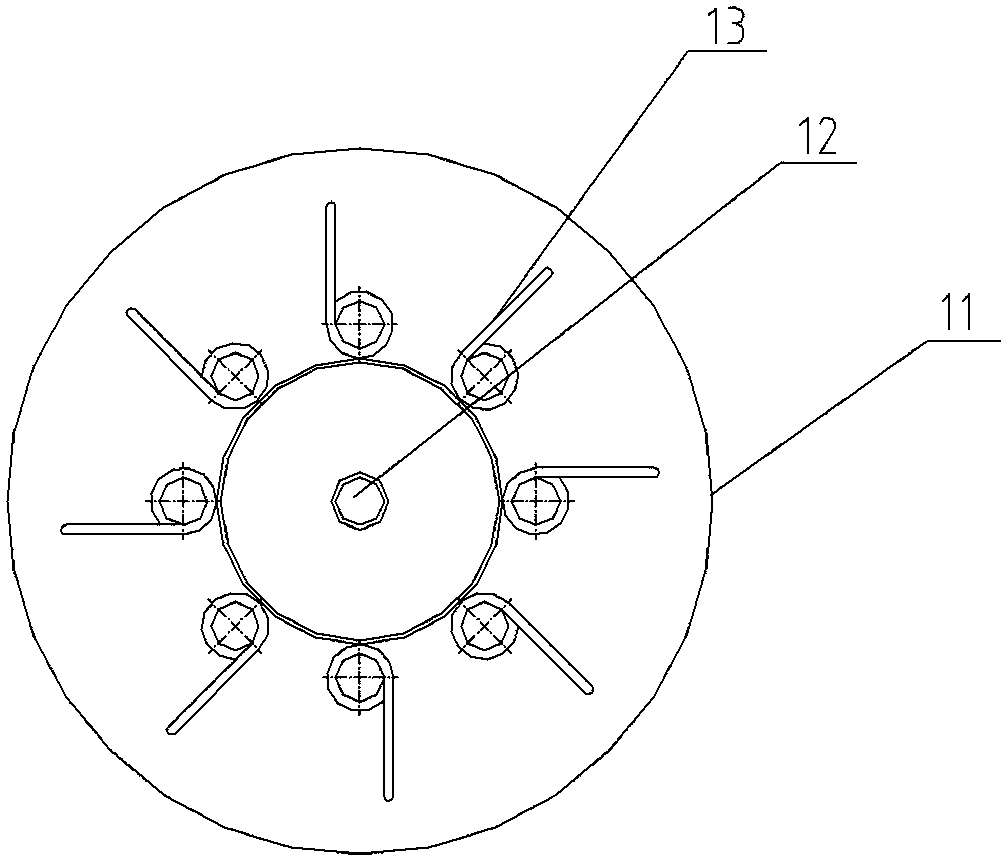

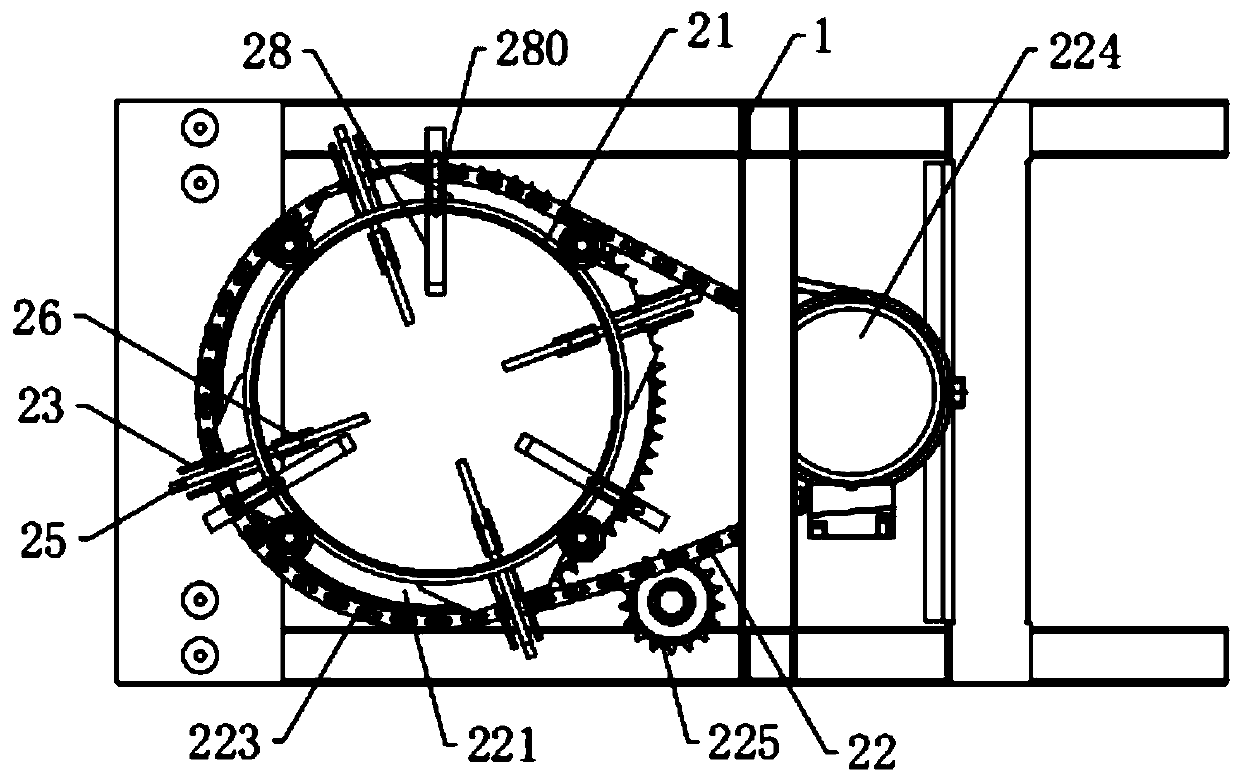

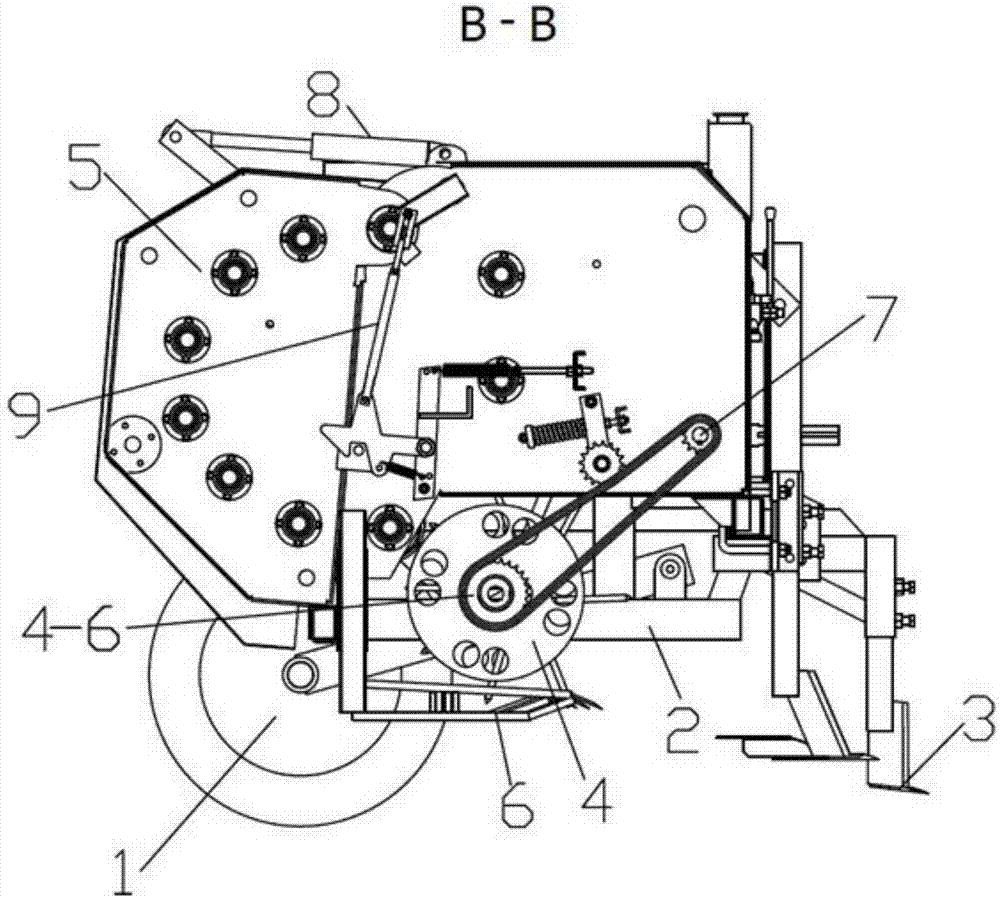

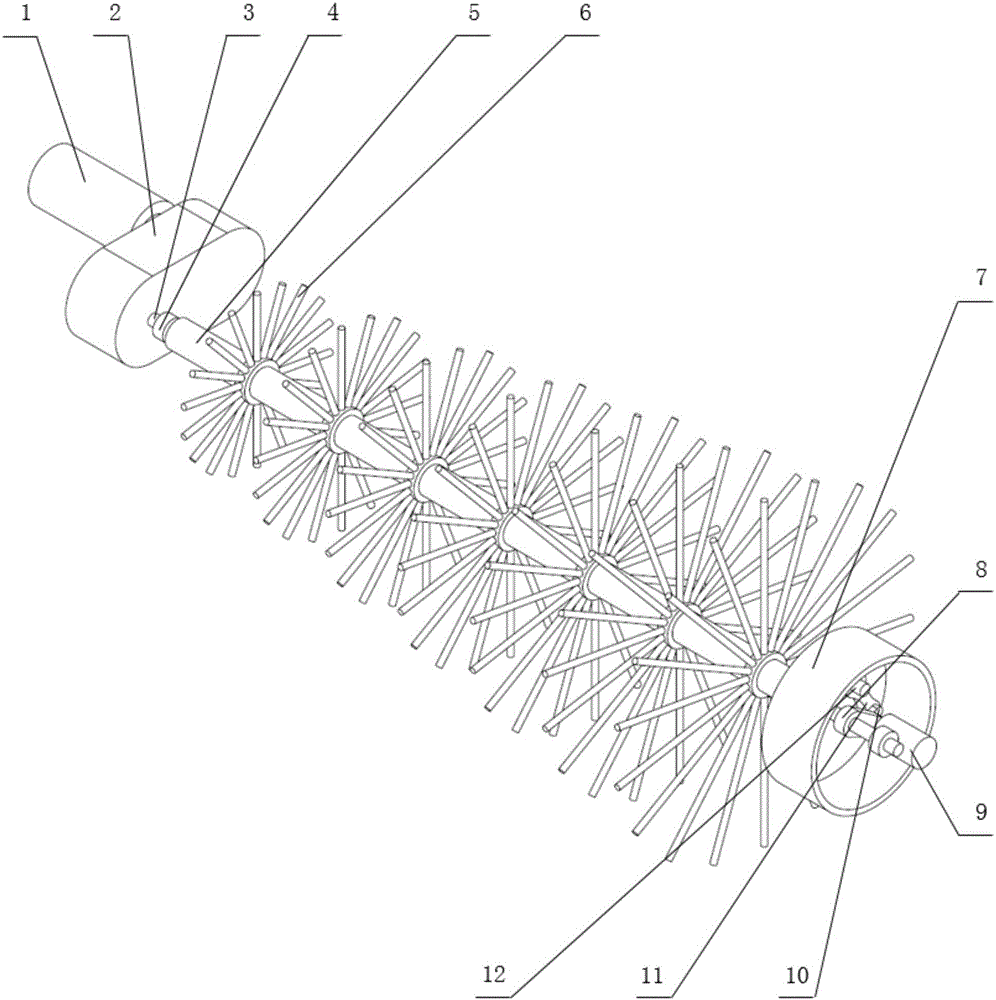

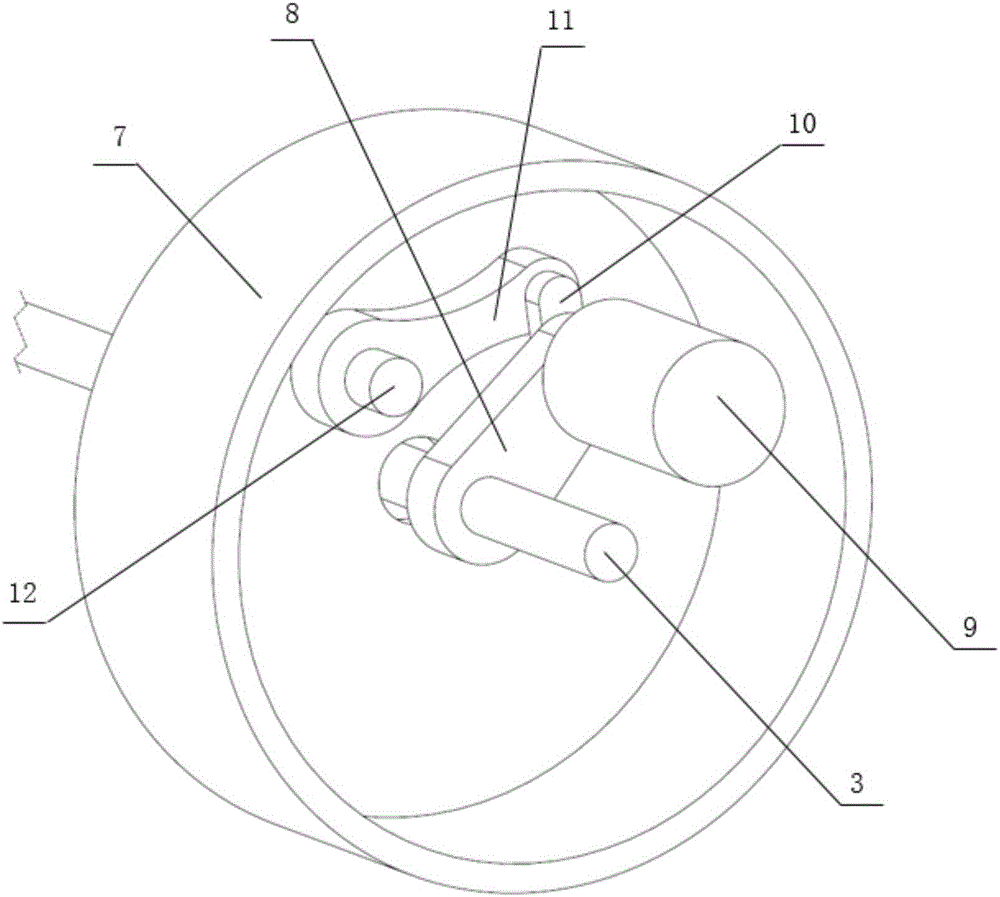

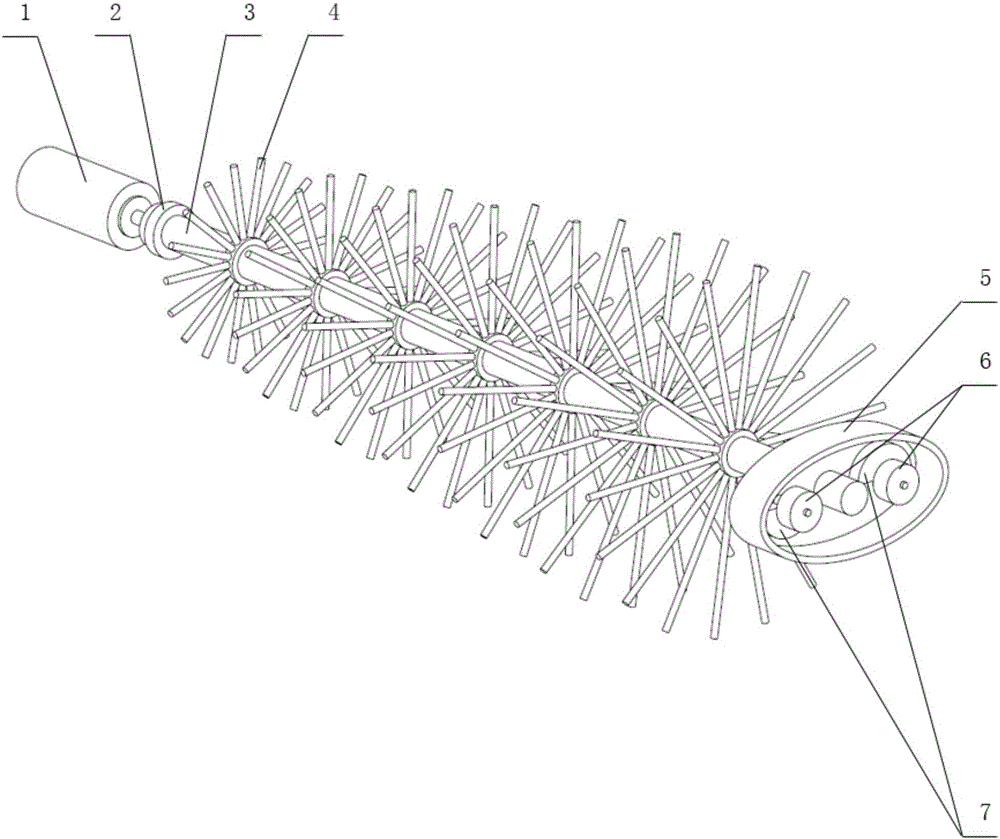

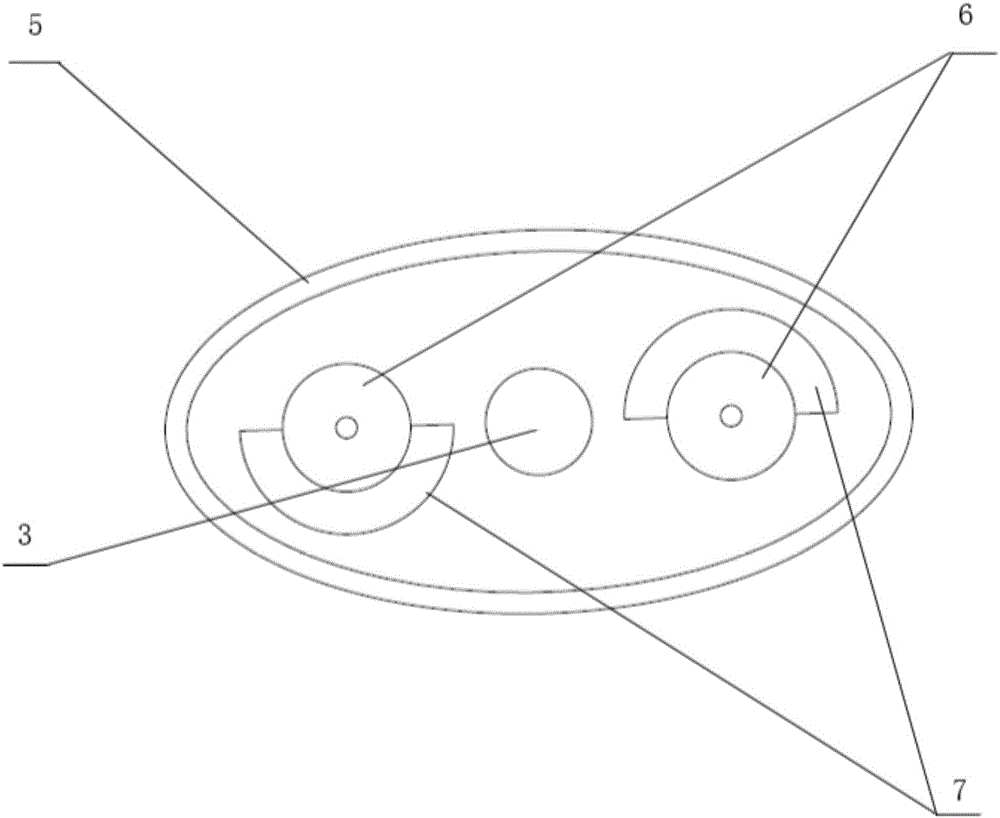

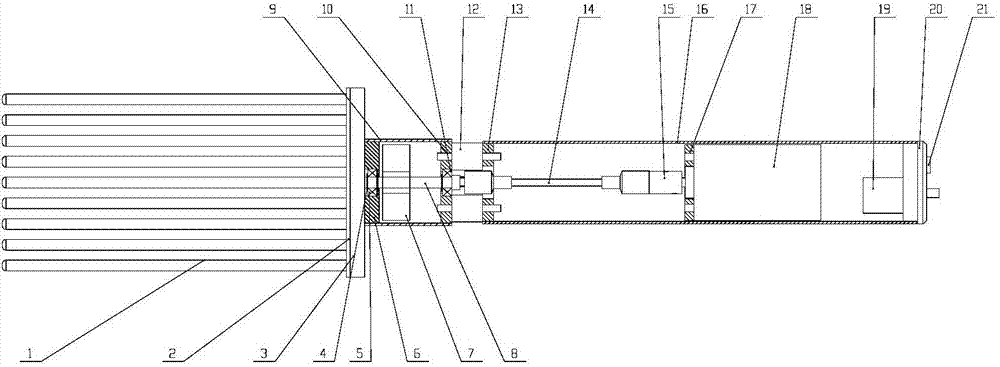

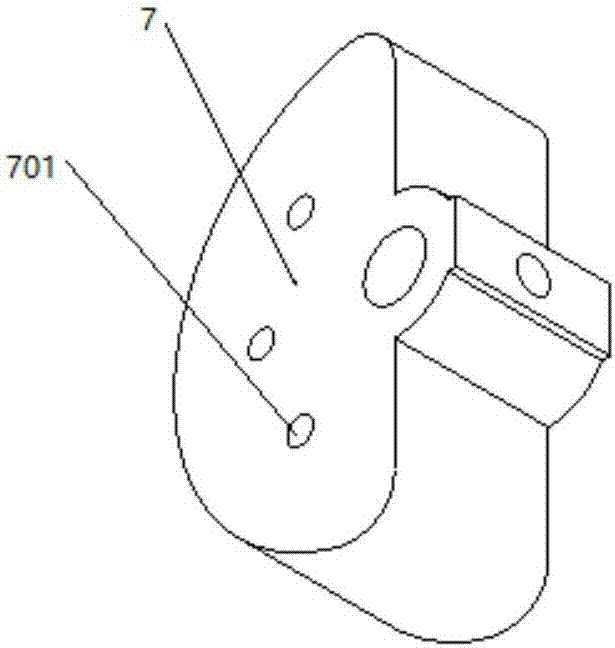

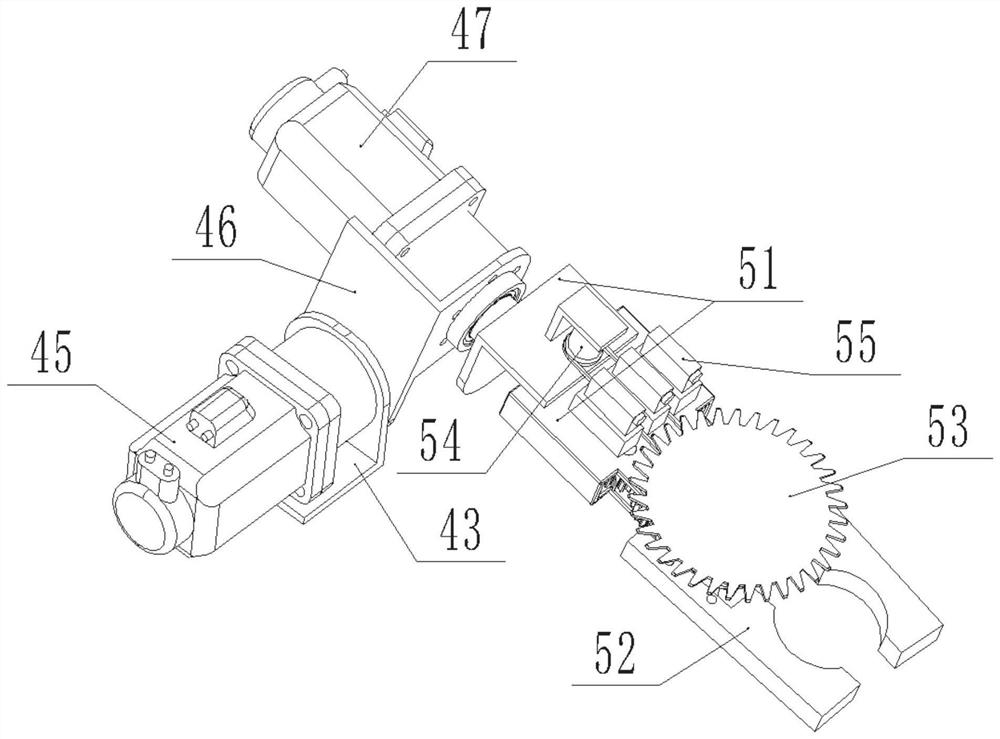

Crank-rocker roll-vibrating mechanism for picking Chinese wolfberry fruit

ActiveCN105766219AContinuous retreatImprove picking effectPicking devicesMotor driveLycium barbarum fruit

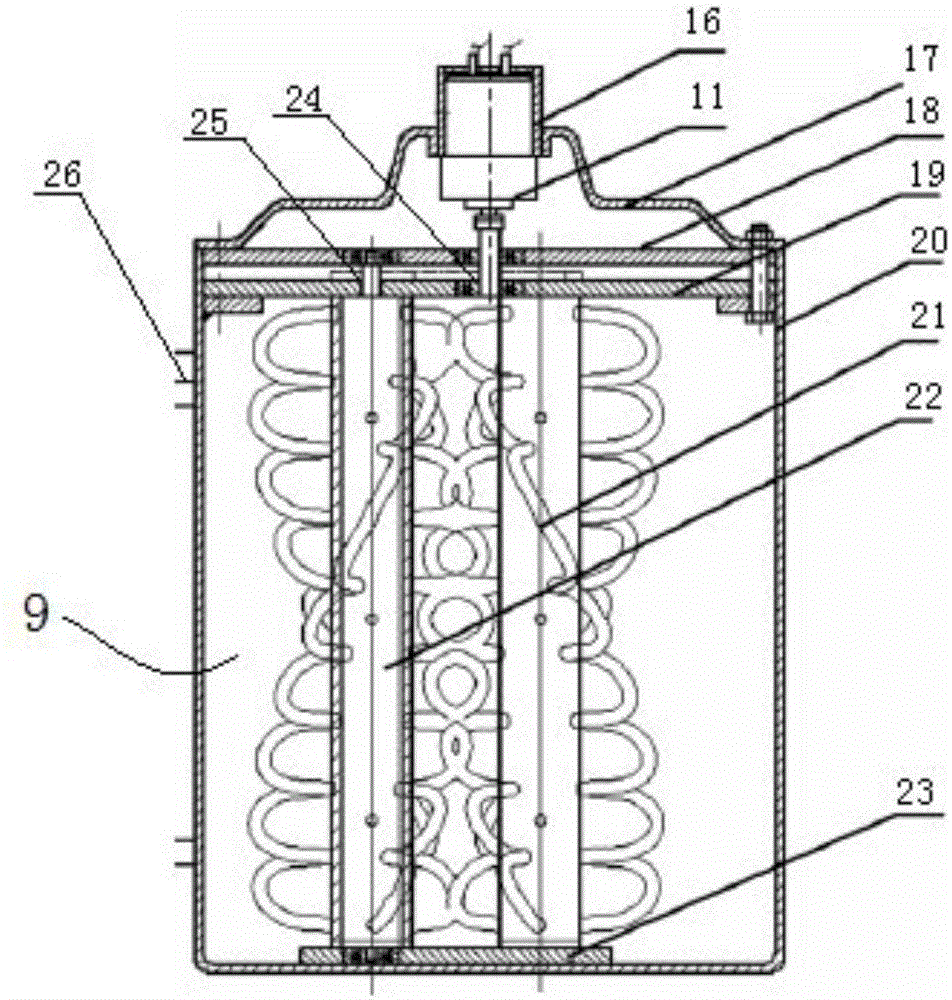

The invention discloses a crank-rocker roll-vibrating mechanism for picking Chinese wolfberry fruit, comprising a spindle motor, a spindle, a sleeve, a plurality of vibrator rings, a crank-rocker mechanism, a crank motor and a rocker carrier. The crank-rocker mechanism comprises a crank motor base, a crank, a link and a rocker cavity. The sleeve sleeves the spindle, the vibrator rings are fixed outside the sleeve, the spindle is fixedly connected with the crank motor base, the crank motor is connected with the crank, the crank is rotationally connected with the link, the link is rotationally connected with the rocker, the inside of the rocker cavity is fixedly connected with the rocker carrier, and the outside of the rocker cavity is fixedly connected with the sleeve. The crank motor drives the crank so as to drive the rocker cavity to rock in a reciprocating manner relative to the crank motor base. Each vibrator ring is composed of a vibrator ring base ring and a vibrator. Compared with the prior art, the crank-rocker roll-vibrating mechanism enables the vibrators to vibrate through reciprocating rotation, the problem that an existing vibratory Chinese wolfberry fruit picking mechanism is unsuitable for continuous picking can be solved, the crank-rocker roll-vibrating mechanism is highly adaptive to different types of Chinese wolfberry fruit, and picking efficiency is improved.

Owner:ZHEJIANG UNIV

Two-way Chinese date picker and method thereof

InactiveCN104541772AReduce friction and collisionImprove picking effectPicking devicesEngineeringSupport plane

The invention discloses a two-way Chinese date picker and a method thereof. The two-way Chinese date picker comprises two picking forks, a telescopic support, a telescopic rod, a box, a support frame and a handle assistor. The picking forks are provided with comb plate structures with the maximum expanding angle of 120 degrees. The handle assistor is connected with the telescopic rod which is connected with the middle of the telescopic frame. Part of the telescopic rod is arranged in the support rod. Two ends of the telescopic support are rotatably connected with the picking forks respectively. Two ends of the support rod are connected with the support frame and the handle assistor respectively. The box is removably arranged outside the support frame. The two-way Chinese date picker and the method thereof have such advantages as improved efficiency and operation quality, less proneness of scratching for people, simple operation, carrying convenience and lowered cost.

Owner:青岛基奥机械制造有限公司

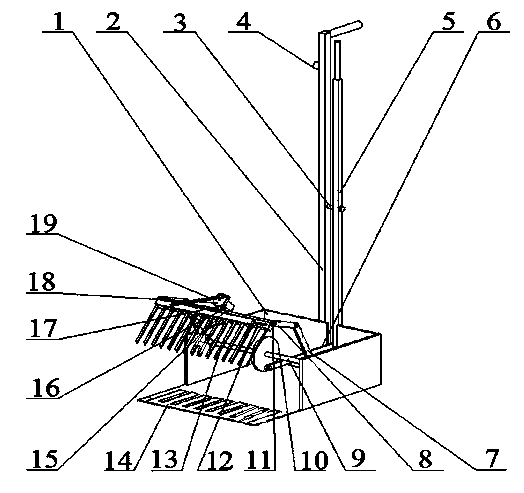

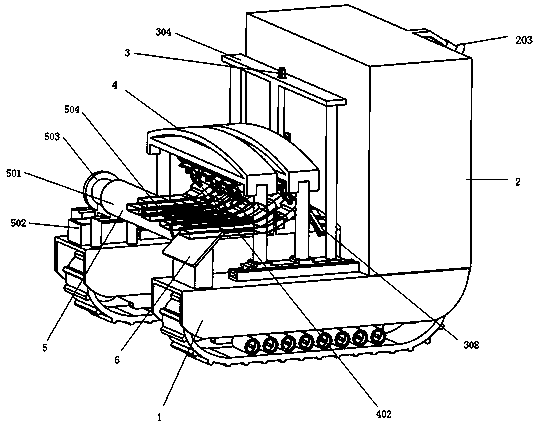

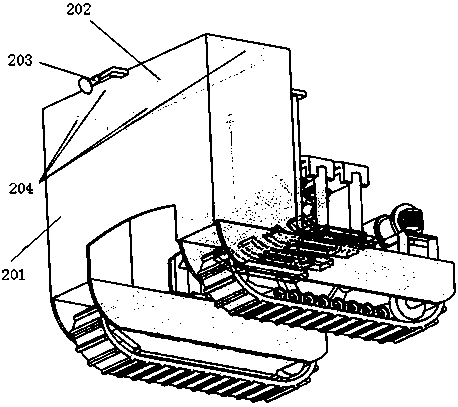

