High-intensity arc voltage gas electrical discharge tube

A gas discharge tube and arc voltage technology, which is applied to electrical components, circuits, overvoltage arresters using spark gaps, etc., can solve the problems that gas discharge tubes cannot be realized and remain unchanged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

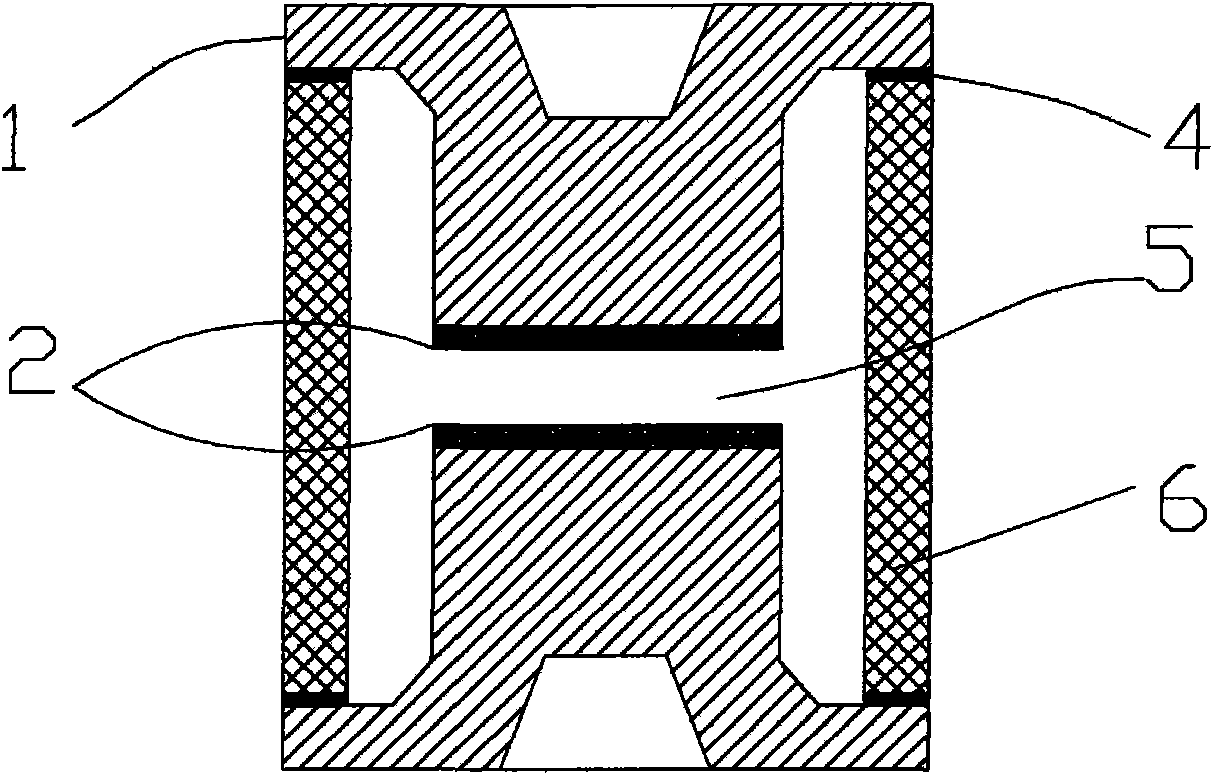

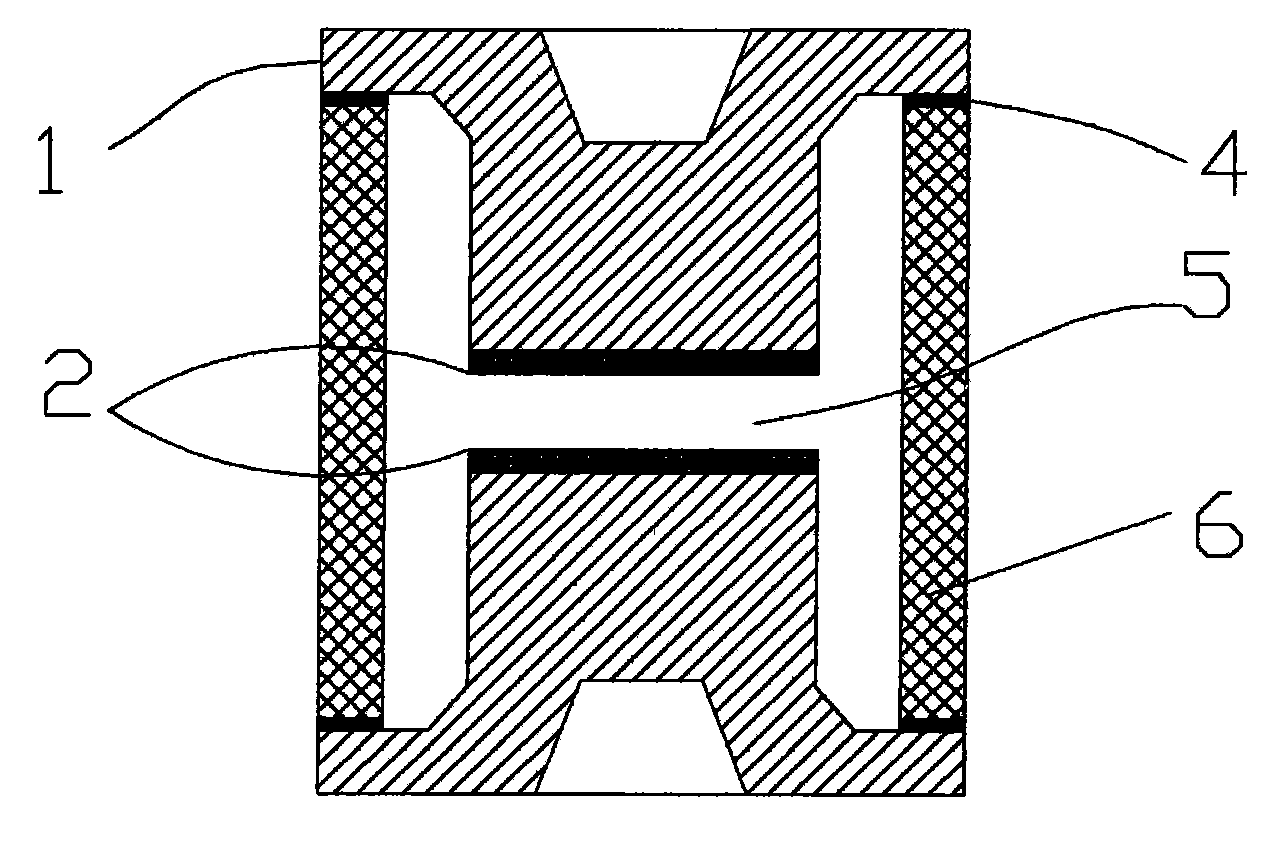

[0014] like figure 1 A two-pole gas discharge tube comprises two metal electrodes 1 and a metallized ceramic tube 6. The emitter stage 2 is arranged on the metal electrode, and after the metal electrode 1 and the metallized ceramic tube 6 at the two ends are installed, the two metal electrodes 11 and the metallized ceramic tube 6 are welded together by silver-copper alloy solder 4 to form an airtight Cavity 5, the gap between the two metal electrodes 1 is set to 1.0 mm, and the cavity 5 is filled with a mixture of nitrogen and hydrogen, wherein the filling ratio of hydrogen accounts for 50% of the volume of the cavity, and nitrogen accounts for 50% of the volume of the cavity.

