Internal comb type posture-changing vibratory wolfberry picking device

An internal comb-type and position-shifting technology, which is applied in the direction of picking machines, agricultural machinery and implements, and applications, can solve the problems of a large amount of manpower input, increase the picking range, and the complexity of wolfberry branches, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

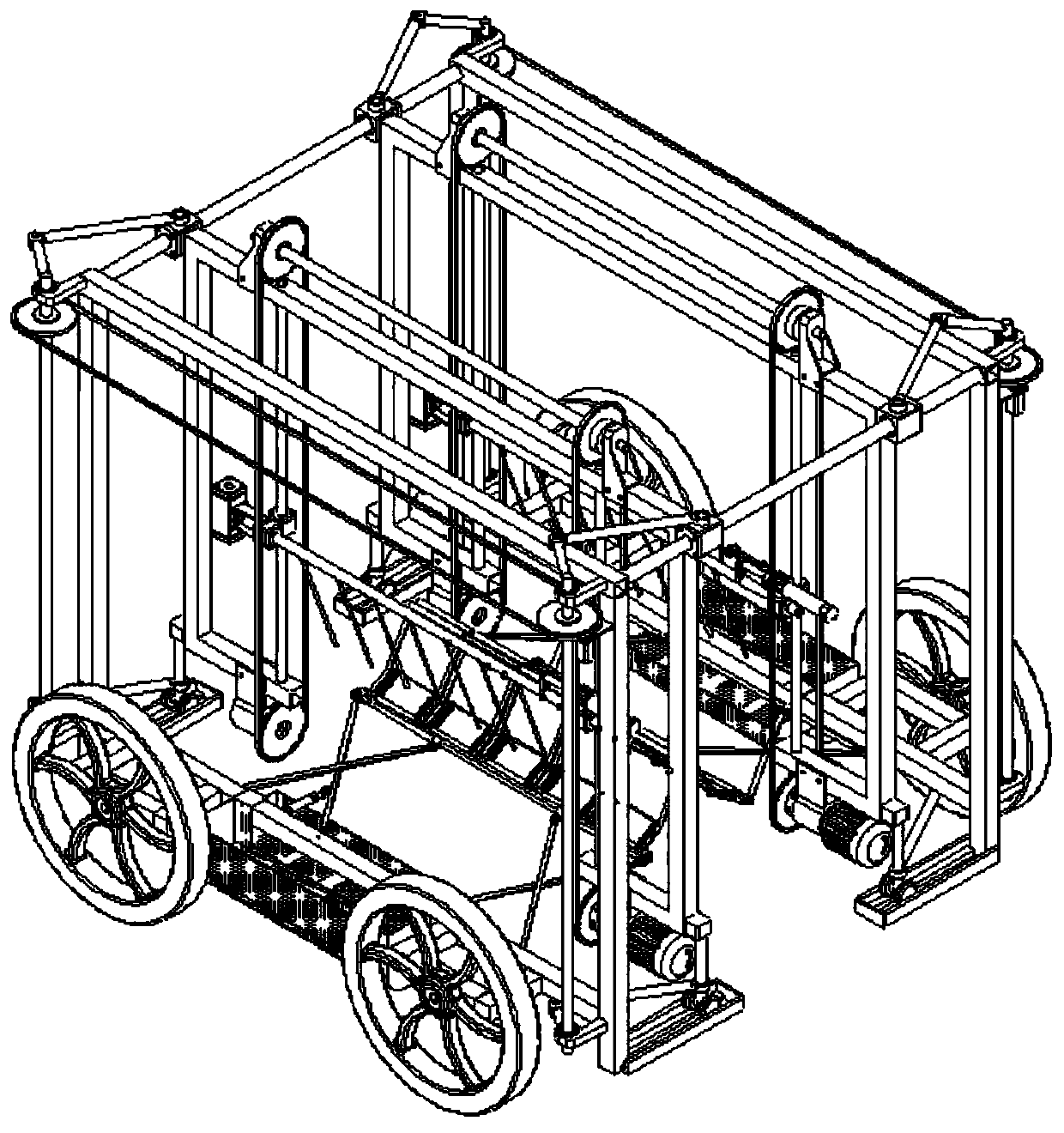