Efficient tea bud picking machine based on mechanical characteristics of tea leaves

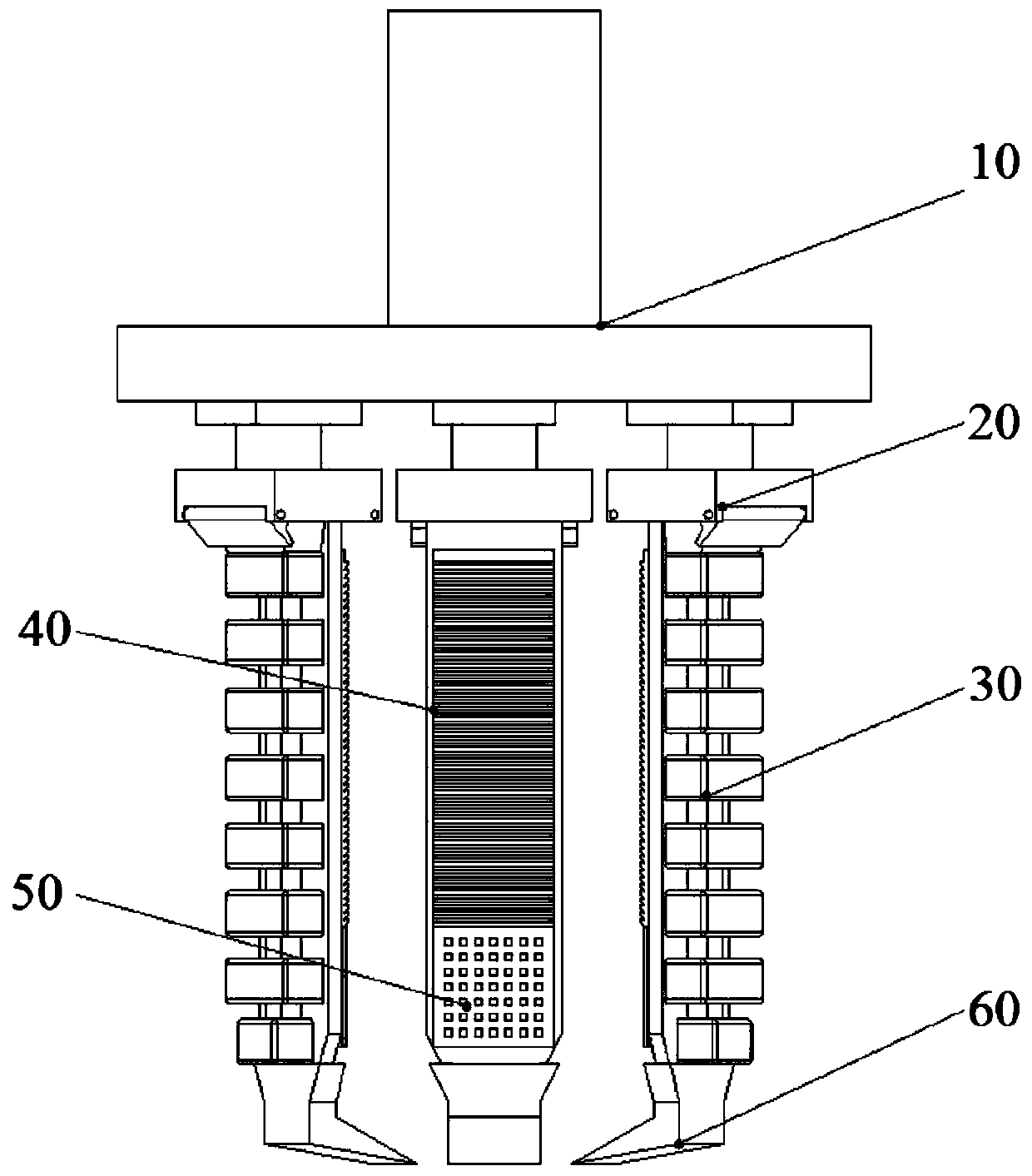

InactiveCN109618661AReduce damage rateImprove picking effectPicking devicesControl systemAgricultural engineering

The invention relates to an efficient tea bud picking machine based on the mechanical characteristics of tea leaves, which acts above a tea ridge and comprises a walking device, a picking device, a depth measuring device, a collecting device and a control system which are arranged on the walking device, wherein the walking device across a tea ridge and moves along the length direction of the tea ridge, the picking device comprises a picking mechanism, the picking mechanism comprises a first roller and a second roller which are rotatably arranged; the first roller and the second roller rotate relatively to clamp the tea bud together and enroll the tea bud between the two rollers; the depth measuring device is used for controlling the picking mechanism to reach the surface of the tea ridge for picking the tea tender bud; the collecting device comprises a collecting box and a tea suction pipe, wherein the tea suction pipe sucks tea tender buds wound between the two rollers into the collecting box; and the control system controls the walking device, the picking device, the depth measuring device and the collecting device to work. The picking machine is high in picking efficiency and accuracy, and can effectively reduce the damage rate to tea trees.

Owner:SICHUAN AGRI UNIV

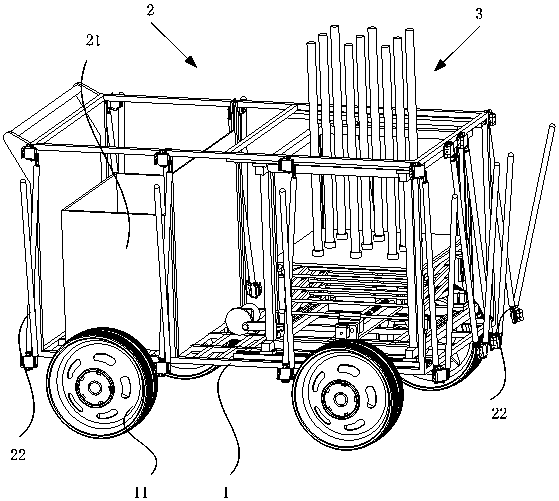

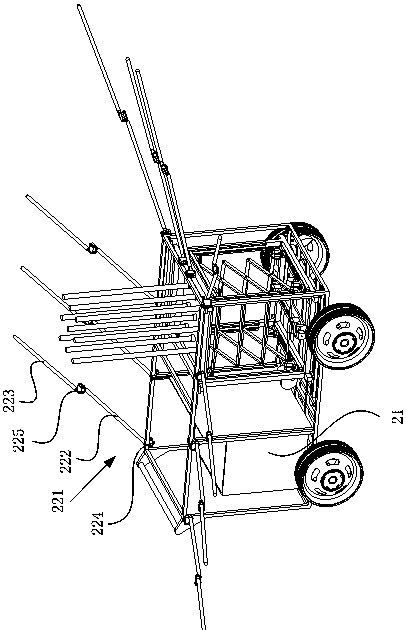

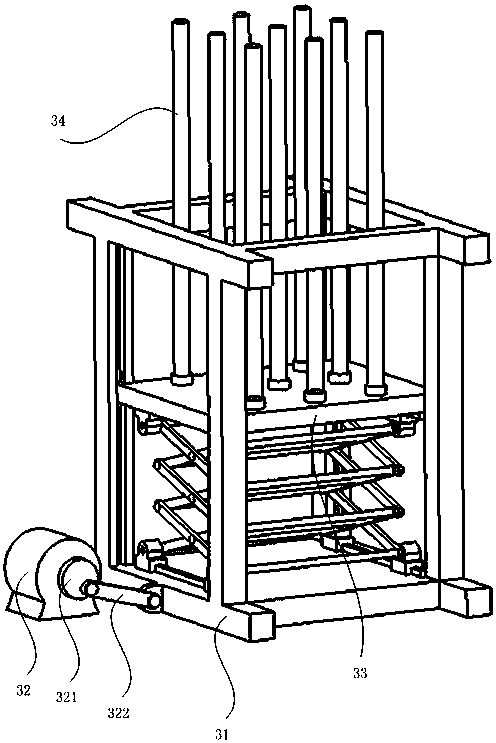

Winter jujube harvester and harvesting method

ActiveCN107548697AAvoid damageCompact structureRenewable energy machinesPicking devicesVehicle frameAgricultural engineering

Owner:QINGDAO AGRI UNIV

High-efficiency cotton harvesting device

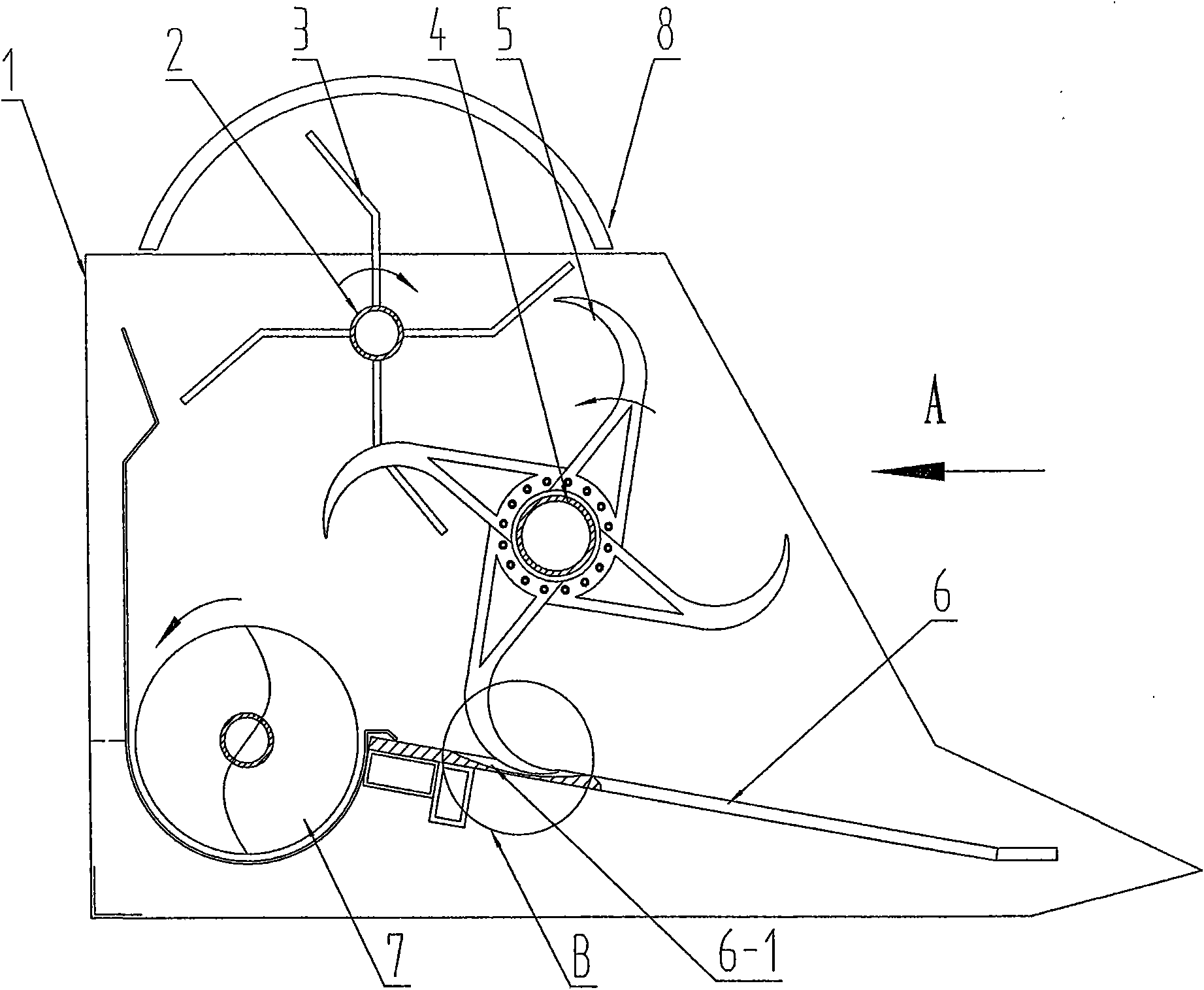

InactiveCN101589671ASolve the picking problemReduce impurityPicking devicesEngineeringTooth position

The invention relates to a high-efficiency cotton harvesting device, which is used for solving the problem that the cotton harvesting device is not suitable for picking in high stalk cotton fields. The technical proposal is that the high-efficiency cotton harvesting device comprises a cotton collection box and a fixed comb tooth, a rotating comb tooth mechanism and a conveying screw feeder which are positioned in the cotton collection box, wherein the rotating comb tooth mechanism consists of a rotating shaft and a rotating comb tooth, the teeth of the rotating comb tooth are evenly distributed along the rotating shaft axially, the comb tooth position of the rotating comb tooth corresponds to that of a fixed comb plate, and after improvement, the rotating comb tooth is a crescent bent hook-shaped tooth. The rotating comb tooth is designed as the hook-shaped comb tooth, thus in the rotating process, the front end of the rotating comb tooth combs off cotton gathered at the root of the fixed comb tooth from a cotton stalk so as to thoroughly separate the cotton from the cotton stalk. The high-efficiency cotton harvesting device is further provided with a comb mechanism additionally, and can continuously eliminate sundries filled in tooth gaps of the rotating comb tooth, so that the rotating comb tooth mechanism is maintained in a high-efficiency working condition.

