High-efficiency and low-trash content cotton picker

A technology with high impurity content and high efficiency. It is applied in the fields of picking machines, agricultural machinery and implements, and applications. It can solve the problems of medium volume, complex structure and low efficiency, so as to reduce the space occupied, improve the picking efficiency, and ensure the transmission. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

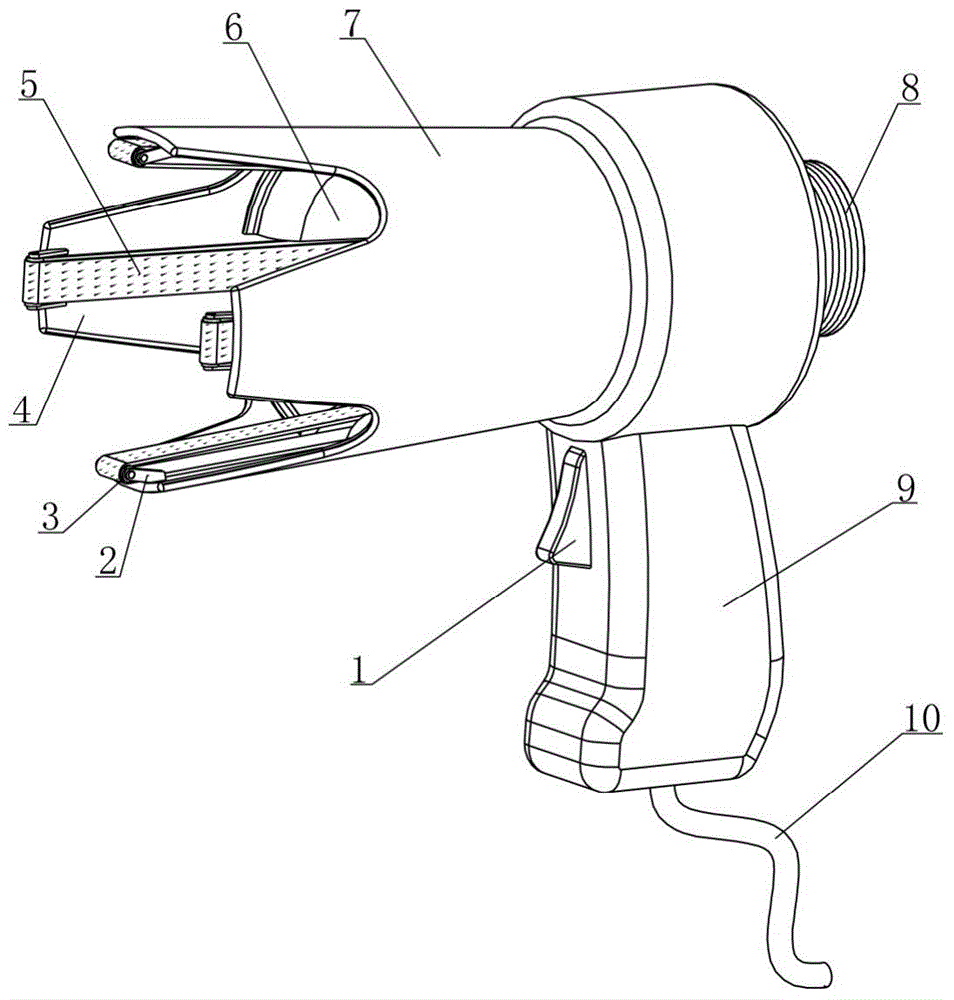

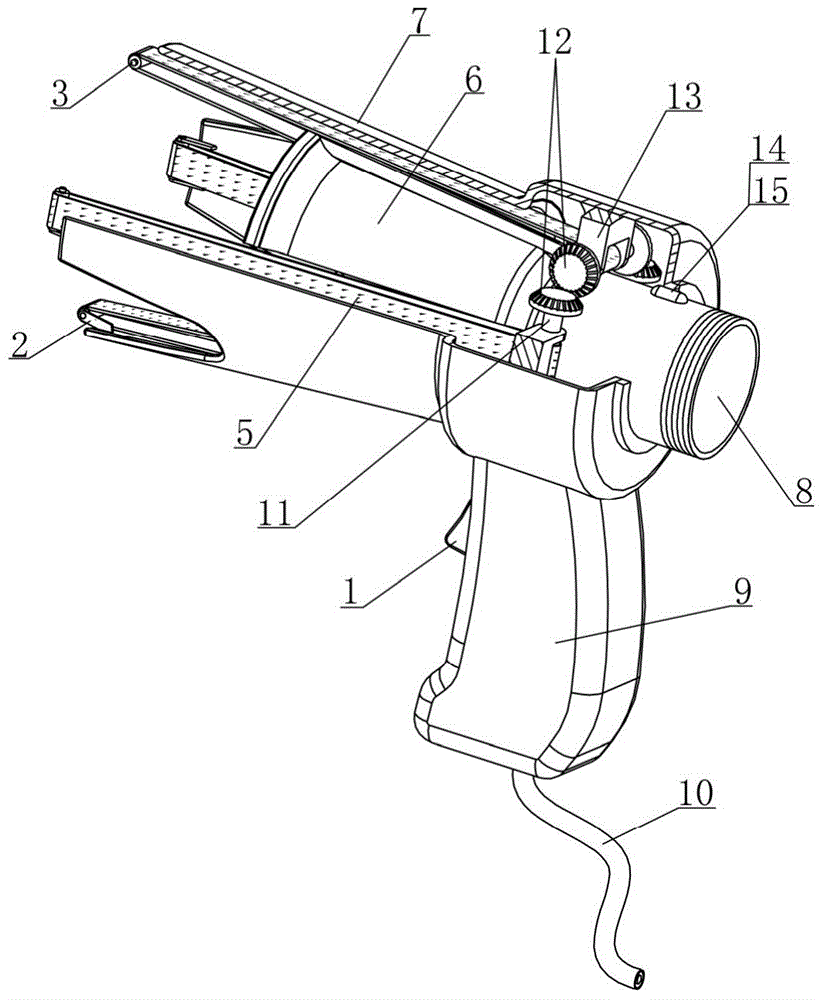

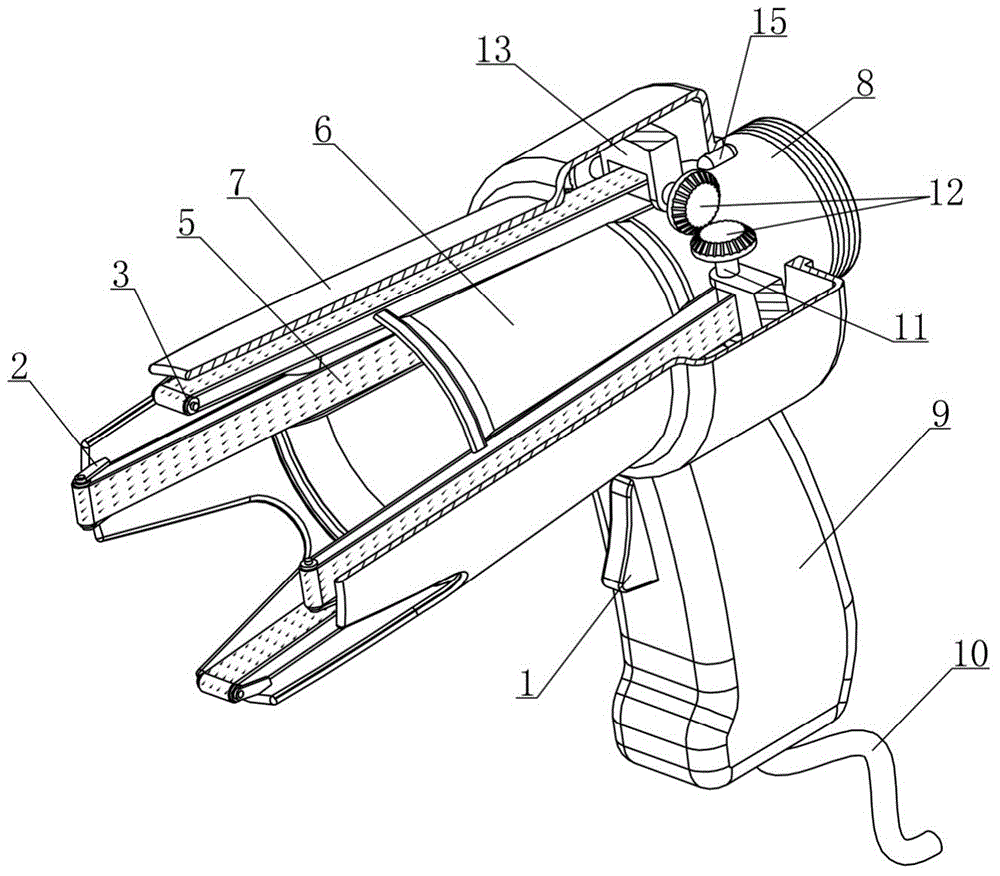

[0027] See attached Figure 1-3 As shown, the invention discloses a cotton picking device with high efficiency and low impurity content, which is composed of a housing, a cotton holding and conveying assembly, a driving assembly and a separation cylinder 6 .

[0028] see figure 1 , 2 As shown, wherein, the housing is composed of a front and rear transparent tube shell 7 and a handle 9 located at the lower side of the tube shell 7. The inside of the shell is hollow and is used to fix other devices. Since the handle 9 is located under the tube shell 7 Side, the two form a gun-like structure, which is more conducive to holding and operating;

[0029] see Figure 2-7 As shown, the cotton holding and conveying assembly includes four conveyor belts 5 distributed up, down, left, and right. The conveyor belts 5 are used to grab cotton and hold and transport cotton backwards in the tube shell 7. The front and rear ends of the four conveyor belts 5 are respectively Supported by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com