Eccentric rolling vibration mechanism for picking wolfberry fruit

An eccentric rolling and eccentric heavy technology, which is applied in the field of agricultural machinery, can solve the problems of poor versatility, low efficiency, and large size, and achieve good picking results, improved picking efficiency, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

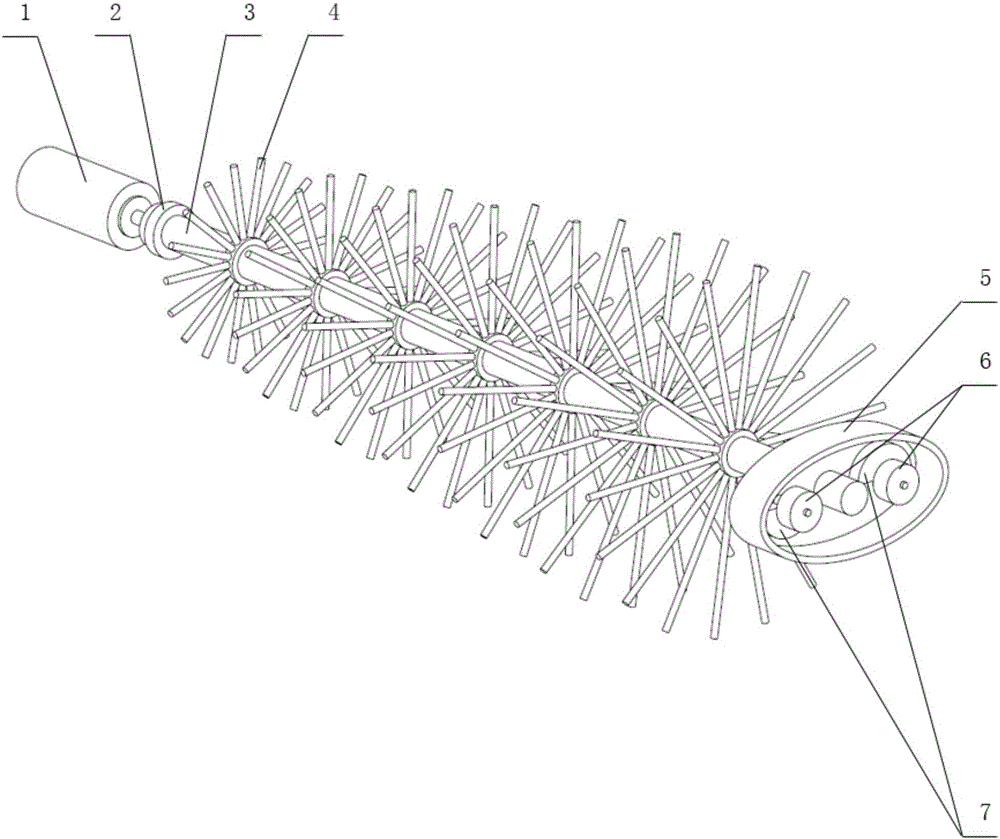

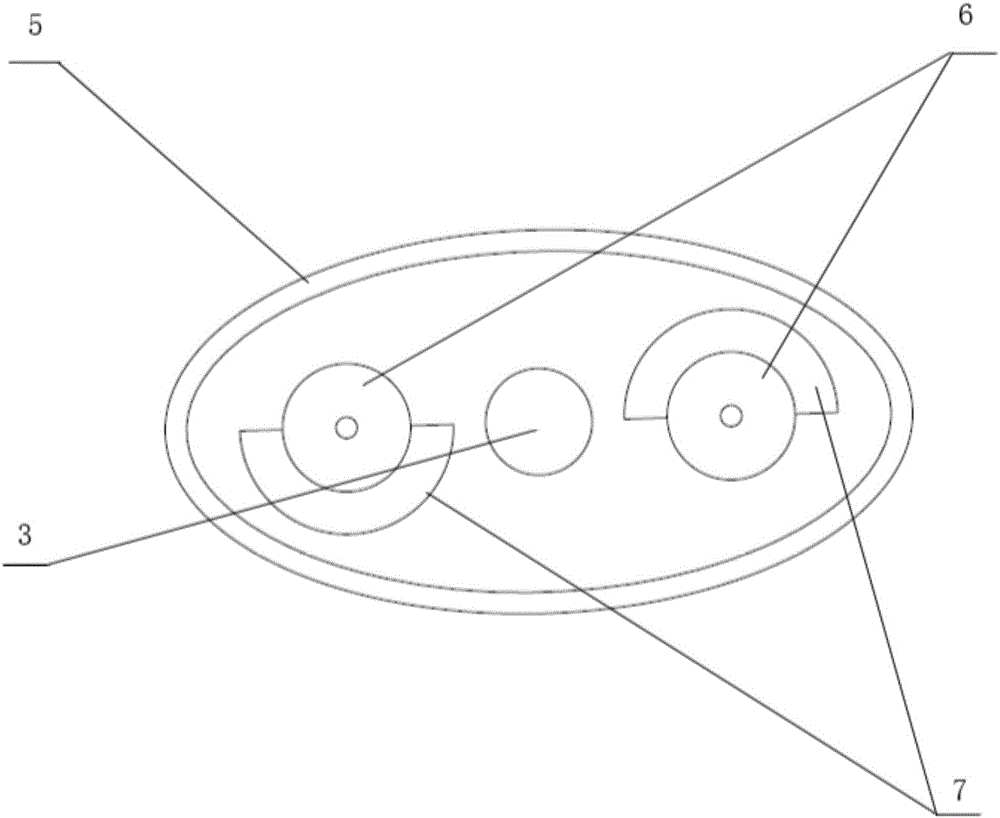

[0021] Such as Figure 1~2 As shown, it is a structural schematic diagram of an embodiment of the present invention, including a main shaft motor 1, a clutch 2, a main shaft 3, several vibrating rings 4, a swing arm 5, a weight motor 6 and two eccentric weights 7; the main shaft motor 1 passes through the clutch 2 Connect the main shaft 3, the vibrating ring 4 is fixed on the main shaft 3, and the main shaft 3 is fixedly connected with the swing arm 5; the two eccentric weights 7 are installed symmetrically on the swing arm 5, driven by the weight motor 6, and the two eccentric weights 7 The direction of rotation is opposite. The vibrating bar coil 4 is composed of a vibrating bar coil base and a vibrating bar.

[0022] Described clutch 2 can adopt friction clutch. Several vibrating coils 4 are distributed on the main shaft 3 in an array. A number of vibration bars ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com