Owner:天津盛大机械制造有限公司

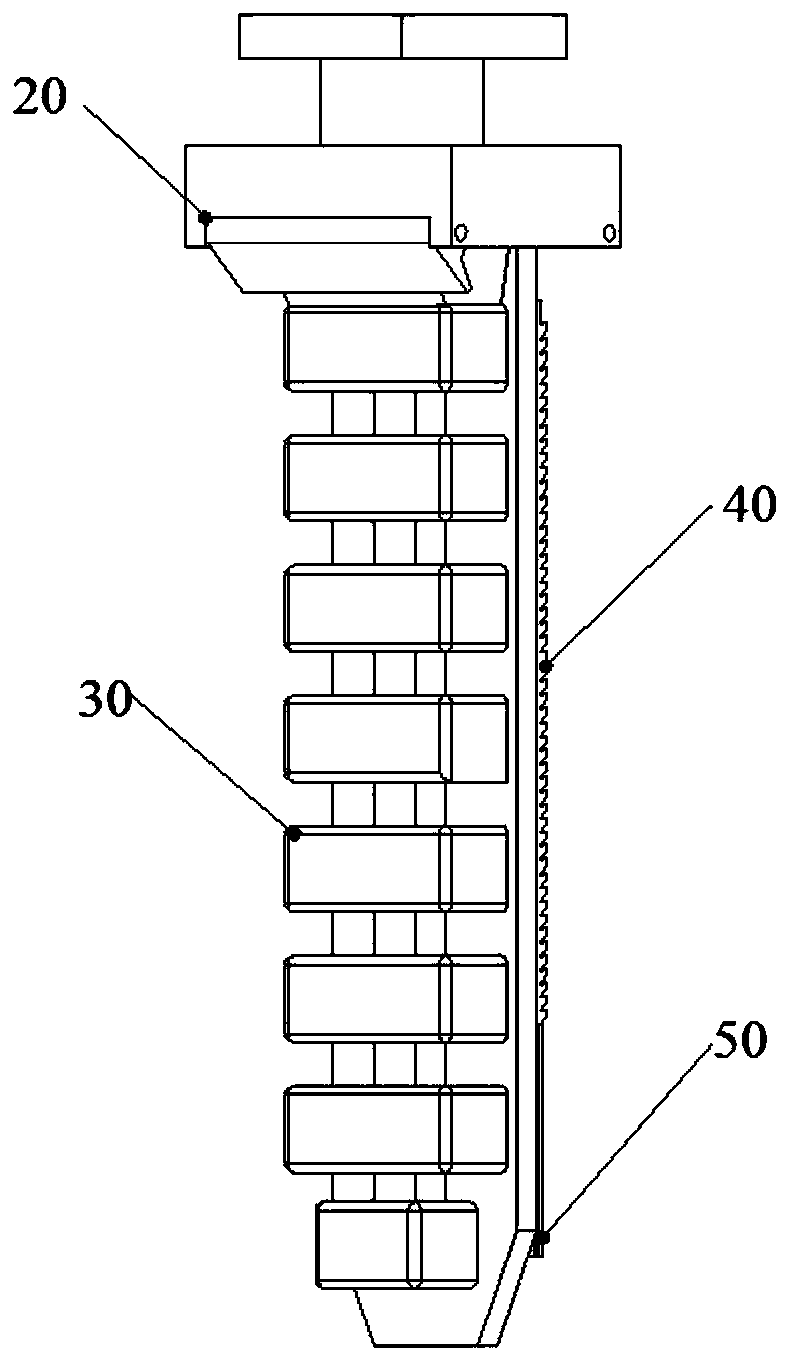

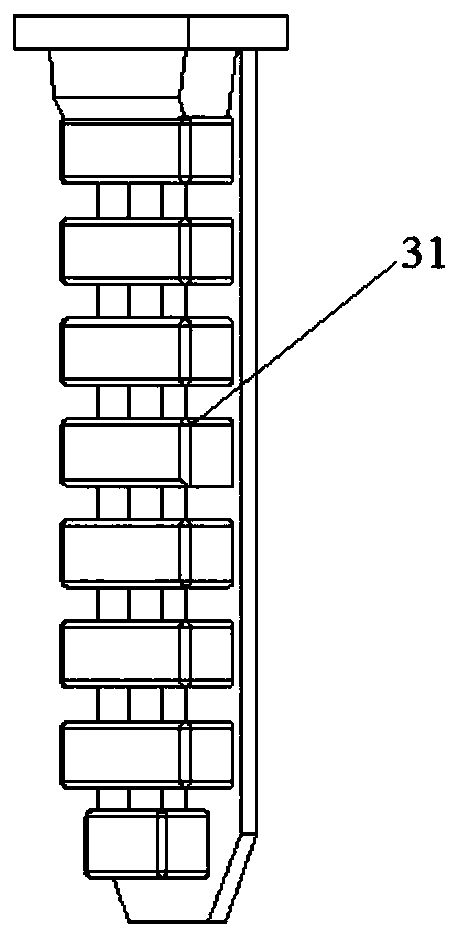

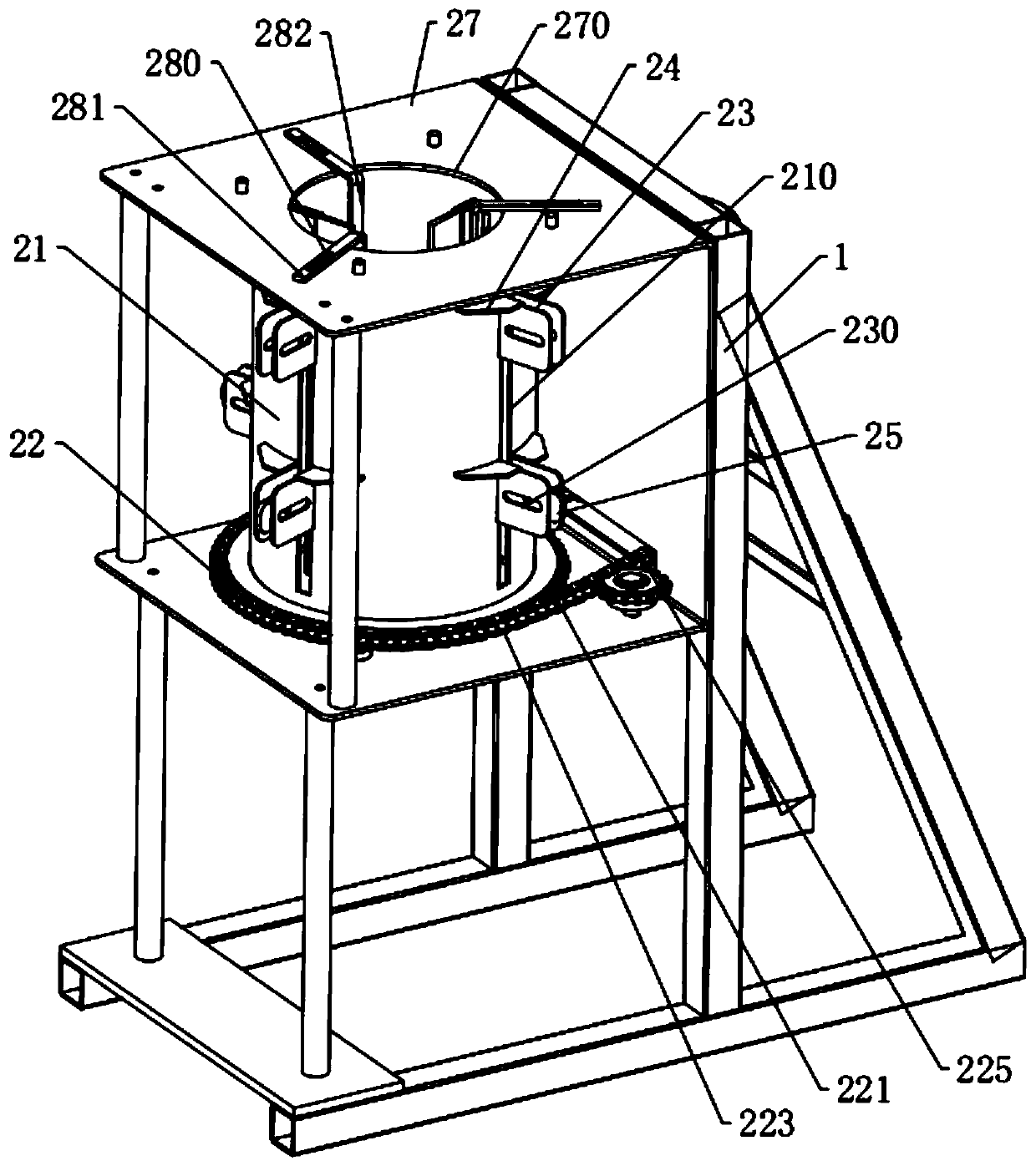

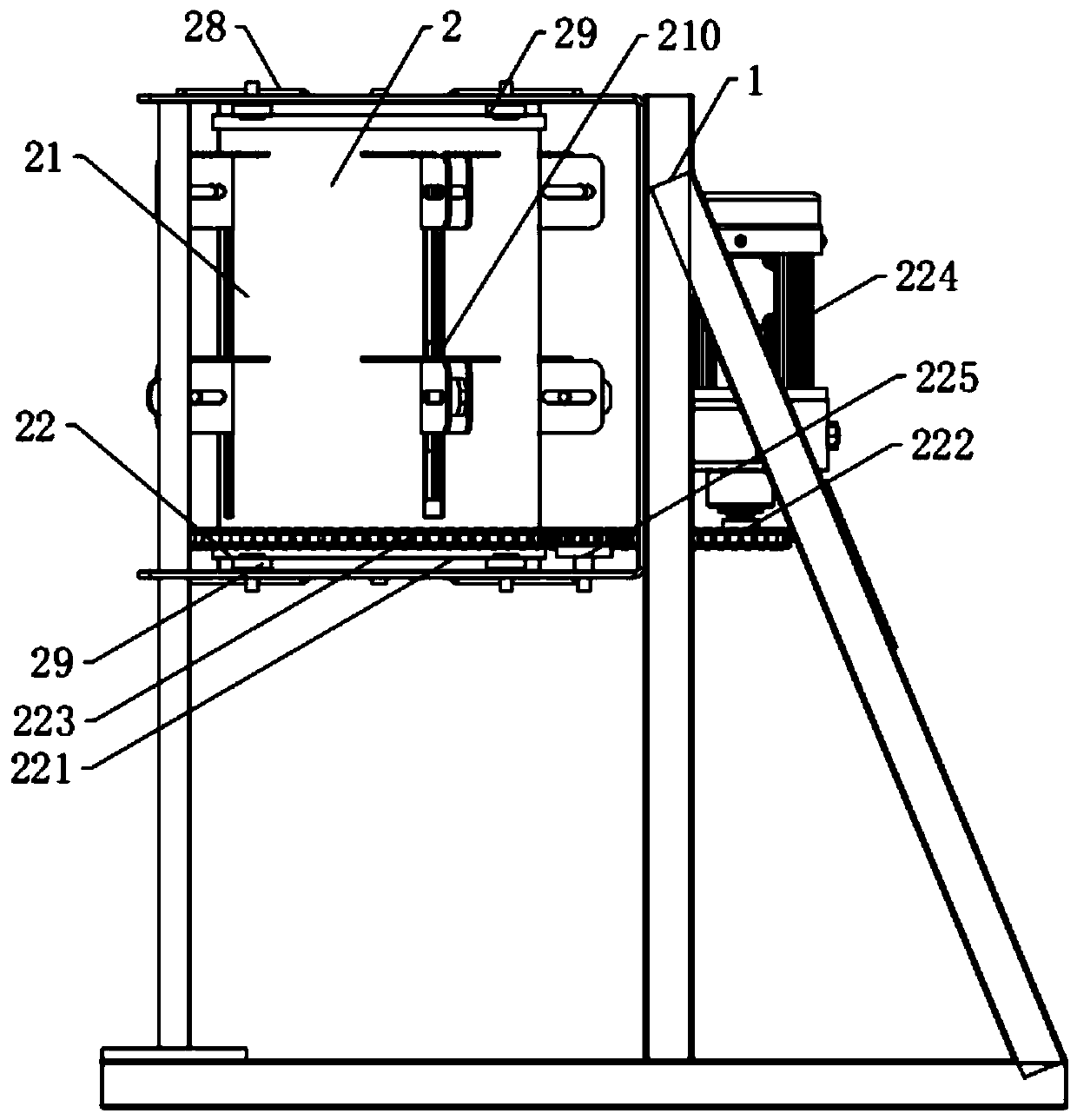

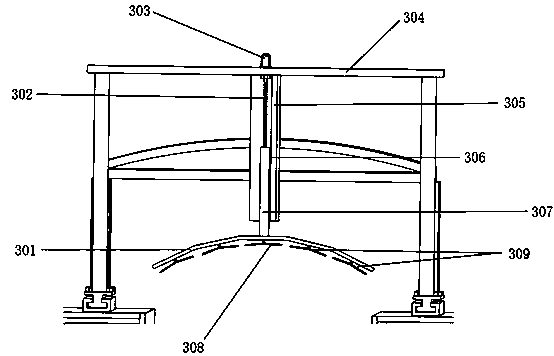

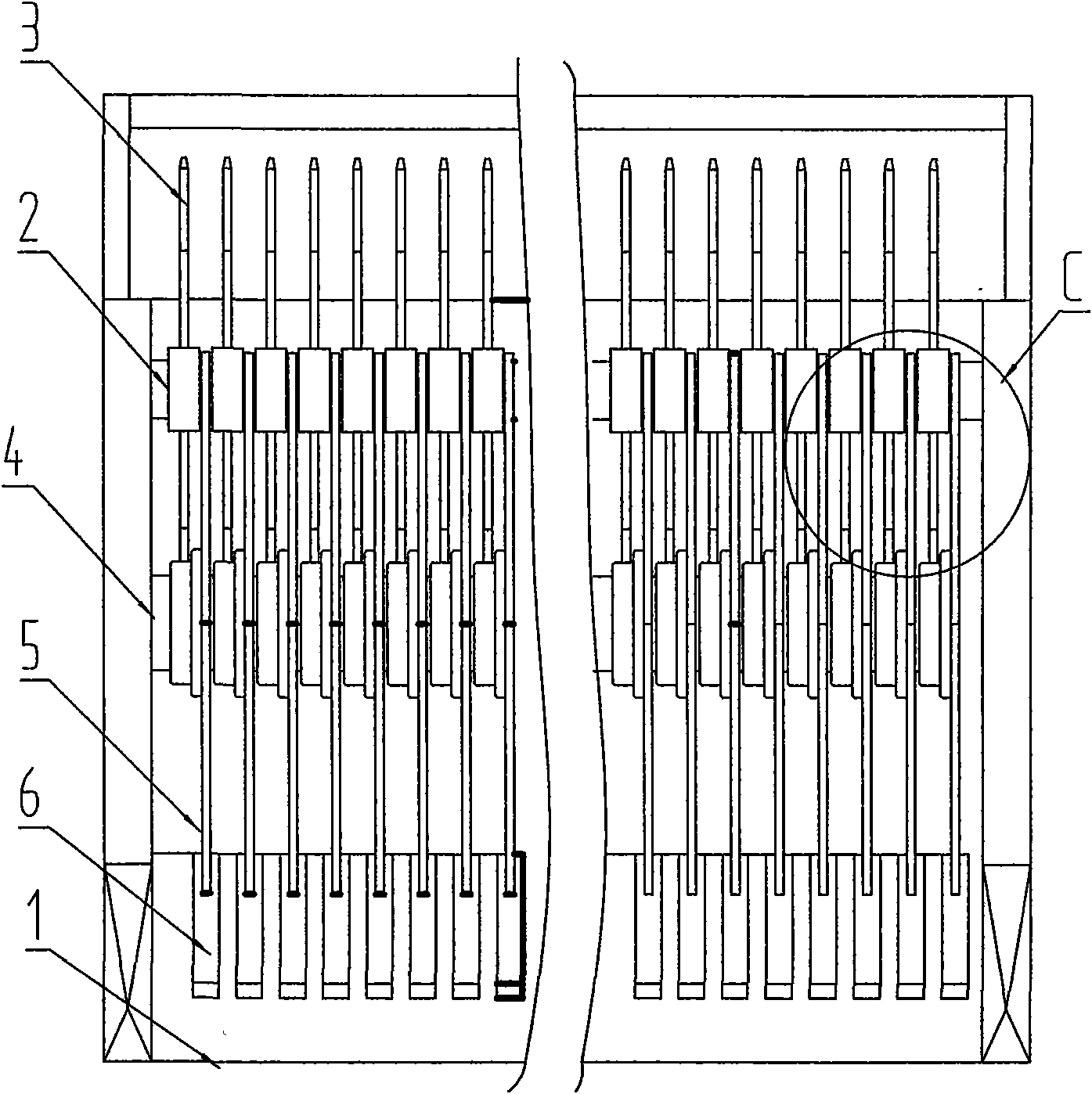

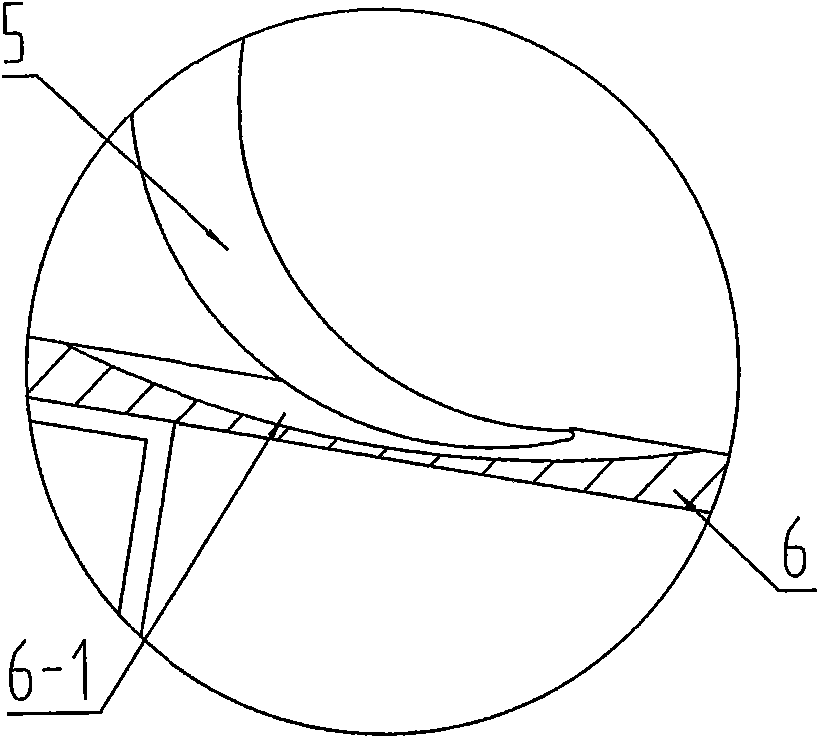

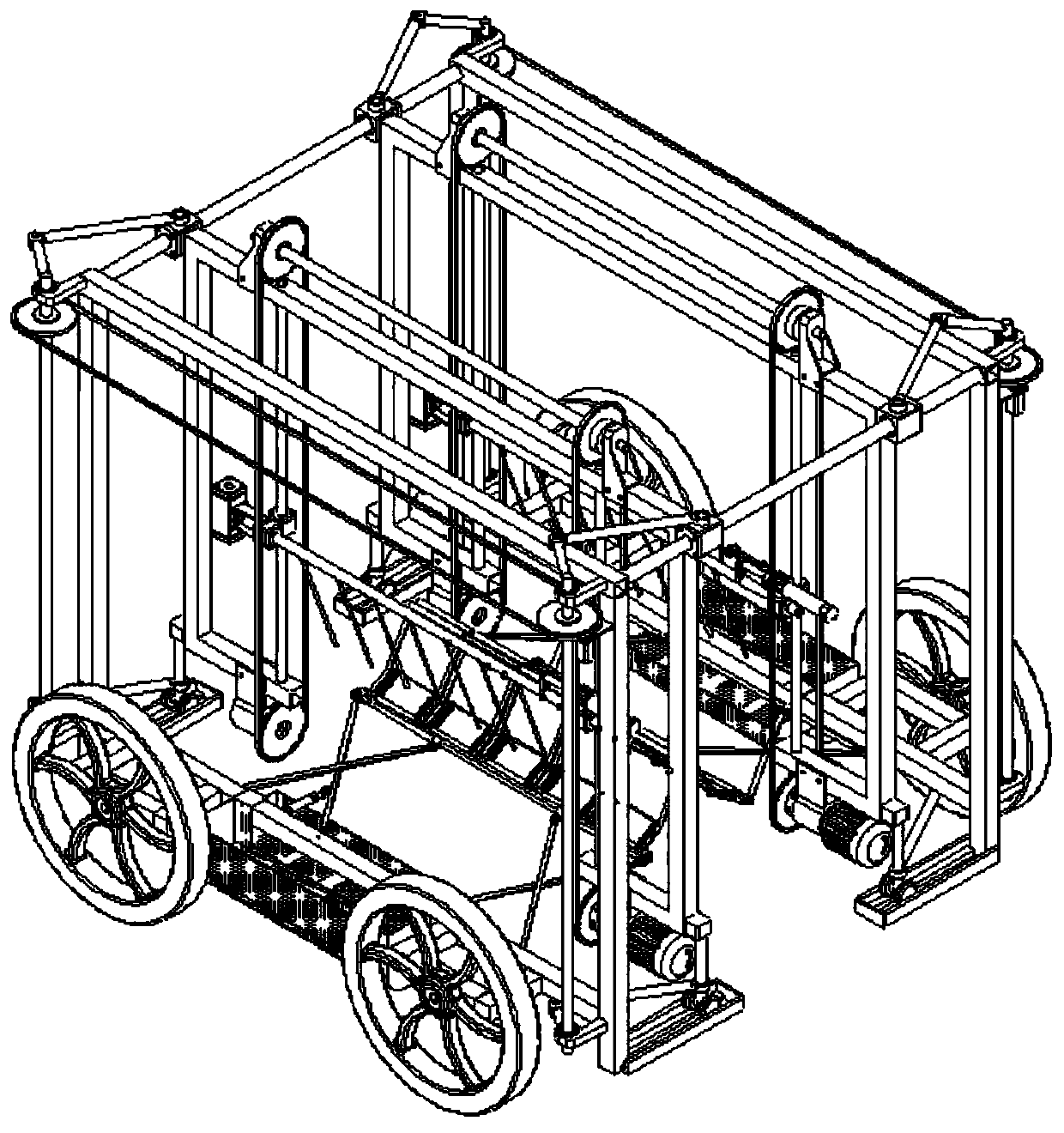

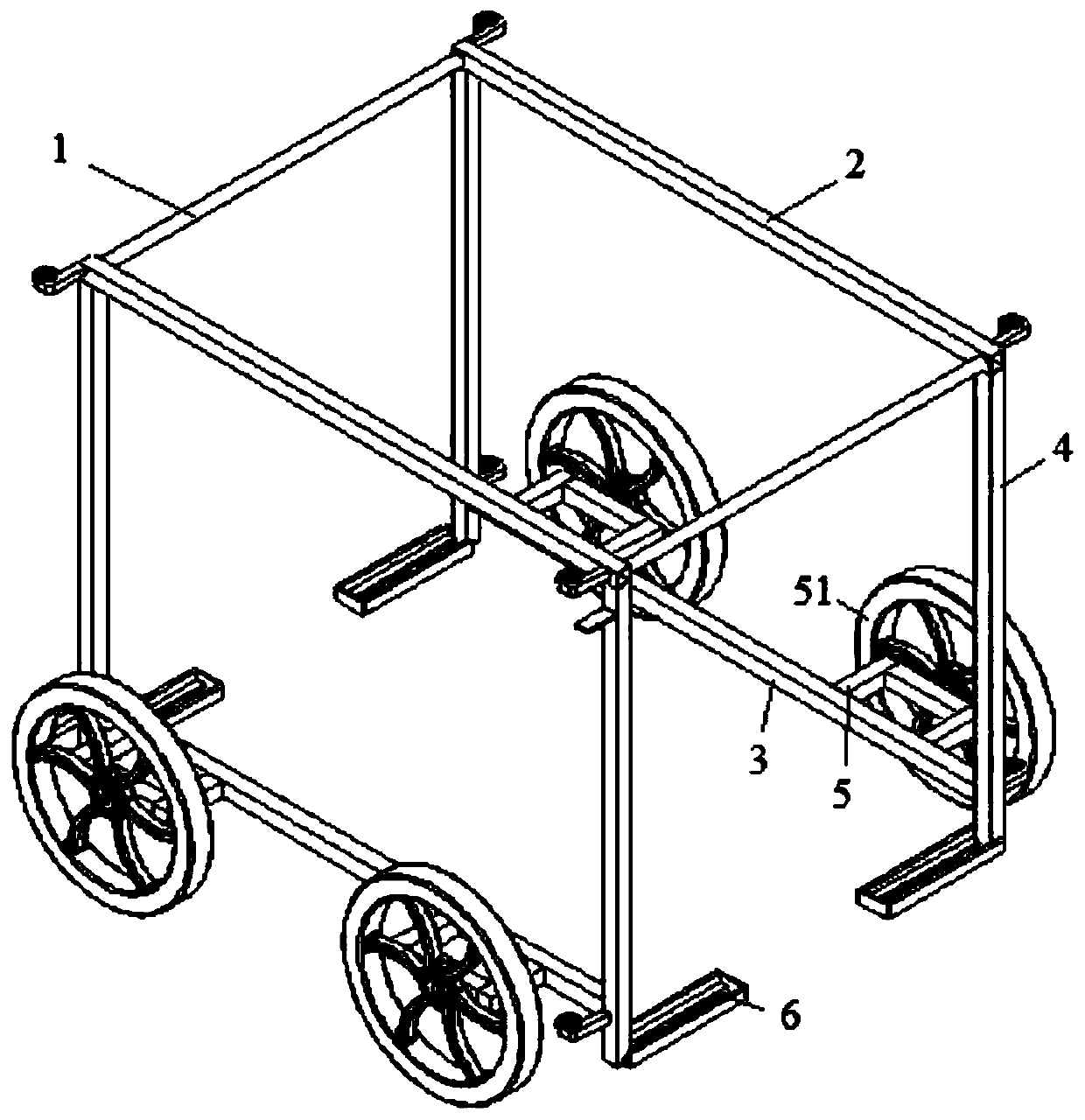

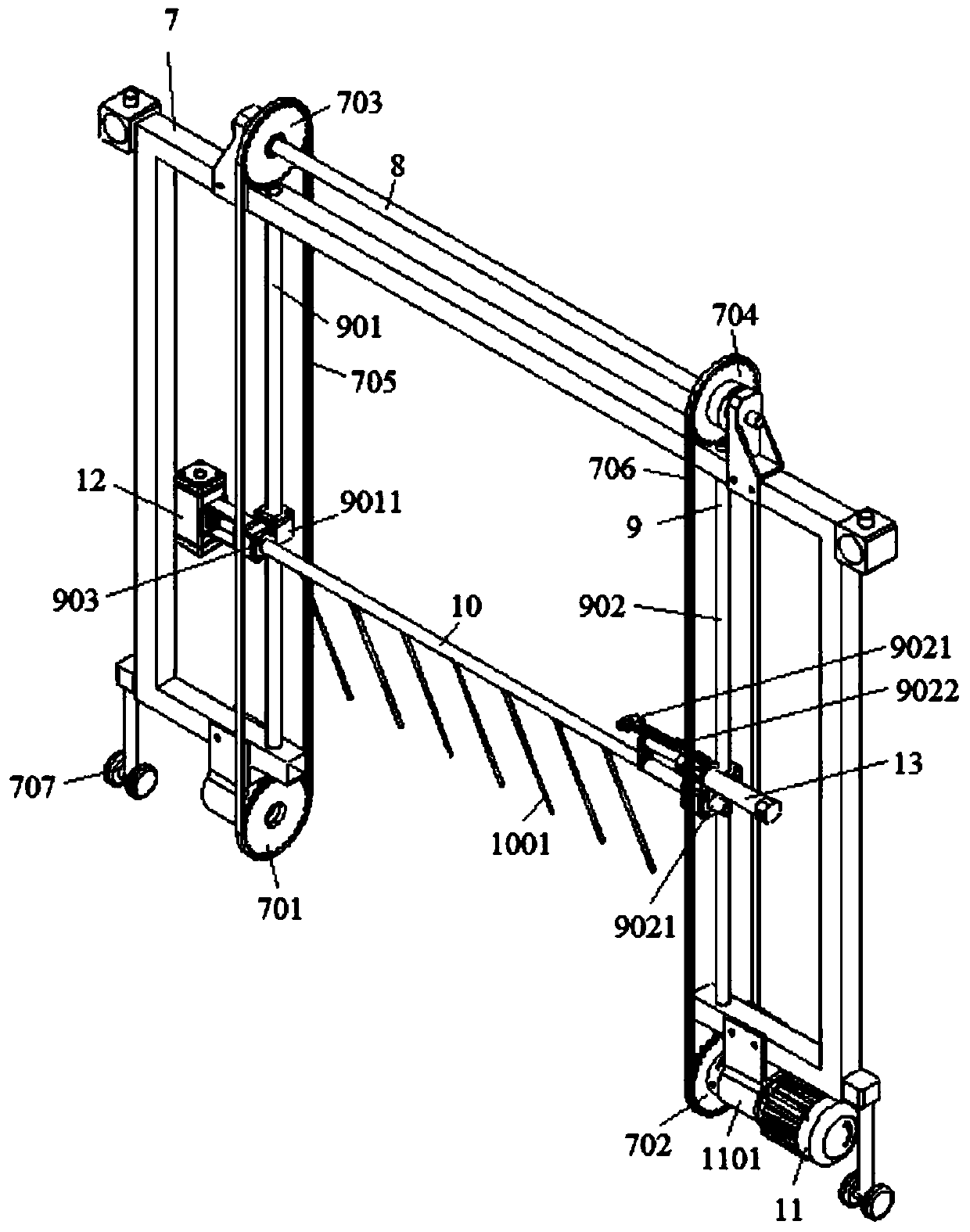

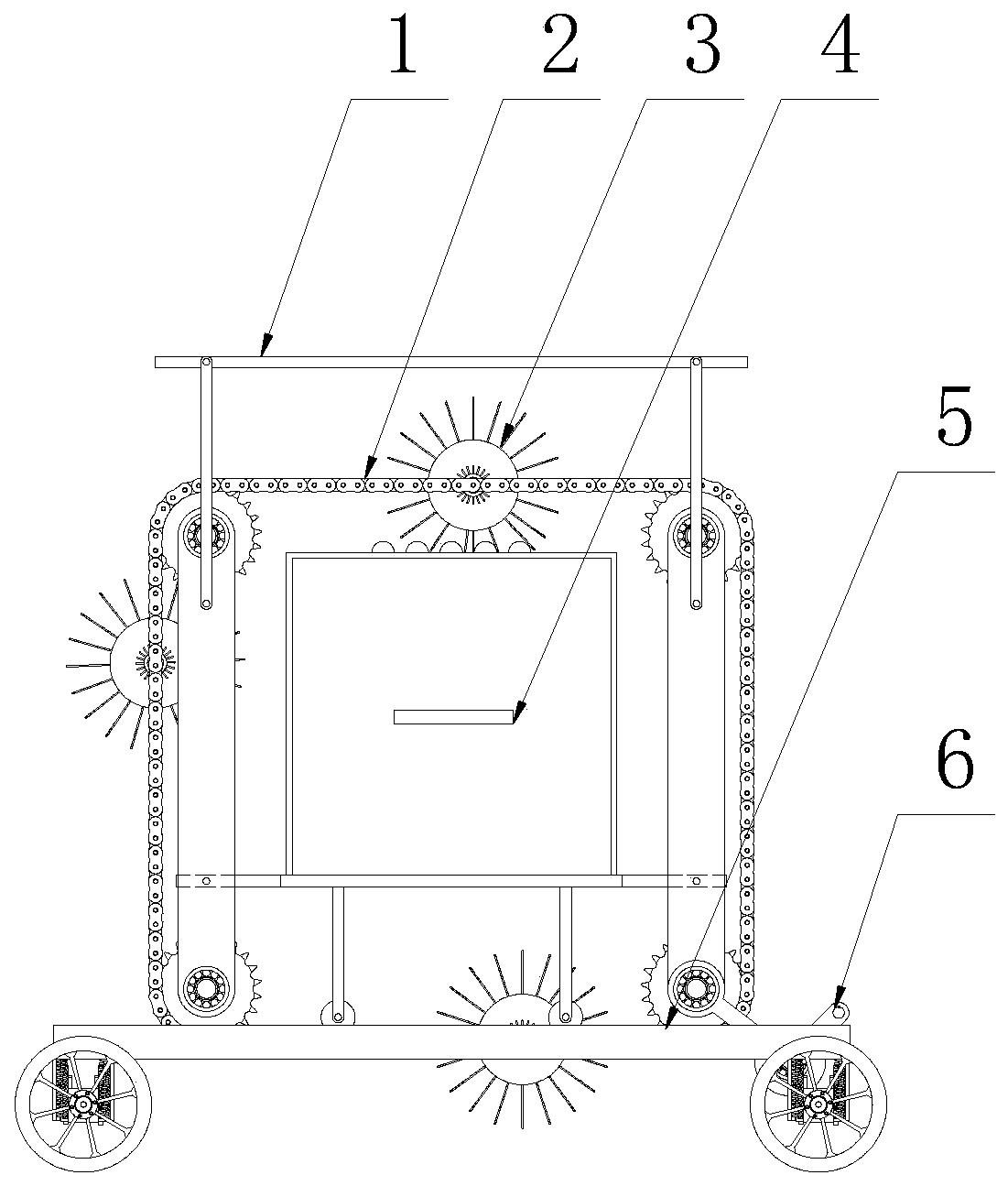

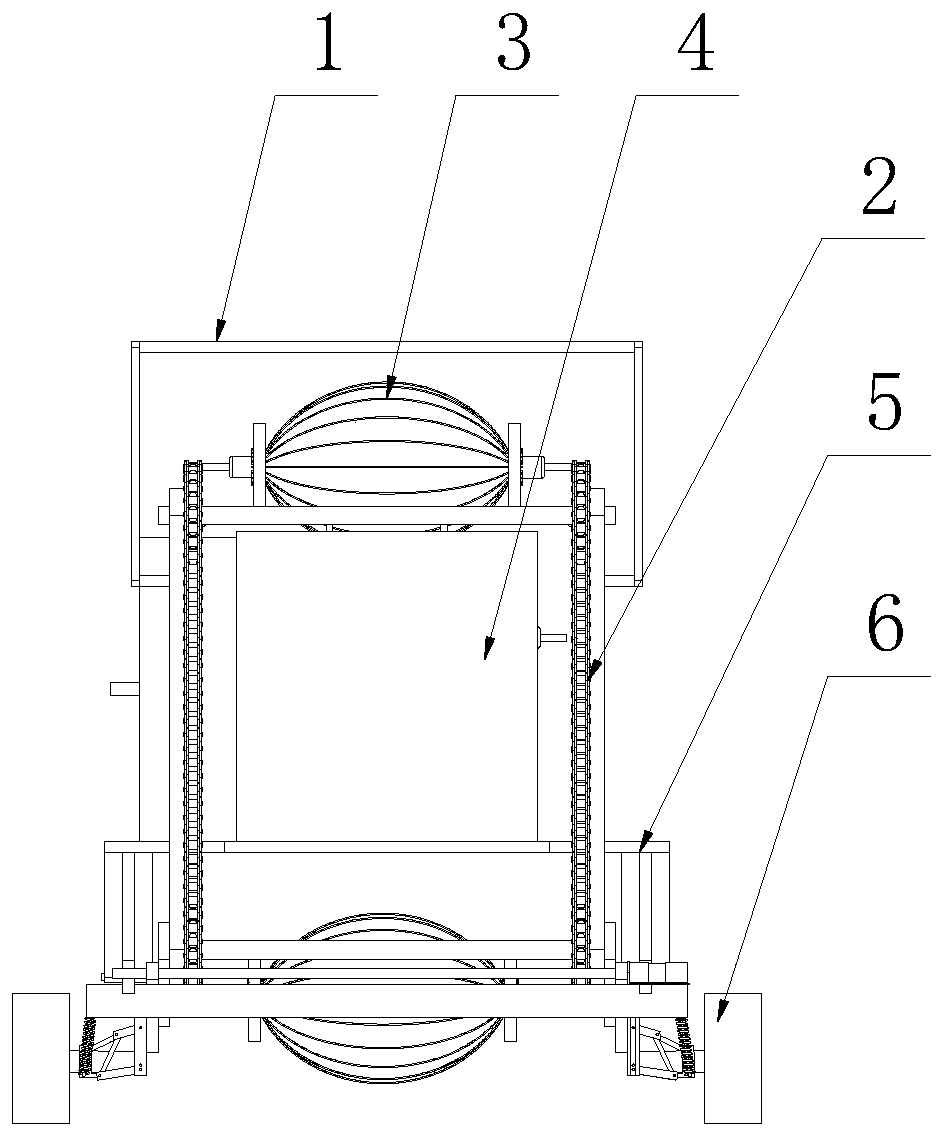

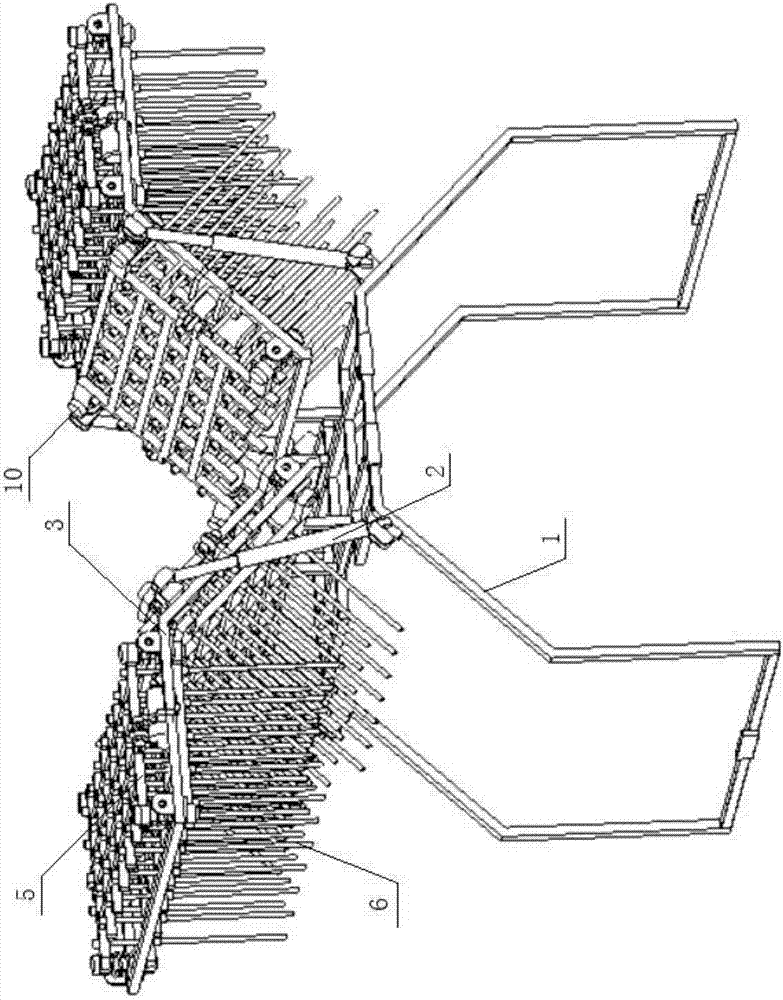

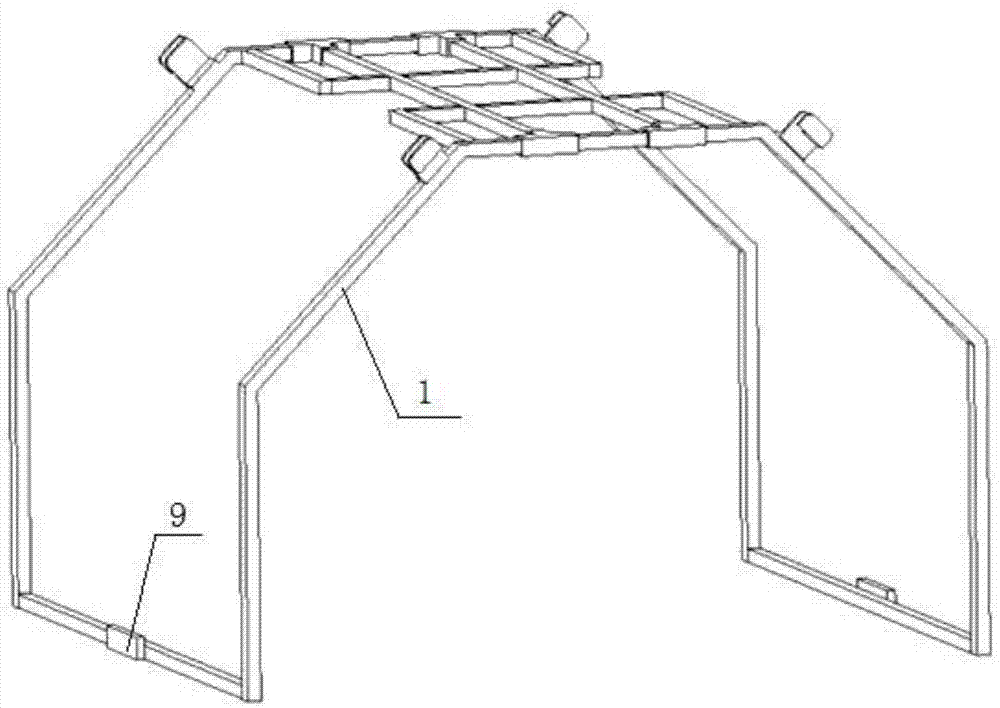

Internal comb type posture-changing vibratory wolfberry picking device

The invention relates to the technical field of fruit picking, in particular to an internal comb type posture-changing vibratory wolfberry picking device. The picking device comprises a supporting mechanism, a picking mechanism and a collecting mechanism; the picking mechanism comprises a door-shaped transverse moving support frame, vertical guide rods, a comb tooth shaft and a crank connecting rod structure; two ends of each vertical guide rod are fixedly connected with the door-shaped transverse moving support frame, one end of the crank connecting rod mechanism is fixed to the supporting mechanism through a chain wheel shaft, and the other end of the crank connecting rod mechanism is slidingly connected with the supporting mechanism after being fixed with the door-shaped transverse moving support frame; two ends of the comb tooth shaft are in sliding connection with the two parallelly arranged vertical guide rods, a plurality of comb teeth are uniformly distributed on the comb toothshaft, and a swinging cylinder and a telescopic cylinder are respectively fixed to the two ends of the comb tooth shaft. The internal comb type posture-changing vibratory wolfberry picking device canadapt to different wolfberry trees, adjust a picking force and the vibration amplitude and frequency of the comb teeth, and adopt to different parameter values aiming at different wolfberry trees soas to achieve the best picking effect.

Owner:NORTHEASTERN UNIV

