Straw pickup with elastic claws embedded in circular tube wall

A picker and spring tooth technology, which is applied in the field of spring tooth embedded round tube wall straw picker, can solve the problems of high production cost, complex structure, easy deformation and damage of U-shaped retainer, etc., and achieves convenient manufacturing and simple manufacturing process , Enhance the effect of picking up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

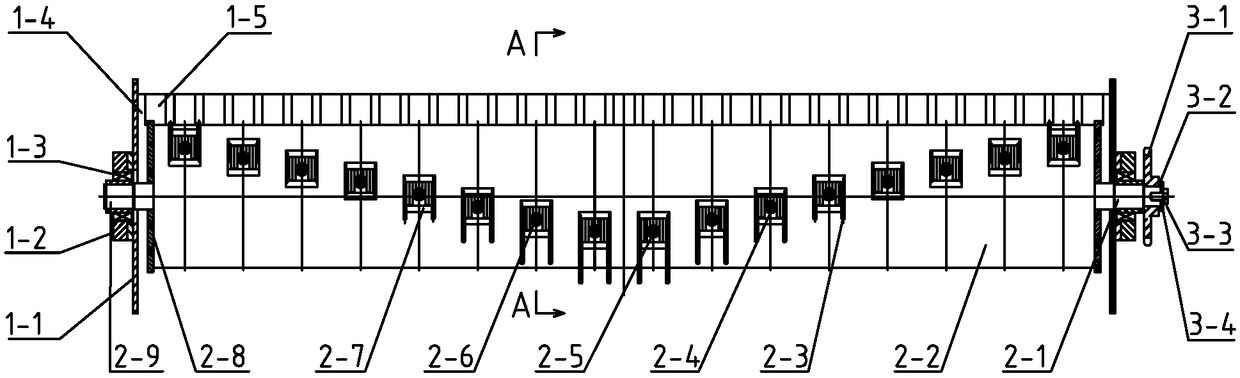

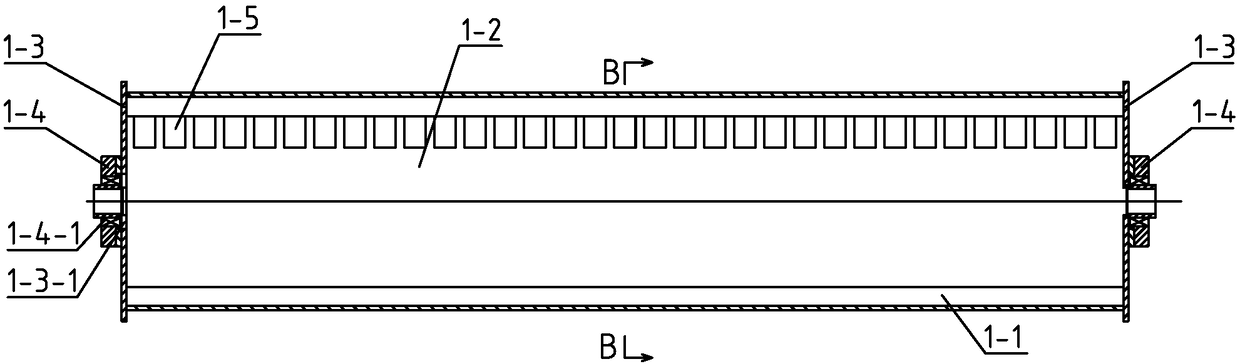

[0021] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, this embodiment comprises frame 1, pick-up mechanism 2 and two transmission sprockets 3;