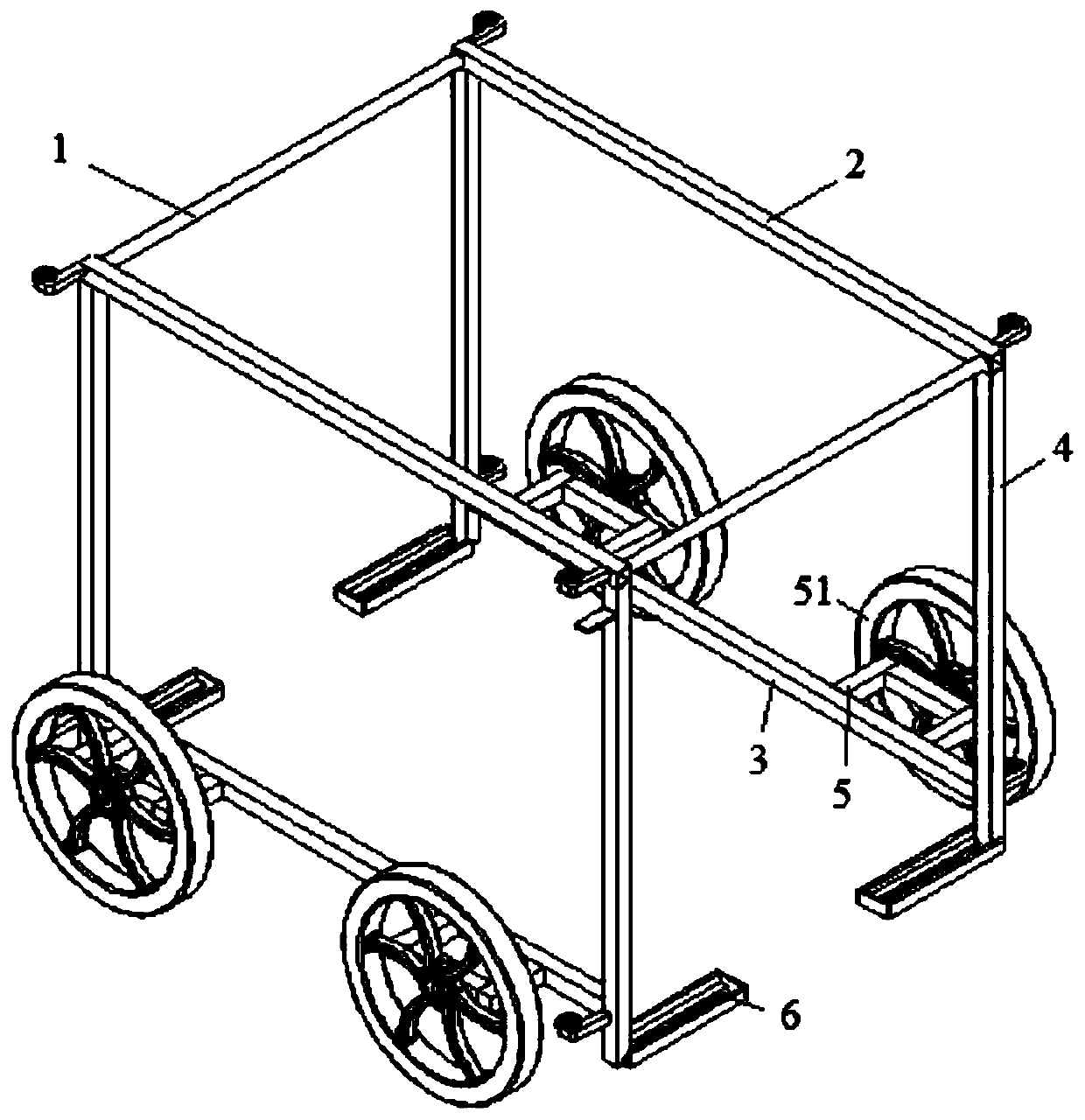

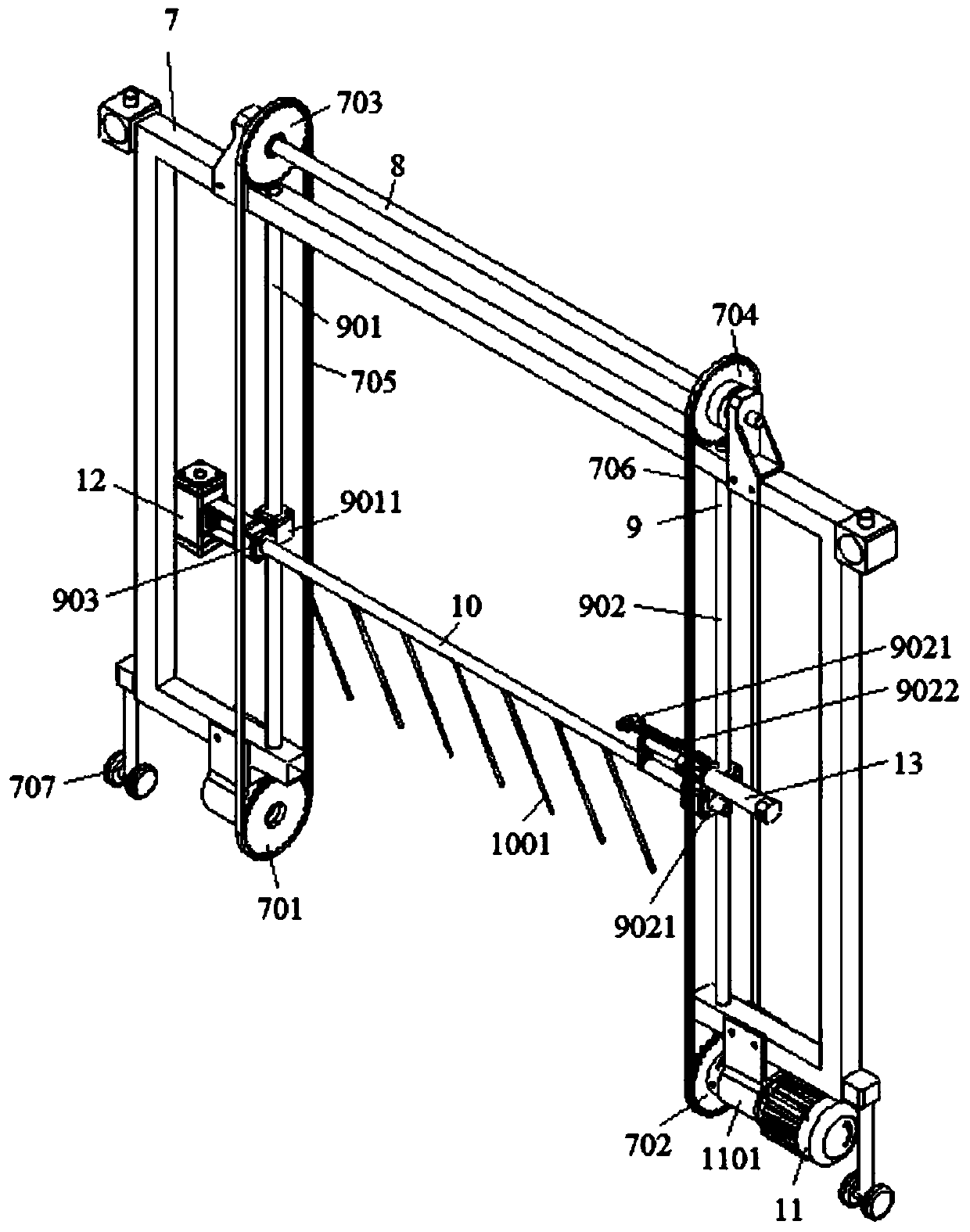

[0042] The present invention provides a kind of vibrating goji berry picking device of internal comb type variable position and posture, such as figure 1 As shown, the picking device includes a supporting mechanism, a picking mechanism and a collecting mechanism. Specifically, the support mechanism includes a guide rod 1, a top beam 2, a bottom beam 3, a column 4 and a roller track 6, and the picking mechanism includes a door-type lateral movement support frame 7, a connecting shaft 8, a vertical guide rod 9, and a comb shaft 10. With motor 11, collection mechanism comprises folding frame and collection basket 23.

[0043] Such as figure 2 As shown, the support mechanism as a whole is a square frame surrounded by four slats. The slats include relatively para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com