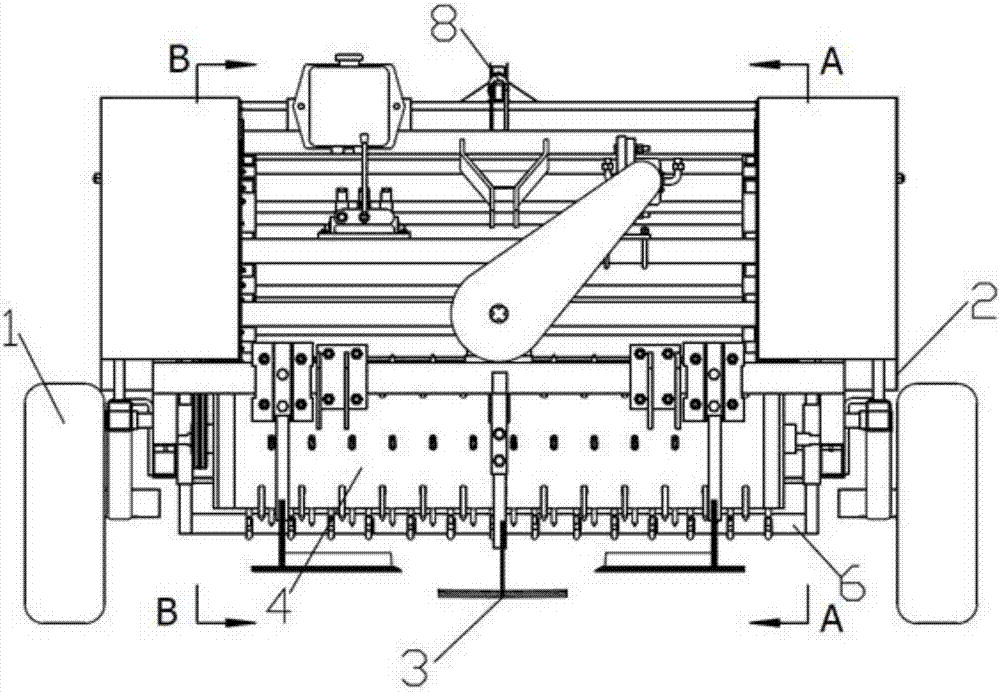

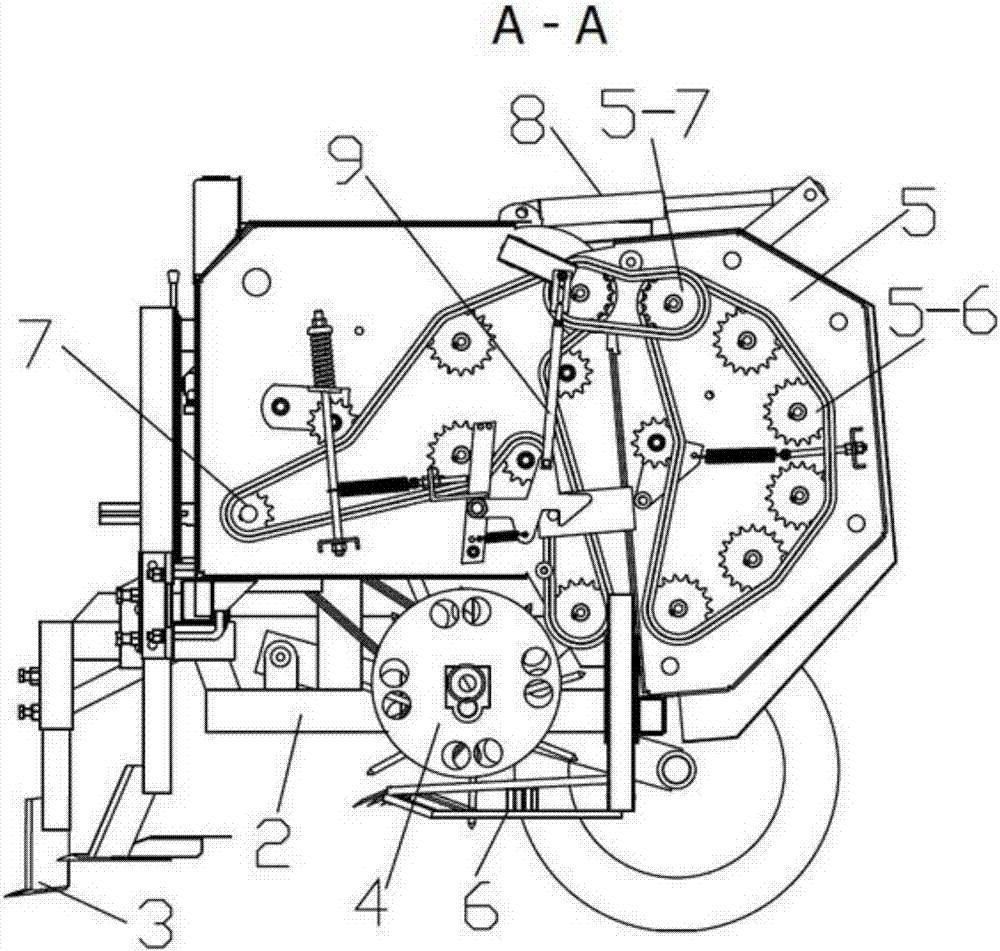

Elliptical tracking excitation type camellia oleifera fruit picking machine

ActiveCN111096150AElliptical track movement realizationAdjustable eccentricityPicking devicesFruit treeCamellia oleifera

The invention relates to the technical field of forest fruit picking machinery and aims at providing an elliptical tracking excitation type camellia oleifera fruit picking machine. The picking machinecan be used for exciting branches of camellia oleifera in multiple directions and driving the camellia oleifera fruits to generate relative motions and fall down, and has the characteristics of simple structure, convenience in operation, good picking effect and high work efficiency. According to the technical scheme, the elliptical tracking excitation type camellia oleifera fruit picking machineis characterized by comprising a motor used for providing power, an excitation device used for exciting branches of the fruit tree, a transmission device which is connected between the motor and the excitation device to transfer power and a fixing device used for supporting the motor and the excitation device, wherein the fixing device comprises a rack and two optical axes which are horizontally distributed and can be positioned on the rack in a vertical sliding manner through a slide pair.

Owner:ZHEJIANG SCI-TECH UNIV

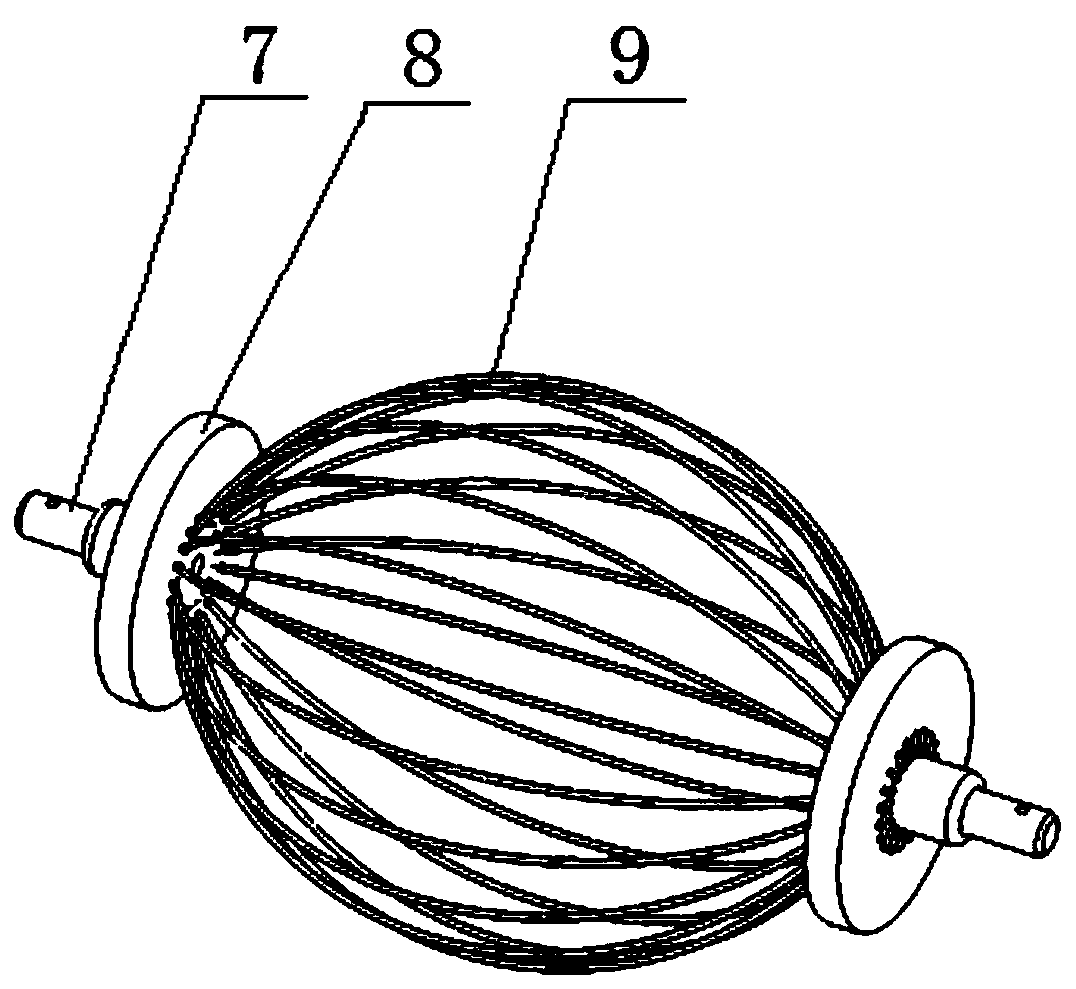

Eccentric rolling vibration mechanism for picking wolfberry fruit

InactiveCN105850374AContinuous retreatGood picking effectPicking devicesLycium barbarum fruitEngineering

The invention discloses an eccentric rolling vibration mechanism for wolfberry picking, which comprises a main shaft motor, a clutch, a main shaft, several vibrating rings, a swing arm, a weight motor and two eccentric weights; the main shaft motor is connected to the main shaft through a clutch, and the main shaft The vibrating ring is fixed on the top, and the main shaft is fixedly connected with the swing arm; the two eccentric weights are symmetrically installed on the swing arm, and are driven by the weight motor; the