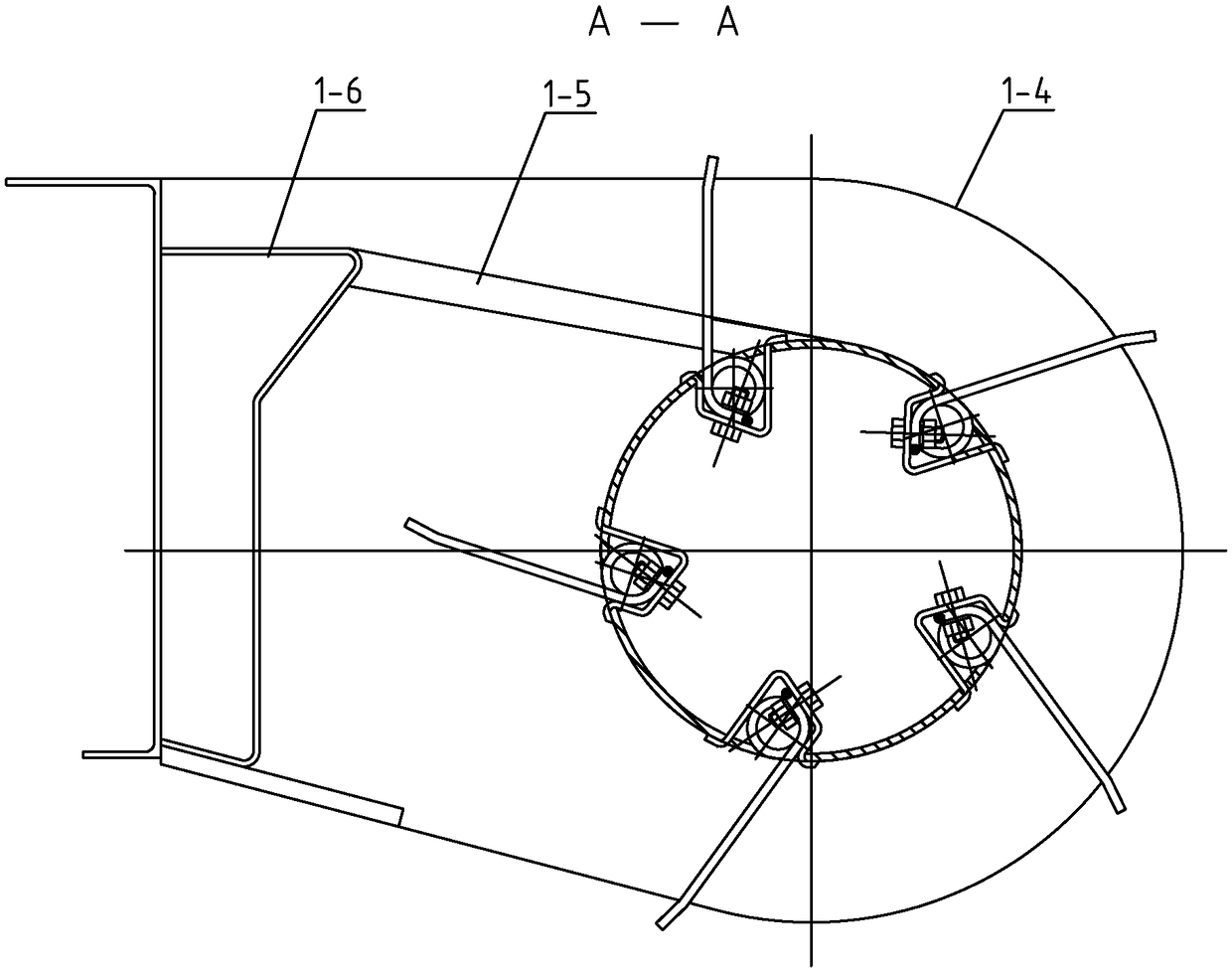

[0022] The pick-up mechanism 2 includes a cylinder 2-1, a left end shaft 2-2, a right end shaft 2-3, two cylinder shaft end plates 2-4, several spring teeth 2-5, and several spring tooth holders 2-6 and several connecting elements 2-7, the cylinder 2-1 is provided with several square holes 2-1-1, and the several square holes 2-1-1 are "V" along the circumference of the cylinder 2-1 Character distribution, each square hole 2-1-1 is embedded with a spring tooth holder 2-6, the spring tooth holder 2-6 is arranged on the inner side of the cylinder 2-1, and the spring tooth holder 2-6 is folded outside The bend is lapped on the outer wall of the cylinder 2-1 for welding and fixing, and a spring tooth 2-5 is installed in each spring tooth fixing seat 2-6, and the spring tooth 2-5 and the spring to...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination image 3 This embodiment is described. In this embodiment, the inner hole 1-4-1 of the bearing housing is smaller than the inner hole 1-3-1 of the end plate. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0026] Specific implementation mode three: combination Figure 6 Describe this embodiment. In this embodiment, the winding part of the spring tooth 2-5 is located inside the cylinder 2-1, and the tooth arm 2-5-1 of the spring tooth 2-5 is located outside the cylinder 2-1. This design makes picking up straw smooth. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0027] Working principle of the present invention:

[0028] The transmission sprocket 3 is linked with the power output sprocket through the transmission chain. The transmission sprocket 3 rotates and drives the pick-up mechanism 2 to rotate. The spring teeth 2-5 are continuously picked up from the ground, and are gradually thrown to the top of the straw bridge 1-5 by the spring teeth 2-5, and the spring teeth are picked up from the adjacent two straw bridges 1-5. Turn around the gap, pick up straw from top to bottom,

[0029] The straw thrown to the straw crossing bridge 1-5 by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com