High-efficiency cotton harvesting device

A cotton bud, high-efficiency technology, applied in the direction of picking machines, harvesters, agricultural machinery and implements, etc., can solve the problems that the cotton buds are not easy to separate, affect the cotton picking efficiency, carry cotton stalks, etc. Good effect and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

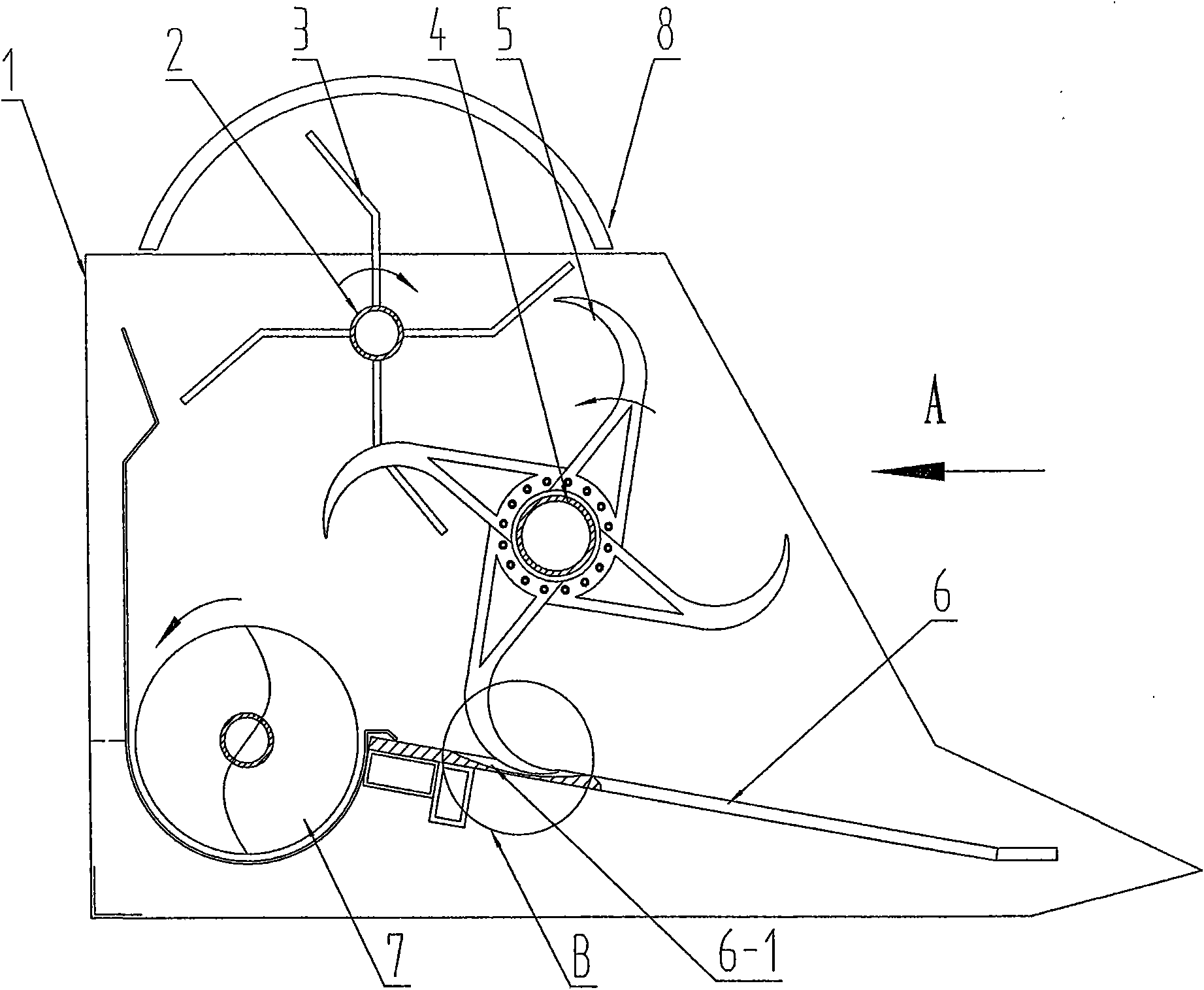

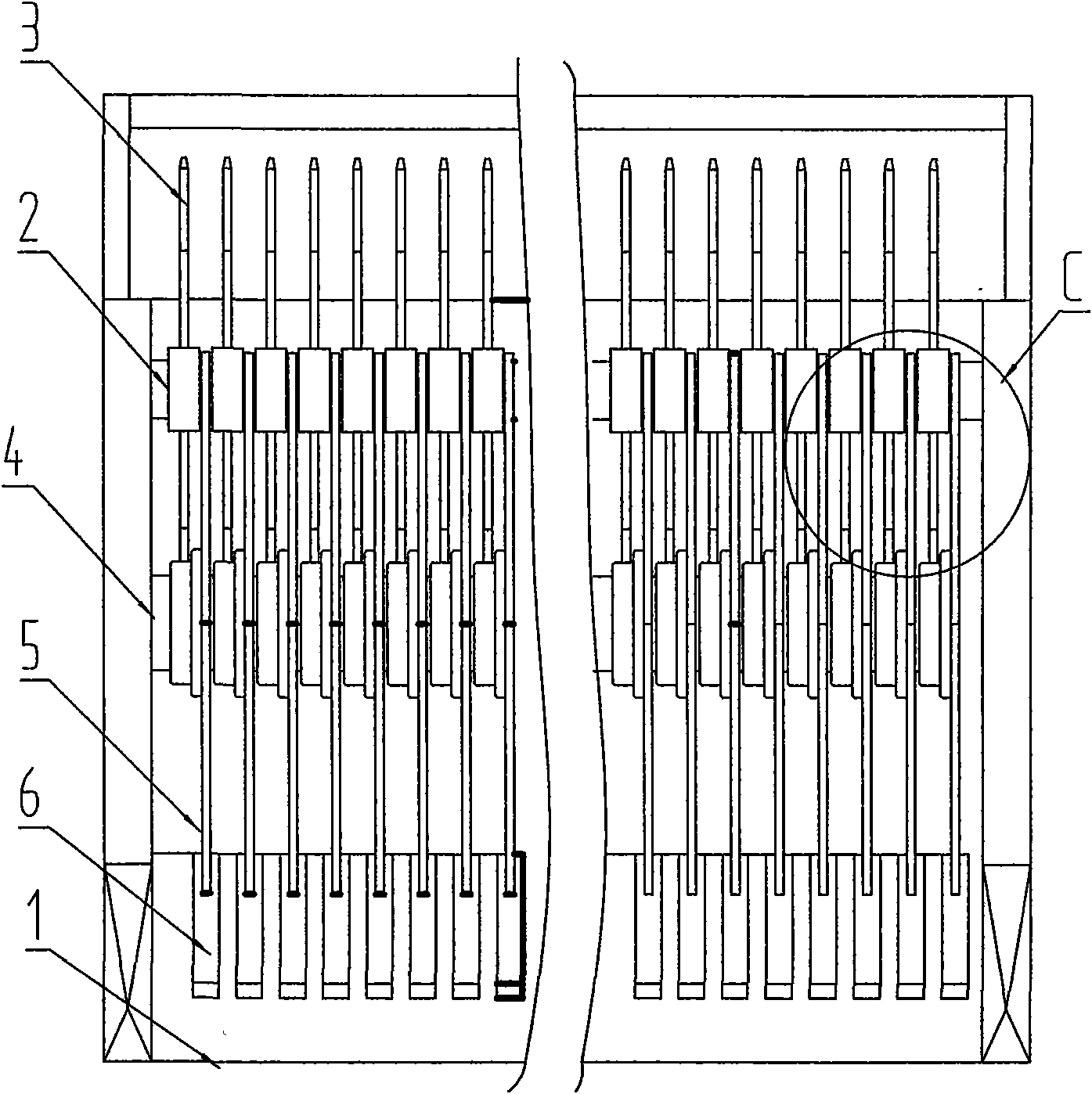

[0018] see figure 1 , figure 2 , comprise cotton collection case 1 and be positioned at the fixed grate tooth 6 in the cotton collection case, rotating grate tooth mechanism and conveying cage 7 in the formation of the present invention, the cotton collection case top is provided with shield 8. The fixed