vibrating ring is composed of a vibrating ring base and a vibrating bar. The invention uses an eccentric weight to realize the rolling action. Compared with the existing picking structure with vertically or horizontally inserted vibrating rods, the invention can continuously draw in and retreat wolfberry branches without any pause, thereby improving picking efficiency. In addition, the ring structure of the vibrating bar circle is more adaptable than the existing linear vibrating bar matrix arrangement, and it still has a good picking effect on branches with many branches and many windings.

Owner:ZHEJIANG UNIV

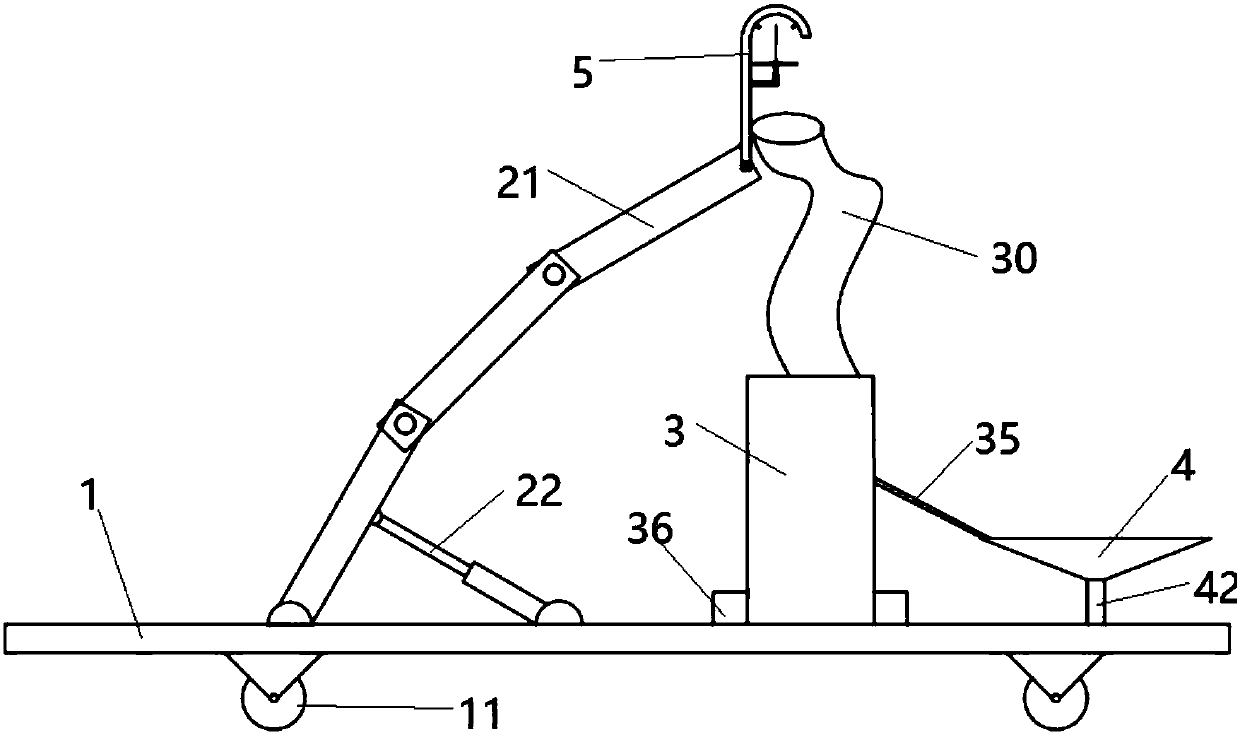

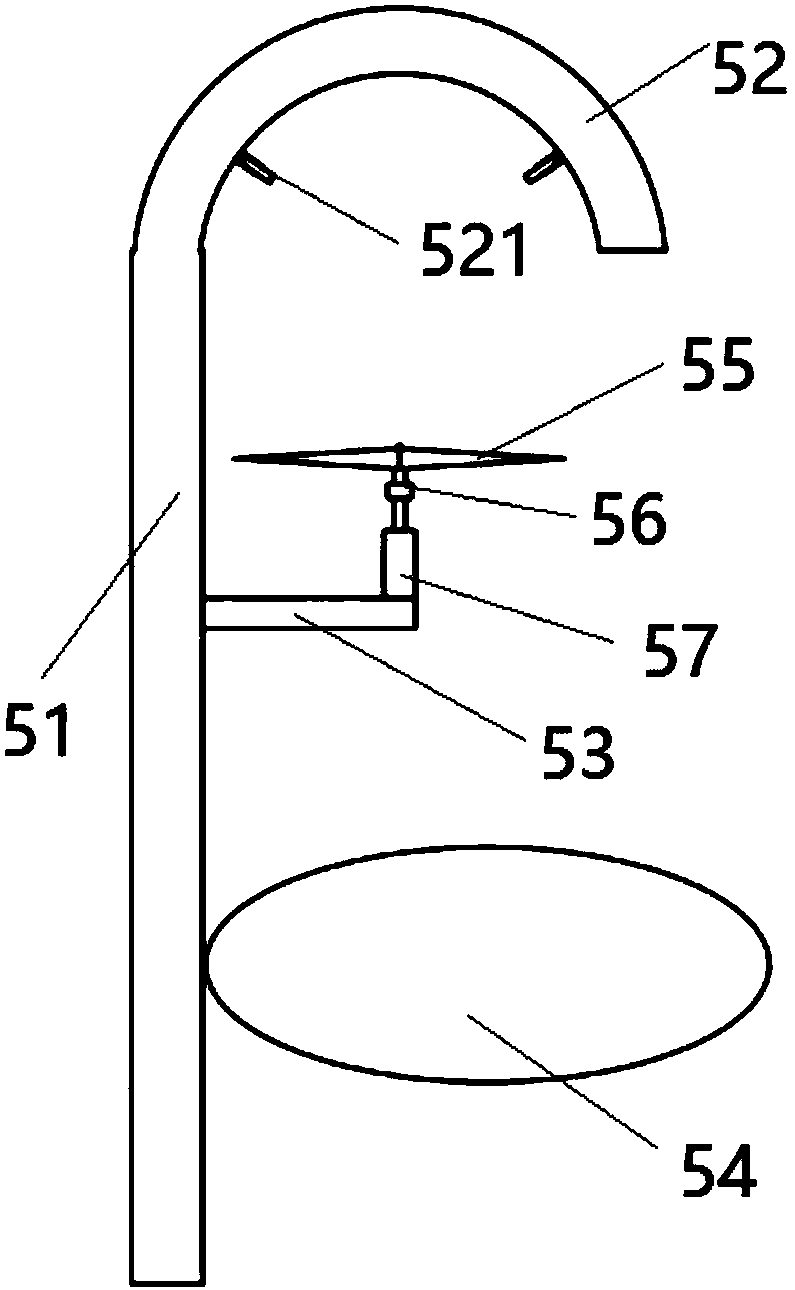

Loquat picking device

The invention discloses a loquat picking device. The loquat picking device comprises a machine seat, a hydraulic adjusting rod, a buffer collecting device and a branch-hanging traveling mechanism, wherein the hydraulic adjusting rod is arranged on the machine seat and comprises a hydraulic lifting rod and an N-section arm beam; the buffer collecting device comprises a collecting guide tube, a buffer collecting box and a fruit collecting box; an air inlet is formed in the lower part of the buffer collecting box; a fruit discharging opening is formed in a side wall of the buffer collecting box;and a chute is formed obliquely and is connected to the lowest point of an air cushion net and the upper part of the fruit collecting box. The branch-hanging traveling mechanism comprises a vertical beam, a traveling beam, a cutter beam and a connecting ring; the lower beam surface of the traveling beam is in the shape of an arc with a downward opening; at least one pair of traveling wheels is symmetrically arranged on the lower beam surface; a rotating motor is mounted on the upper end surface of the cutter beam; a driving shaft of the rotating motor is fixedly connected with the center of adisc-shaped cutter; and the upper end of the collecting guide tube is fixed on the connecting ring. The loquat picking device has the advantages of safety, reliability, high working efficiency, good picking effect and the like.