Embodiment 2

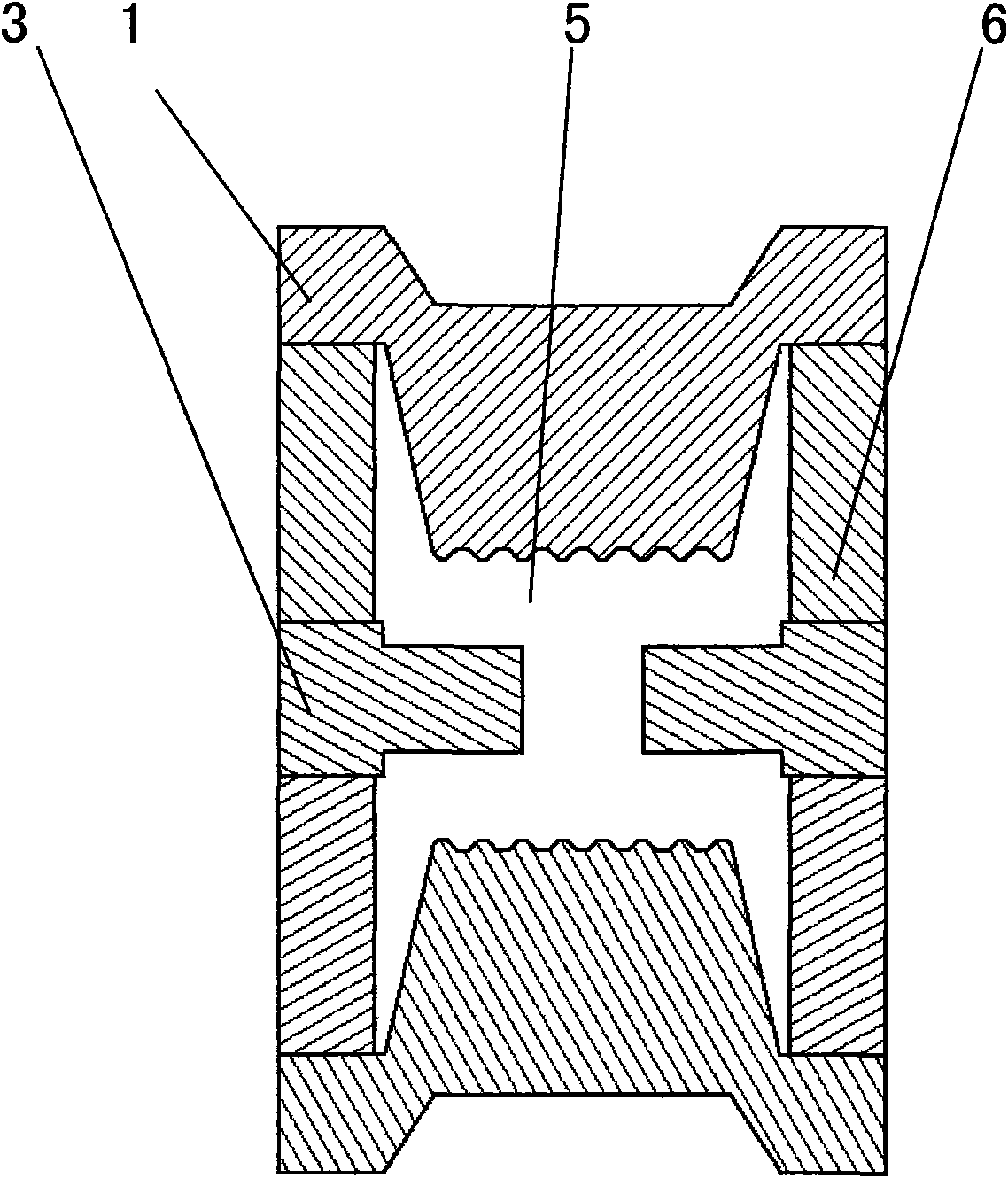

[0016] like figure 2 A three-electrode gas discharge tube, comprising two end electrodes 1, an intermediate electrode 3 and a hollow metallized ceramic tube 6, and the two end electrodes 1, the intermediate electrode 3 and the hollow metallized ceramic tube 6 are welded together to form a closed The cavity 5 is filled with a mixture of nitrogen and hydrogen, wherein the filling ratio of hydrogen accounts for 30%, and the filling volume of nitrogen is 70%; the gap between the middle electrode and the electrodes at both ends of the gas discharge tube is set to 1.2mm.

[0017] According to the experimental results, the arc voltage of the gas discharge tube manufactured by the technical solutions of the above two embodiments can be guaranteed to be 26V or above. When the discharge tube of the present invention is used, the problem of freewheeling of the discharge tube is effectively improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com