Film pick up and separating device

A separation device and film technology, applied in the field of laser imagers, can solve the problems of film entanglement and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

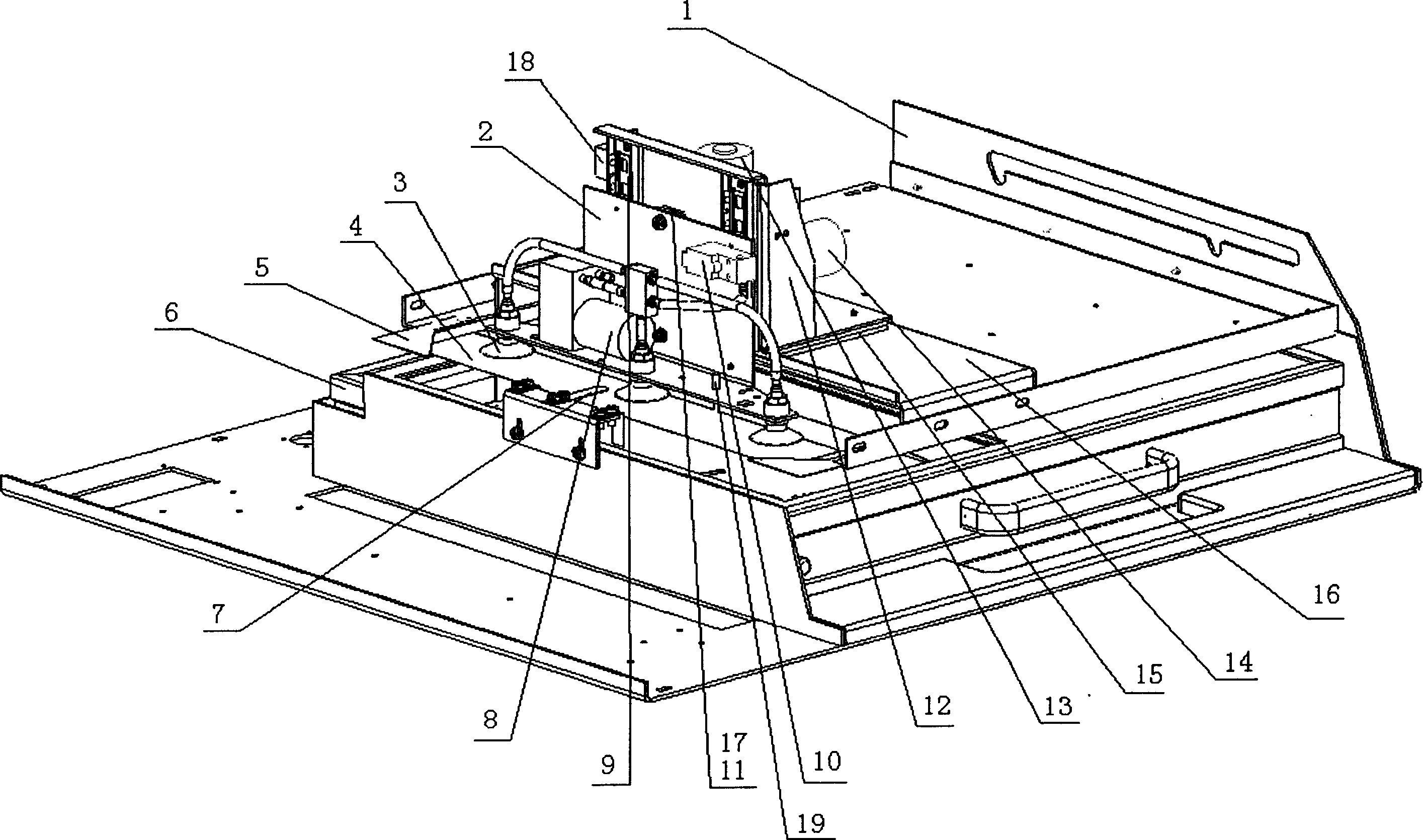

[0010] Embodiments of the present invention, in conjunction with the above description of the accompanying drawings: in the figure, a film feeding box (1) is equipped with a suction film device bracket (16), and the film feeding box (6) for loading the film (4) is contained in the suction film feeding box (16). One end of the device support (16) is respectively equipped with a plectrum shrapnel 2 (5) at the left and right corners of the film suction device bracket (16), and a plectrum shrapnel 1 (7) is housed on its middle edge, The pick shrapnel is made of 1Cr18Ni9Ti or PVC, and its finish requires 1.6 grades; the vertical sliding frame (2) in the film suction device is fixed and connected to the horizontal sliding frame (12) through the vertical sliding rail (9), and the horizontal The sliding frame (12) is fixed on the film suction device support (16) through the horizontal slide rail (15). A horizontal control motor (13), a vertical control motor (14) (two motor models are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com