Owner:重庆稻梦空间农业发展有限公司

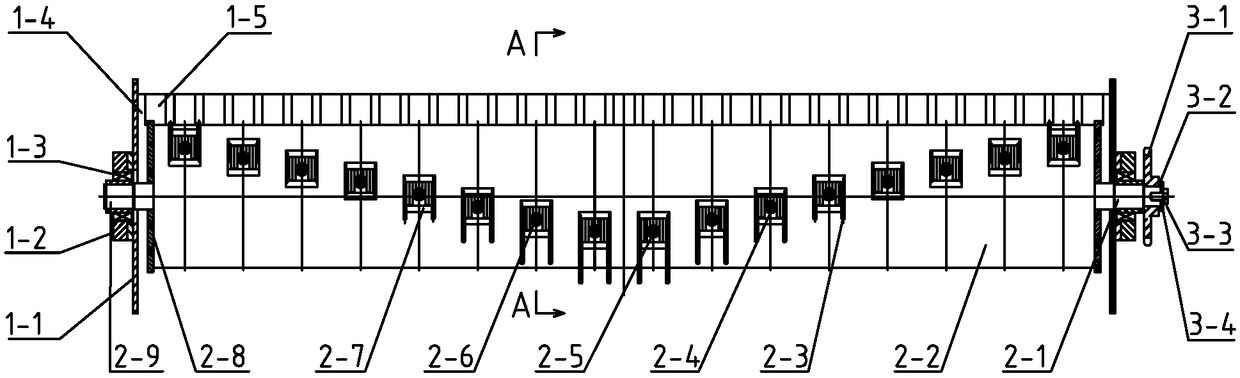

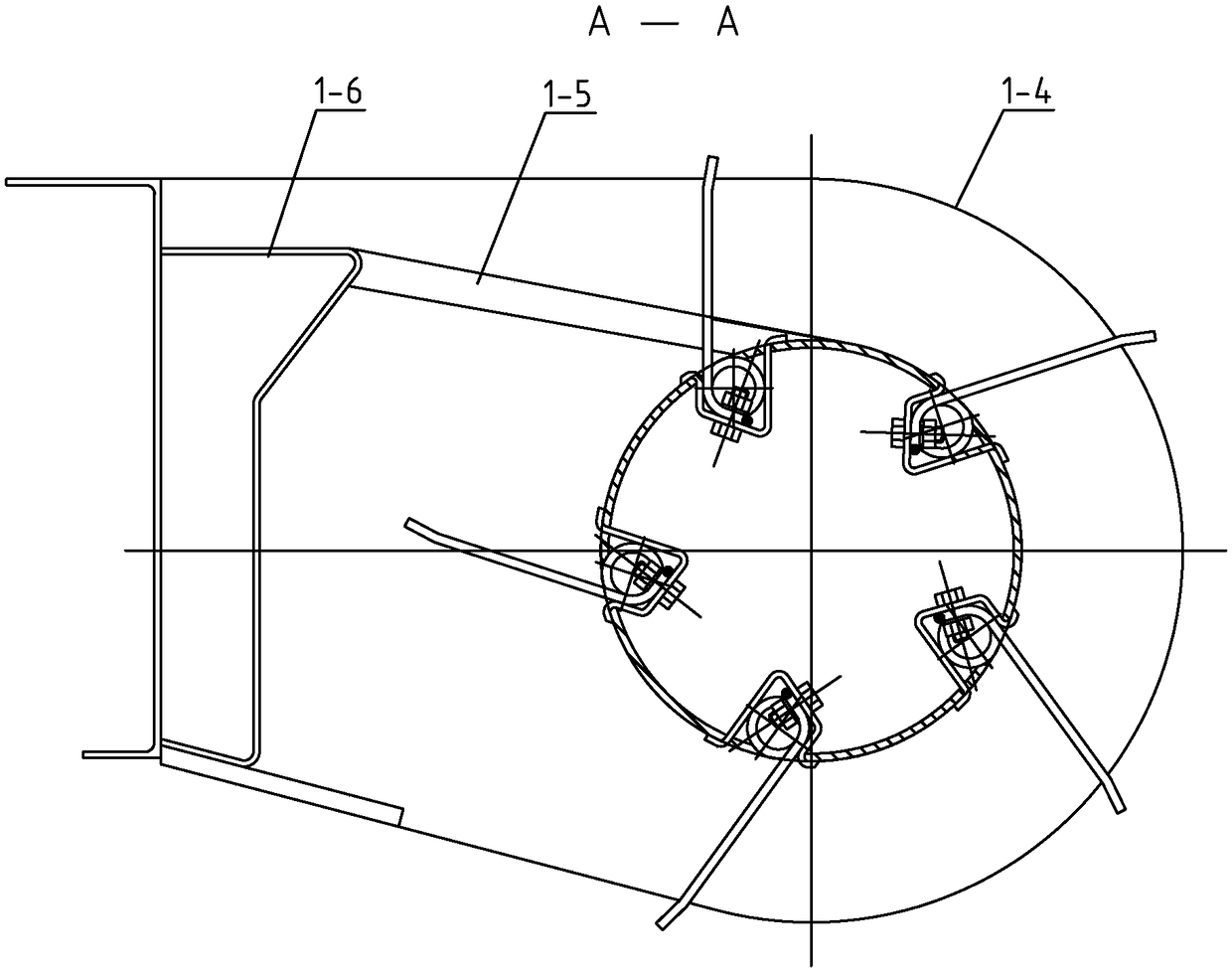

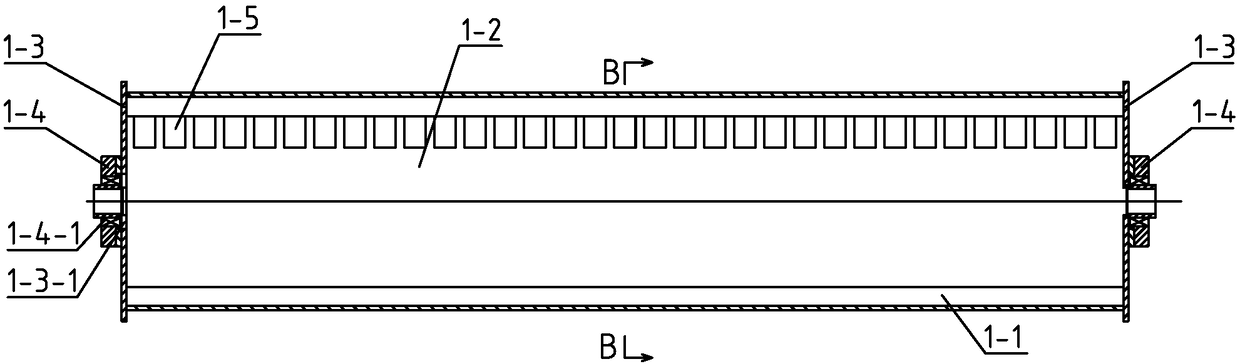

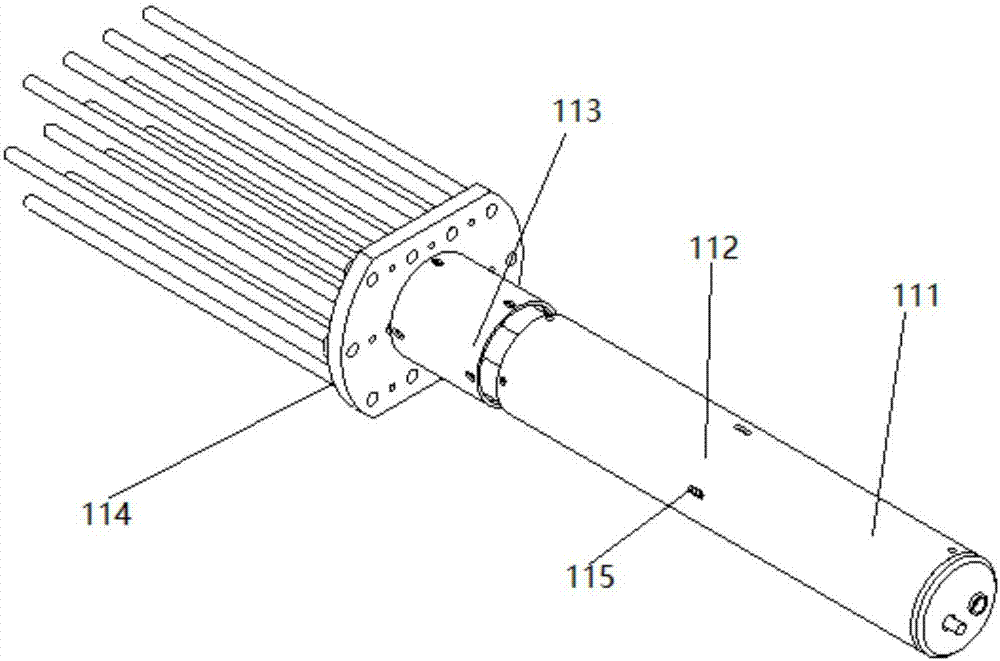

Straw pickup with elastic claws embedded in circular tube wall

The invention provides a straw pickup with elastic claws embedded in a circular tube wall, and aims to solve the problems of an existing straw pick-up unit that the structure is complex, the production cost is high, and a U-shaped retainer is deformed and damaged easily. The straw pickup comprises a rack, a pick-up mechanism and two drive sprockets, wherein the pick-up mechanism comprises a cylinder, a left end shaft, a right end shaft, two cylinder shaft end plates, a plurality of elastic claws, a plurality of elastic claw fixing seat and a plurality of connecting elements, the cylinder is provided with a plurality of square holes, the square holes are distributed in a shape of V around the circumference of the cylinder, each square hole is internally embedded with an elastic claw fixingseat, each elastic claw fixing seat is internally provided with an elastic claw, and the elastic claws and the elastic claw fixing seats are connected through the connecting elements; the two cylindershaft end plates are respectively and fixedly connected to the two ends of the cylinder, and the left end shaft and the right end shaft are respectively welded on the cylinder shaft end plates; the pick-up mechanism is arranged in the rack, the left end shaft is supported in a shaft supporting seat in the left side of the rack, the right end shaft is supported in a shaft supporting seat in the right side of the rack, and the two drive sprockets are respectively and fixedly arranged on the left end shaft and the right end shaft. The straw pickup with elastic claws embedded in the circular tubewall is applied to picking up straws.