grate teeth are evenly distributed on the lower part of the cotton collection box, and the rotating grate gear mechanism is located on the upper part of the fixed grate teeth. It is composed of the rotating shaft 4 and the rotating grate teeth 5. The tooth positions are corresponding, and the tooth width of the rotating grate is smaller than the tooth width of the fixed grate, and four rows of rotating grate 5 are evenly distributed on the rotating shaft 4 .

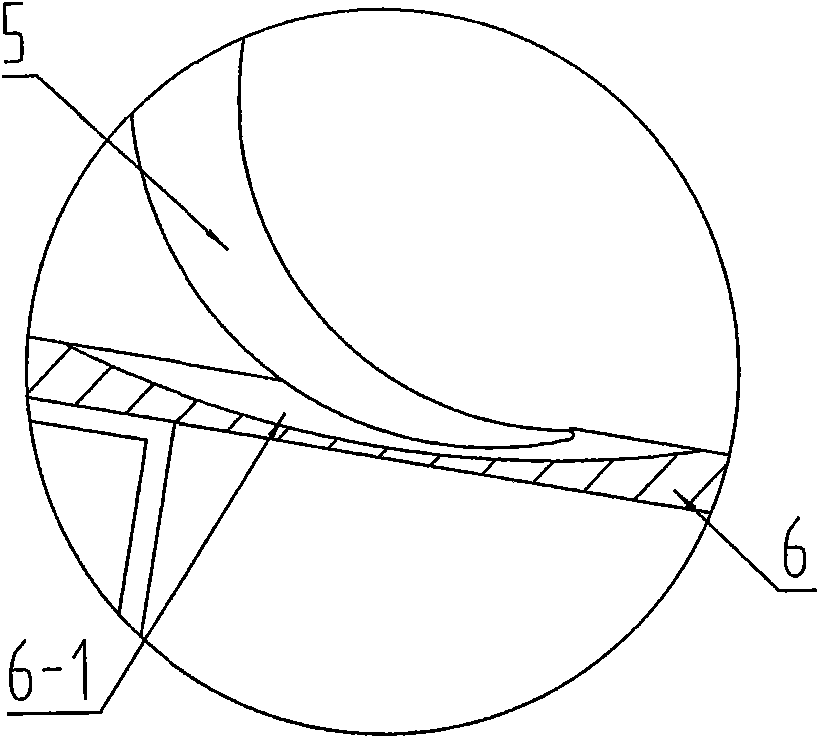

[0019] see figure 1 , image 3 , the rotating grate 5 of the present invention is a crescent-shaped curved hook-shaped tooth, and the fixed grate 6 is provided with an arc groove 6-1 on the upper side near its root. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com