Owner:唐大平

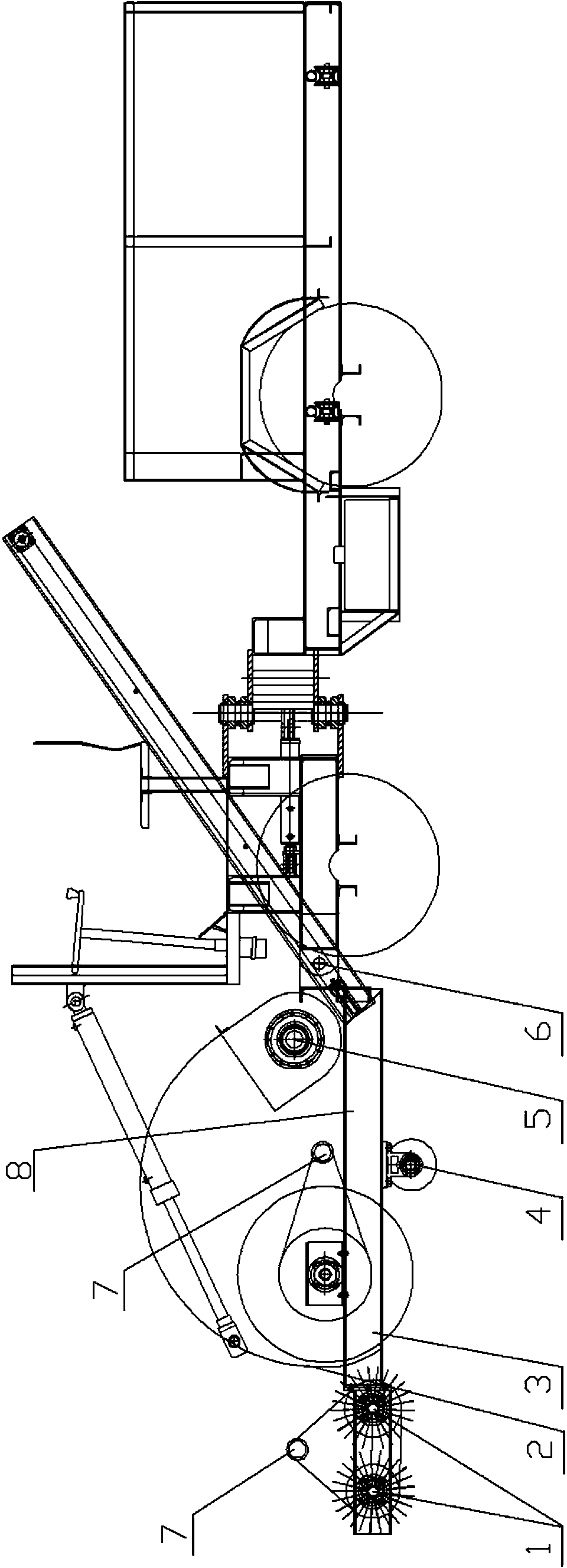

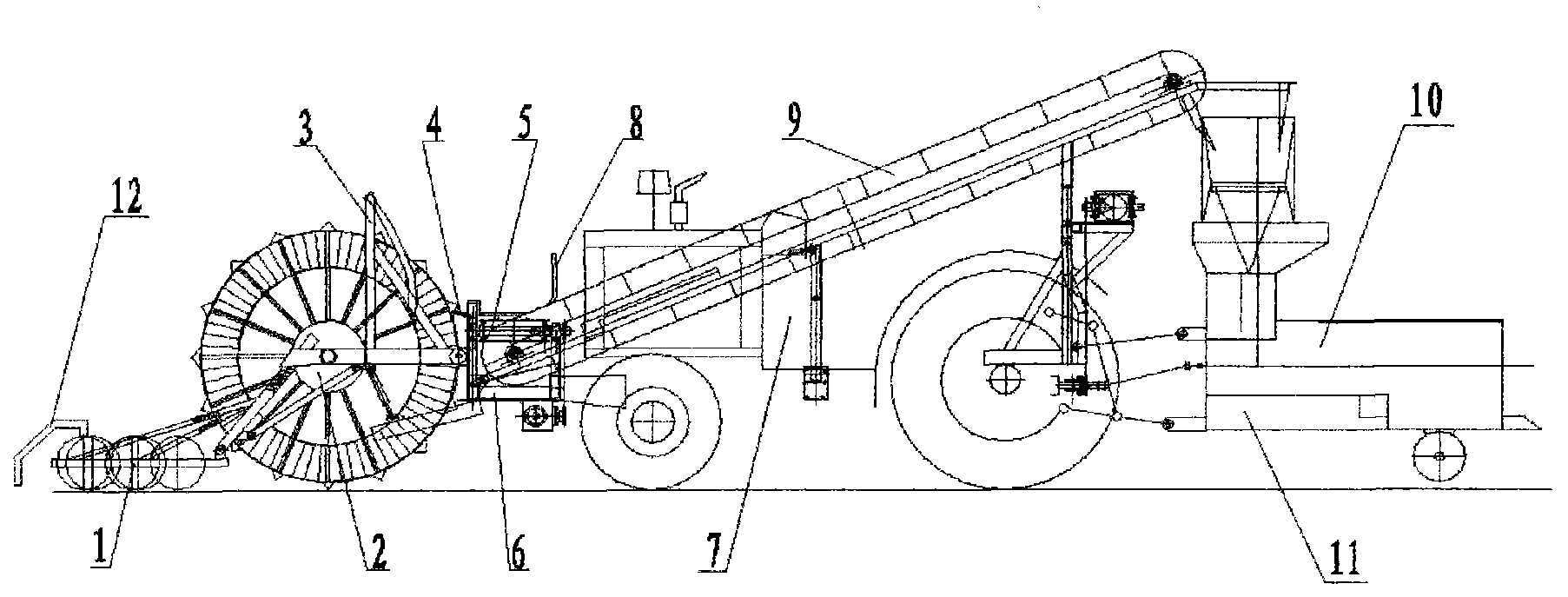

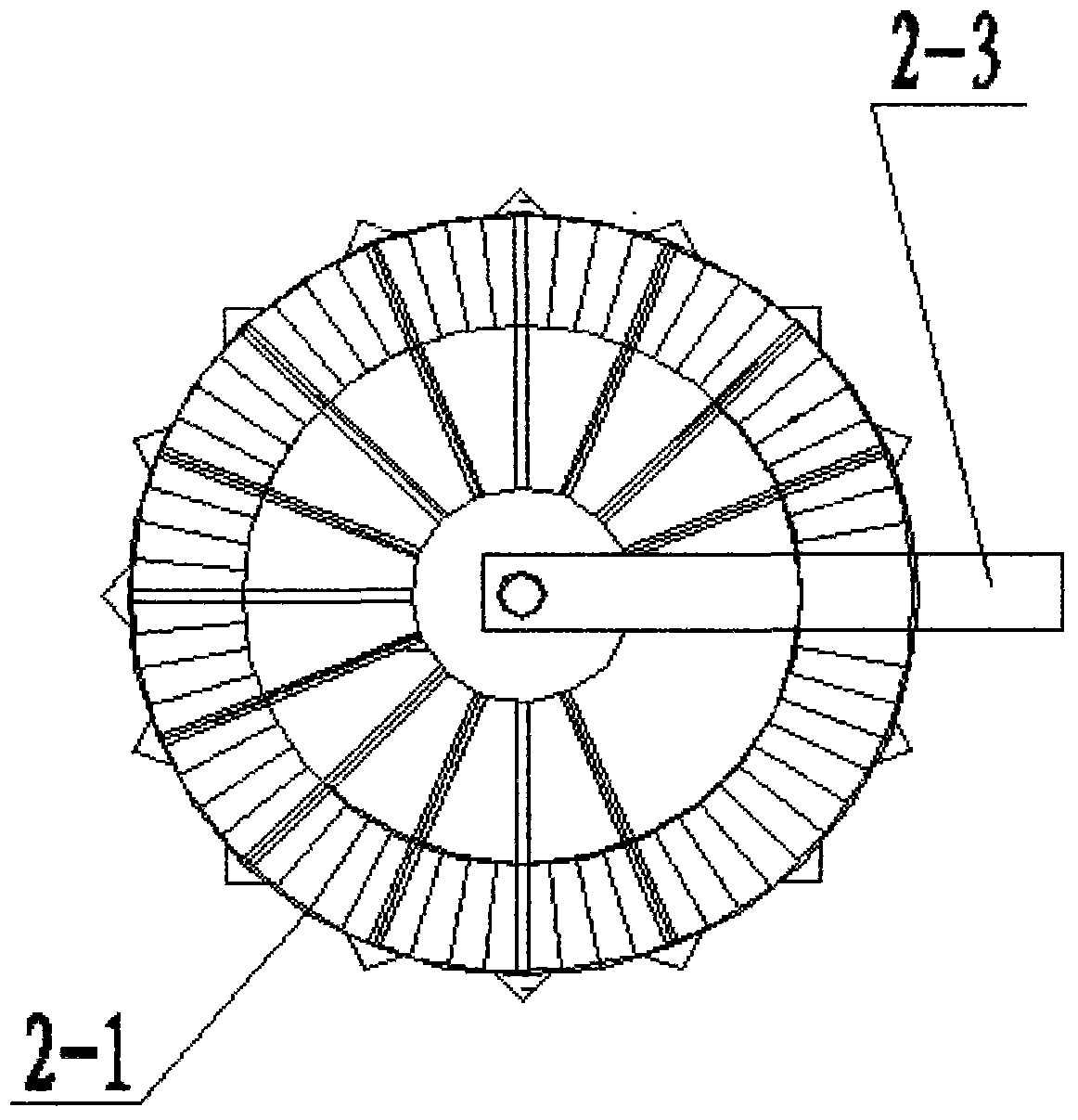

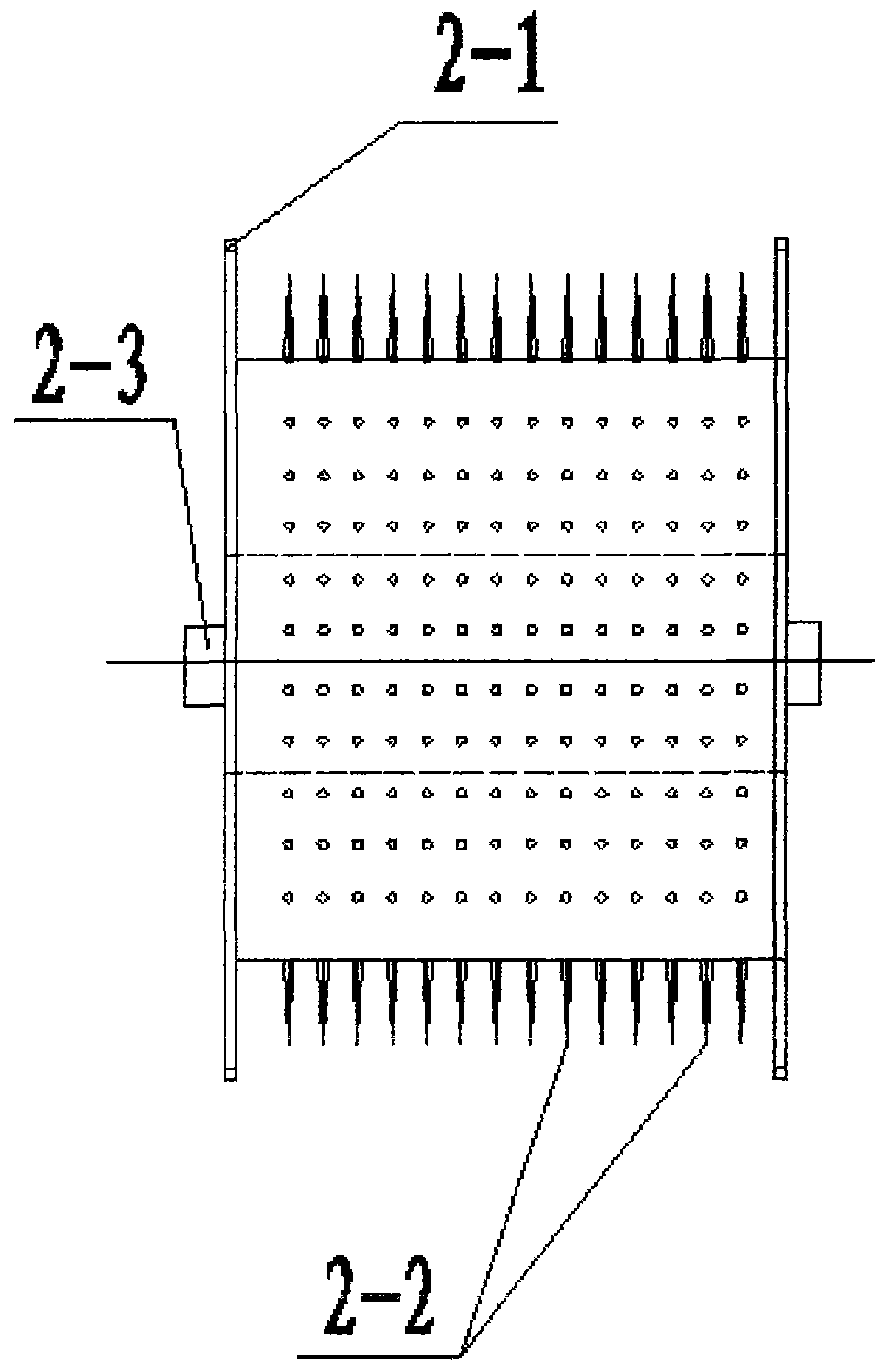

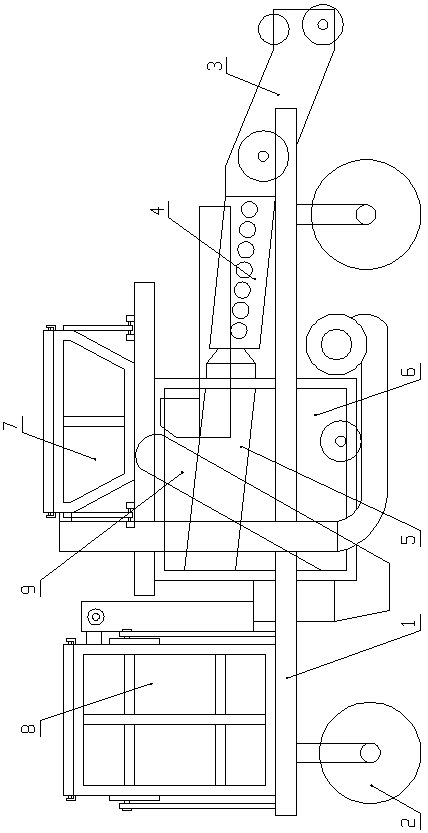

Backpack seed melon combined harvester

The invention discloses a backpack seed melon combined harvester which comprises a transverse conveyor device, a pickup machine, a melon distributor, a melon guiding device, a melon discharging device, a lift conveyor and a melon seed extractor. The transverse conveyor device is mounted at the front of an engine, the pickup machine is mounted at the front of the transverse conveyor device, the melon distributor is arranged below the front of the pickup machine, the melon guiding device is arranged between the pickup machine and the transverse conveyor device, the melon discharging device is mounted on the rear upper portion of the pickup machine and corresponds to a melon inlet of the melon guiding device, the lift conveyor is mounted on the engine, and the melon seed extractor is mounted at the rear of the engine; a melon outlet of the melon guiding device corresponds to a melon inlet of the transverse conveyor device, a melon inlet and a melon outlet of the lift conveyor respectively correspond to a melon outlet of the transverse conveyor device and a melon inlet of the melon seed extractor, the pickup machine is of a roller type structure and comprises a pickup machine framework and a roller, the roller is movably connected onto the pickup machine framework, a plurality of pickup teeth are fixedly arranged on the peripheral surface of the roller, and the pickup machine framework is hinged to a framework of the transverse conveyor device. The backpack seed melon combined harvester has the advantages of high seed melon pickup efficiency and production efficiency and good profiling effect.

Owner:新疆郅拓农机科技有限公司

Portable vibration-type picking machine with function of adjusting amplitude-frequency in stepless manner

PendingCN107278518AReduce hand vibrationReduce fatigue strengthPicking devicesDrive shaftControl engineering

The invention discloses a portable vibration-type picking machine with a function of adjusting amplitude-frequency in a stepless manner. The machine comprises a motor control part, a vibration damping part, a driving part and a vibrating head. The vibration damping part is provided with a vibration damping flexible shaft. The driving part is provided with a driving shaft. The motor control part is connected with the driving shaft through the vibration damping flexible shaft. The driving shaft is provided with an eccentric block. The driving shaft drives the eccentric block such that the vibrating head generates vibration. The portable vibration-type picking machine with the function of adjusting amplitude-frequency in a stepless manner has the following beneficial effects: due to the fact that the vibration damping part is utilized and power transfer is carried out by flexible-shaft connection, so that vibration sense when a user holding the machine is reduced significantly, the fatigue intensity to the user is reduced and picking efficiency is increased.

Owner:西安汇星机械科技有限公司

High-efficiency and low-trash content cotton picker

The invention discloses a high-efficiency and low-trash content cotton picker, which comprises a shell, a cotton clamping and conveying assembly, a driving assembly and a separating tube; the shell comprises a tubular shell and a handle; the cotton clamping and conveying assembly comprises an upper conveyer belt, a lower conveyer belt, a left conveyer belt and a right conveyer belt, the front end and rear end of each conveyer belt are respectively supported by a driven roller and a driving roller, bevel gears are arranged at both ends of the driving roller, and the neighboring driving rollers are engaged through the bevel gears; the driving assembly comprises a motor and a speed reducer, and the speed reducer is transmissively connected with one of the driving roller in the cotton clamping and conveying assembly through a transmission part; the separating tube is used for separating cotton from the conveyer belts. The high-efficiency and low-trash content cotton picker adopts a hand-held structure, is reasonably designed, and is convenient to hold; in addition, a trigger type switch is used for controlling the switching and rotational speed of the motor, so operation is flexible; the high-efficiency and low-trash content cotton picker can perform specific picking, decreases the trash content of cotton, increases the efficiency of cotton picking, and has remarkable practicability.

Owner:NANTONG QIWU AGRI PROD CO LTD

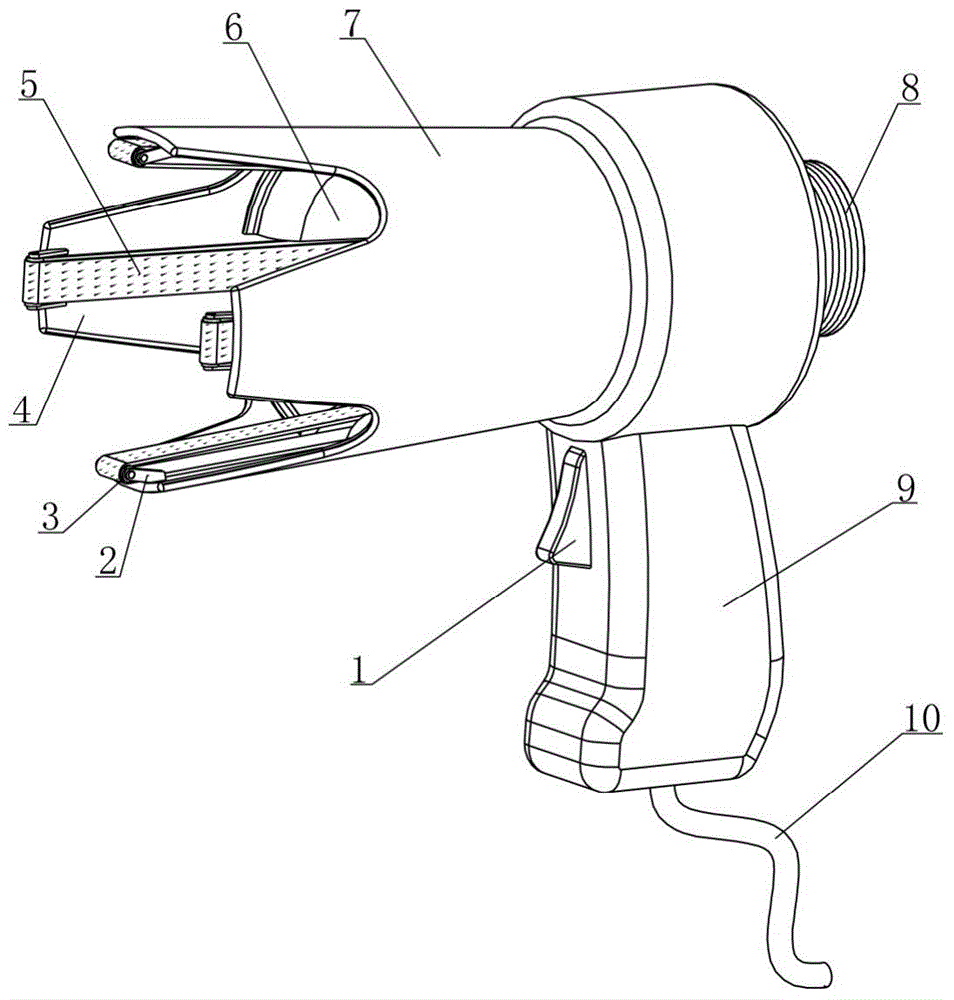

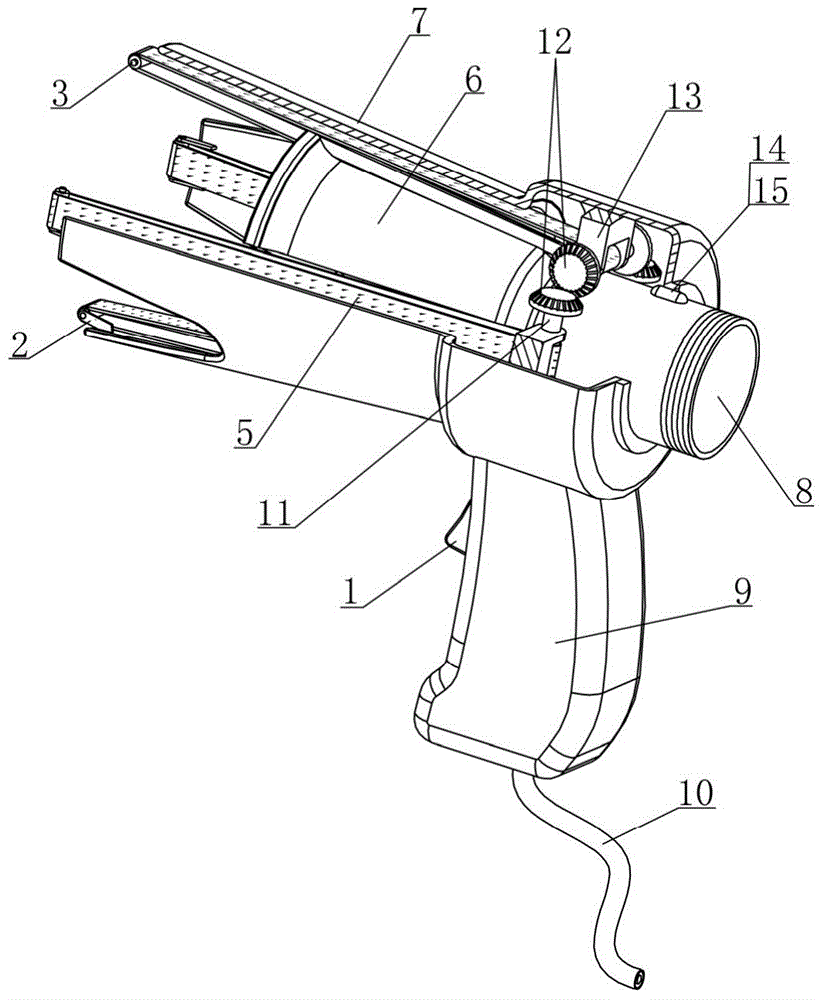

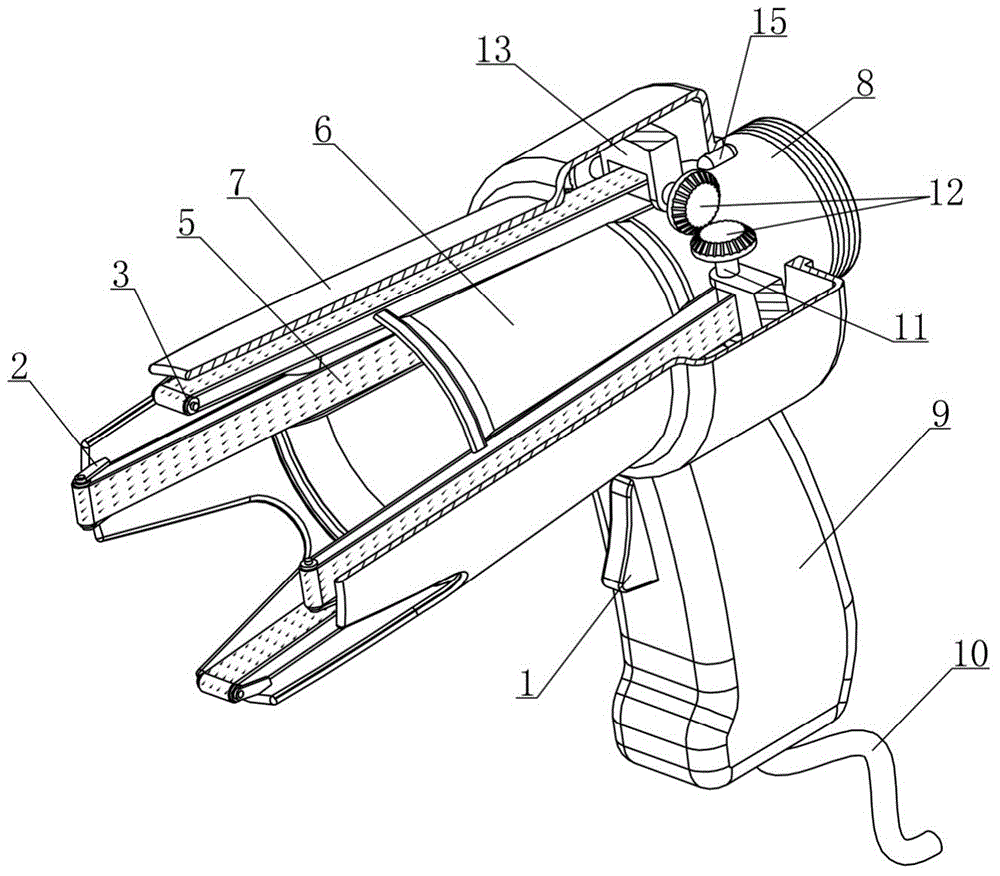

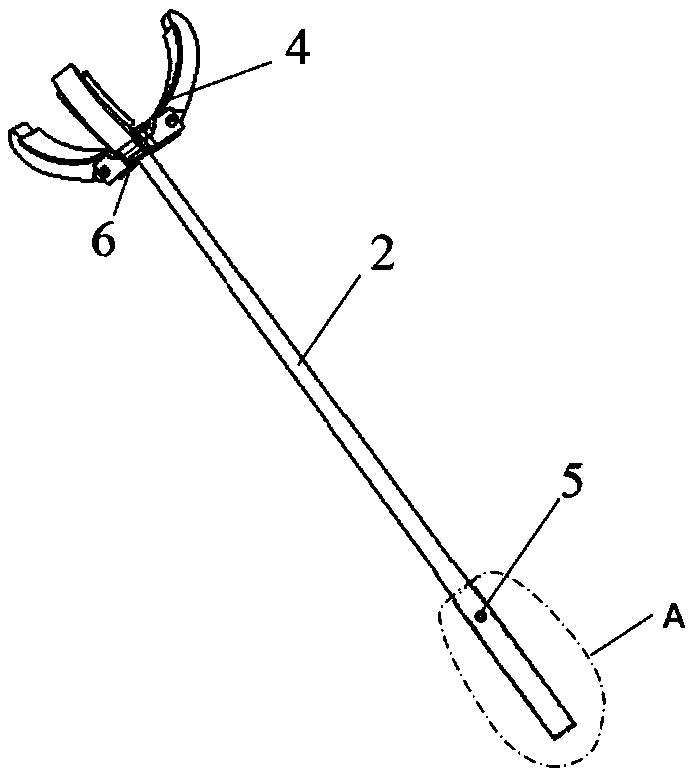

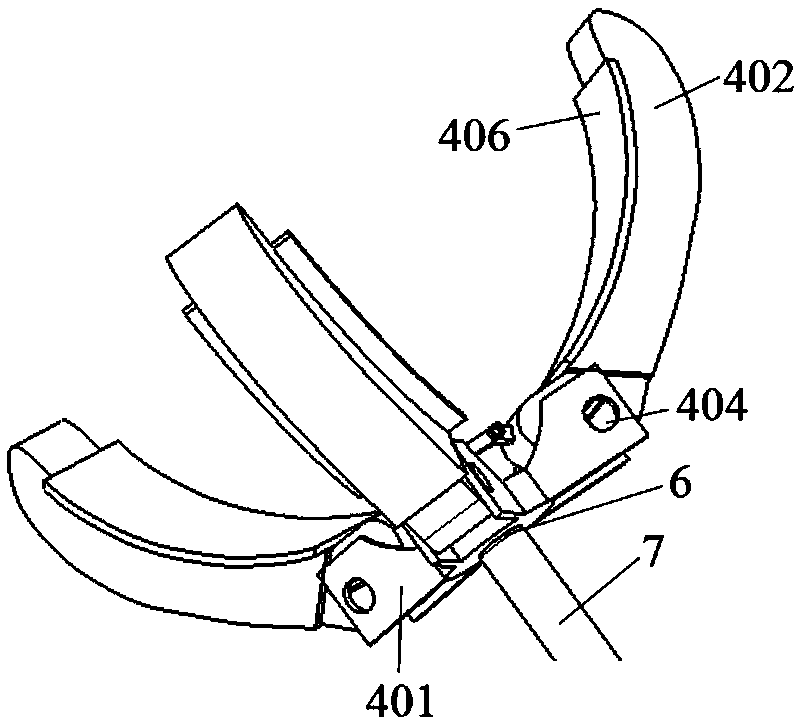

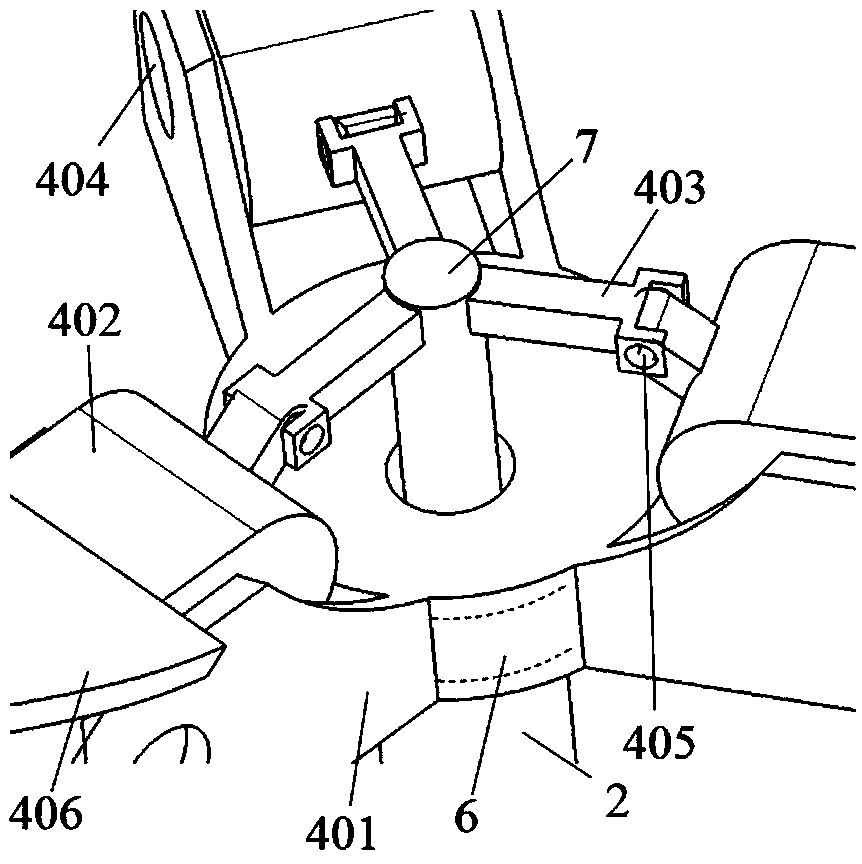

Rotary-picking rechargeable high-altitude fruit picker

The invention discloses a rotary-picking rechargeable high-altitude fruit picker. The fruit picker comprises a support rod, a grasping device which is arranged on the support rod and is used for grasping fruits, and a control device for controlling the grasping device to switch between a clamping state and a release state; the control device comprises a push-pull rod connected with the grasping device, a driving motor used for controlling the push-pull rod to rotate relative to the support rod and move along the shaft direction, and a storage battery for providing electric energy for the driving motor; and the support rod sleeves the push-pull rod. According to the rotary-picking rechargeable high-altitude fruit picker provided by the invention, an inner rod is driven to move linearly androtationally by the motor, and the grasping and rotary picking of fruits are realized. The structure is simple, the whole use process is simple in operation, and the fruit picker has the advantages ofefficient work, wide application range and good picking ability, can effectively reduce the labor intensity of workers, can improve the fruit picking efficiency, and can be widely applied to the agricultural production field.

Owner:张振阳

Falling forest fruit pickup robot

InactiveCN111194615AAdapt to complex and diverse terrain conditionsWith mobile capabilitiesSievingScreeningControl engineeringAgricultural engineering

The invention belongs to the technical field of automation, and relates to a falling forest fruit pickup robot. The robot comprises a combined power supply device, a self-propelled moving chassis anda manipulation control device, and is characterized by further comprising pickup units, a fruit collector, a conveying mechanism and horizontal swinging mechanisms; the fruit collector is arranged onthe self-propelled moving chassis in a rolling manner; the conveying mechanism is arranged on the fruit collector; the combined power supply device and the pickup units are all arranged on the conveying mechanism; ends of the horizontal swinging mechanism are symmetrically arranged on the self-propelled moving chassis, and the other ends of the horizontal swinging mechanisms are hinged with the conveying mechanism; and the manipulation control device is in a control connection with the self-propelled moving chassis, the conveying mechanism and the horizontal swinging mechanisms. The robot hasthe advantages of being scientific and reasonable in structural design, automatically moving and avoiding obstacles, performing picking and impurity removal synchronously, adapting to complex and diverse topographic conditions of orchards, being high in picking efficiency and less in damage, having a good effect and a wide application range, and the like, and is a falling forest fruit pickup robotwith a relatively high innovation.

Owner:TIANJIN AGRICULTURE COLLEGE

Self-propelled peanut gathering harvester

Provided is a self-propelled peanut gathering harvester. The harvester comprises a rack, the lower portion of the rack is provided with walking wheels, a gathering mechanism, a delivering mechanism and a peanut picking mechanism are successively arranged on the rack from front to back, the rack is provided with a screening mechanism located below the peanut picking mechanism, a peanut dischargingmechanism located above the peanut picking mechanism and a seedling separating mechanism located behind the peanut picking mechanism, and a secondary peanut returning mechanism is arranged between theside portion of the peanut picking mechanism and the delivering mechanism. The harvester is compact in structure, stable in work, high in automation degree, convenient to operate, high in peanut picking efficiency, and high in picking net rate, can automatically gather peanuts and respectively collect peanut seedlings and peanuts, and is high in production efficiency.

Owner:正阳县豫丰机械有限公司

Picking robot

The invention discloses a picking robot. The robot comprises a chassis, a walking mechanism, a rotation mechanism and a picking mechanical arm, and the walking mechanism is installed below the chassis; the rotation mechanism is mounted above the chassis; the picking mechanical arm is connected with the rotation mechanism; the picking robot further comprises a fruit containing barrel, a pressing mechanism and a limiting mechanism; the limiting mechanism comprises a first linear movement driving piece and a limiting plate, a containing hole and a containing groove are formed in the limiting plate, the first linear movement driving piece is installed on the chassis, and the first linear movement driving piece is connected with the limiting plate; the fruit containing barrel is placed in the containing hole; and the pressing mechanism comprises a motor, a gear, an arc-shaped gear ring, a supporting rod, a driving motor, a pressing rod, a second linear movement driving piece and a movable sliding block. Automatic picking of fruits is achieved, the picking effect of the fruits is greatly improved, manpower is saved, and the labor intensity of workers is reduced.

Owner:湖南翰坤实业有限公司

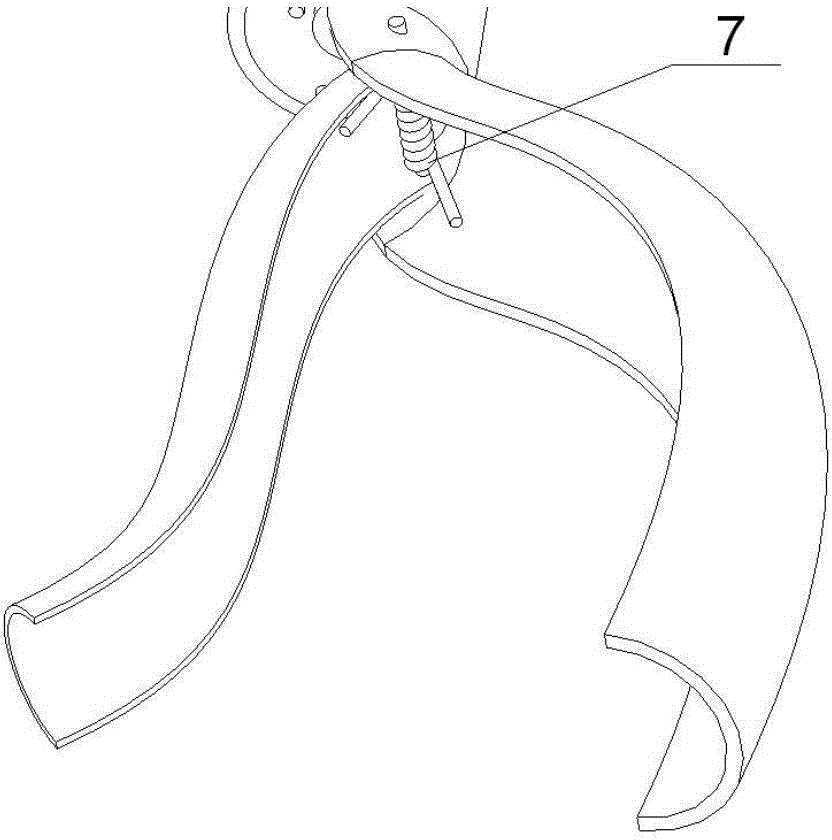

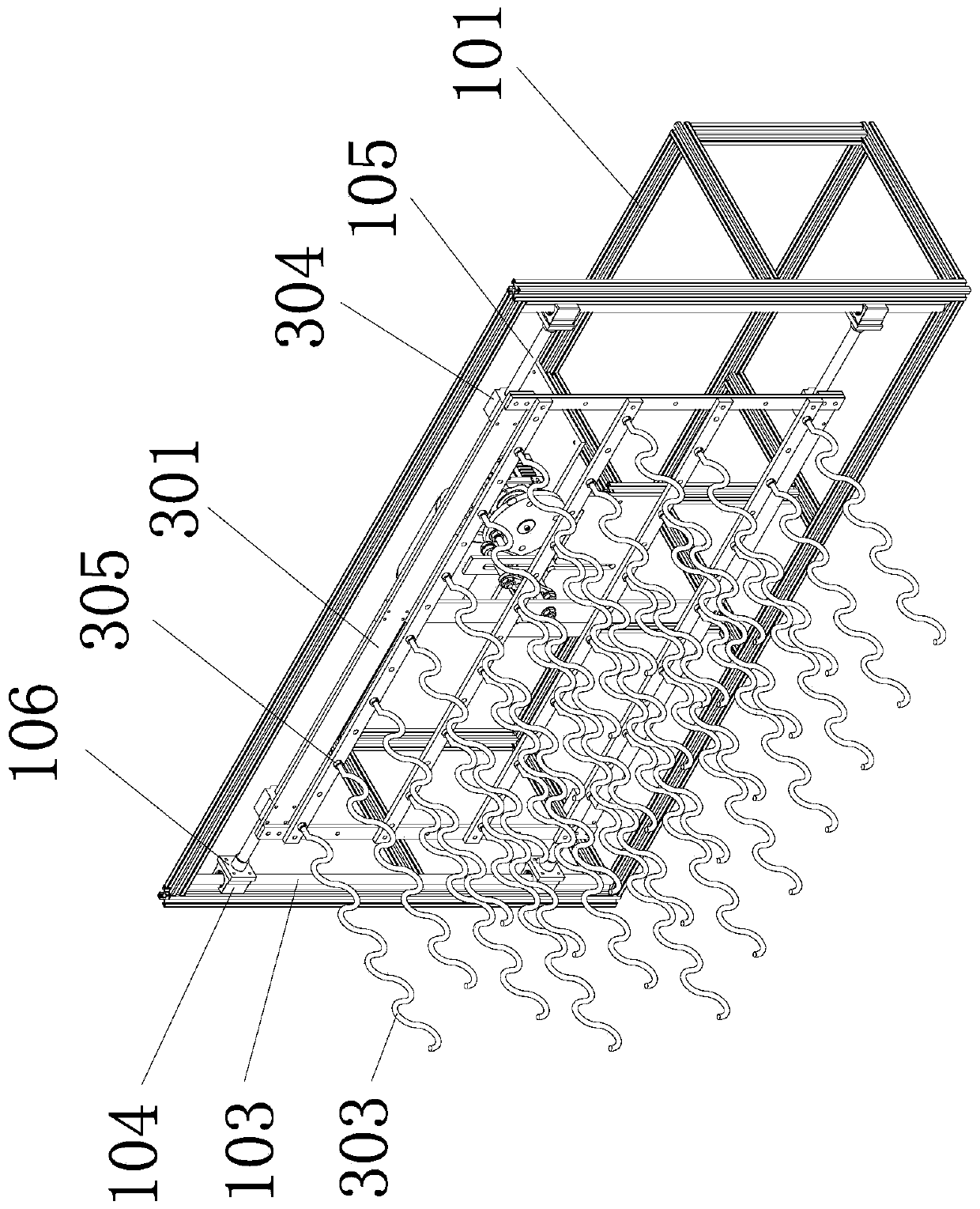

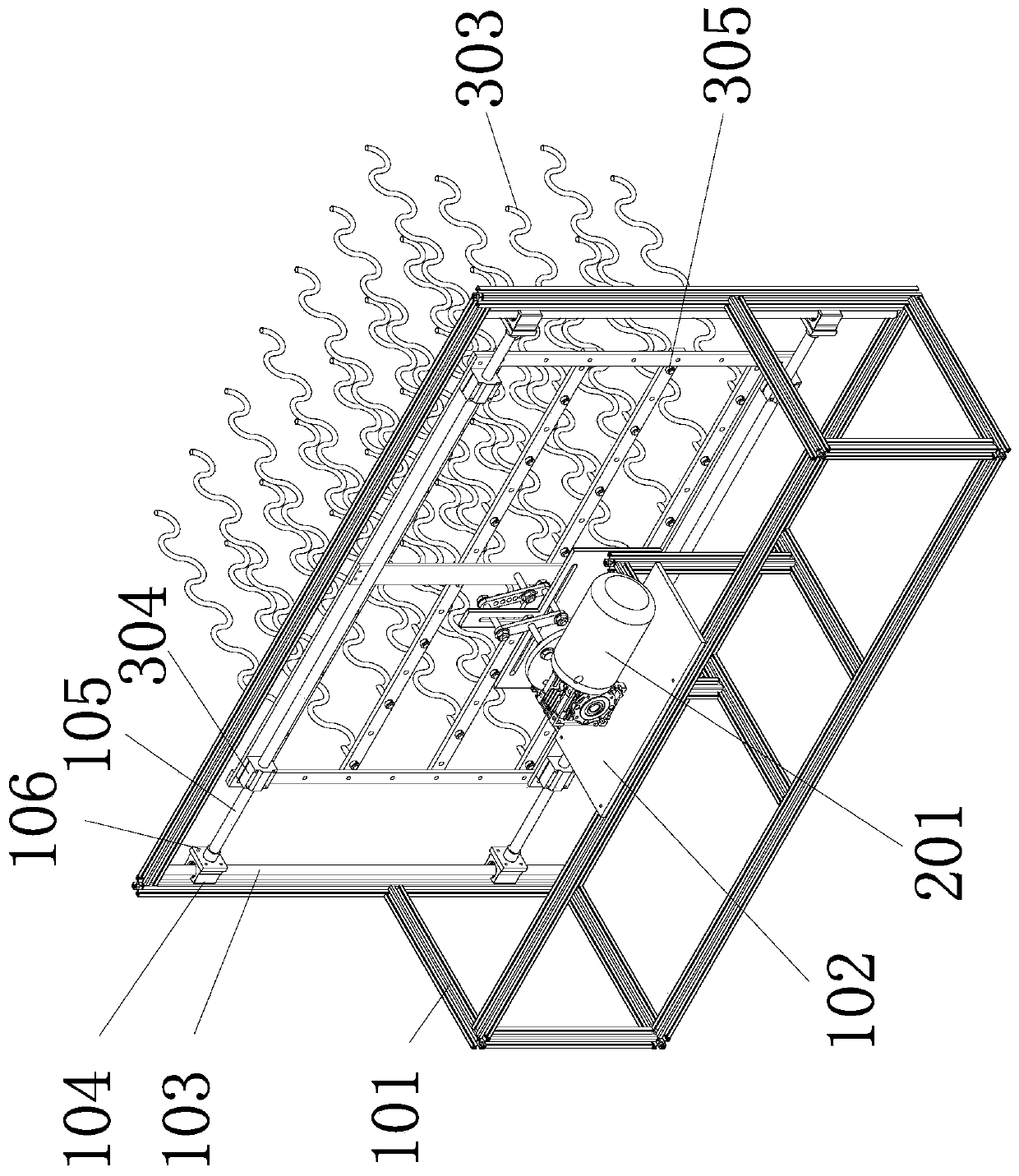

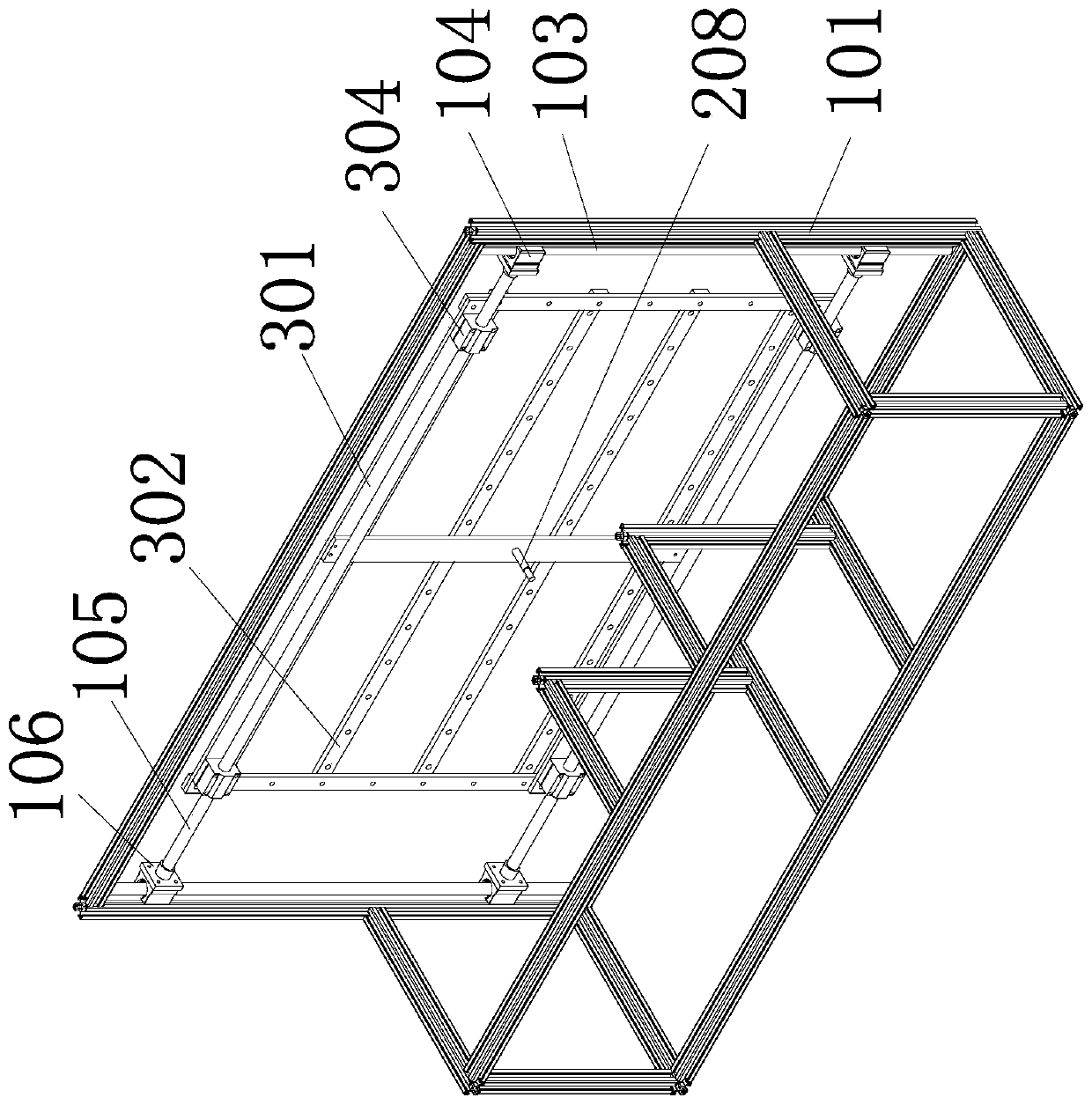

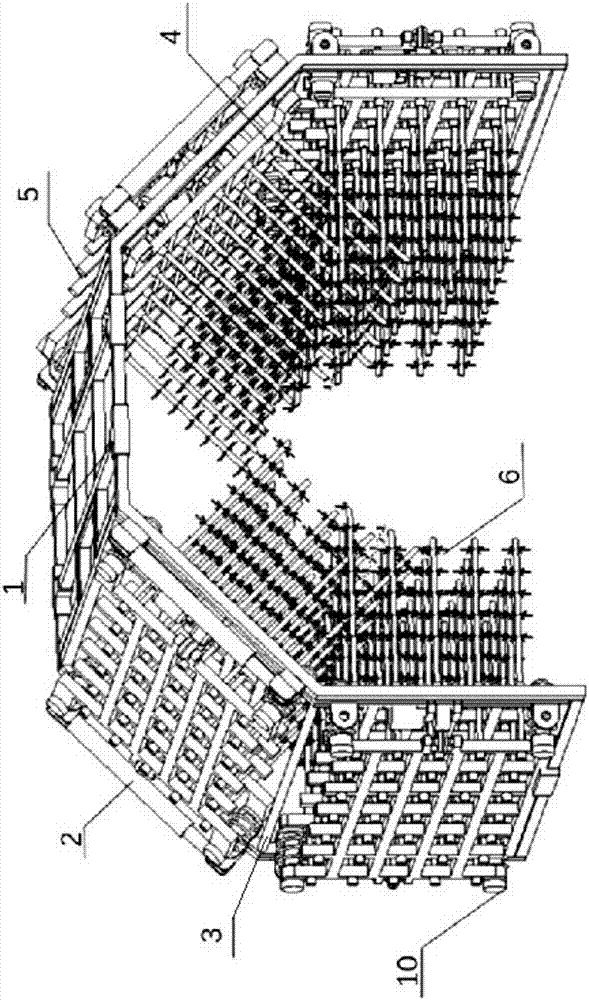

Flexible medlar-picking device with bionic-type structure

ActiveCN107567819AHarvest low lossNo damageRenewable energy machinesPicking devicesEngineeringDrive motor

The invention discloses a flexible medlar-picking device with a bionic-type structure. The device comprises a gull-wing door support and vibration picking units. Each vibration picking unit comprisesa gull-wing door framework, a vibration rack, a vibration rod group, a driving motor and a cam mechanism. Each vibration rod group is fixedly arranged on each vibration rack and vertical to the vibration rack. Each driving motor is fixed on each gull-wing door framework. Each cam mechanism is connected with each driving motor. One vibration generation device is composed of each driving motor and each cam mechanism. According to the growth structure model of medlar plants, a fruit distribution model and other features, a multi-surface multi-area picking structure is designed. Additionally, flexible combing rods, which are capable of extending and contracting and made of a flexible material, are arranged on vibration rod groups. Operation is performed by adopting a combing-vibration mode offlexible contact brushes. The combing-vibration mode replaces a conventional rigid contact working mode of branches. Therefore, low-loss highly-efficient medlar-harvesting operation is finished. The harm to branches, leaves, flowers, and ripe fruits of medlar plants is reduced. The fruit quality is increased. Meanwhile, the flexible medlar-picking device with the bionic-type structure is adapted to harvesting of other bush fruit.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com